Cutting wire tensity and temperature measurement and control device for EPS (Expanded Poly Styrol) slab cutting machine

A measurement and control device, cutting wire technology, applied in metal processing and other directions, can solve problems such as affecting cutting accuracy, worker injury, easily causing wire breakage, etc., to achieve the effect of improving cutting quality and eliminating manual installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

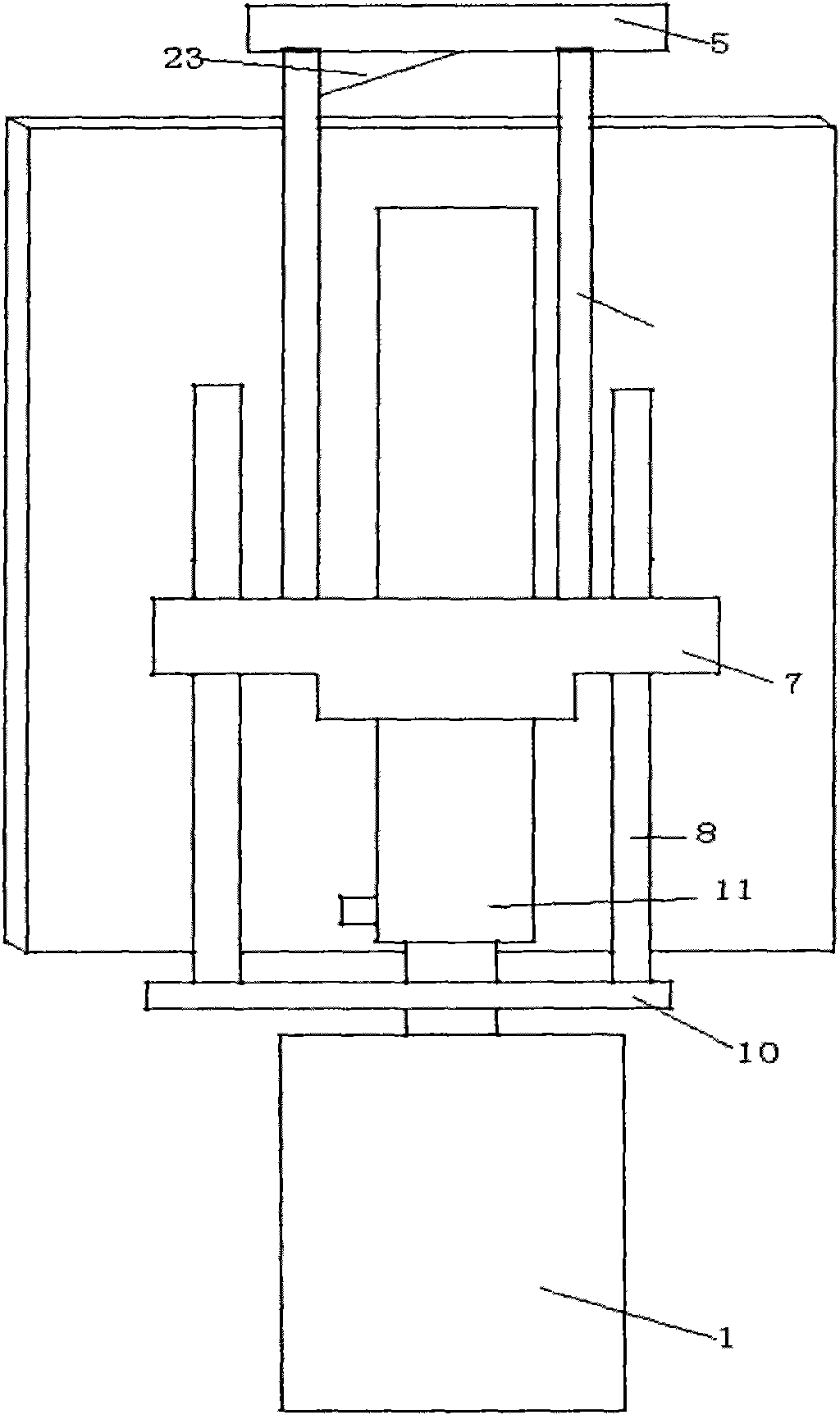

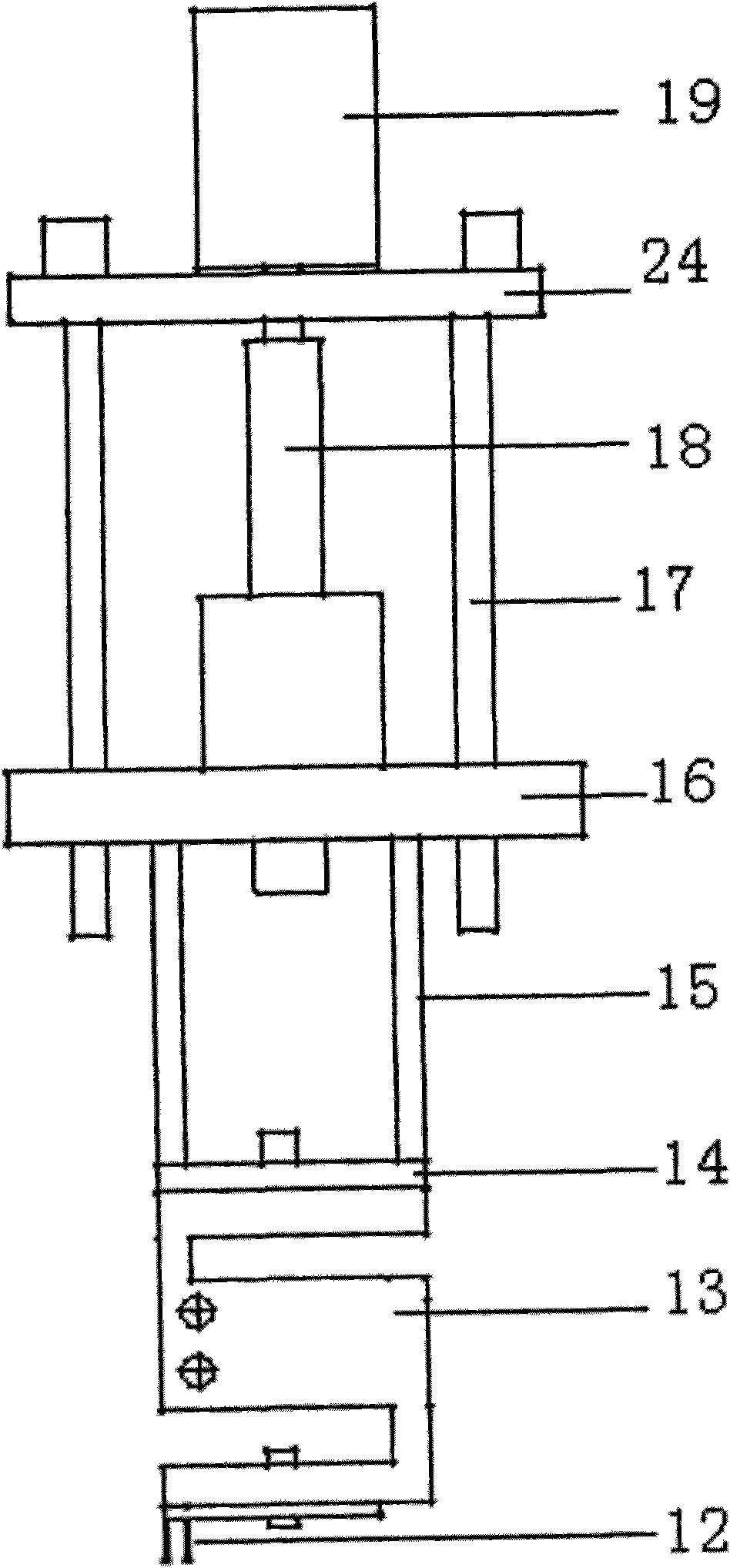

