Patents

Literature

123 results about "Embospheres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

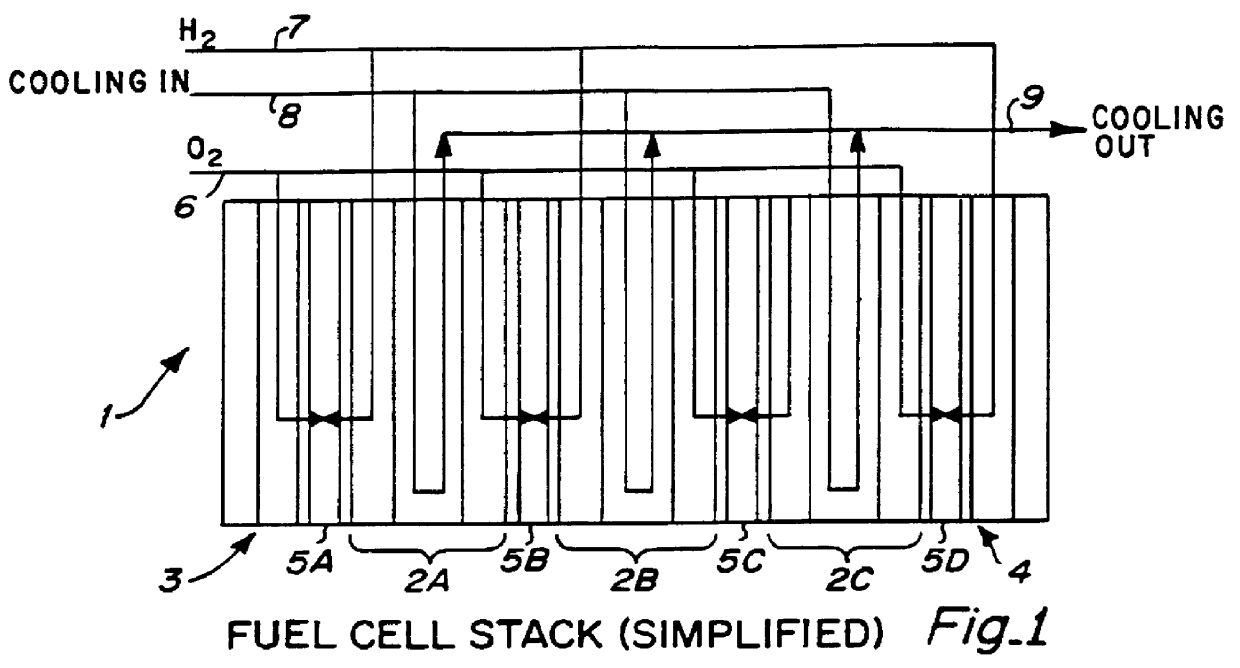

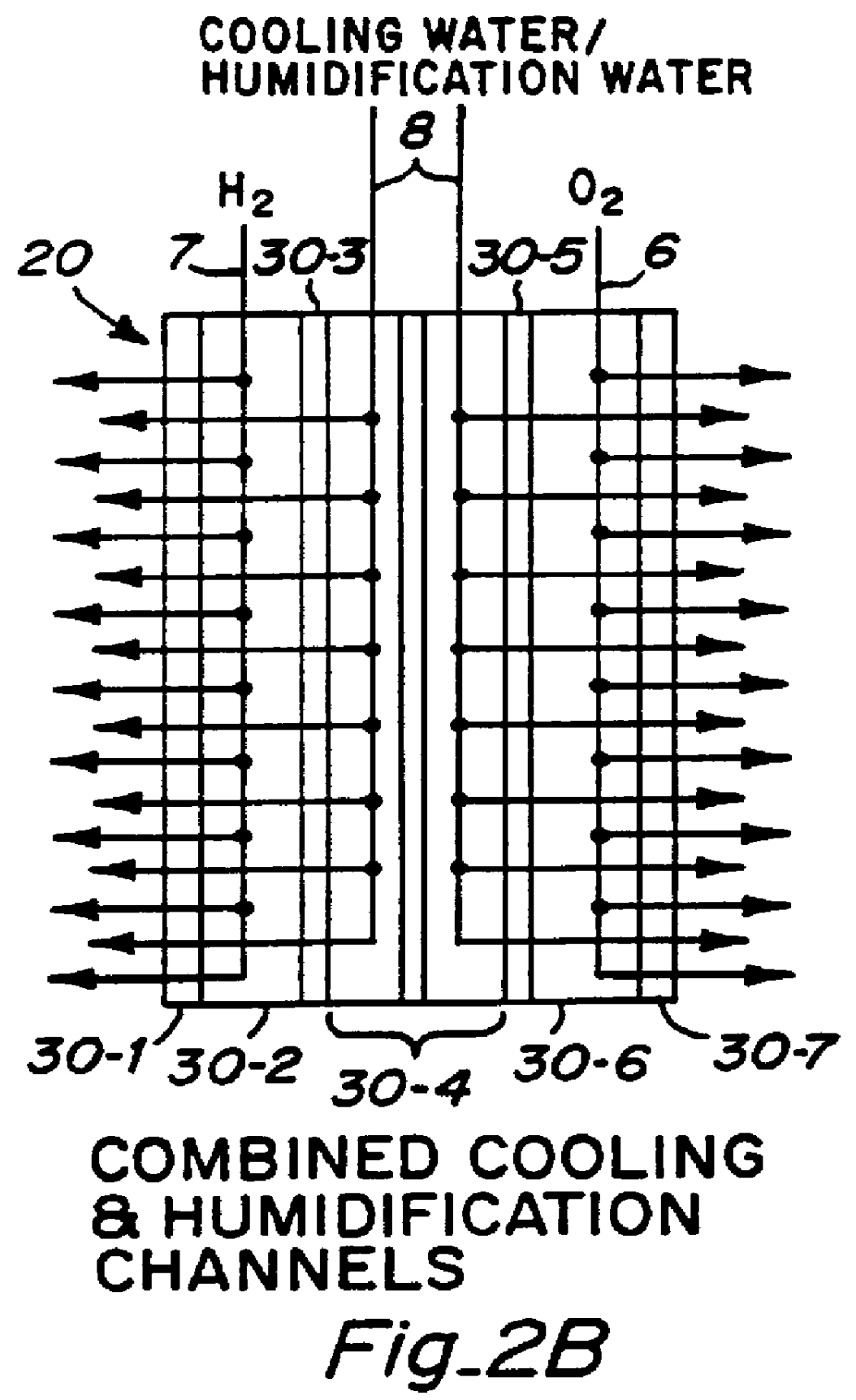

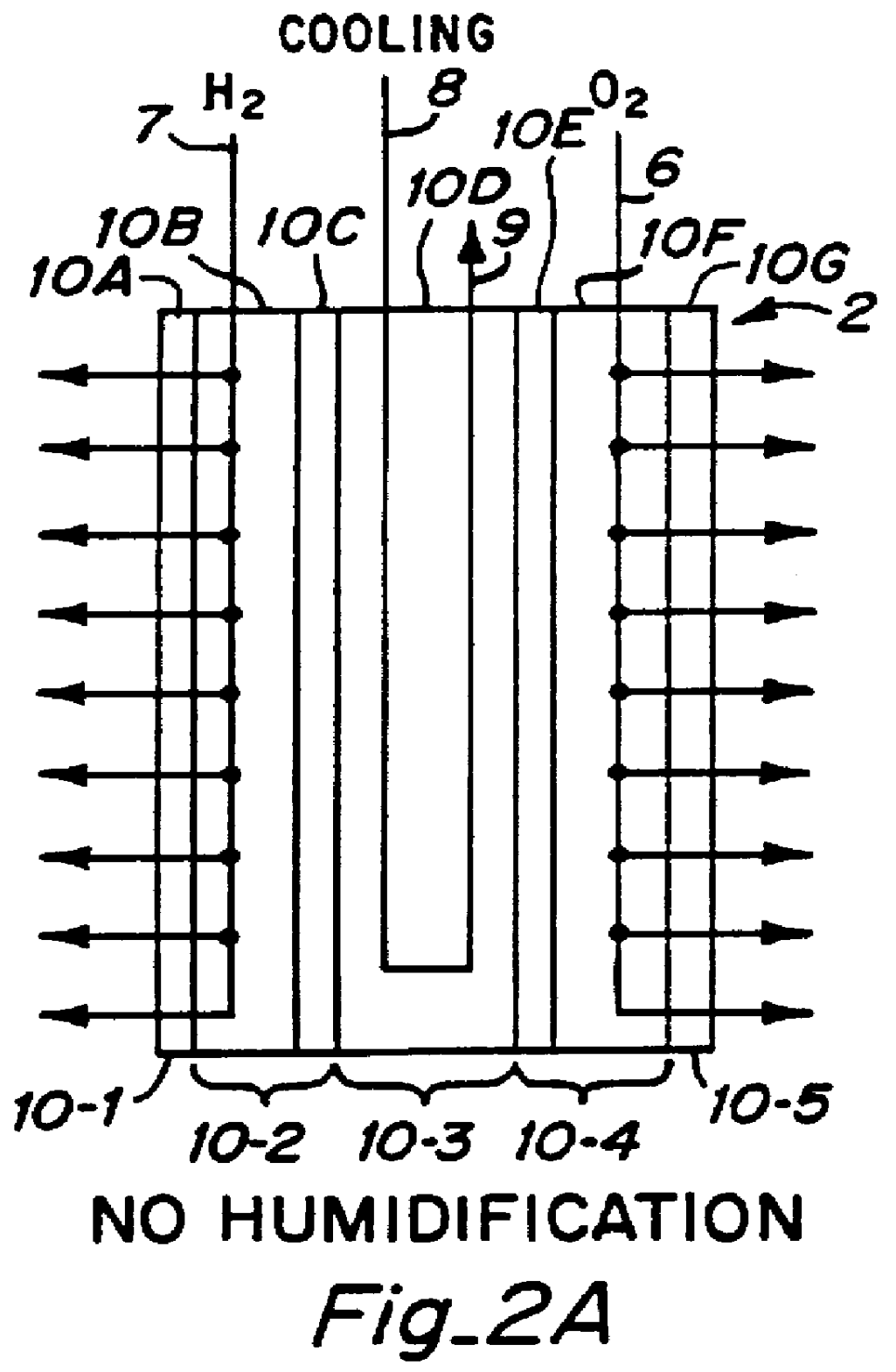

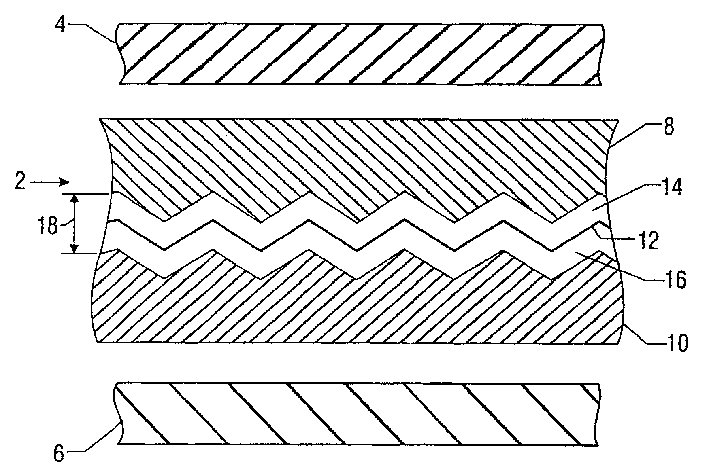

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

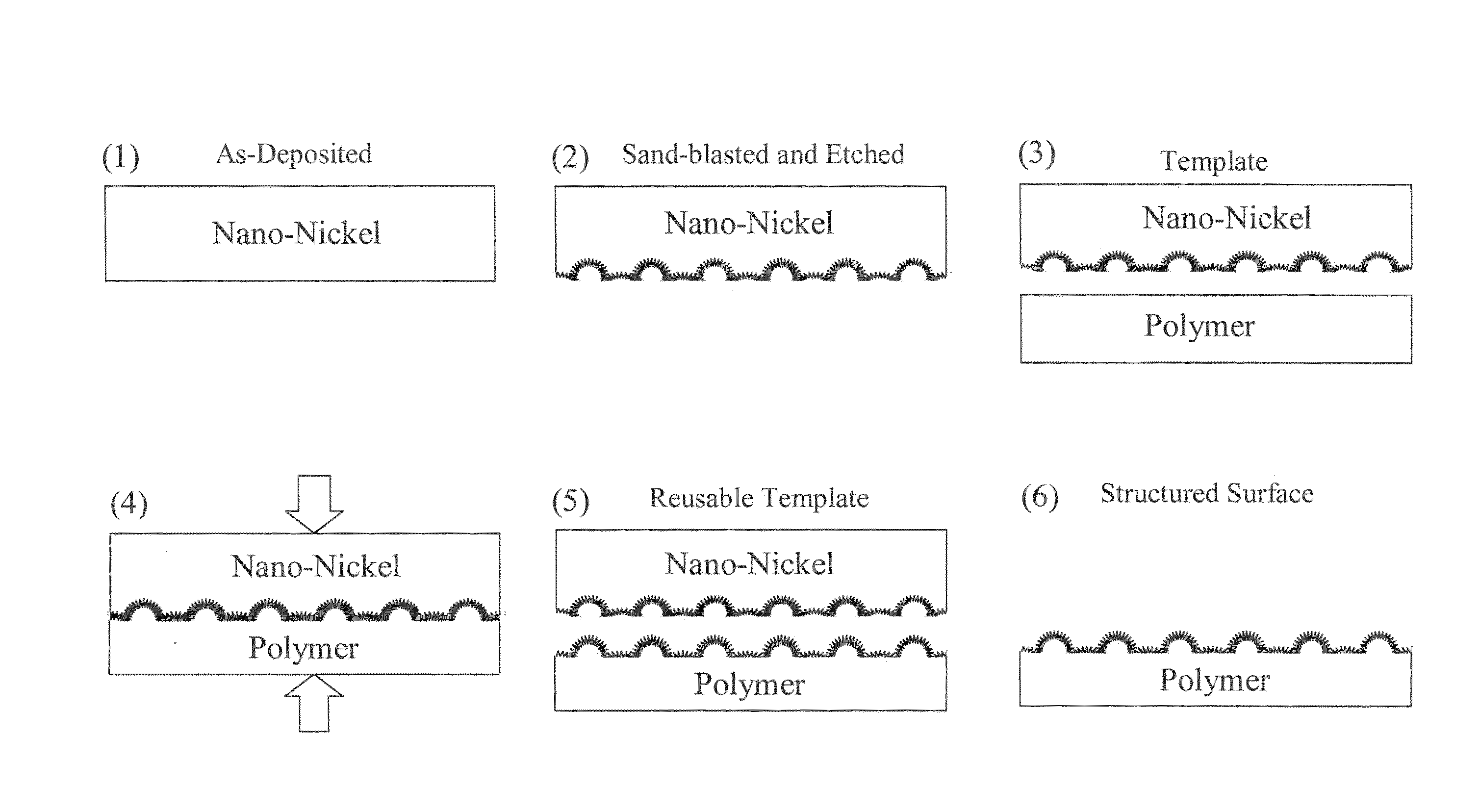

Articles with super-hydrophobic and/or self-cleaning surfaces and method of making same

