Airbag-loading potable weak and soft interlayer direct shear apparatus

A soft interlayer, portable technology, used in the application of stable shear force to test the strength of materials, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of sample disturbance, heavy equipment, large sample volume, etc. The tangential force is continuous and stable, the precision is simple and easy, and the afterburner is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

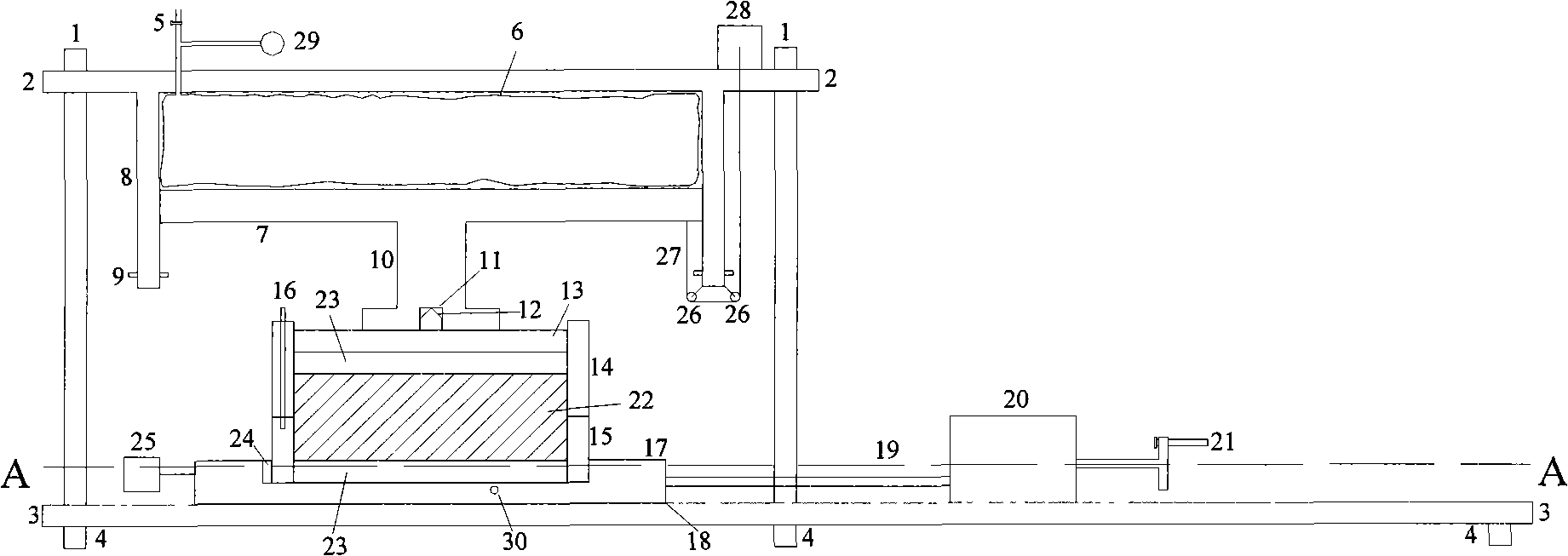

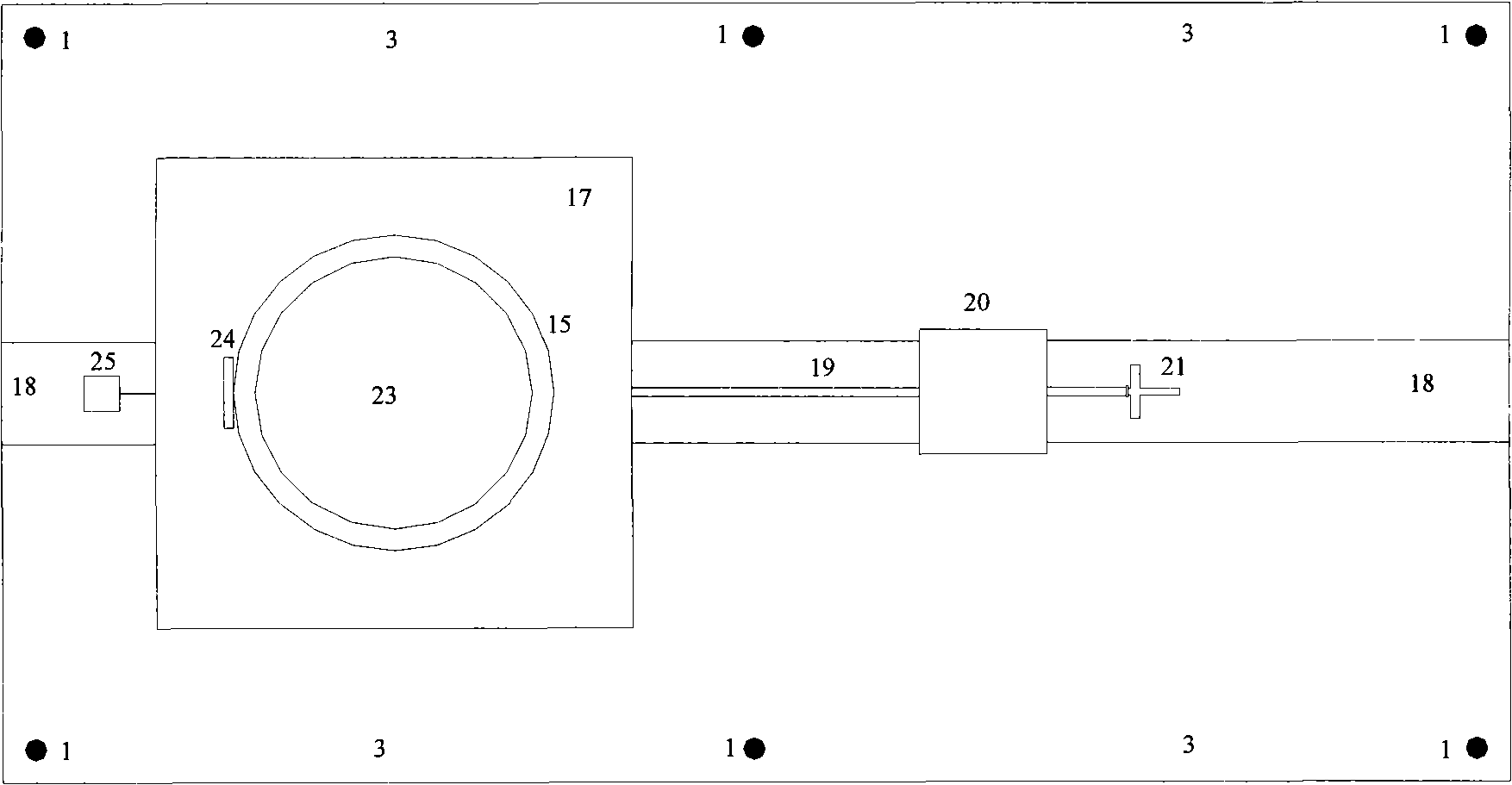

[0015] 1. After the sample 22 is installed, use a spirit level to level the lower base 3 of the instrument, and use a portable inflator to pressurize the air bag 6 until the barometer 29 reaches the predetermined pressure.

[0016] 2. According to the specific test requirements, rotate the screw handle 21 to make the sample base 17 move horizontally along the linear guide rail 18, gradually rotate the screw handle 21, apply more and more tangential stress and read the corresponding displacement until the pressure When the reading of the sensor 24 remains unchanged or drops, it indicates that the sample 22 has been cut off. Write down the pressure sensor 24 readings, and read out the displacement value of the horizontal displacement sensor 25. The maximum value of the pressure sensor 24 is the sum of the pressure when the sample 22 is sheared and the friction force of the linear guide rail 18. Using the previously measured friction coefficient of the linear guide rail 18, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com