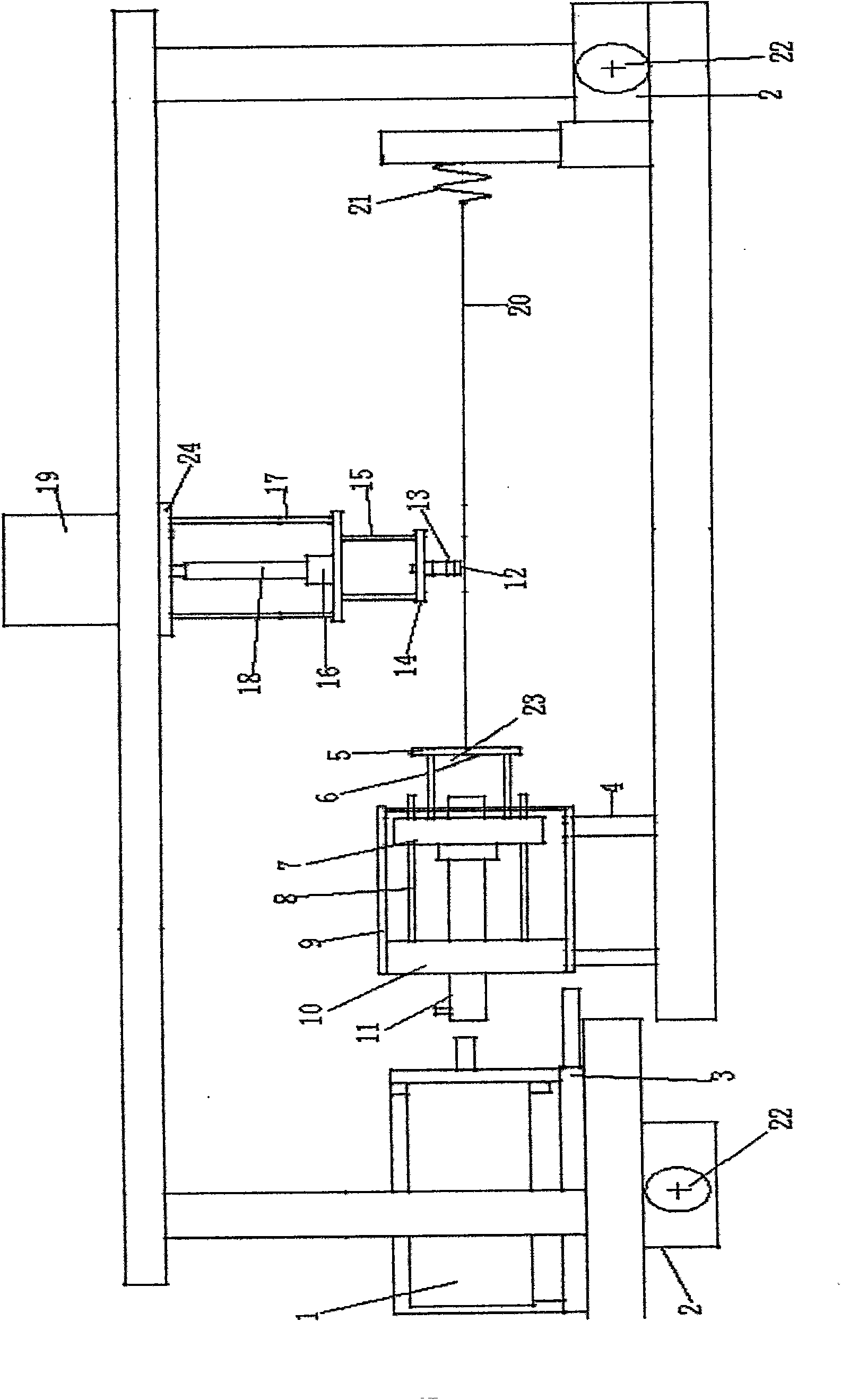

[0015] refer to figure 1 A support plate 10 connected to the suspension frame, a stepping motor 1 installed on the outside of the support plate, and a lead screw 11 driven by the stepping motor are installed at one end of the cutting wire hanger, and the threaded screw fits on the lead screw The moving disc 7 is fixed on the support plate, and the optical axis 8 that is slidingly matched with the hole on the moving disc is fixed on the cutting wire side hanging wire plate or beam 5 on the moving disc. It is fixed at the position of the stepper motor 1; the tension sensor 13 is fixed to the F-type contactor 12 by one end of the cutting wire; The moving disk 16 is fixed on a fixed plate 24 with an optical axis 17 . The other end of the fixing plate 24 is equipped with a stepping motor 19 connected with the lead screw 18 . Fix cutting frame stepper motor 19 positions. The temperature sensor 23 adopts a PT100 type temperature sensor and the cutting wire is closely wound and ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com