ActiveUS20110287203A1Lower contact angleLarge scaleDischarging arrangementMouldsFine grainSelf-cleaning surfaces

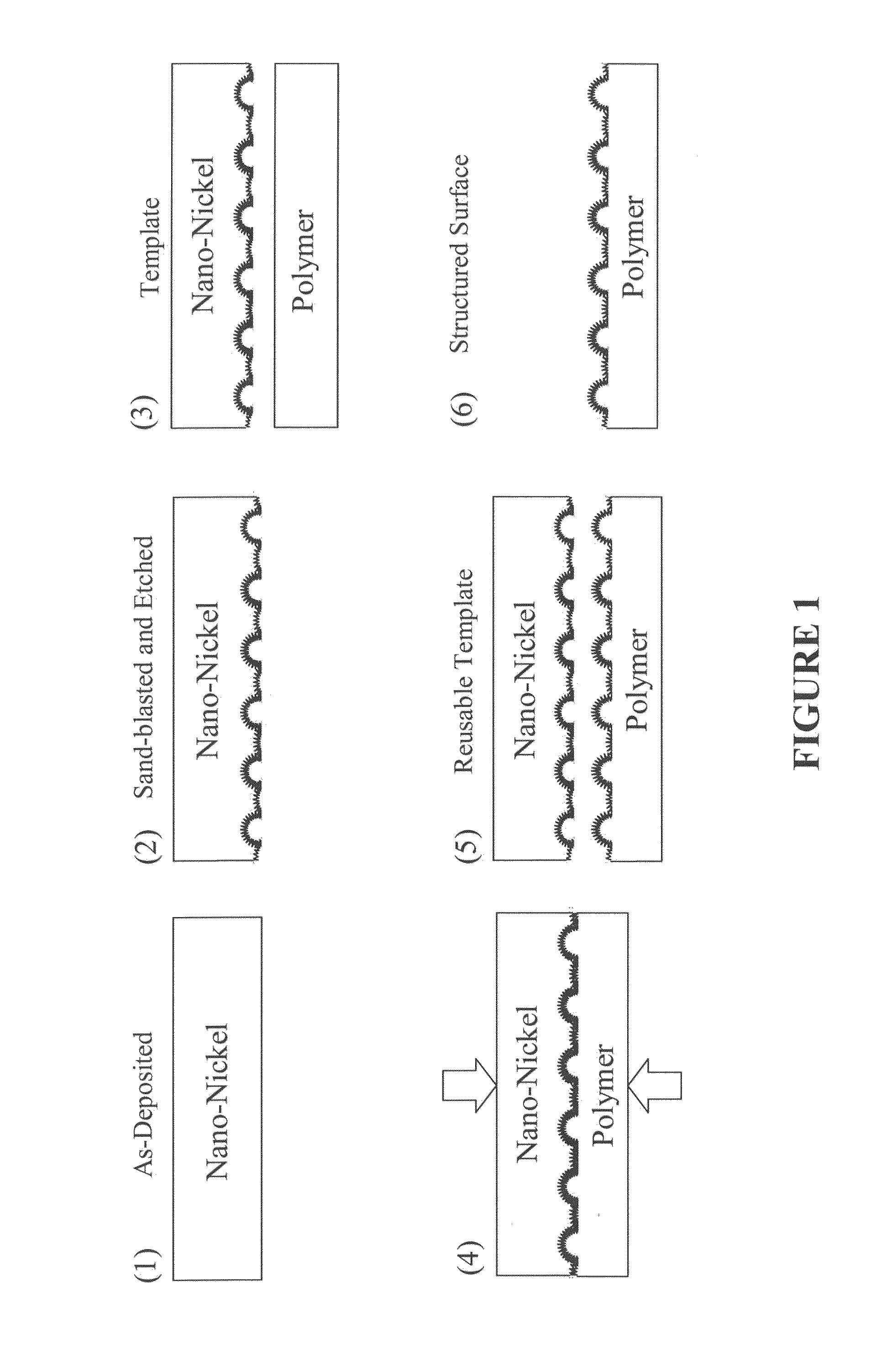

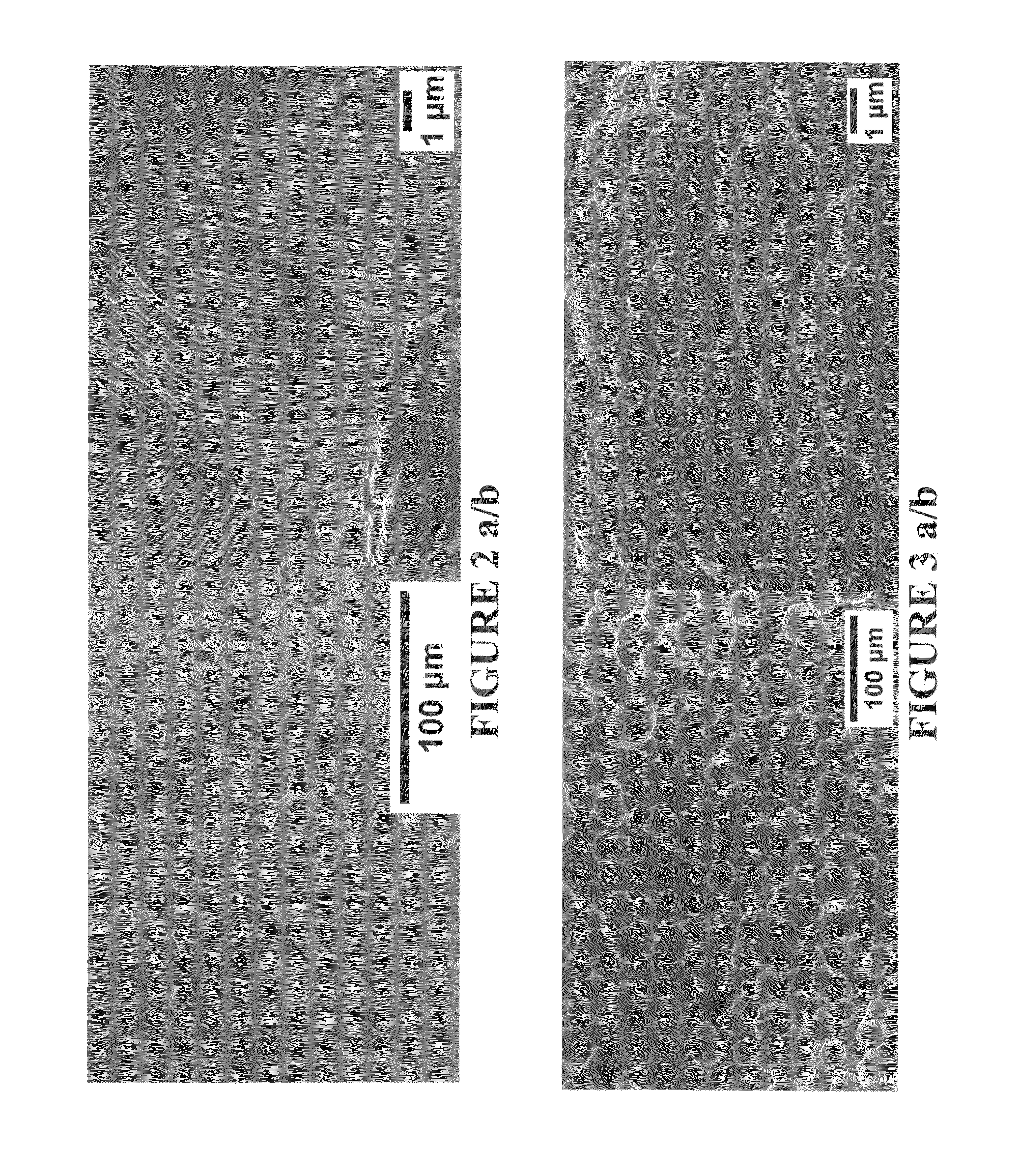

Super-hydrophobic and self-cleaning articles produced by imprinting exposed surfaces with suitable fine-grained and / or amorphous metallic embossing dies to transfer a dual surface structure, including ultra-fine features less than or equal to 100 nm embedded in and overlaying a surface topography with macro-surface structures greater than or equal to 1 micron are disclosed.

