Varnished wire pulling and winding device

A winding device and enameled wire technology, which are applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material handling, etc., can solve the problems of low winding quality, laborious and inefficient, enameled wire winding, etc., and improve the winding speed. Quality, effortless installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

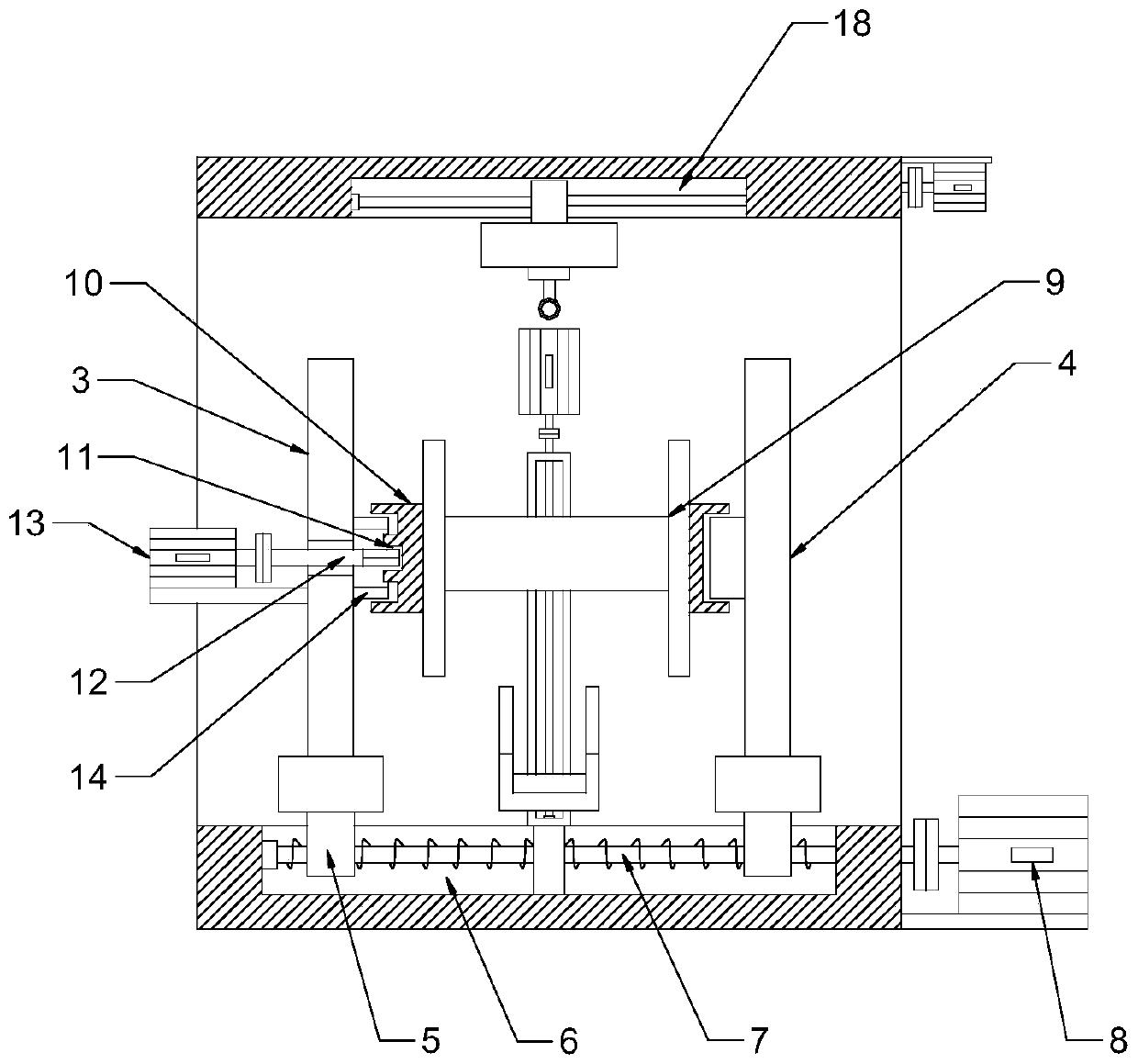

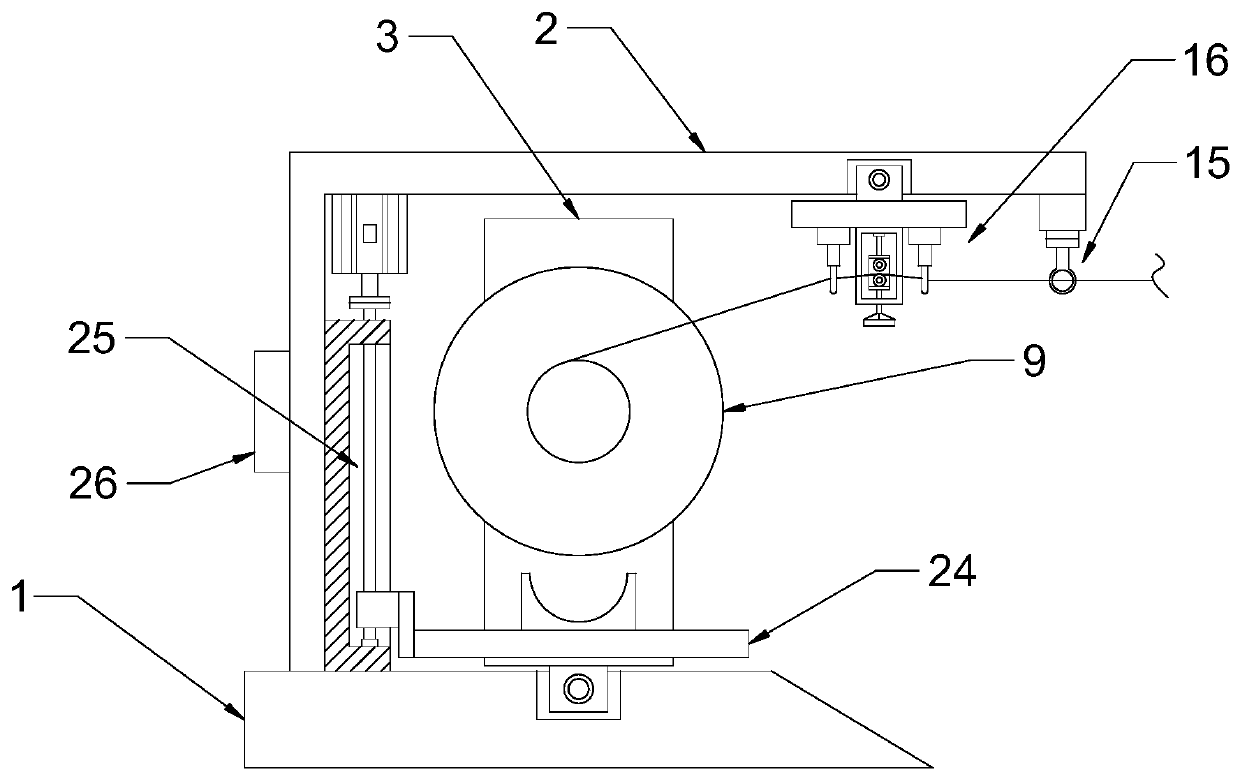

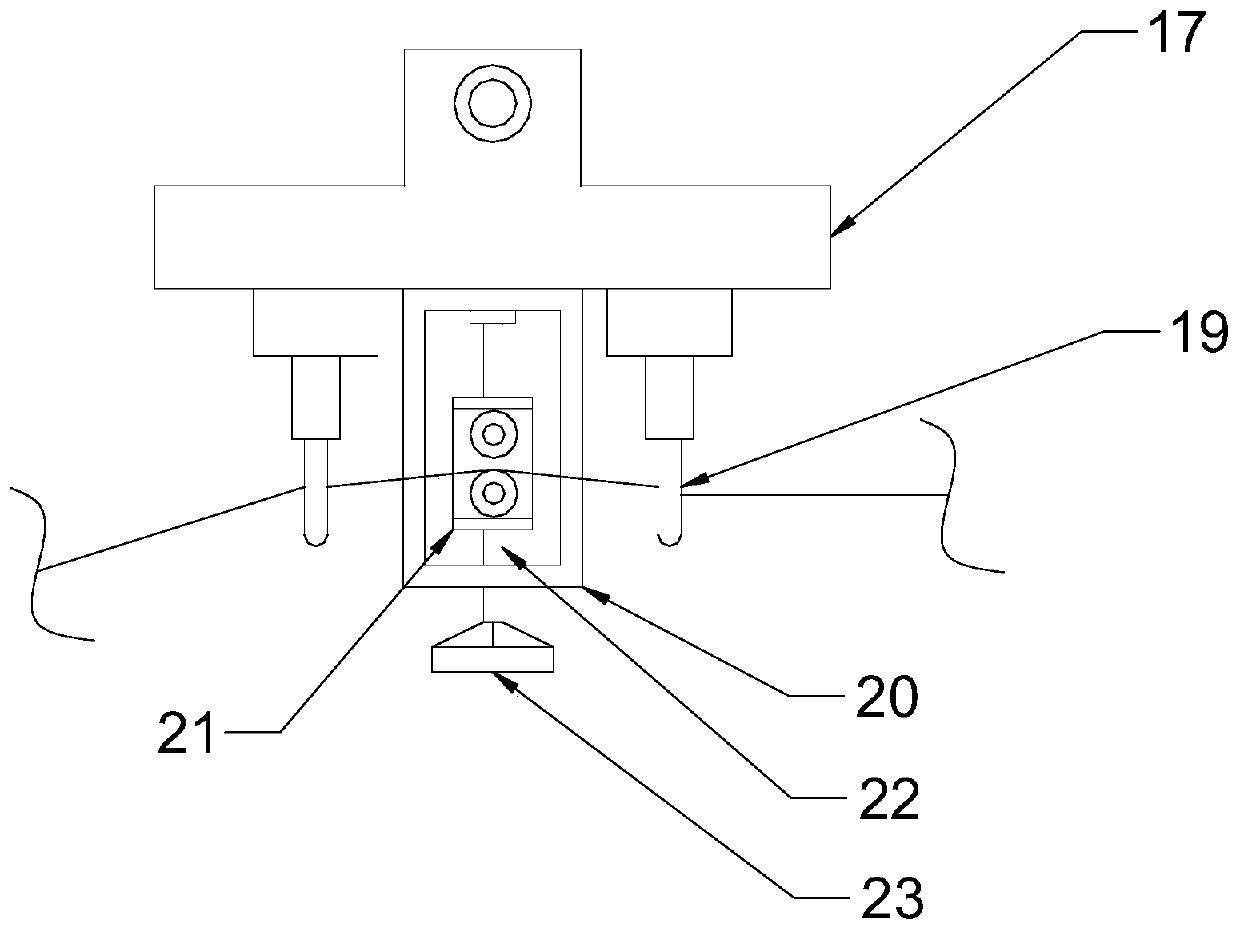

[0021] see Figure 1~4 , in an embodiment of the present invention, an enameled wire pulling and winding device includes a base 1, a mounting frame 2 fixedly connected to the base 1 and protruding forward, and a coil 9; a coil 9 is provided above the