Adaptive butt-joint locking and releasing mechanical structure of combinable movable robot

A combined movement and release mechanism technology, applied in the direction of manipulators, joints, manufacturing tools, etc., can solve the problems of unreliable locking, inflexible release operation, and difficult docking, so as to achieve high docking reliability and good terrain adaptability , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

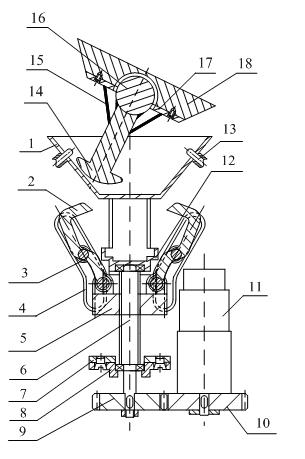

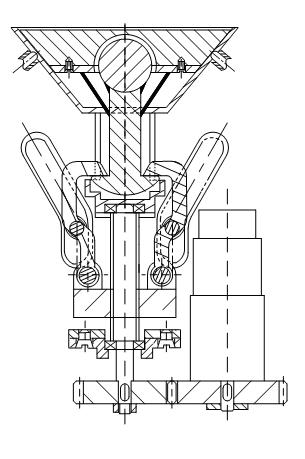

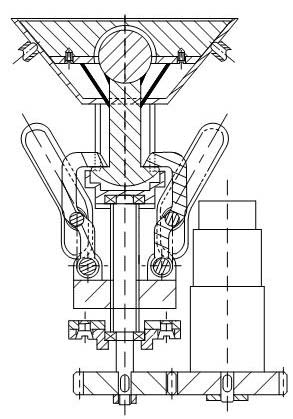

[0014] combine figure 1 and figure 2 To illustrate this embodiment, the self-adaptive docking locking and releasing mechanism of the combinable mobile robot is composed of a docking joint 01 and a docking seat 02, which is characterized in that there is a flanged contact head 14 on the docking joint 01; The docking seat 02 has a conical bowl-shaped mating inlet 1 and two relatively open and close tension hooks 2, and the contact head 14 of the docking joint 01 can be inserted into the docking under the guidance of the mating inlet 1 of the docking seat 02. Seat 02 is hooked by tension hook 2 to catch and realize docking.

Embodiment 2

[0016] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0017] combine figure 1 and figure 2 , the structure of the butt joint 01 is: the contact head 14 is fixedly connected with the ball pair 16, the ball pair 16 is matched with the concave round seat 18 through the gland 17, and the contact head 14 is connected with the round seat through the spring 15 18; the structure of the docking seat 02 is: the motor assembly 11 is fixedly connected with the driving gear 10, the gear 10 is meshed with the driven gear 9, and the gear 9 is fixedly connected with the screw rod 6, and the screw rod 6 Cooperate with the nut 5 screw, and the nut 5 is hinged with the two tension hooks 2, each of the tension hooks 2 is equipped with a roller 3, and the two rollers 3 are respectively connected with the two chute 4 Sliding contact, the two ends of the screw rod 6 are respectively matched with a bearing support 7 and a docking guide groove 12 t...

Embodiment 3

[0018] Example Three: Combining figure 1 and 2 To illustrate this embodiment, the screw rod 6 and the nut 5 in this embodiment cooperate through self-locking threads to ensure the tightness and reliability of the butt joint. Other compositions and connections are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com