Owner:INTEGRAN TECH

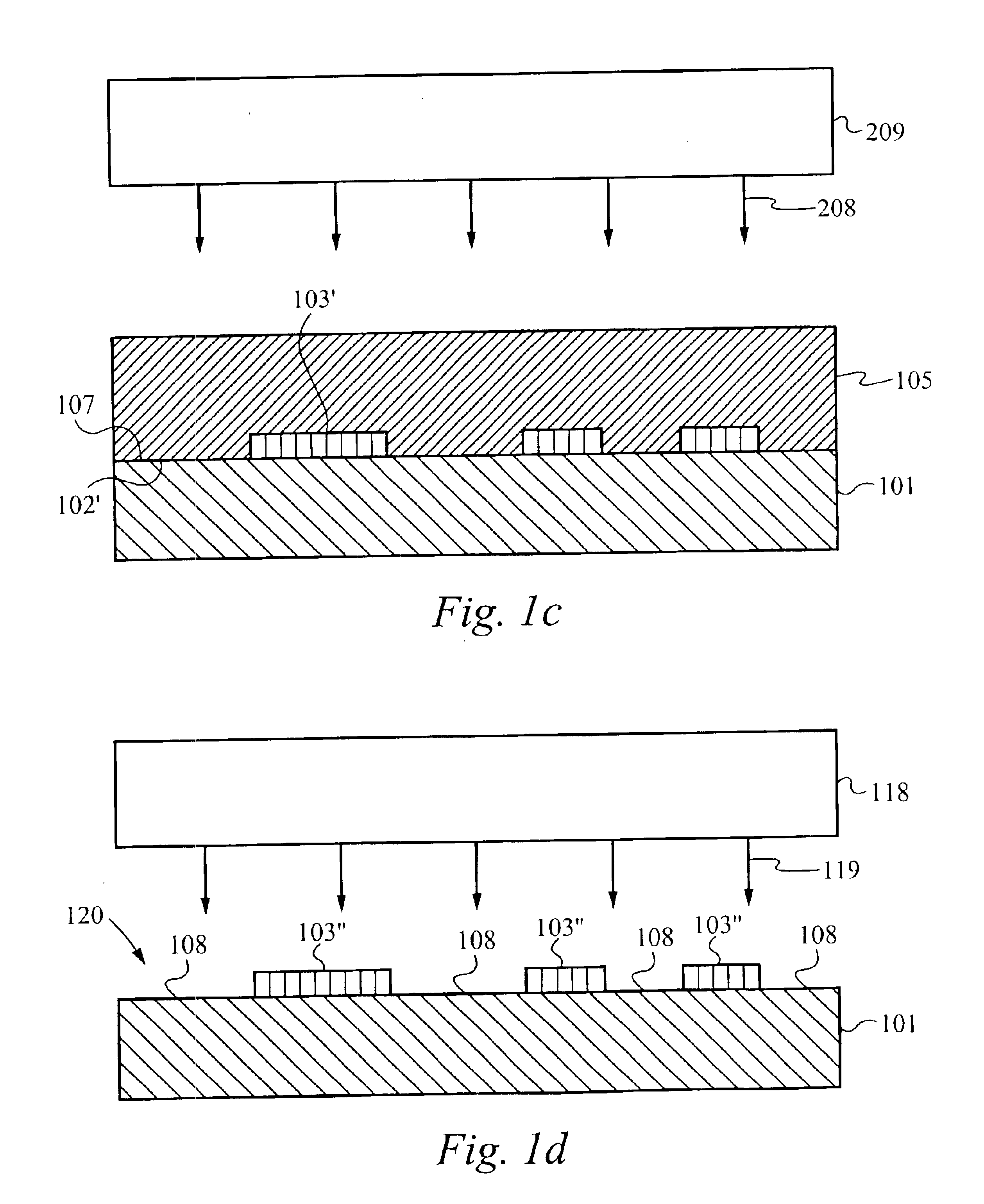

Methods for patterning using liquid embossing

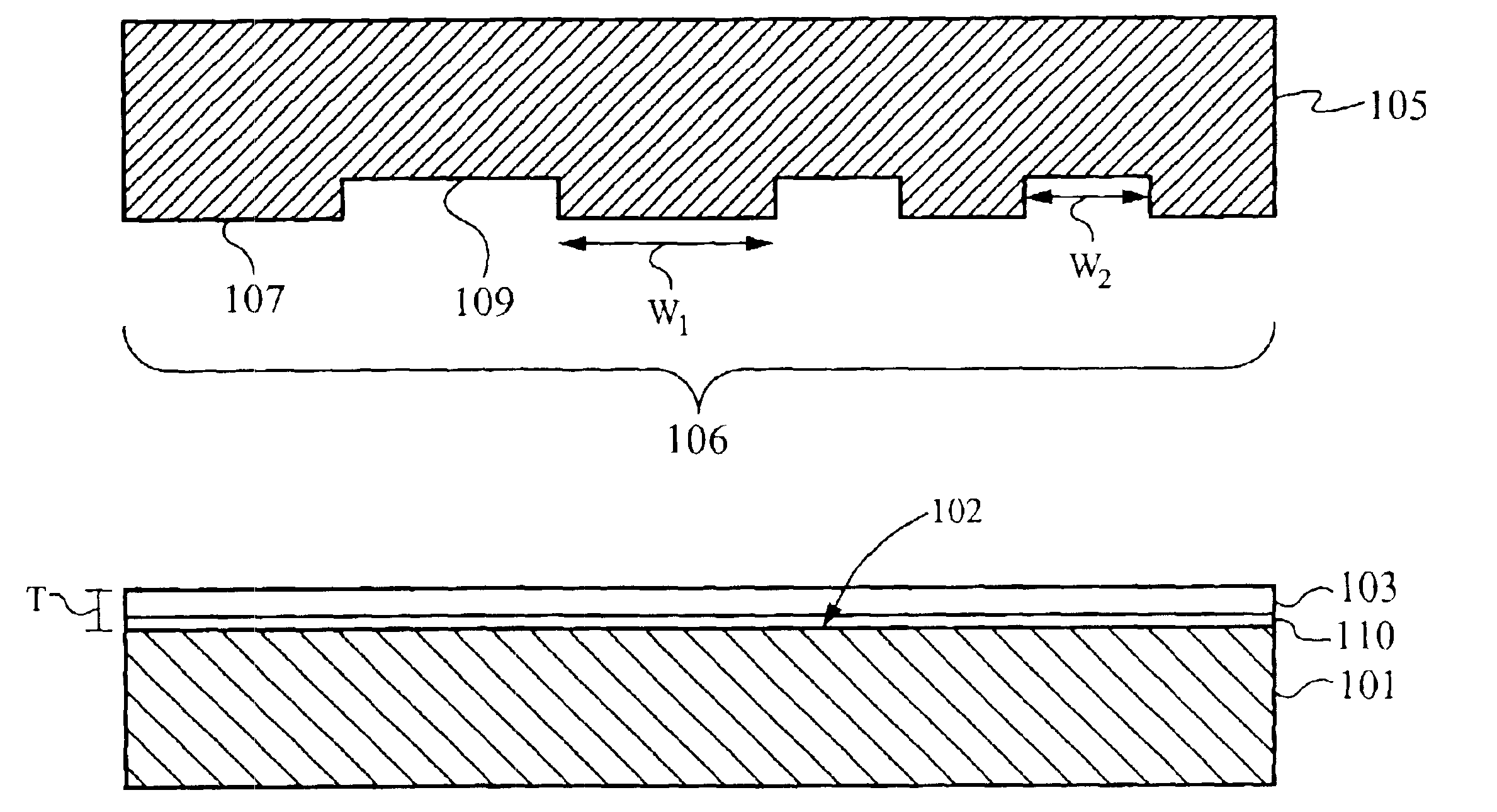

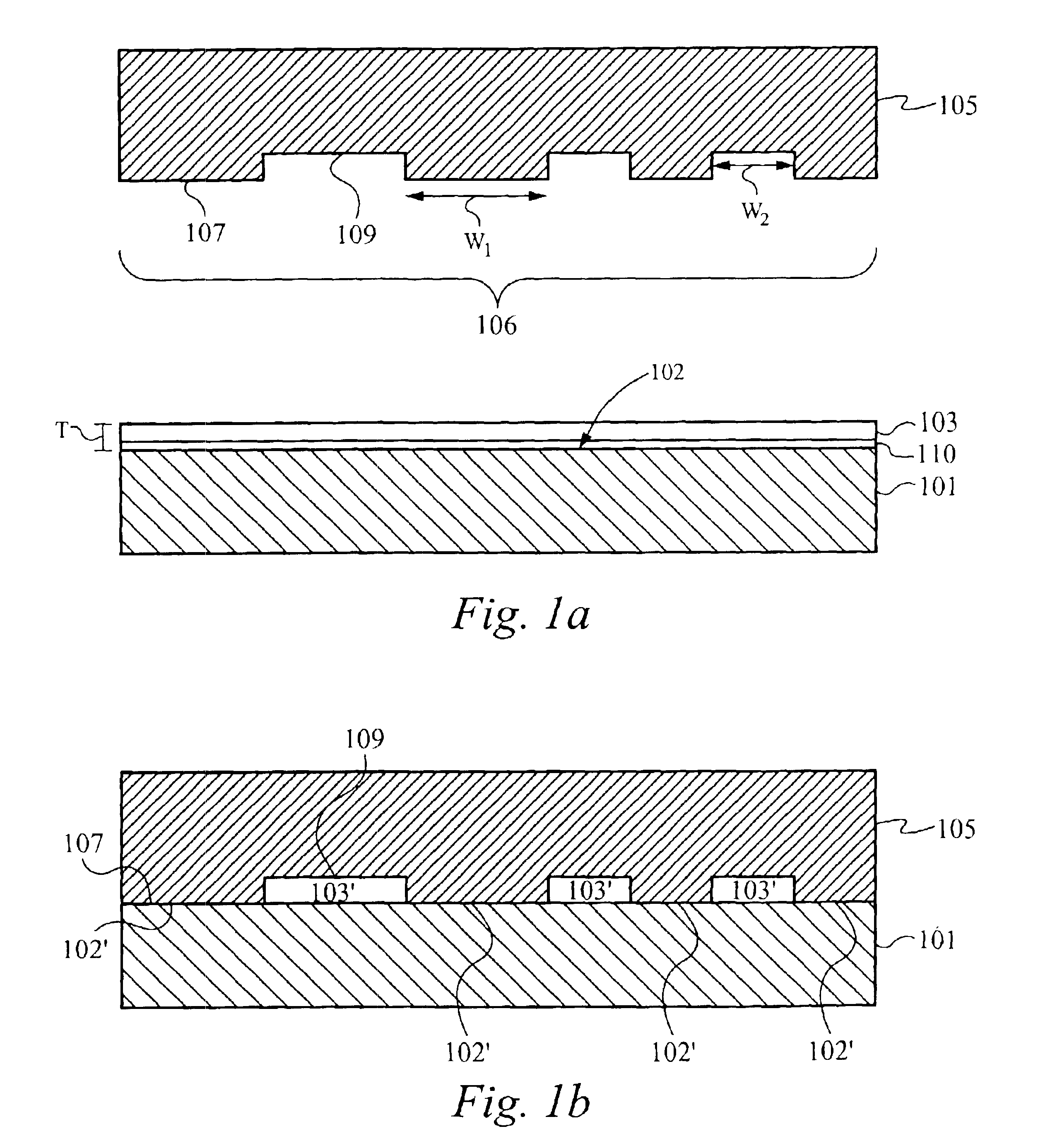

The current invention is directed to a method of patterning a surface or layer in the fabrication of a micro-device. In accordance with a preferred embodiment of the invention, a first mask structure is formed by depositing a layer of a first material onto the surface or layer and embossing the layer with a micro-stamp structure. The layer is preferably embossed as a liquid, which is solidified or cured to form the first mask structure. The first mask structure can be used as an etch-stop mask which is removed in a subsequent processing step or, alternatively, the first mask structure can remain a functional layer of the micro-device. In further embodiments, unmasked regions of the surface or layer are chemically treated through the first mask structure and / or a second material is deposited onto the unmasked regions of the surface or layer through the first mask structure to form a second mask structure and / or a second functional layer of the micro-device.

