Polyurethane coated resilient surface covering having improved fidelity of texture and process of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

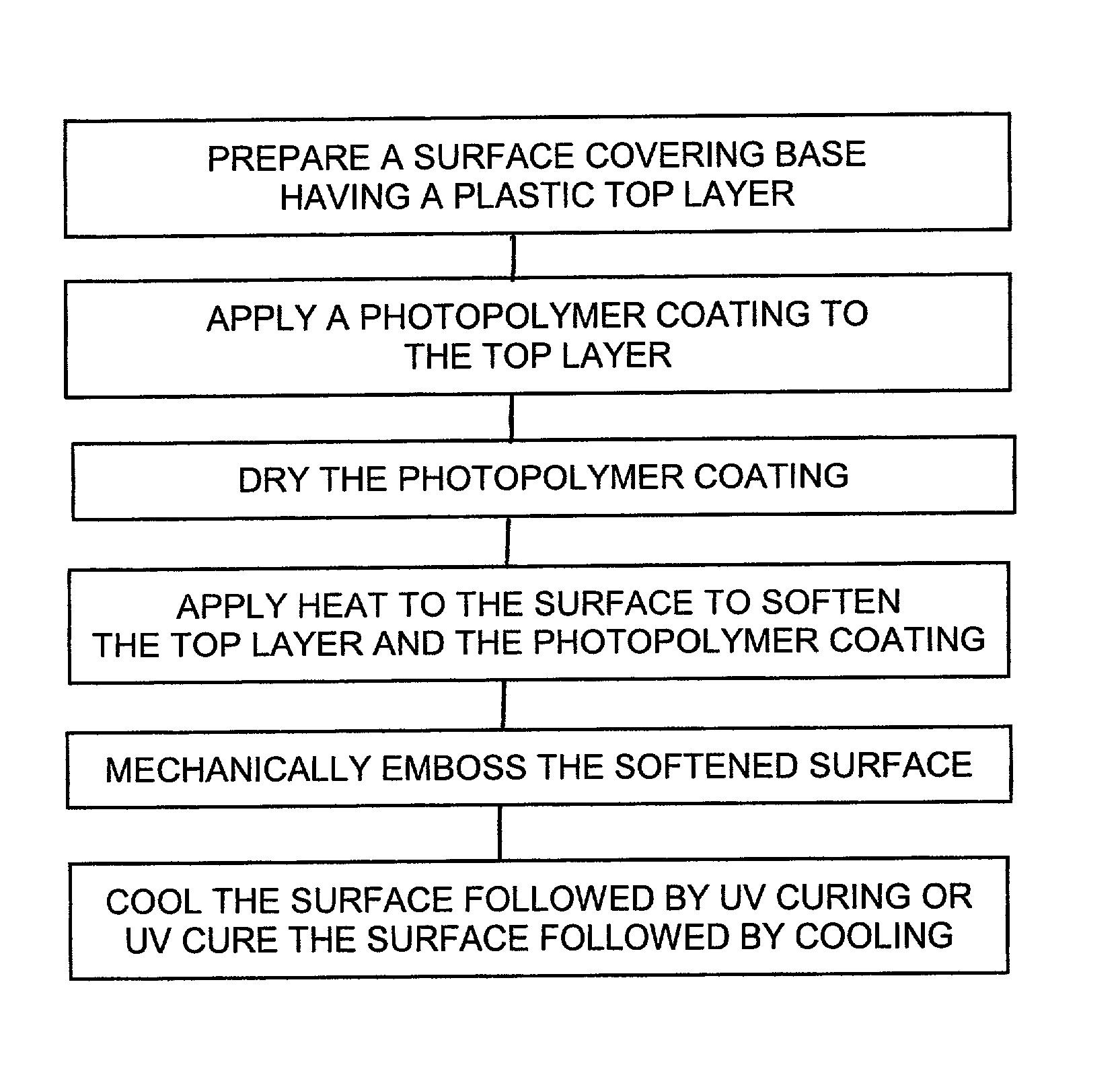

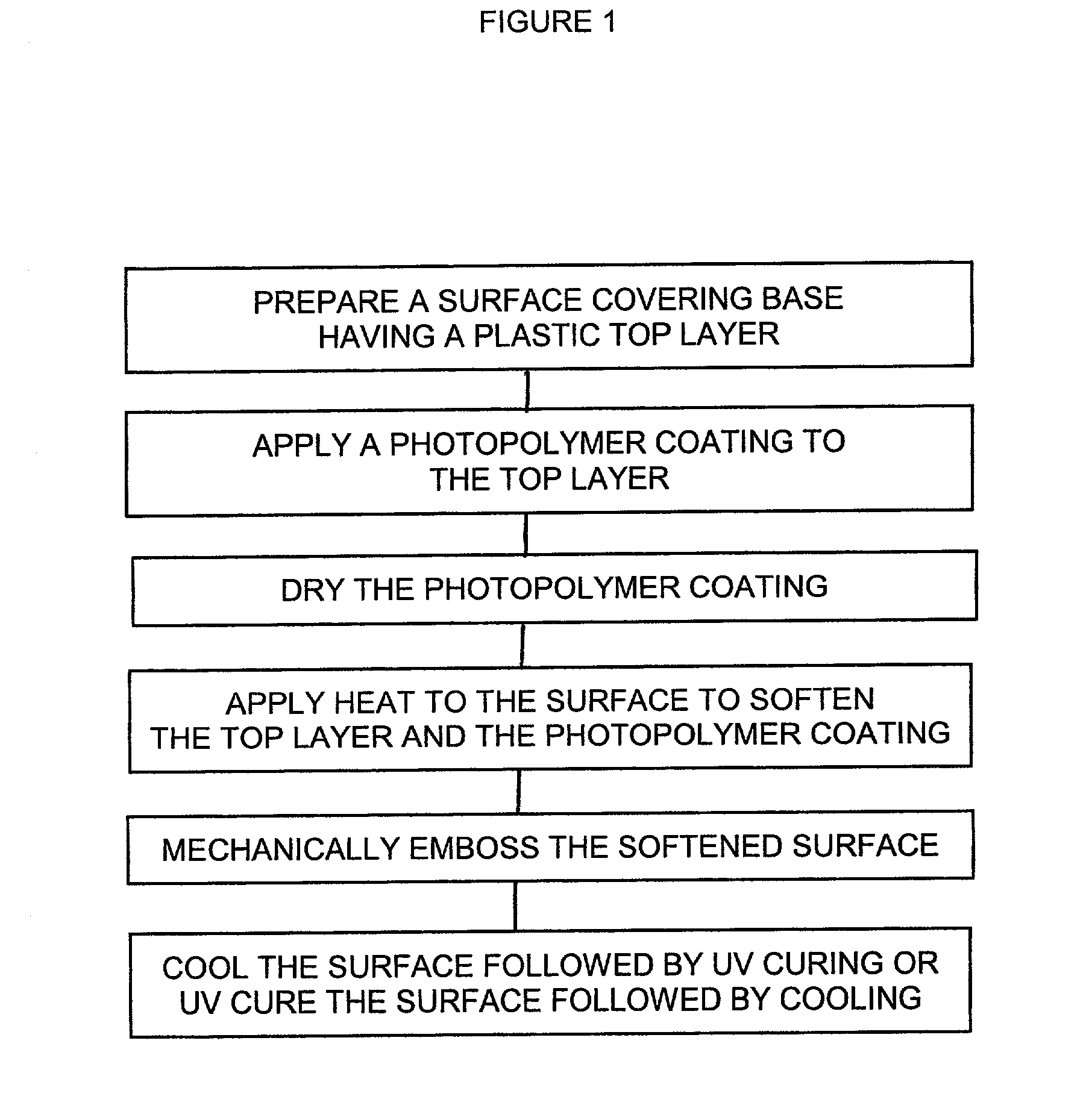

Method used

Image

Examples

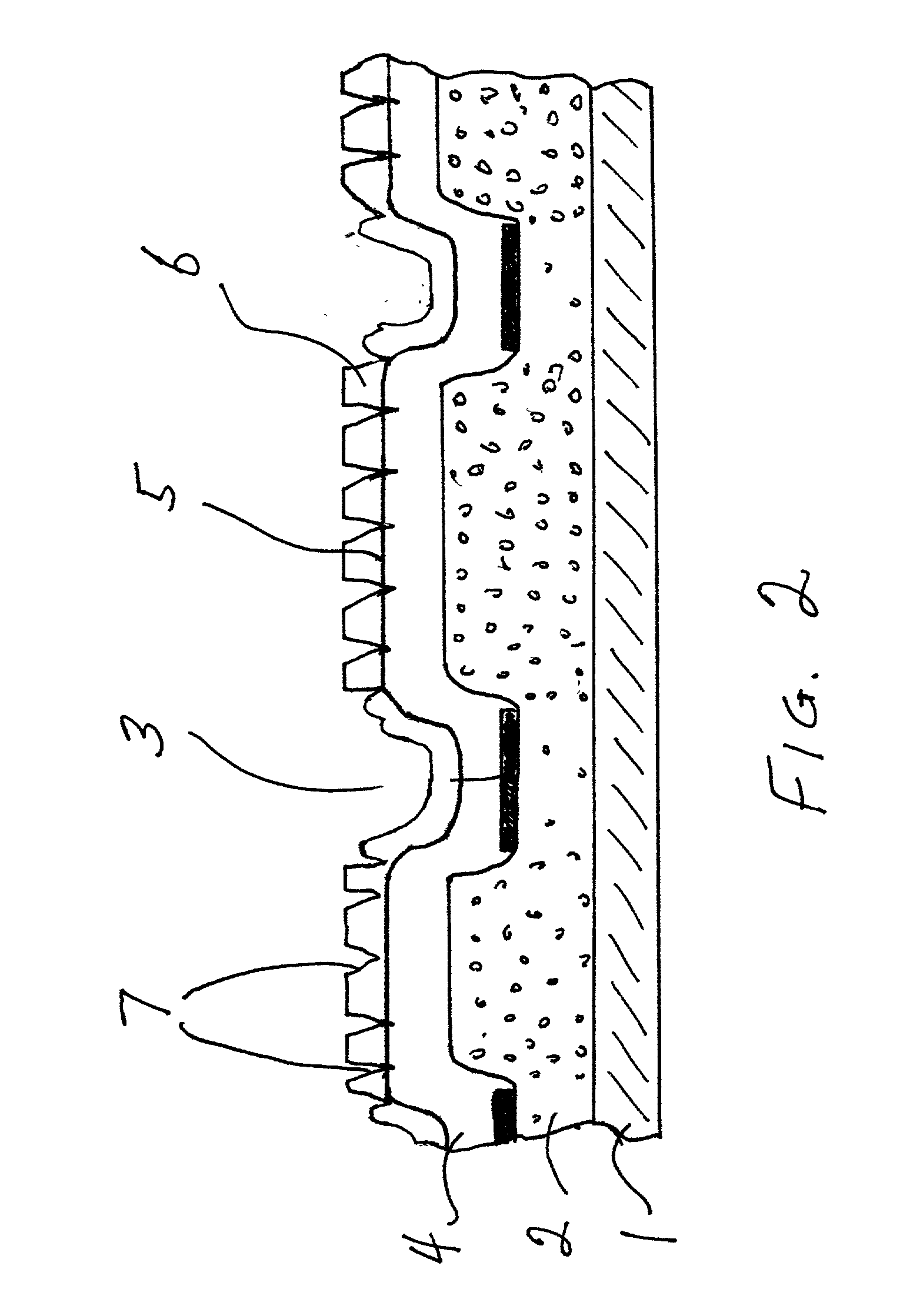

Embodiment Construction

[0052] The polyurethane is applied in excess with a roll coater. Thereafter an air knife is used to control the exact amount to be laid on the flooring material. In our experiments, we applied 15 micrometers ("um") dry. We used various means to dry the polyurethane, including an air blown oven, microwave oven and an oven combining IR@2.5 .mu.m wavelength with air blowing 3,000 m.sup.3 / h, the exhaust being around 5,000 m.sup.3 / h and this was the most preferred drying method. This oven is available from Glenro in the USA or Olbrich in Germany with IR elements from Krelus in Germany. With an installed power of 250 KW over a length of 2 m, the drying time is 8 seconds and the flooring material surface temperature reaches about 100.degree. C.

[0053] The UV crosslinkable PU can be formulated with or without acrylics, in a solvent or water phase or as an emulsion in a water / alcohol mixture. We prefer the water borne system to minimize fire risks and to protect the environment. The preferred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com