Piezoelectric-type four-dimensional cutting force-measuring platform

A piezoelectric and force measurement technology, applied in the field of sensing measurement and control, can solve the problems of narrow sensor application area and low torque measurement accuracy, and achieve the effects of high sensitivity, small lateral interference and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

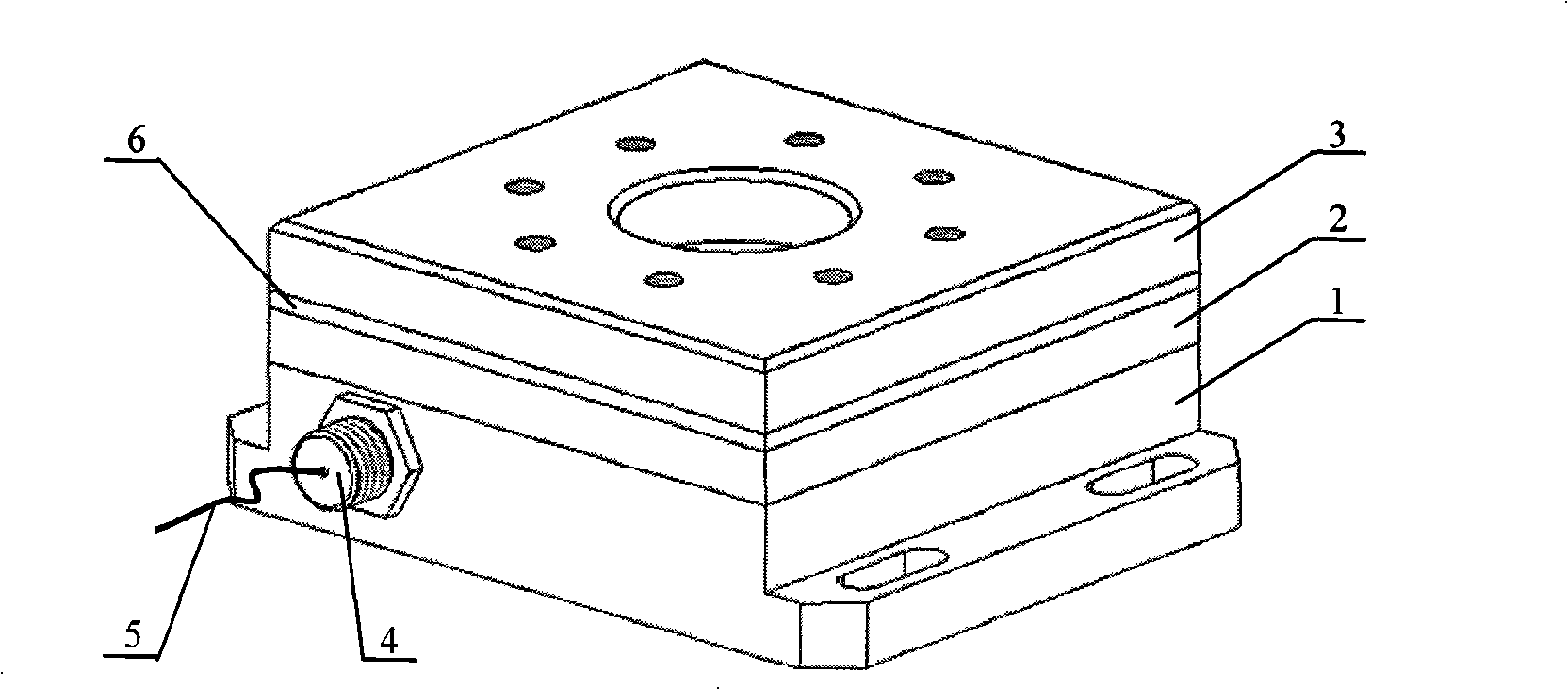

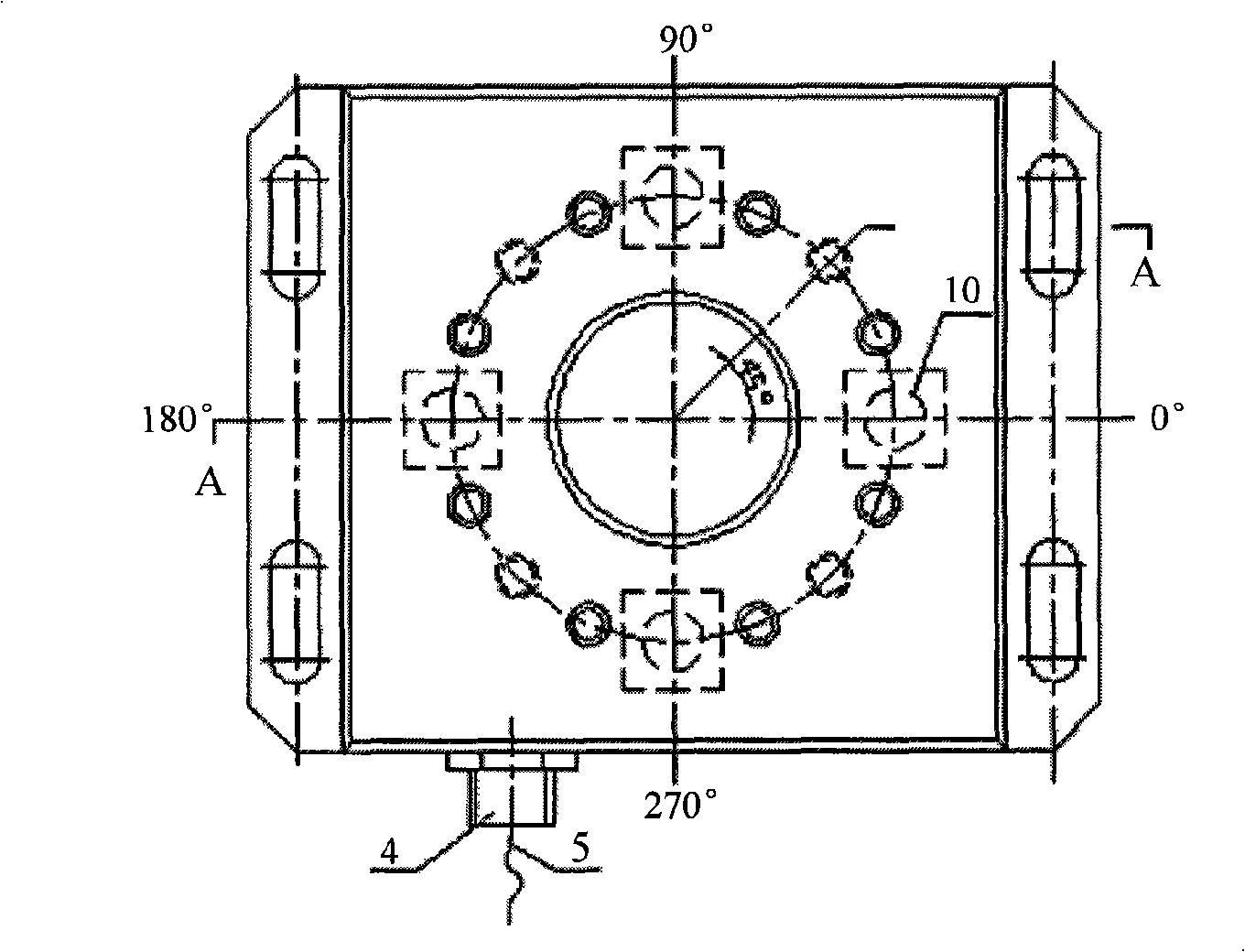

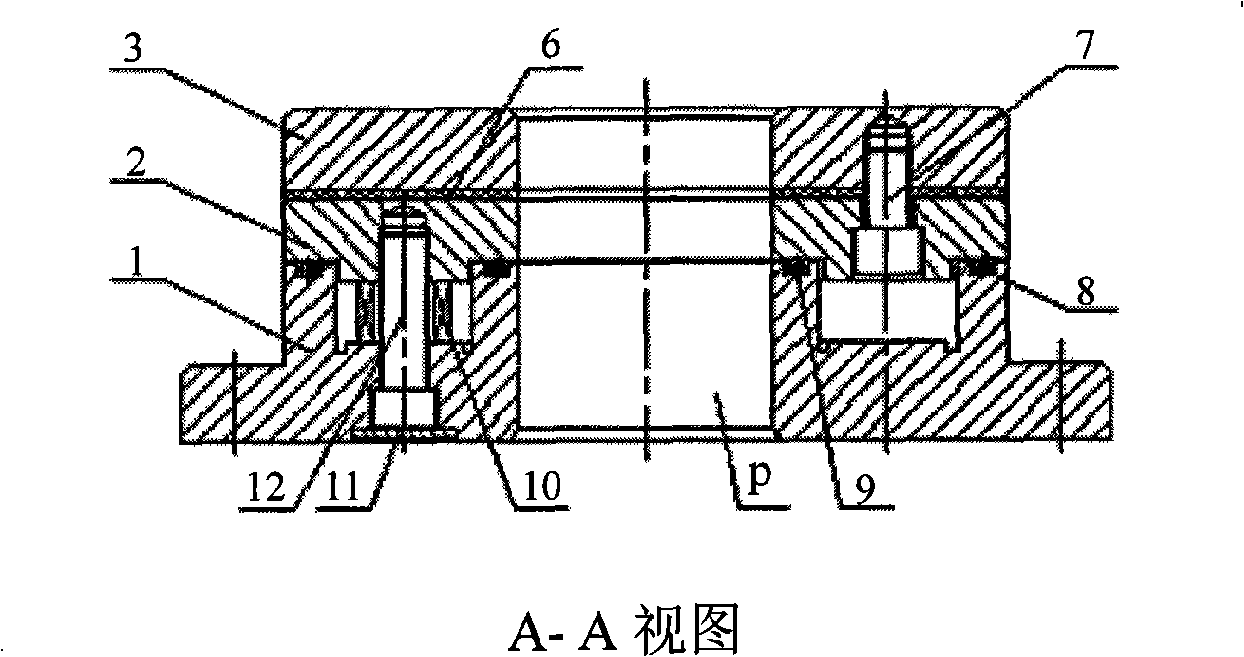

[0015] The specific implementation manner of the present invention is described in detail in conjunction with accompanying drawing and technical scheme, as appended Figure 1-11 As shown, during assembly, four connecting screws 12 are used to rigidly connect the base 1, the middle plate 2 and the four piezoelectric quartz sensors 10 through four stepped holes e and four threaded holes j respectively, while the four connecting screws 12 Preload the four piezoelectric quartz sensors for sufficient preload. Four connecting screws 7 are used to rigidly connect the middle plate 2 and the upper plate 3 through four stepped holes i and four threaded holes n respectively. Four screws are used to fix the piezoelectric four-dimensional cutting force measuring platform to a on the base.

[0016] When external force and torque act on the sensor, the external force can be decomposed into tangential component force F X , F Y , normal force component F Z Component force in three directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com