Owner:KOVIO

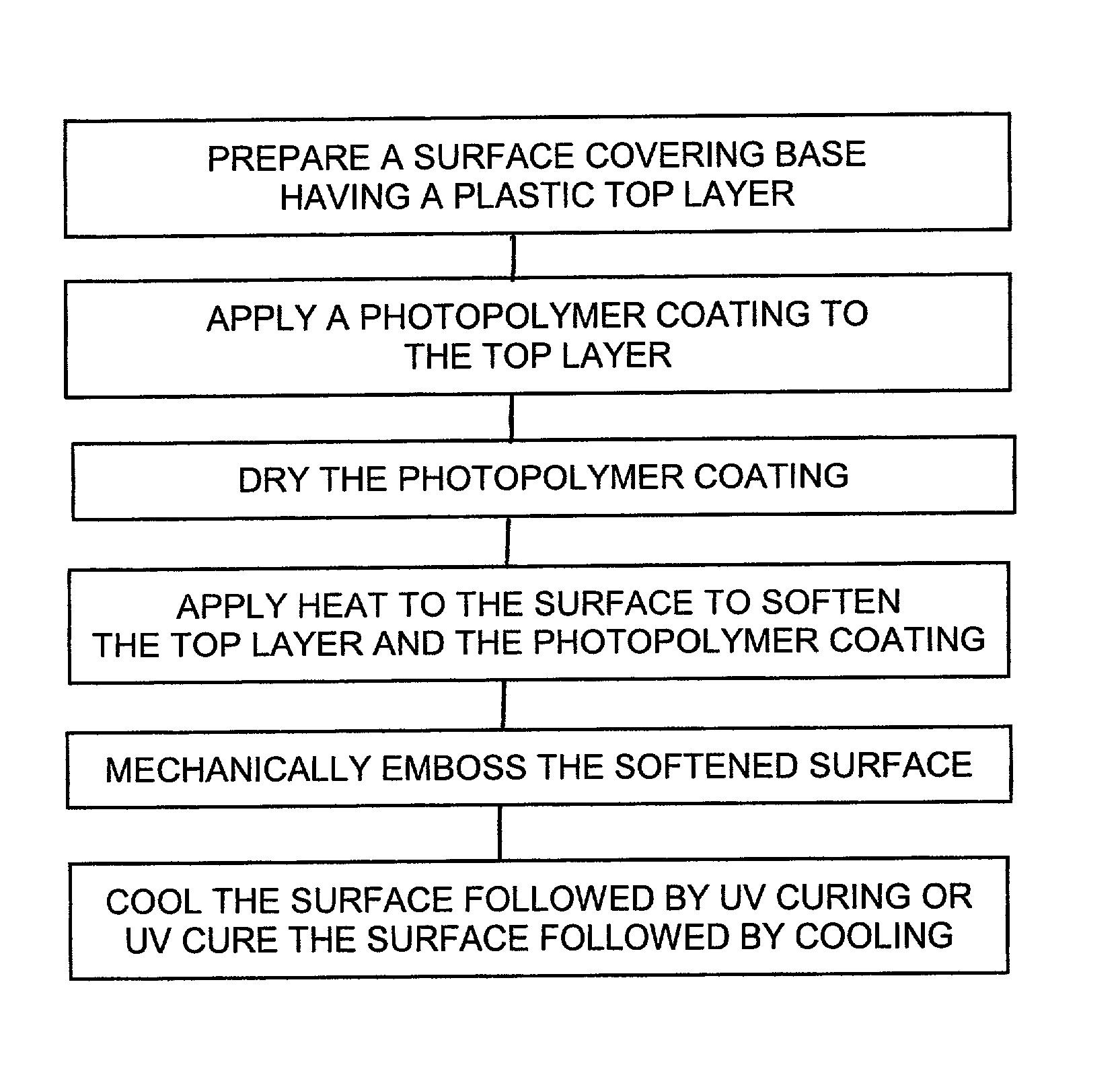

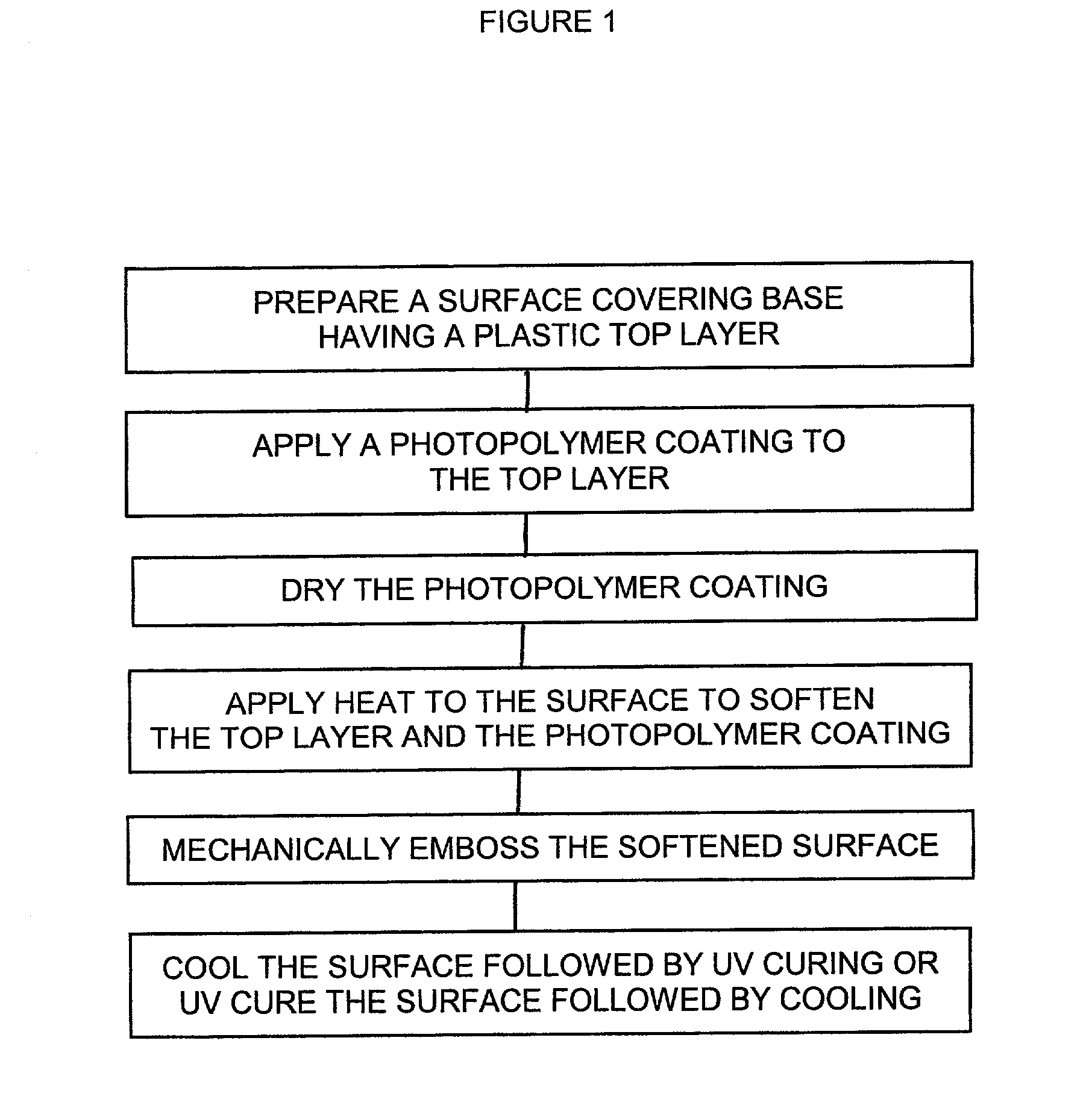

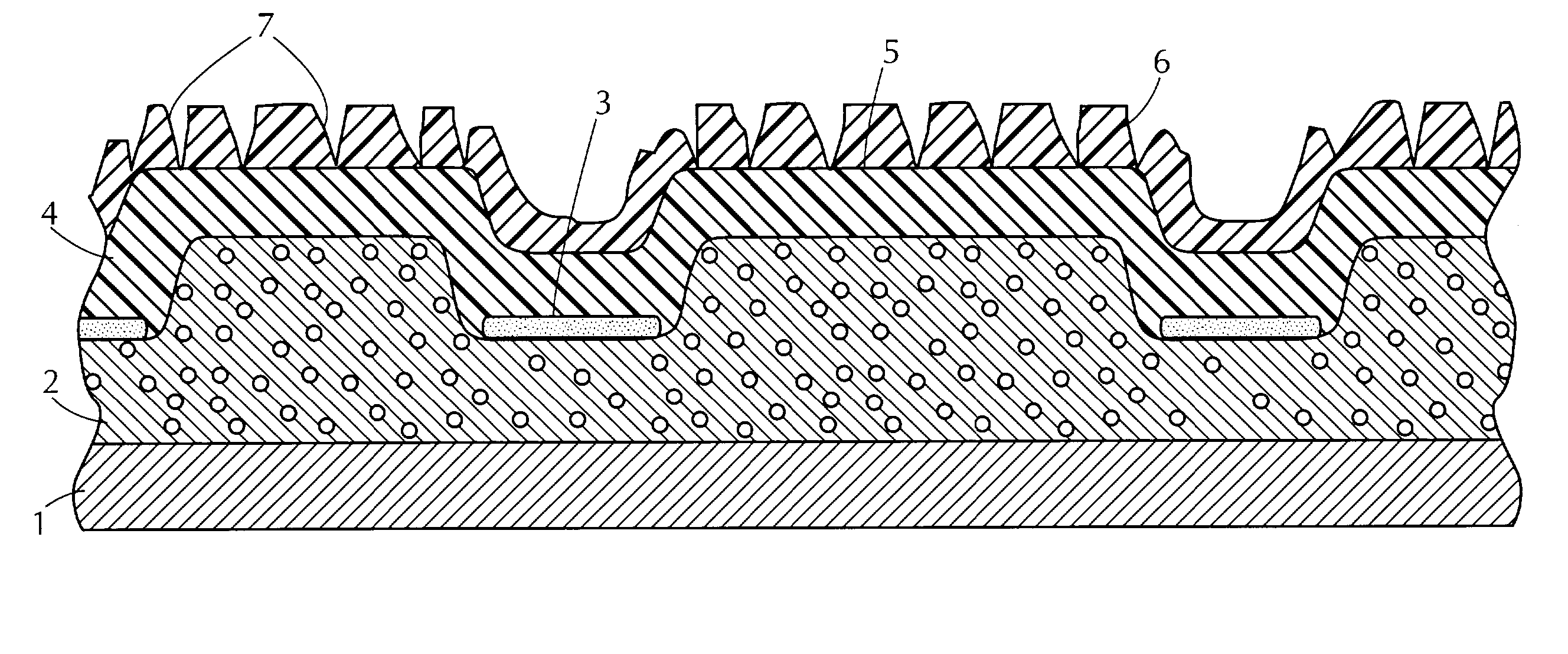

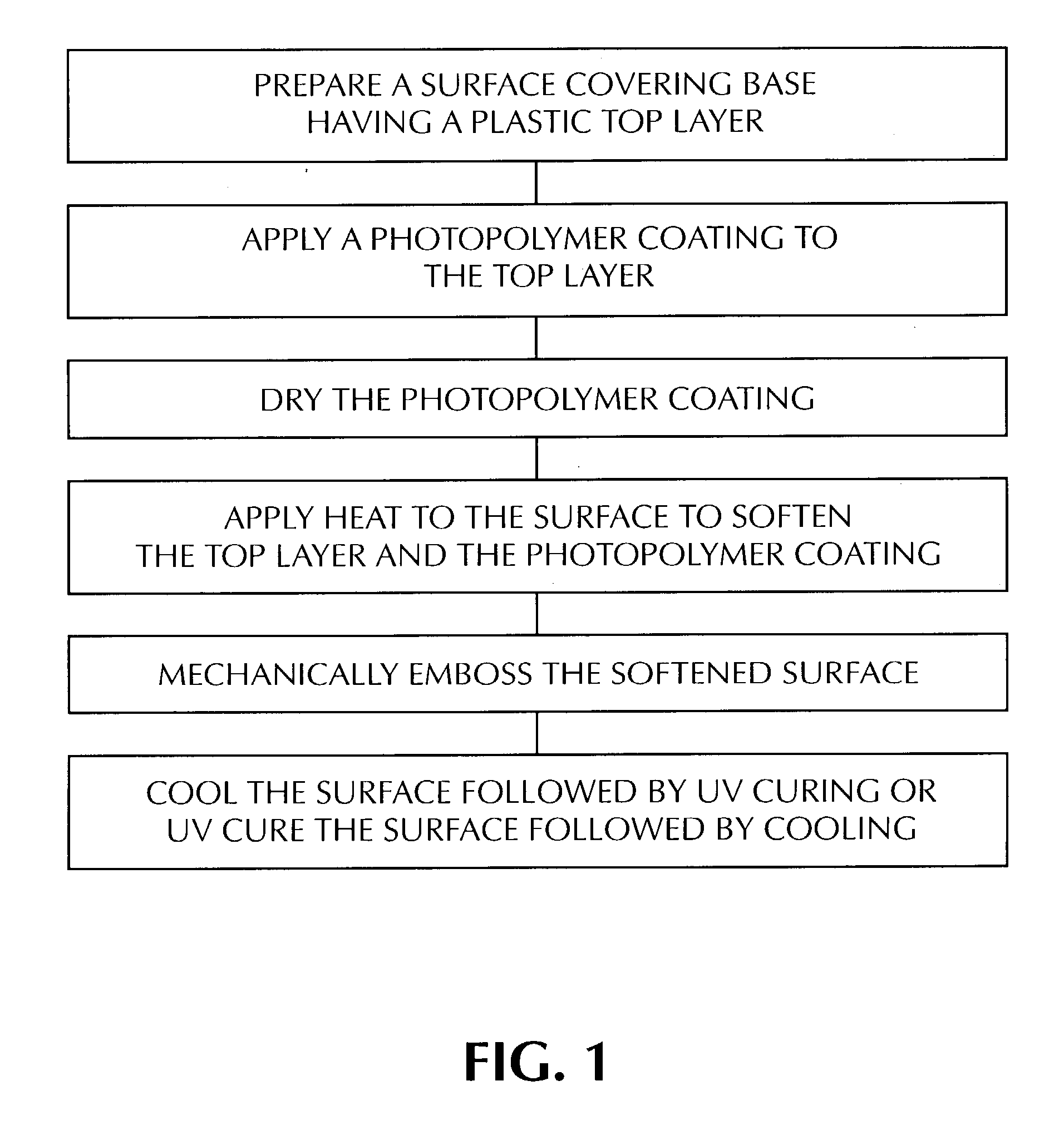

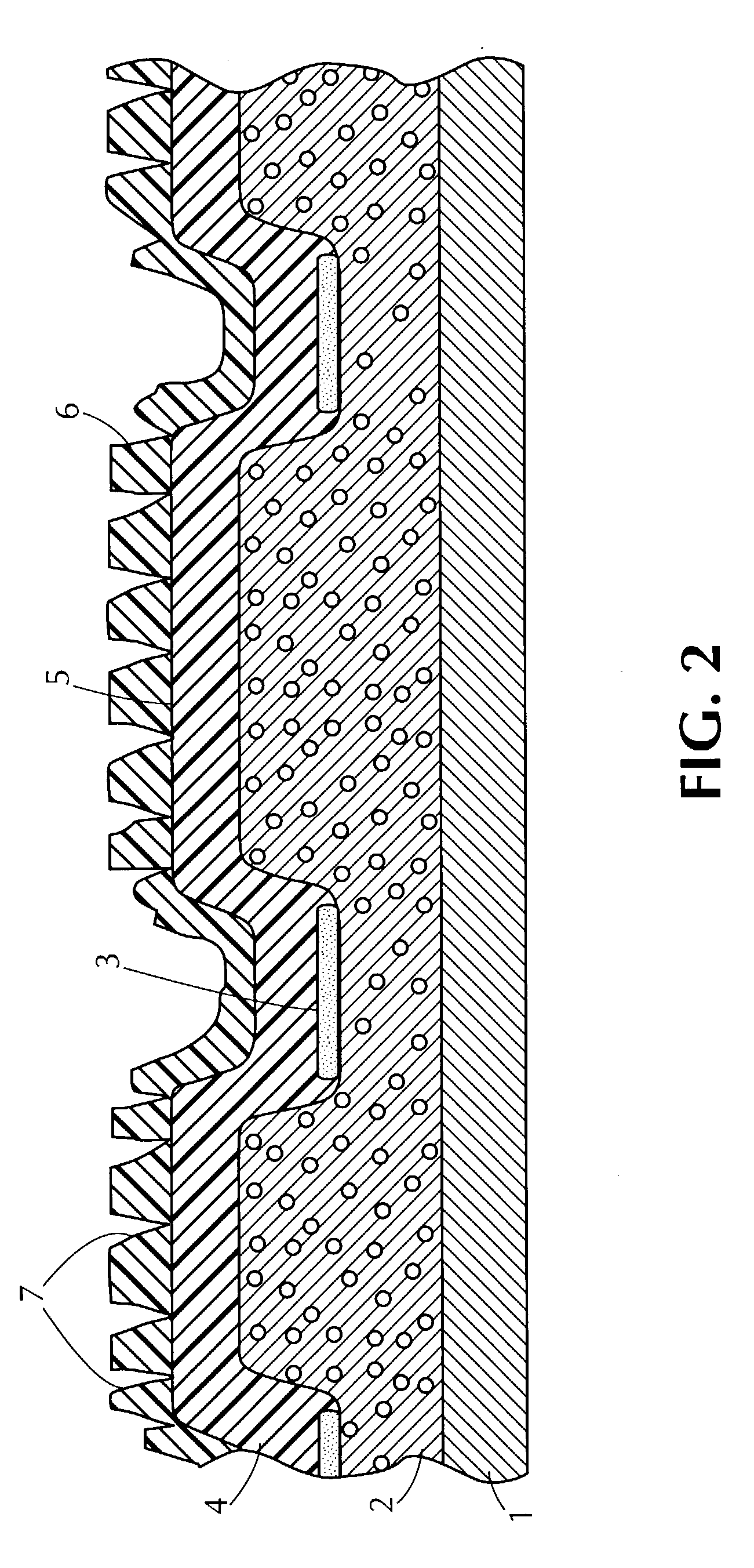

Polyurethane coated resilient surface covering having improved fidelity of texture and process of manufacture

Mechanically embossed resilient surface coverings having superior textural fidelity are prepared by mechanically embossing a polyurethane coated floorcovering before the polyurethane is cured. The mechanical embossing is conducted when the polyurethane is dry and the underlying plastic layer and the polyurethane are softened by heating. After the mechanical embossing step, the polyurethane is cured using ultraviolet (UV) light. The product can be cooled before or after UV curing. The invention is applicable to a variety of resilient surface covering products including floor and wall coverings which otherwise have a wearlayer which can be softened by heating. This includes surface coverings having the full range of decorative effects available in the art, including surface coverings which also have been, for example, chemically embossed, mechanically embossed, chemically and mechanically embossed or not embossed at all prior to application of the process of the invention.

Owner:TARKETT INC +1

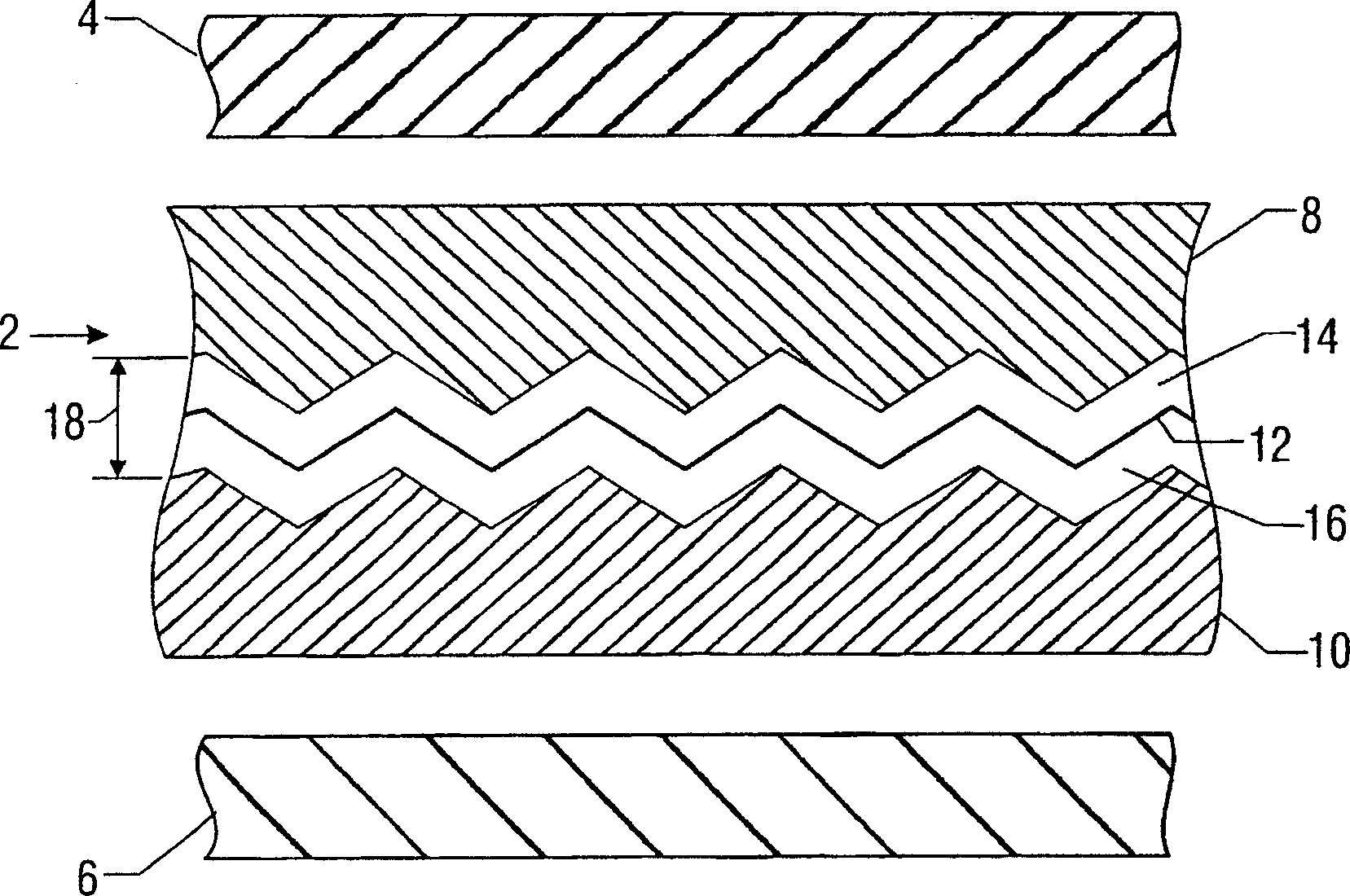

Embossed multi-ply fibrous structure product and process for making same

InactiveUS20060013998A1Non-fibrous pulp additionNatural cellulose pulp/paperFiber structureComposite material

