Inflatable paper winding shaft of high speed paper machine

A high-speed paper machine and paper reel technology, applied in the field of papermaking, can solve the problems of low reliability, inconvenient maintenance, complex structure, etc., and achieve the effects of flexible operation, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

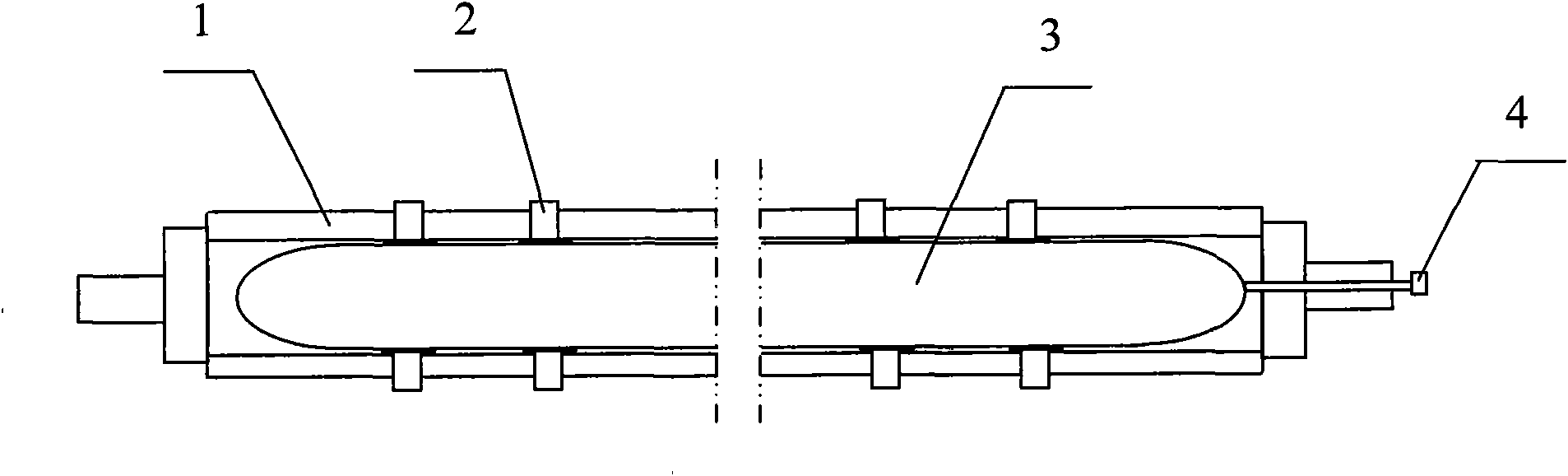

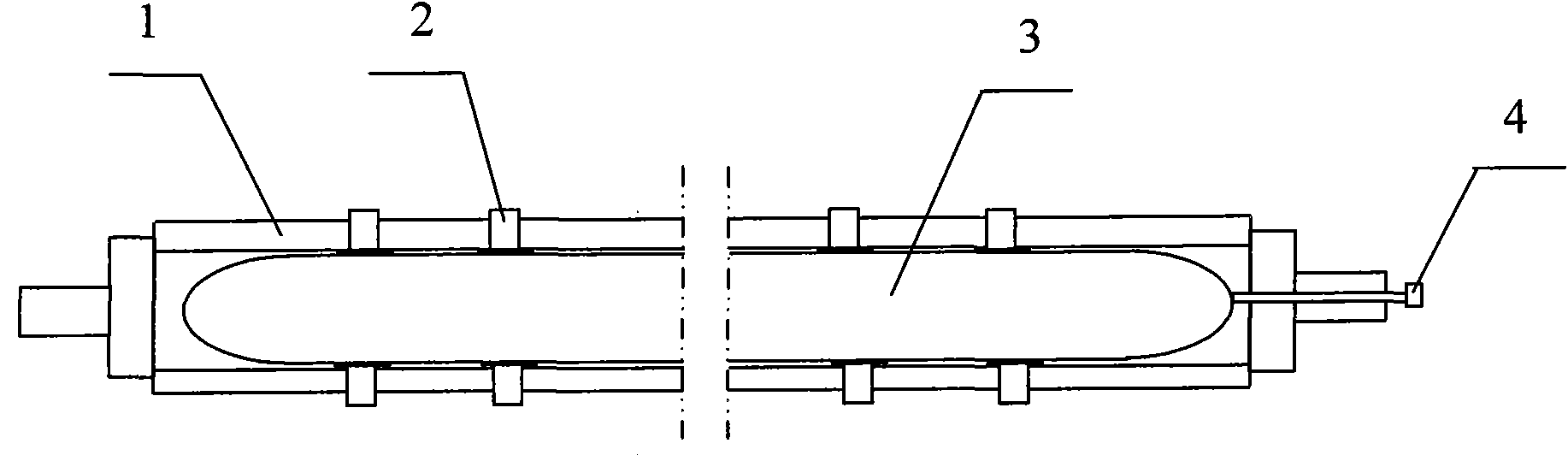

[0012] The schematic diagram of the air-expanding reel shaft of the high-speed paper machine of the present invention is as follows figure 1 As shown, it includes the shaft body of the hollow paper reel, and the shaft body is provided with a plurality of through holes, and each through hole is embedded with a tension block moving along the direction of the shaft diameter, and the inside of the shaft body is provided with an inflatable air bag, The end of the inflatable airbag is provided with an air nozzle protruding from the outside of the shaft body.

[0013] When in use, there is less gas in the inflatable air bag, and the tension block is retracted into the shaft body, so it is easy to wrap the paper core on the roll paper shaft. Inflate the air from the air nozzle to the inside of the inflatable airbag. After the inflatable airbag is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com