Self-traveling mini underground pipeline tunneling machine

An underground pipeline and self-propelled technology, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of not being able to automatically correct the forward trajectory, soil structure damage, and self-propelling, etc., to improve service life and reduce cutting resistance , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

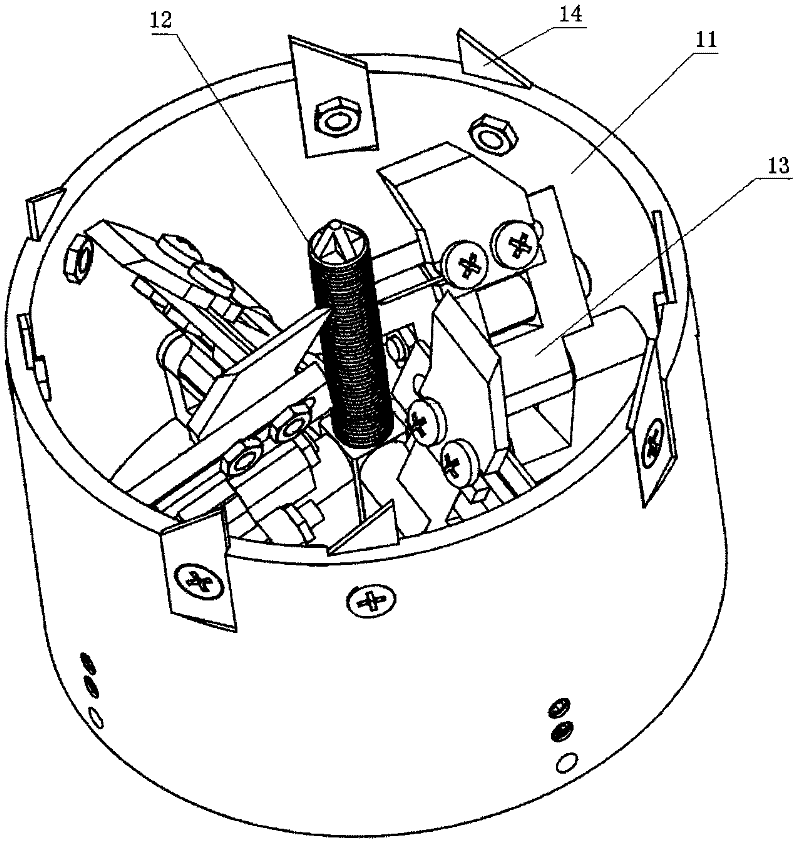

[0046] This embodiment is used in the tunneling construction of an underground pipeline with a diameter of 1 meter and a diameter of 20 cm. The environment for laying the pipeline is dry clay or sandy soil with uniform soil quality and a small amount of impurities.

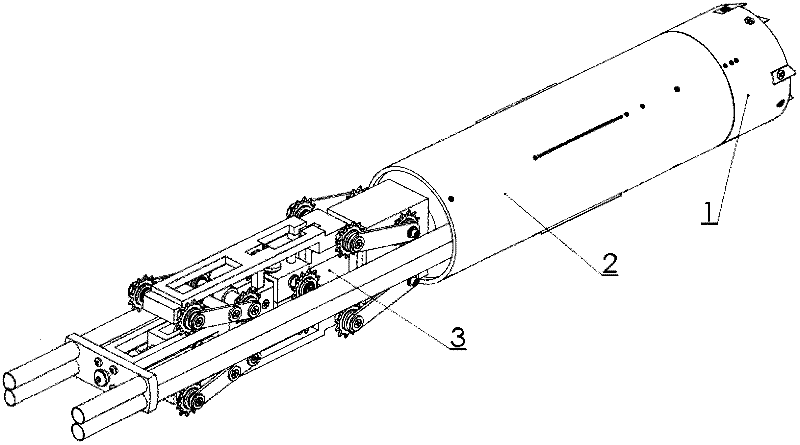

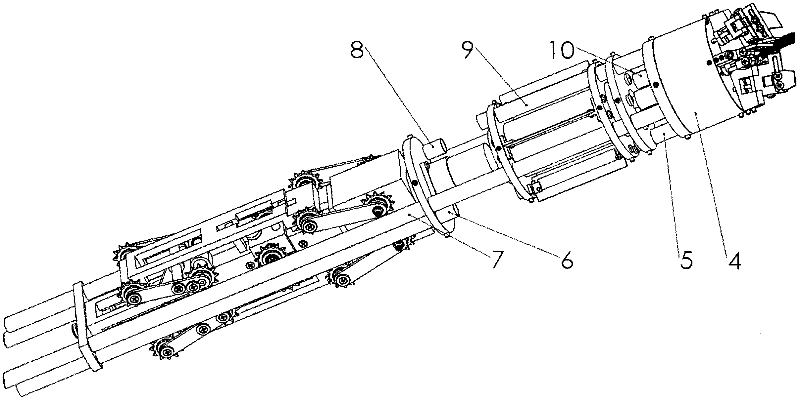

[0047] Refer to attached figure 1 , in this embodiment, the self-propelled miniature underground pipeline boring machine has a cutter head mechanism 1 at the front, a walking mechanism 3 at the rear, and a power mechanism at the middle, and a middle shell 2 is arranged outside the power mechanism to separate the power mechanism from the external soil. .

[0048] Refer to attached image 3 , The cutter head mechanism 1 includes three parts: a shell cutting mechanism, a main body cutting tool and a spindle 12 with a drill bit. The shell cutting mechanism includes a cutter head shell 11 and a circumferential blade 14; the cutter head shell 11 is a thin-walled cylindrical structure, the outer cylinder wall circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com