Owner:PROCTER & GAMBLE CO

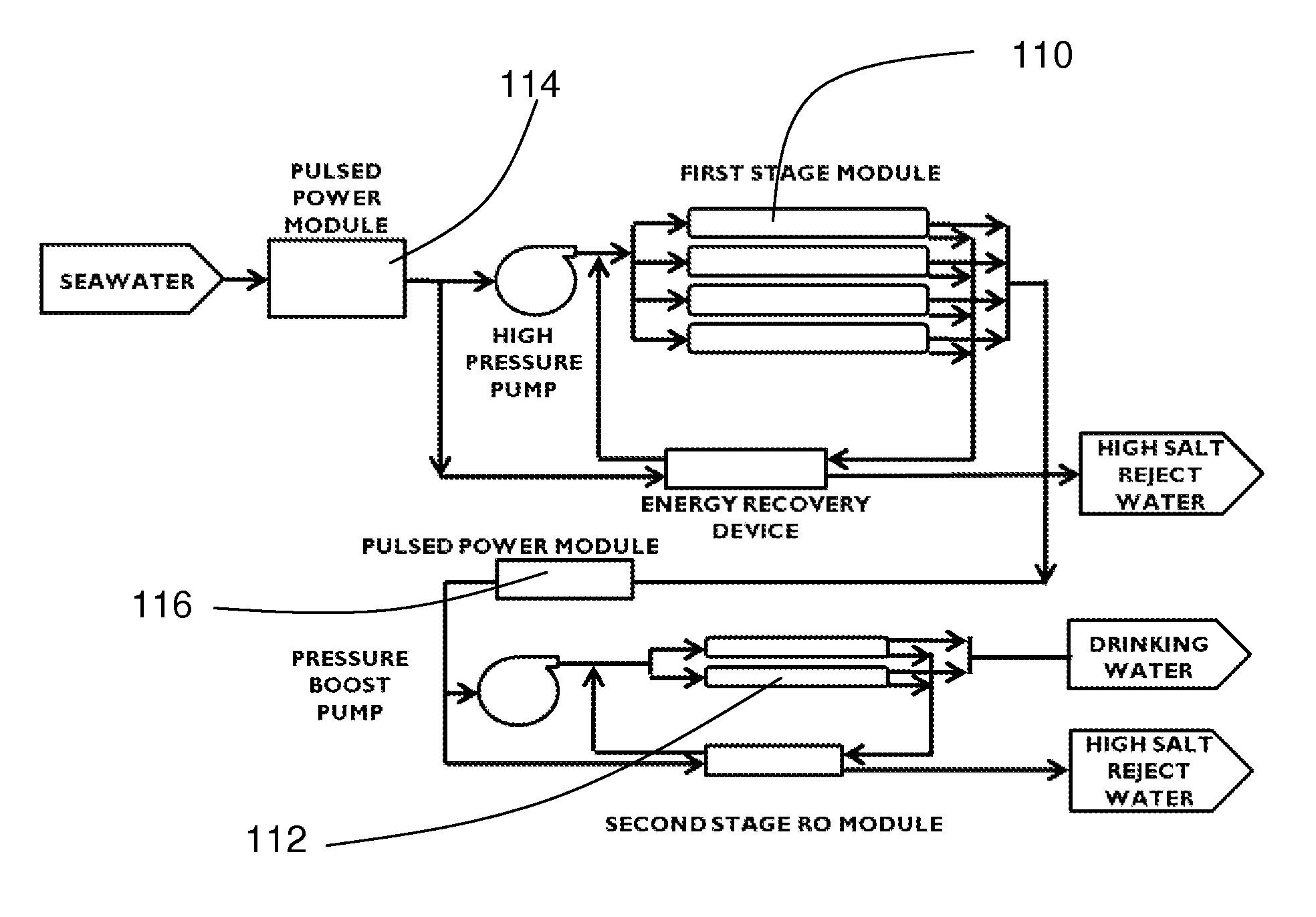

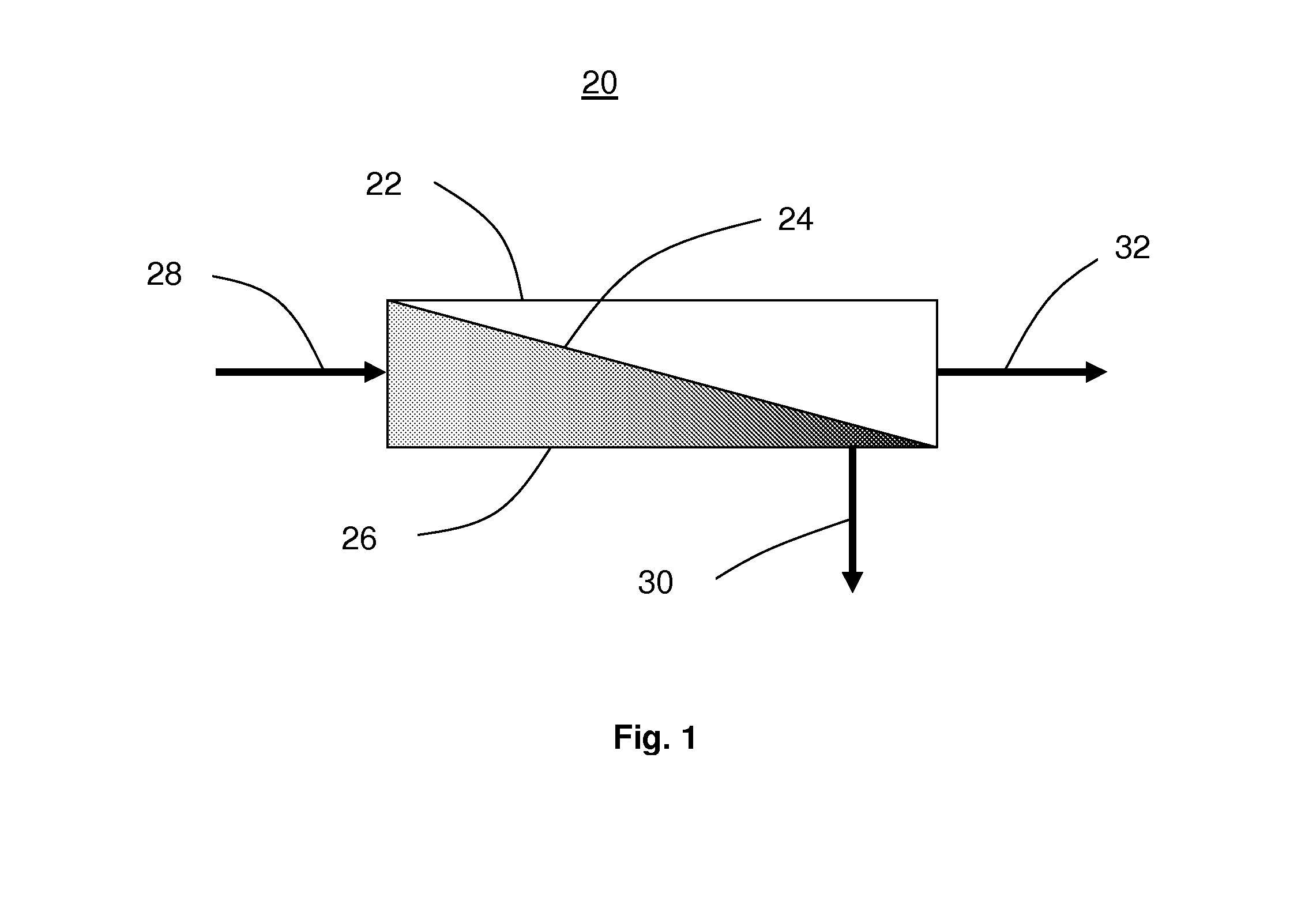

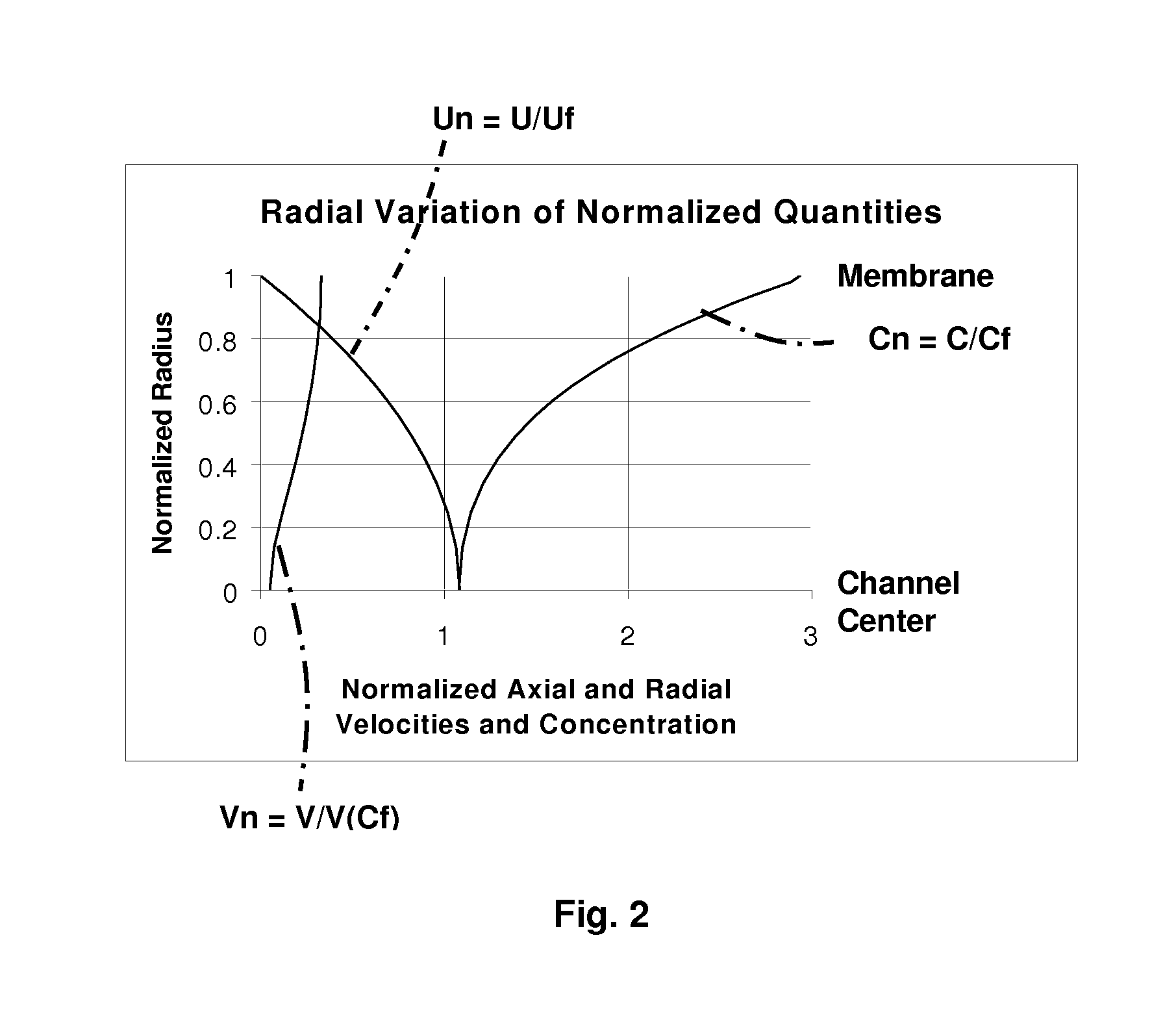

Systems and methods for filtration

InactiveUS20120298578A1Reduce foulingImprove water qualityMaterial nanotechnologyGeneral water supply conservationMicroorganismFiltration membrane

Filtration systems (40) utilize a pre-treatment method to cause scale formation to occur on particles (94) in the fluid stream (96) rather than on the filter surface and may also destroy microorganisms in the fluid stream. More specifically, but not limited to, a filtration device can be a filtration membrane, such as spiral wound filtration membrane (60), that utilizes an open feed spacer (80), such for example an embossed or printed pattern on the membrane, to create a thin feed spacer channel which replaces a conventional feed spacer mesh material. System (40) further utilizes a treatment device (54) to enable a pulsed power, magnetic, electro-magnetic, electro-static, or hydrodynamic fluid treatment scheme to condition particles in the fluid stream (96) such that scale forming elements precipitate (94) on to the particles in the fluid stream rather than on the filtration surfaces.

