Colored radiation solidifed wearing-resistant layer

A technology of radiation curing and anti-wear layer, applied in coating, lamination, insulating layer, etc., can solve the problems of opaque coating, difficult curing of coating, and reduced durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

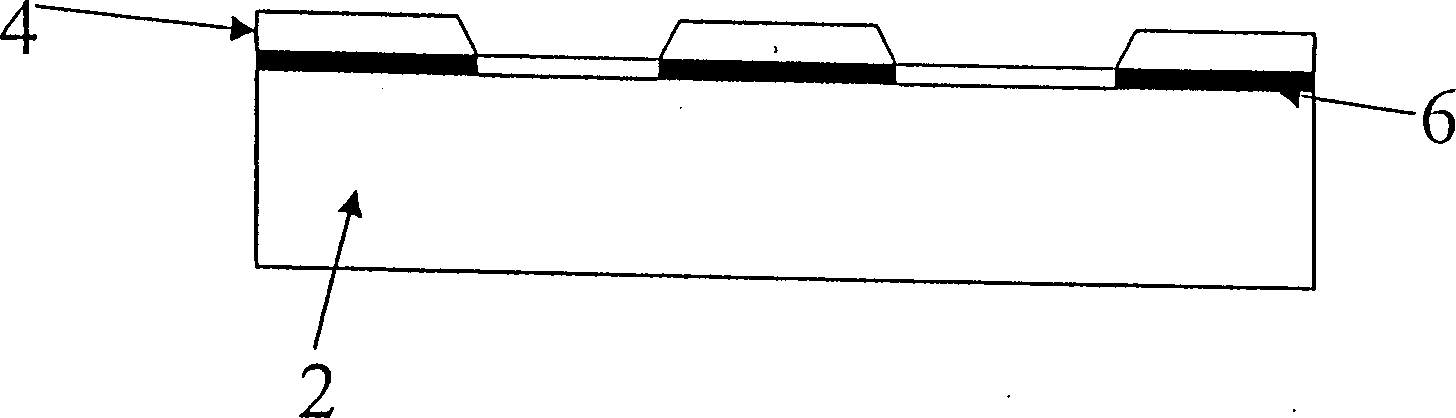

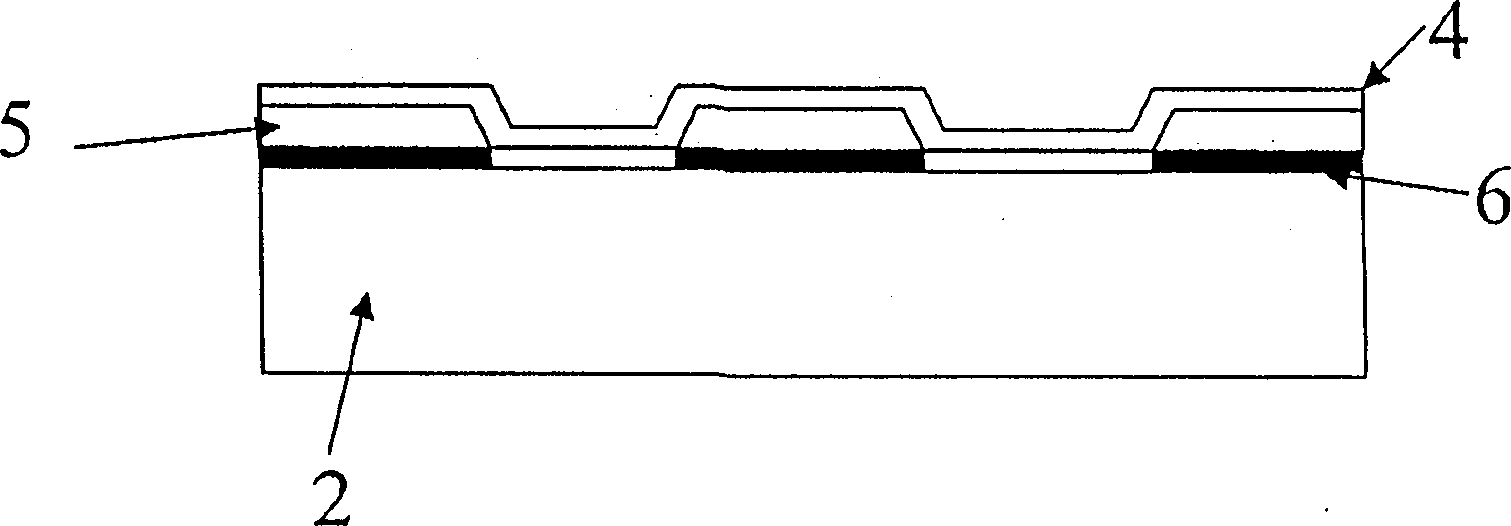

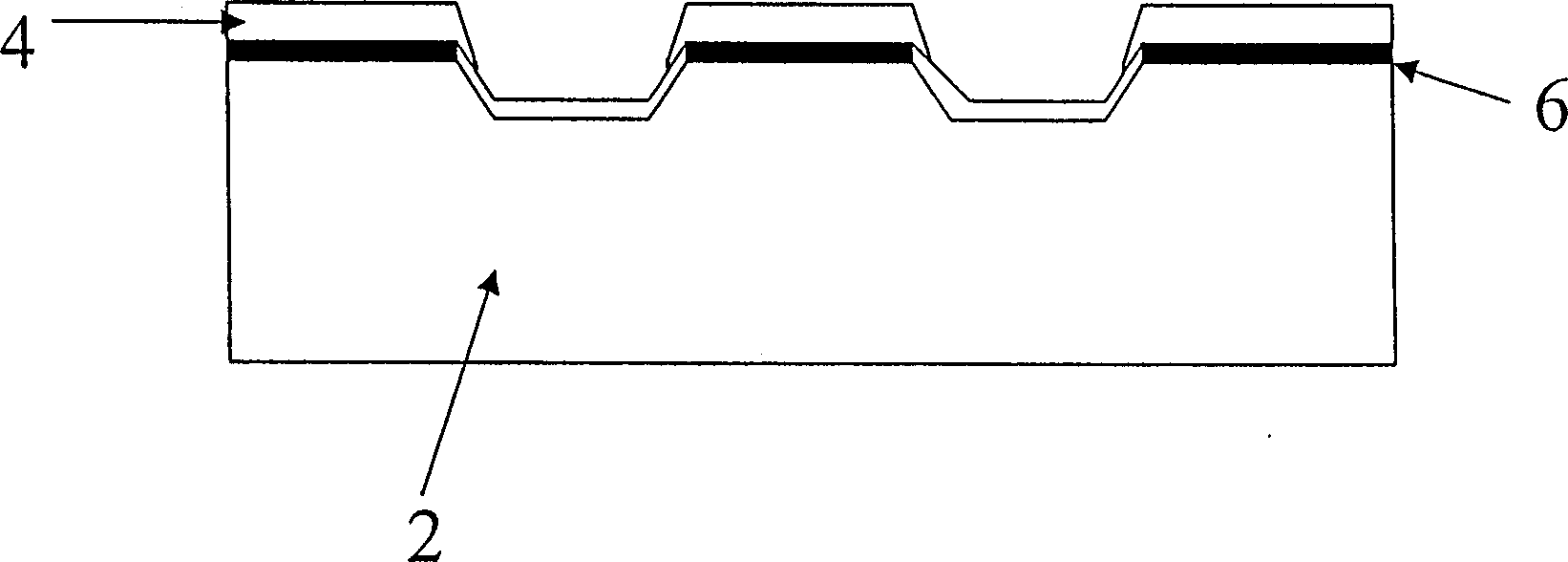

Image

Examples

Embodiment 1

[0051]A hydroxyl terminated polyester PE1 was prepared according to Example 1 of UPS No. 5,663,003, incorporated herein by reference. The polyester is prepared based on the following composition:

[0052] 1,6 hexanediol 992.7g

[0053] Glycerin 133.5g

[0054] Phthalic anhydride 1071 g

[0055] Dibutyltin dilaurate 0.5 g

[0056] The reaction mixture was cooled to obtain the final product with an acid number of 2.4 and a hydroxyl number of 179.

[0057] A coating composition was prepared as described in UPS No. 5,719,227, incorporated herein by reference. The following composition was charged to a 2 L flask equipped with a heating mantle, stirrer, and purged with dry air at a rate of 0.25 scf / hr:

[0058] Tone M-100 Hydroxyacrylate by Union Carbide 126g

[0059] Monomer mixture (27.5 wt.% of Sartomer SR499, 27.5 wt.% of 125 grams of Sartomer SR502, 45 wt.% of Sartomer SR351)

[0060] PE1 35g

[0061] The mixture was heated to 100°F and 87 grams of Desmo...