base 1, and the coil 9 is The two sides of volume 9 are connected with the first supporting plate 3 and the second supporting plate 4 which are symmetrically arranged respectively in rotation; 5 is nested in the sliding groove 6 provided in the base 1, the sliding groove 6 is provided with a bidirectional screw rod 7, the bidirectional screw rod 7 runs through the symmetrically arranged first moving block 5 and is threadedly connected with the first moving block 5, bidirectional The screw rod 7 extends to the rear side of the base 1 and is connected with a first screw motor 8 through a coupling. The first screw motor 8 drives the two-way screw rod 7 to rotate, so that the first moving block moves toward or back, and then drives T...

Embodiment 2

[0026] see figure 1 and figure 2 The difference between this embodiment and Embodiment 1 is that a lifting frame 24 is provided below the coil 9, and the lifting frame 24 includes a group of support plates with arc-shaped grooves at the upper end, and the lifting frame 24 is connected with a vertical screw drive. Mechanism 25, the vertical screw drive mechanism includes a vertical screw rod and a vertical chute and a moving block nested in the chute and fixedly connected to the lifting frame 24, the vertical screw drive mechanism 25 drives the lifting frame 24 up and down Moving, when installing and dismounting the coil, the coil is lifted and moved down, so that the installation and removal of the coil is convenient and labor-saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com