Owner:AQUA MEMBRANES +1

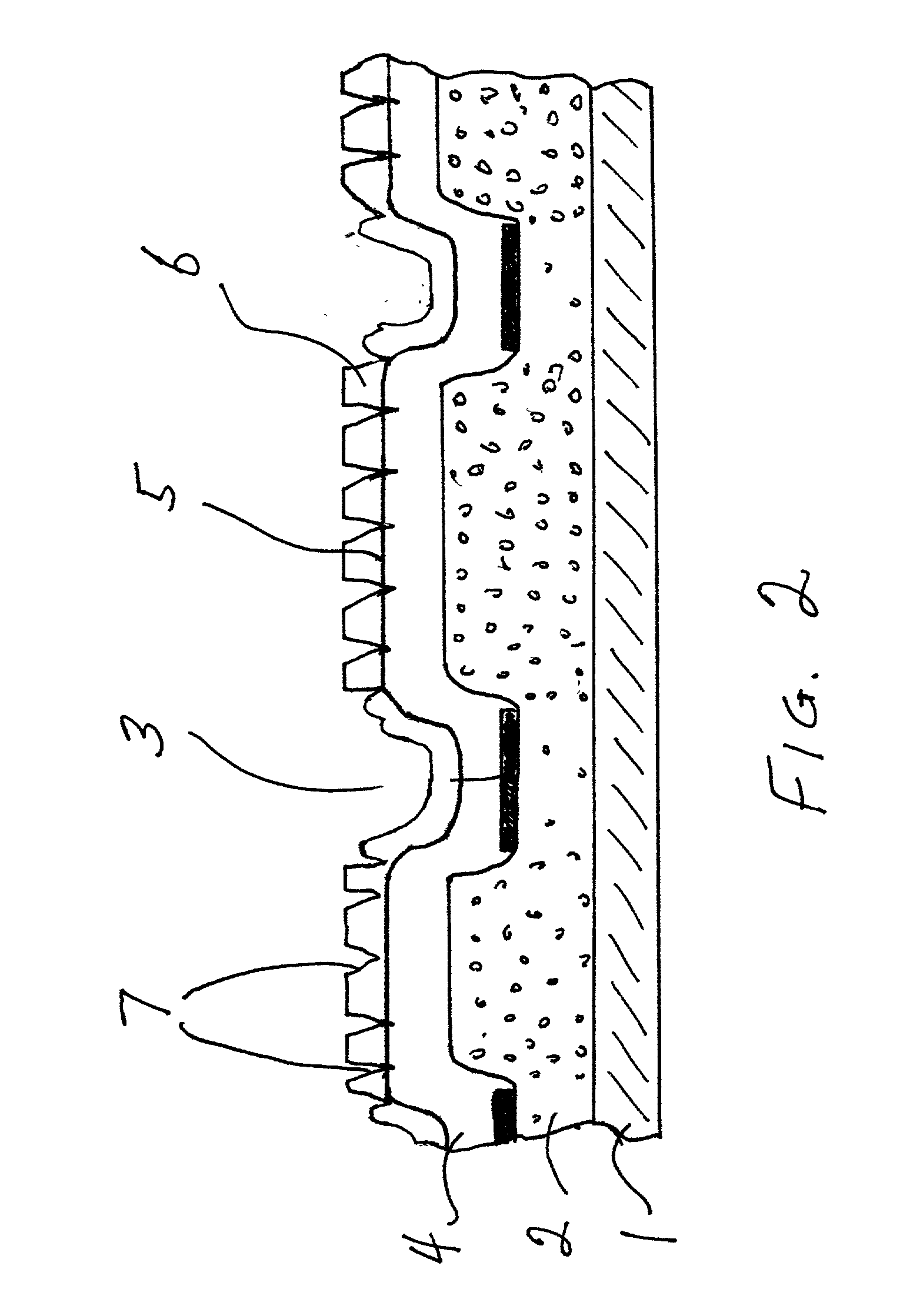

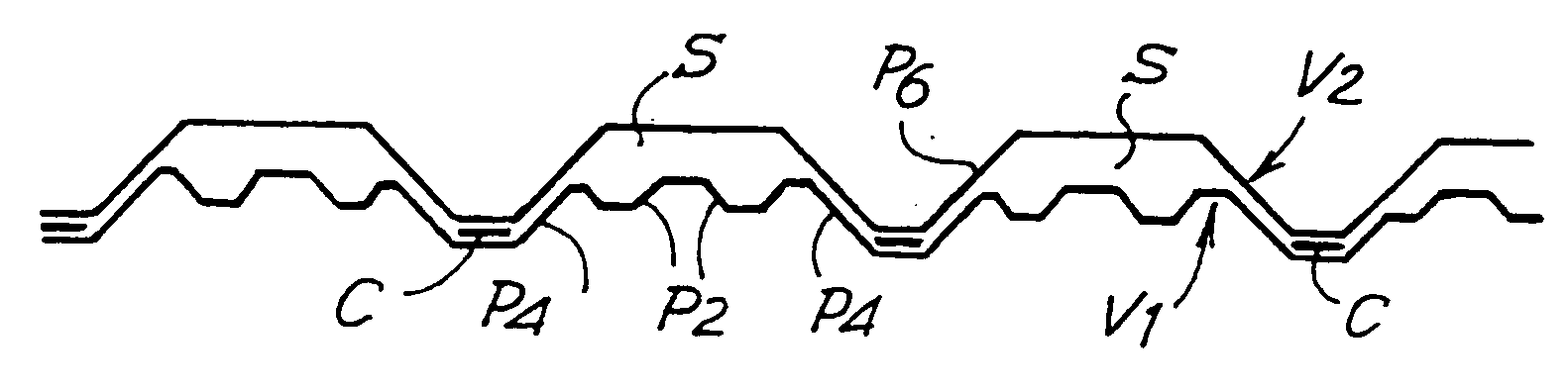

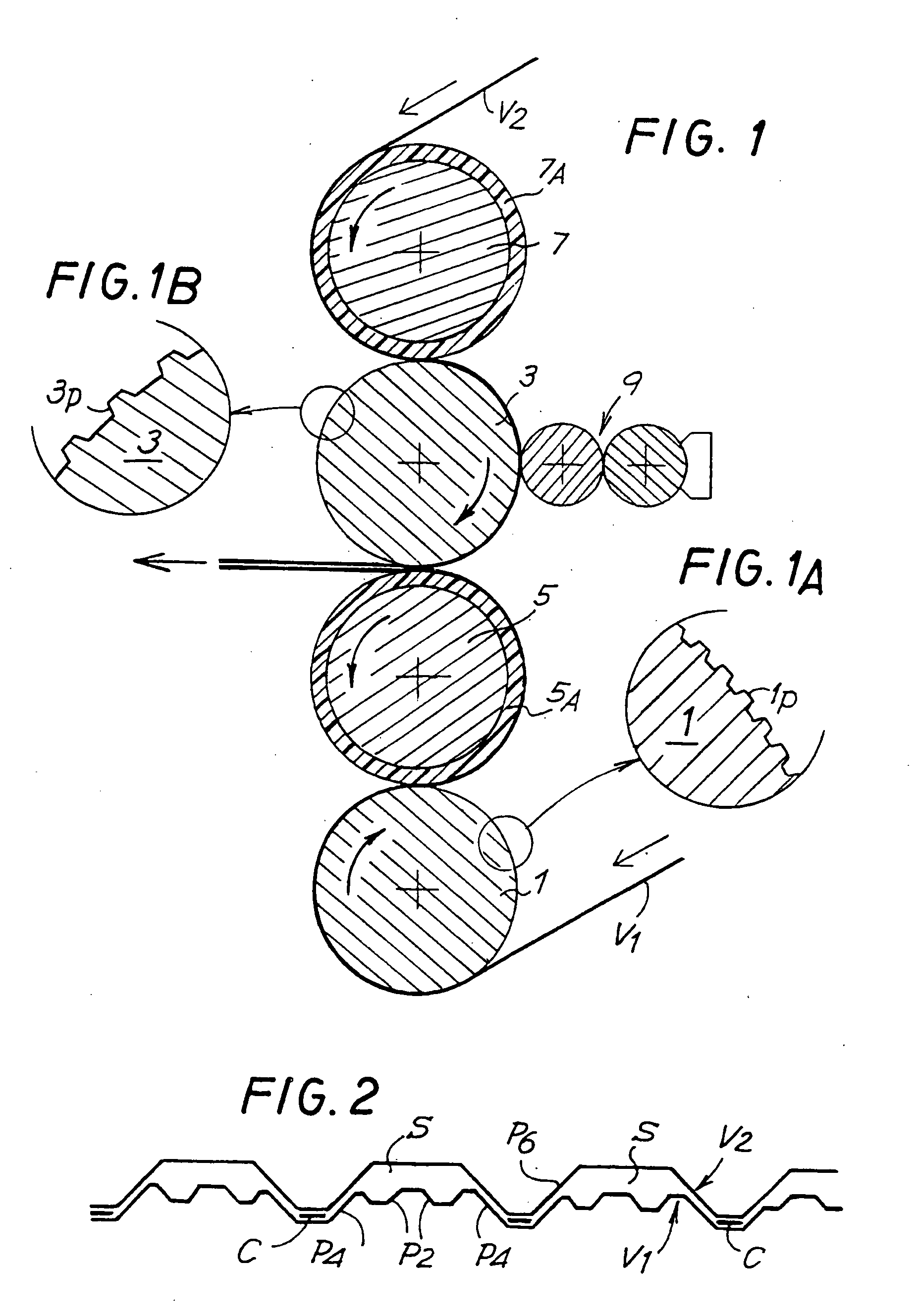

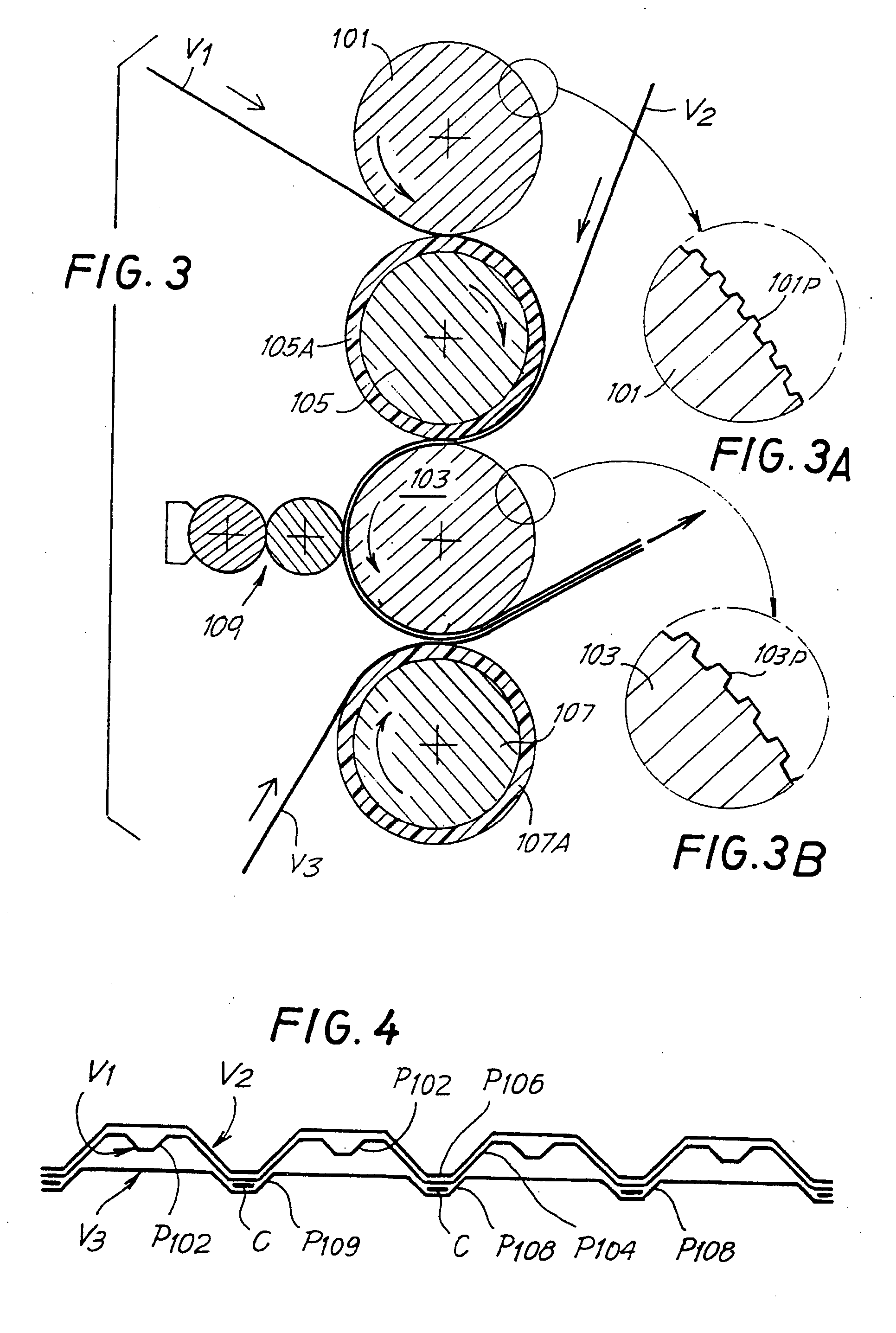

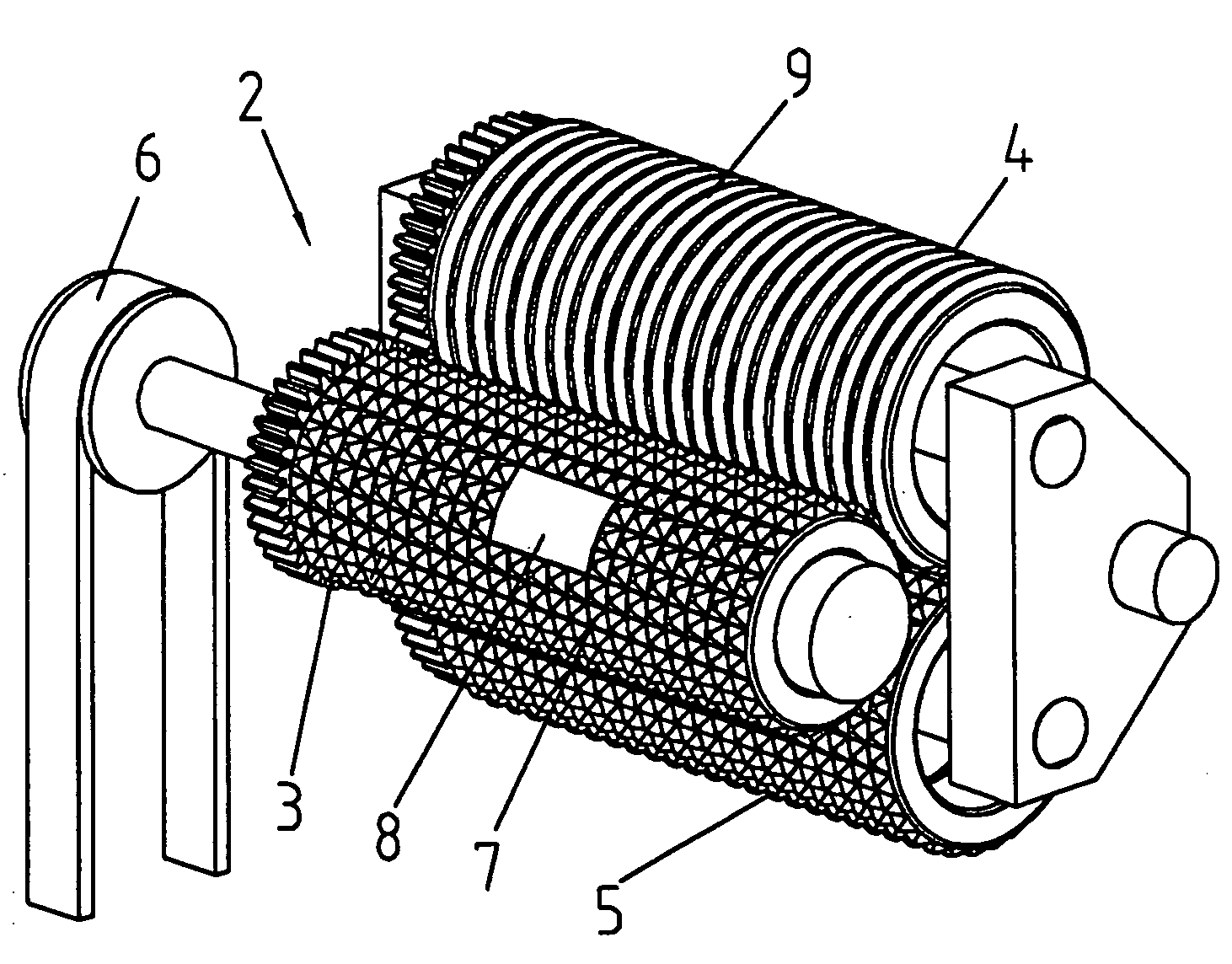

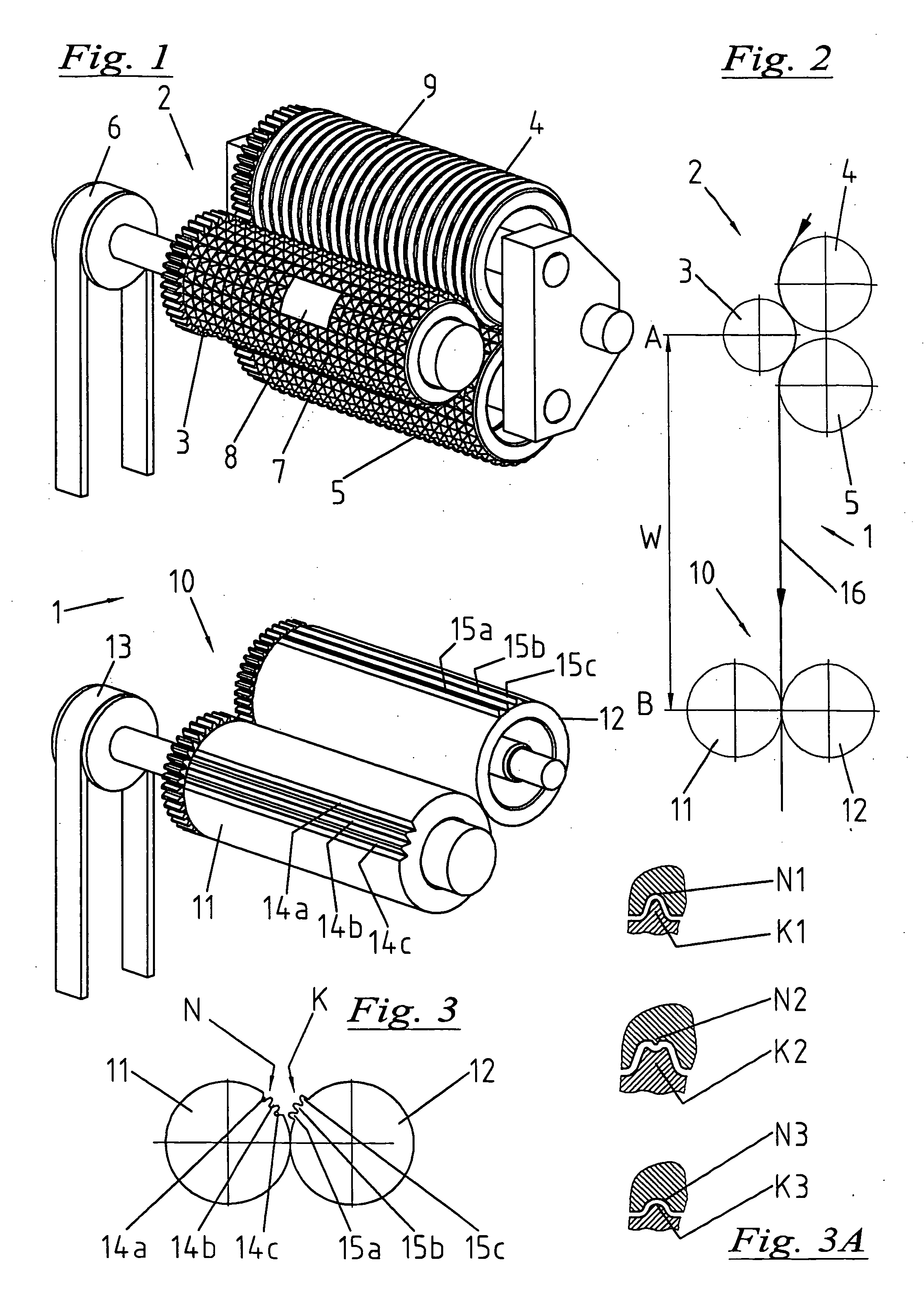

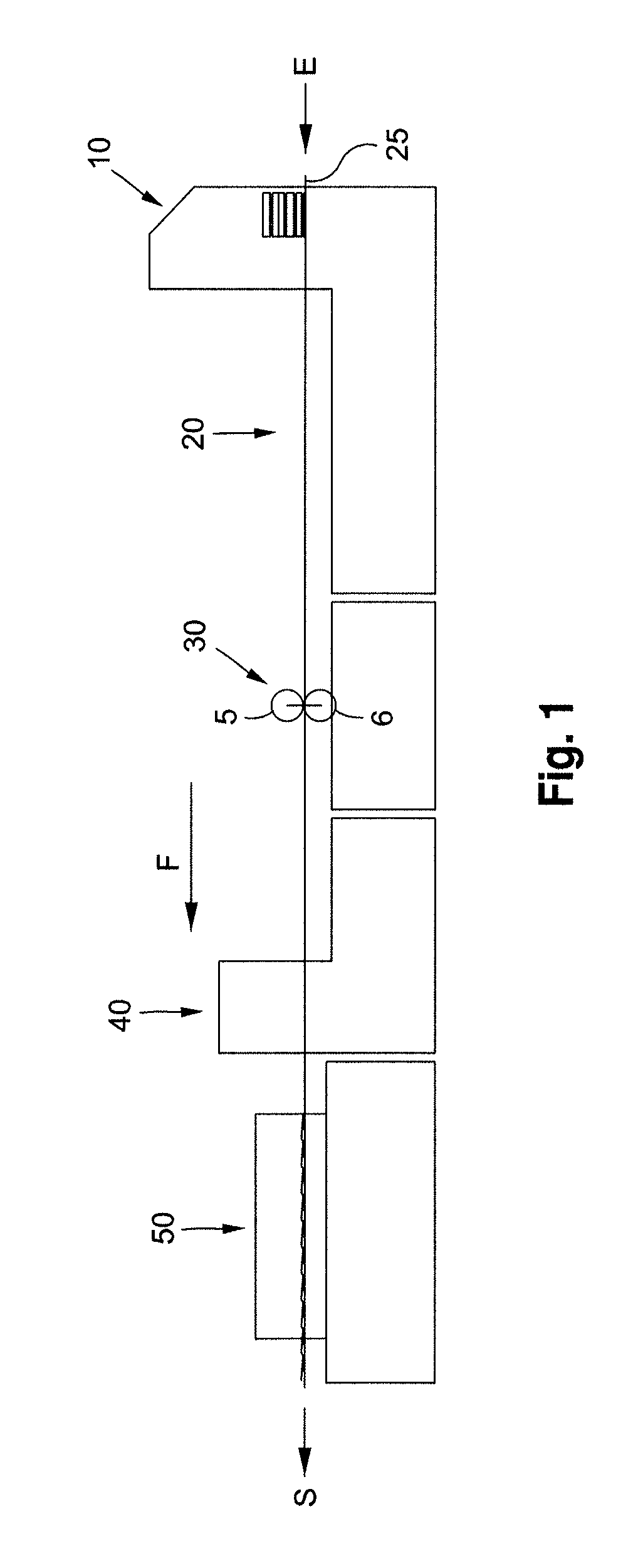

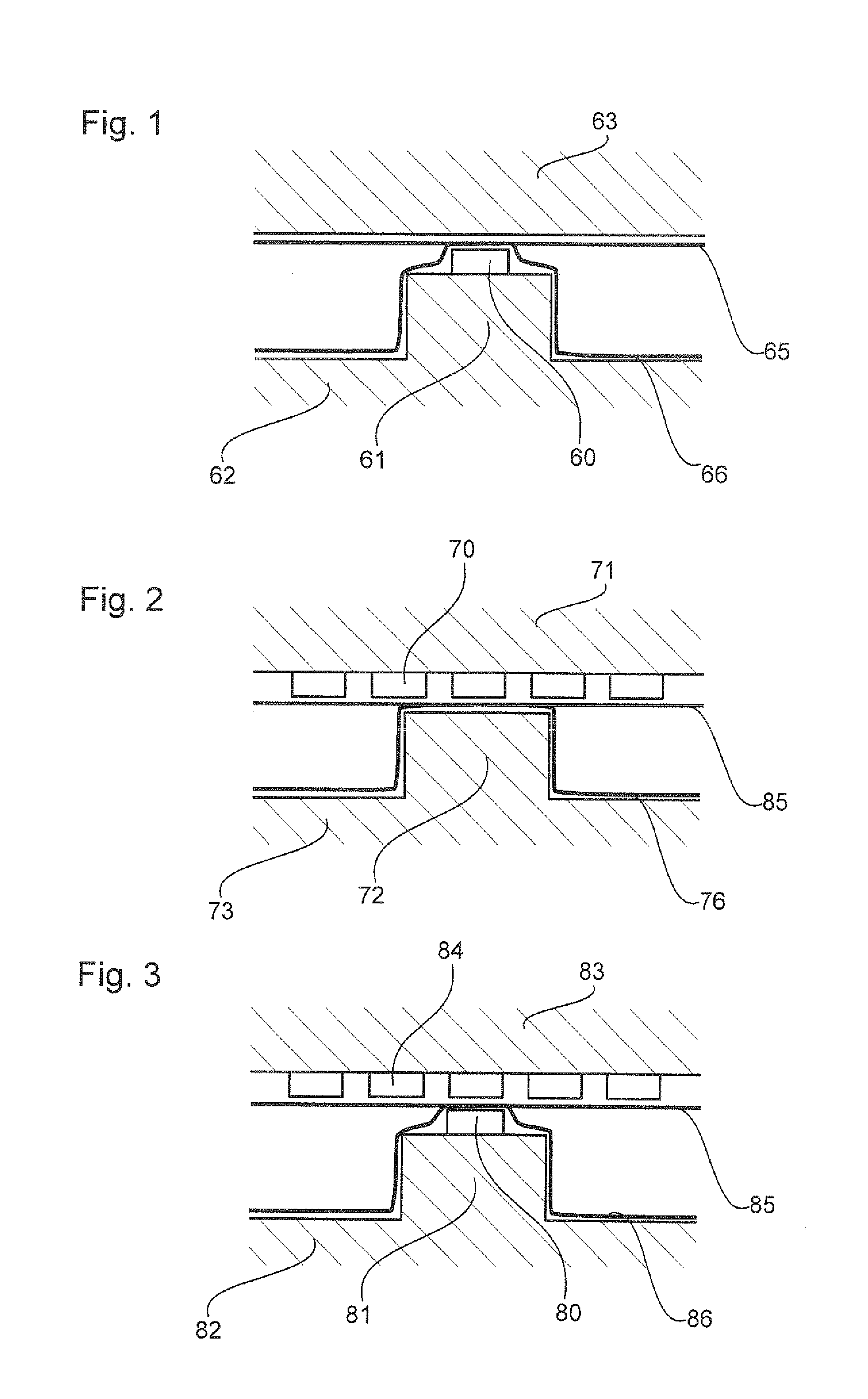

Method and device for producing an embossed web material and product made in this way

InactiveUS20040247836A1Quality improvementLow modification costMechanical working/deformationLaminationEngineeringMechanical engineering

For the production of a sheet product including at least two layers (V1, V2) it is suggested, among other things, an embossing device including a first pressure roller (5; 105) interacting with a first and a second embossing cylinder (1, 3; 101, 103) provided with respective points (1P, 3P; 101P, 103P) on their cylindrical surface.

