Decoration garbage treatment equipment

A technology of waste treatment equipment and bevel teeth, applied in the field of decoration waste treatment equipment, can solve the problem of inability to adjust the degree of crushing of decoration waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

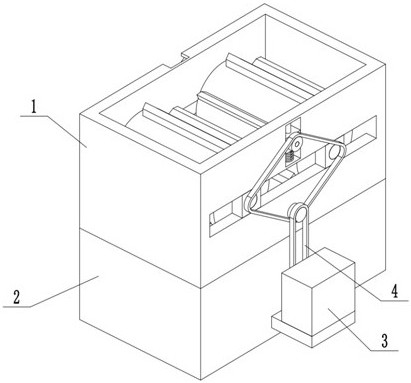

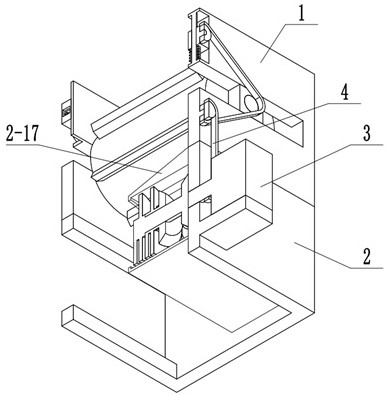

[0029] Combine below Figure 1-10 Describe this embodiment, a decoration garbage treatment equipment, including a crushing assembly 1, a separation assembly 2, an input motor 3, and a connecting belt 4, the crushing assembly 1 and the separation assembly 2 are assembled and connected up and down, and the input motor 3 is arranged On the side of the component 2, the input motor 3 is connected to the crushing component 1 through a connecting belt 4;

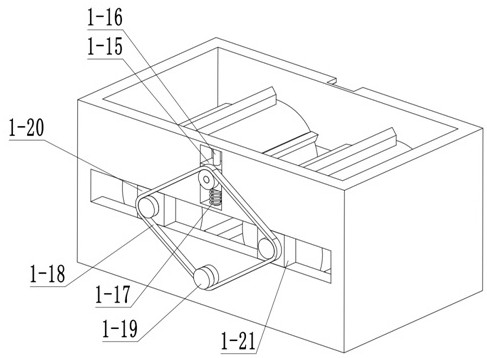

[0030]The crushing assembly 1 includes an outer frame 1-1, a rectangular chute 1-2, a rectangular slider 1-3, a rectangular slider 2 1-4, a middle rotating column 1-5, and a middle rotating column 2 1-6, hinged connecting rod one 1-7, hinged connecting rod two 1-8, driving slider 1-9, slot one 1-10, crushing roller one 1-11, crushing rod one 1-12, crushing roller Two 1-13, crushing rod two 1-14, rear end slider 1-15, rear end slide bar 1-16, rear end slide bar push spring 1-17, belt 1-18, input pulley 1-19, Rectangular slider thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com