Adjustable motor cabinet

A motor base and adjustable technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of large structural installation space, inconvenient disassembly and installation, and reduced mechanical efficiency, so as to achieve small installation space requirements, convenient use, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

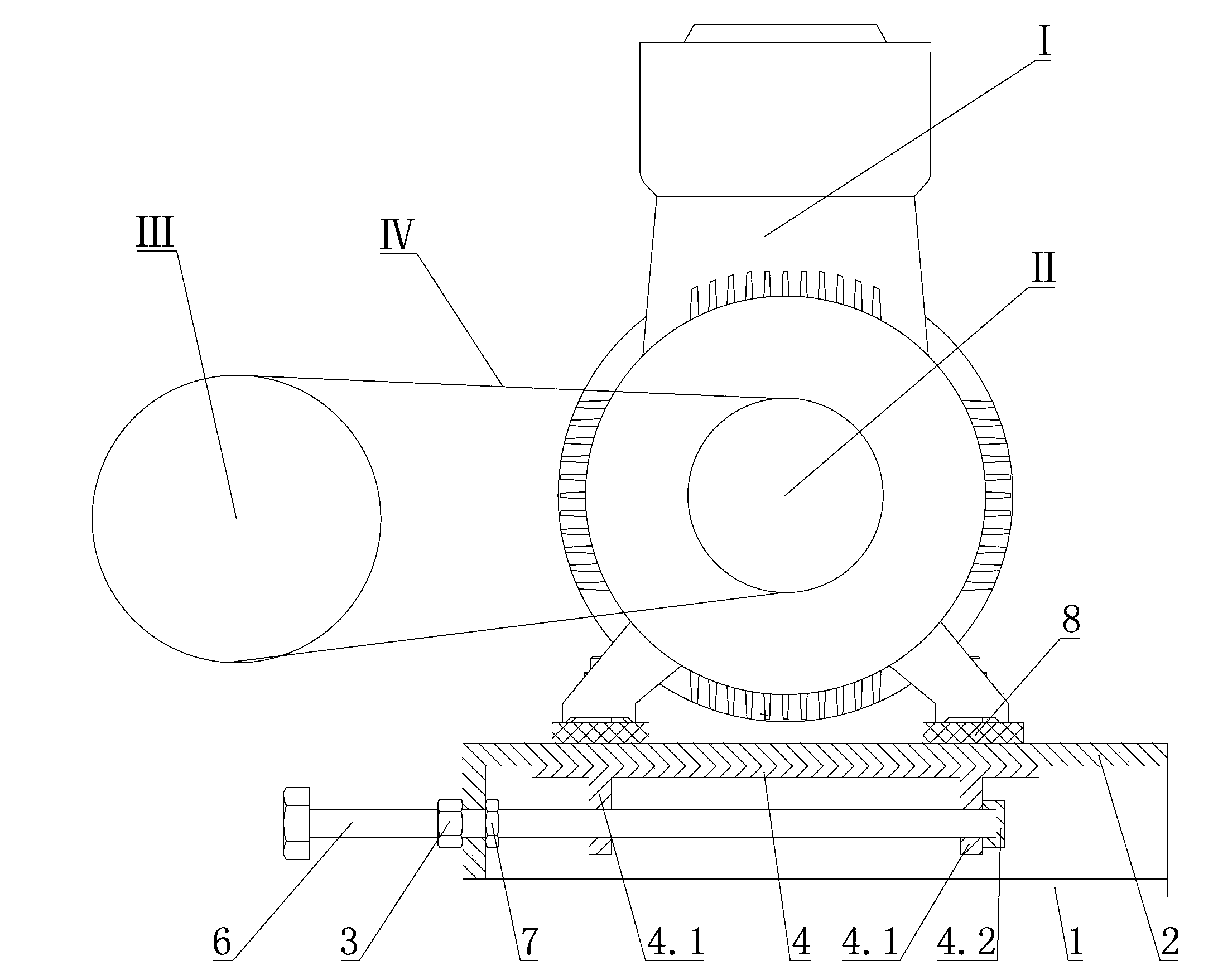

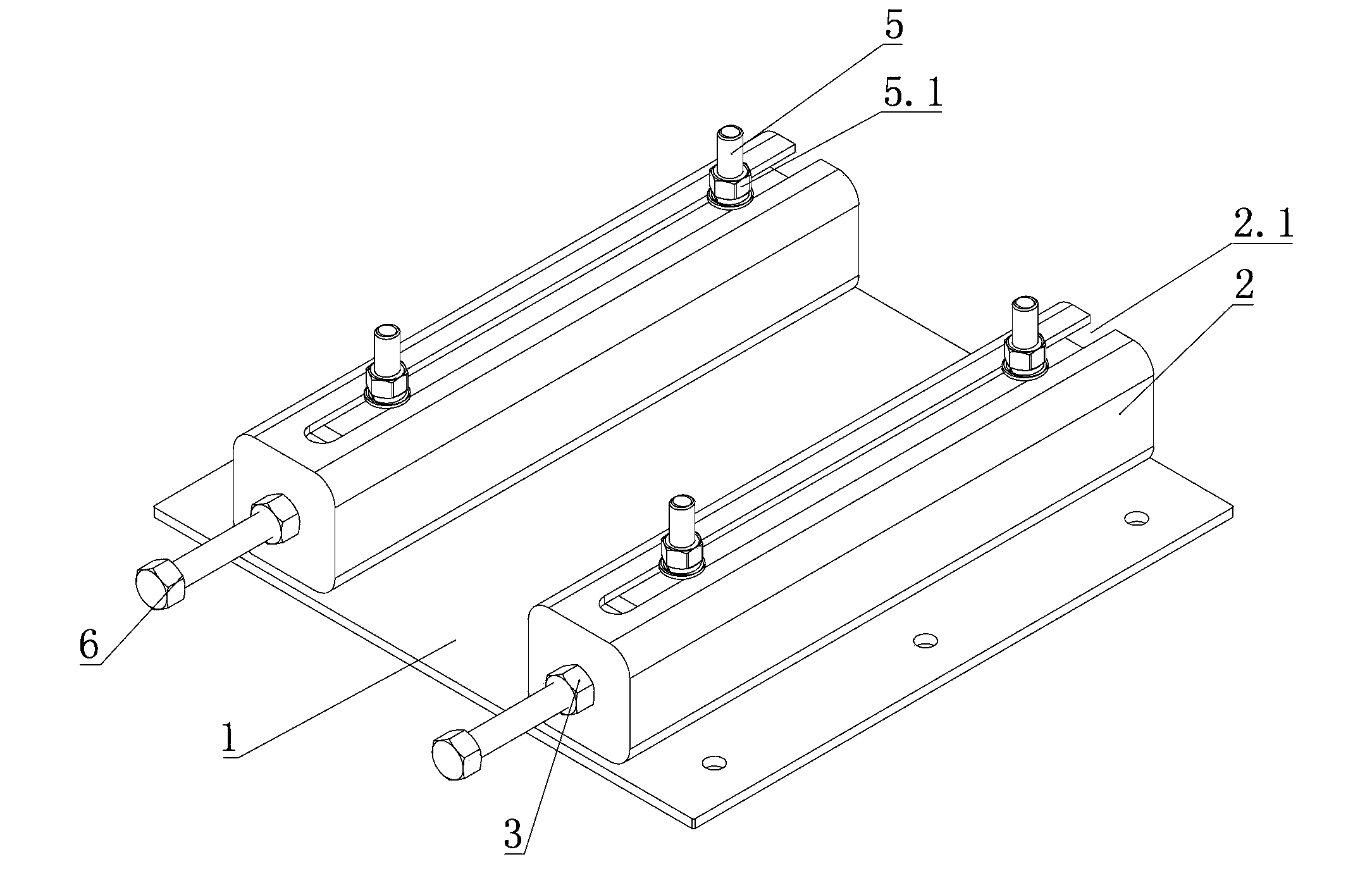

[0016] Such as figure 1 with figure 2 As shown, the adjustable motor base includes a base (not shown), and the mounting plate 1 is fixed by the bolt base; the fixed guide rail body 2 is arranged above the mounting plate 1, and the top of the fixed guide rail body 1 is provided with a slot. There is a through hole, and the outer side of the side shell is fixedly connected with a sliding fixing nut 3, and the inner side is provided with a guide nut 7; the other side of the shell is an opening; the π-shaped sliding plate assembly 4 passes through the motor fixing bolt 5 arranged on the top It is hoisted inside the fixed guide rail body 2; the lifting lug 4.1 of the sliding plate assembly 4 is provided with a through hole, and the outer side of one of the lifting lugs 4.1 is provided with a limit block 4.2, and the limit block 4.2 is provided with an internal thread; the adjustment screw 6 passes through the slide and is fixed Nut 3 fixes the through hole on the guide rail body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com