Embodiment 2

[0063] Top coat #1 is TiO 2 Pigment (R-HD6X, supplied by Huntsman) formulated with additional UV photoinitiator. The composition was preheated and applied to a backside printed rigid vinyl film to a thickness of 2 mils. The coated film was conveyed through a 12.75 inch heated drum maintained at about 150°F. With a wrap angle of about 90 degrees, the film is exposed to ultraviolet radiation using a conventional medium pressure mercury vapor lamp or a doped (V bulb) lamp whose spectral output covers the entire UV 200-450nm range. The coated and pigmented abrasion resistant film is then laminated to a tile substrate. The coating had good adhesion and acceptable floor abrasion resistance as judged by the Modified Tabor Abrasion Test Method. Table 1 shows the TiO 2 Various formulations of pigmented paints. All amounts are parts by weight unless otherwise indicated.

[0064] The formula of the colored paint of table 1 embodiment 1

Embodiment 3

[0066] With a kind of pearlescent pigment (Golden Bronze 2.24 μ m, provided by Mearl Corp), prepare top coat coating composition, be coated on the rigid vinyl film, carry out by the method for embodiment 2 with medium pressure mercury vapor lamp UV curing. The cured topcoat was used in flooring applications with acceptable performance.

[0067] The formula of the colored paint of table 2 embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com