Owner:FABIO PERINI SPA

Methods for embossing and embossed articles formed therby

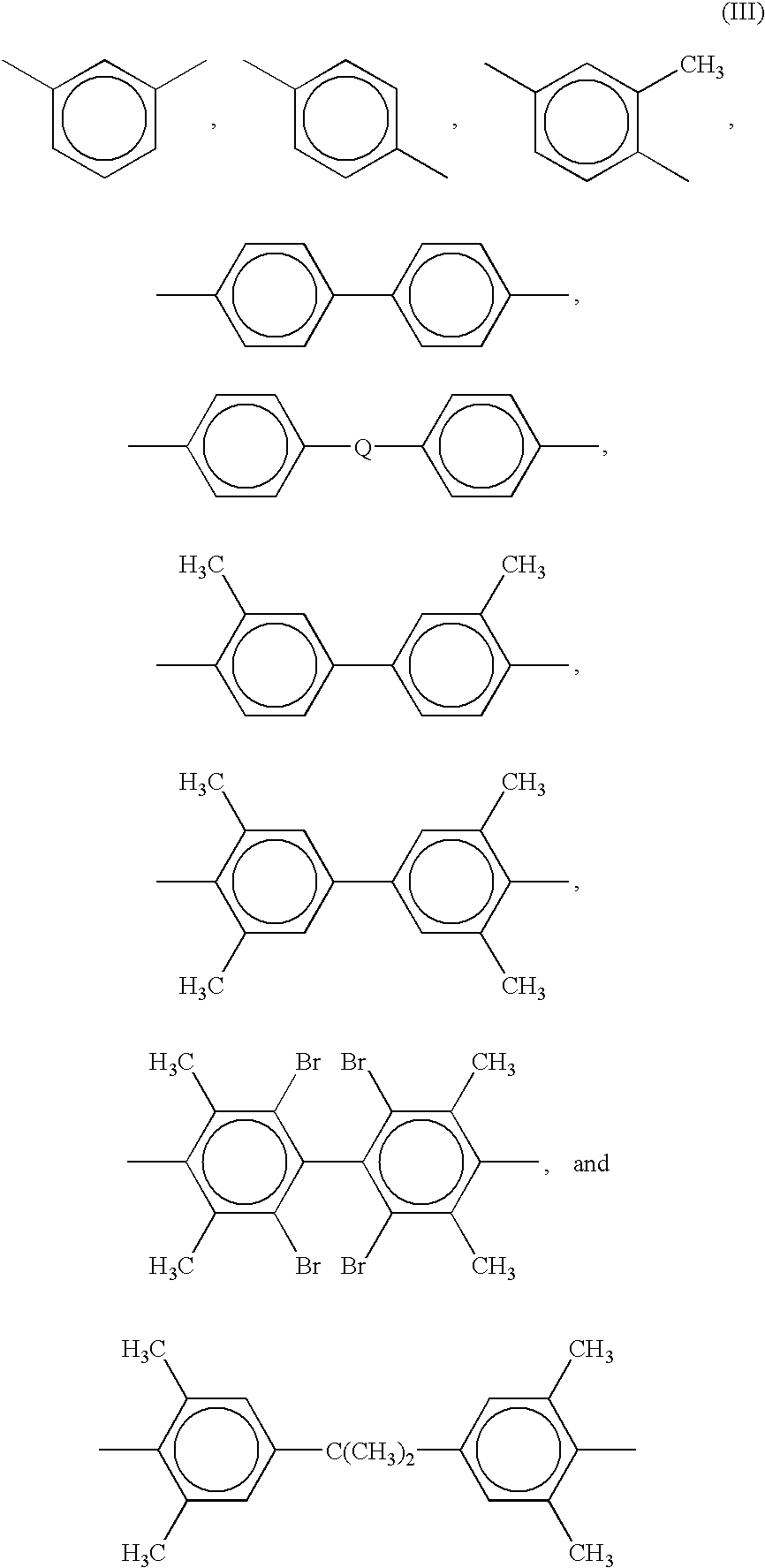

InactiveUS20030057601A1Facilitated releaseImprove adhesionDifferent record carrier formsPlastic/resin/waxes insulatorsPolymeric surfacePolymer science

A method for manufacturing an embossed surface comprising a polymer with a first glass transition temperature Tg1 comprises embossing the surface a temperature Temb; and raising the first glass transition temperature Tg1 of the embossed polymeric surface to a second glass transition temperature Tg2 such that Tg2>Temb. In another embodiment, a method for improving the release of a polymeric surface from an embossing tool comprises incorporating of one or more of fluorine atoms, silicon atoms, or siloxane segments into the backbone of polymer. The methods are particular suited for direct patterning of photoresists, fabrication of interdigitated electrodes, and fabrication of data storage media.

Owner:SABIC INNOVATIVE PLASTICS IP BV

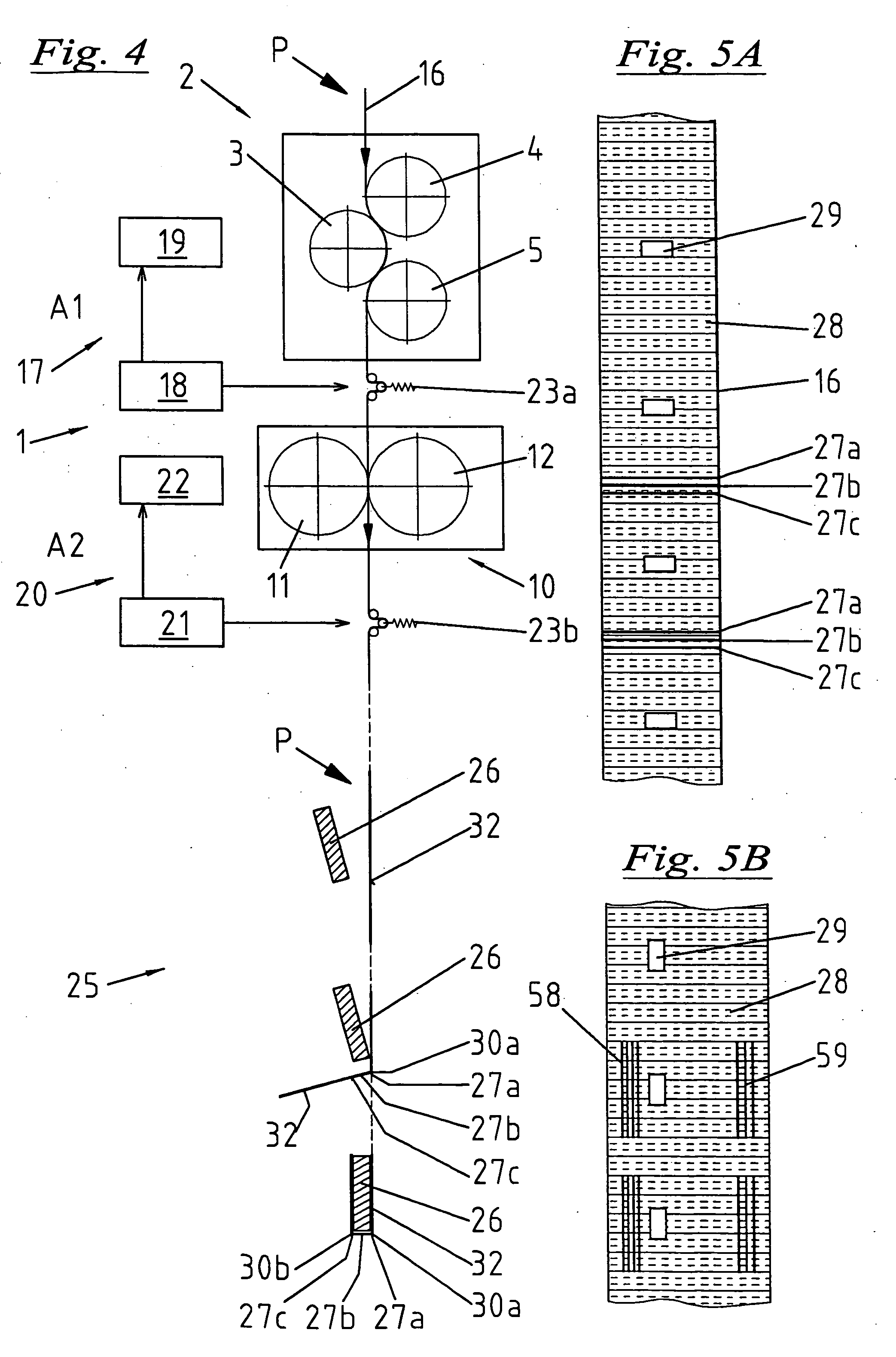

Device for the treatment of packaging foils

ActiveUS20090050001A1Improve foldabilityMechanical working/deformationBoxes/cartons making machineryEngineeringAuthentication

The invention relates to a device for the treatment of packaging foils, comprising a first embossing unit having at least one embossing roll provided with embossing structures (7) that are arranged in a basic grid for satinizing and / or with embossing structures which deviate from the basic grid for the application of logos and / or of authentication features, the work cadence (A1) of the first embossing unit being synchronizable to a process cadence (P) of the packaging process, as well as a first regulating unit of the first embossing unit that is synchronizable to the process cadence (P) of the packaging installation, and a second regulating unit of the second embossing unit, the second regulating unit serving for the synchronization of the work cadence (A2) of the second embossing unit to the work cadence (A1) of the first embossing unit. To ensure a superior foldability of the packaging foil at a high process velocity during the subsequent packaging process, a subsequent second embossing unit is suggested which comprises at least one folding roll for applying folding breaks to the packaging foil.

Owner:BOEGLL GRAVURES SA

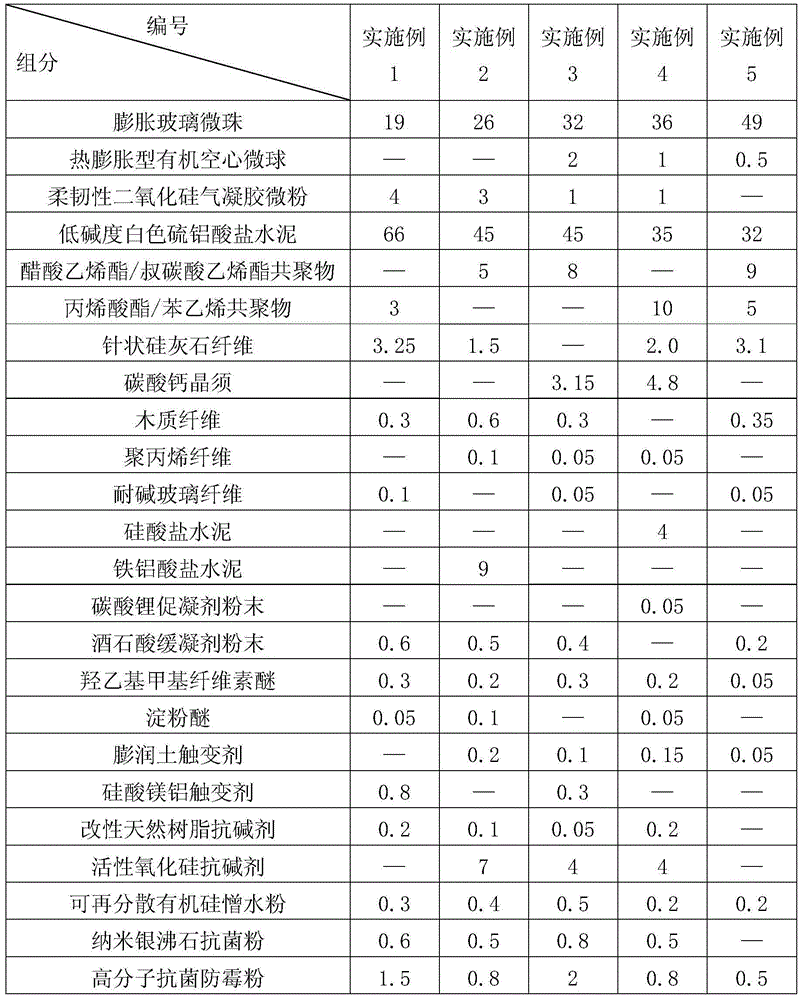

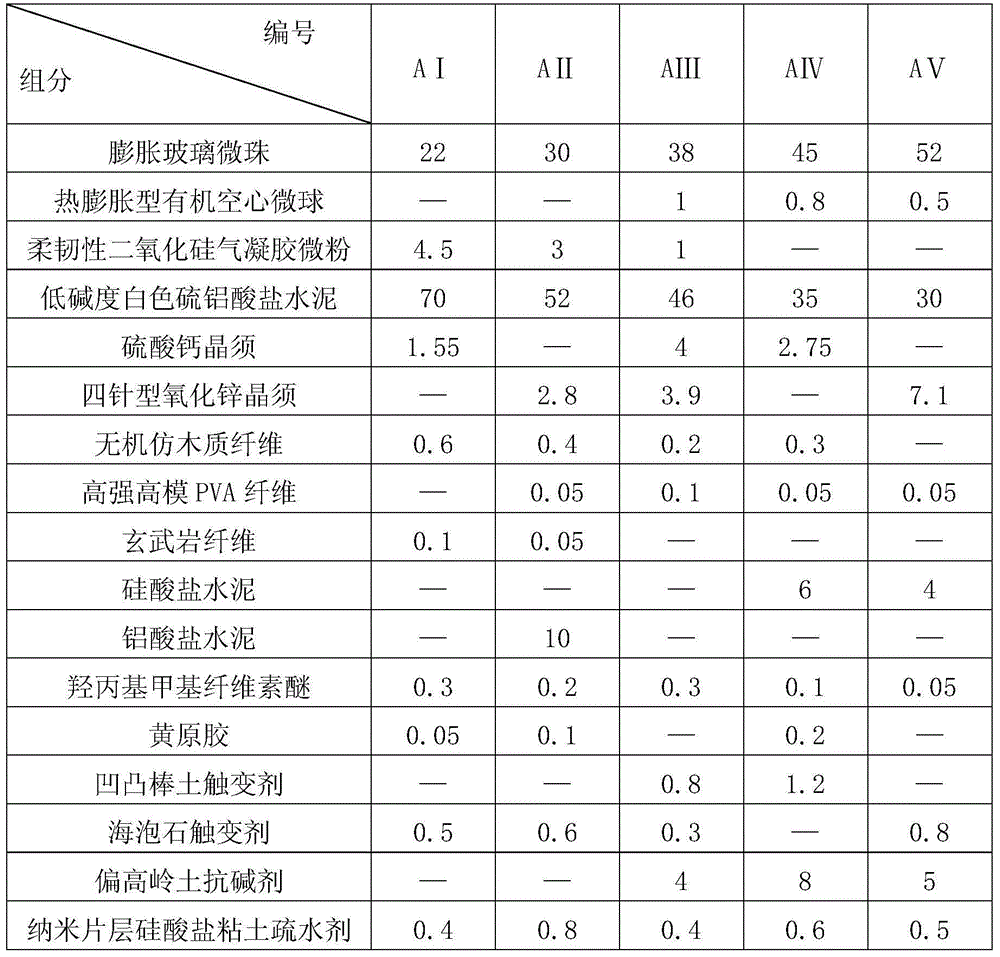

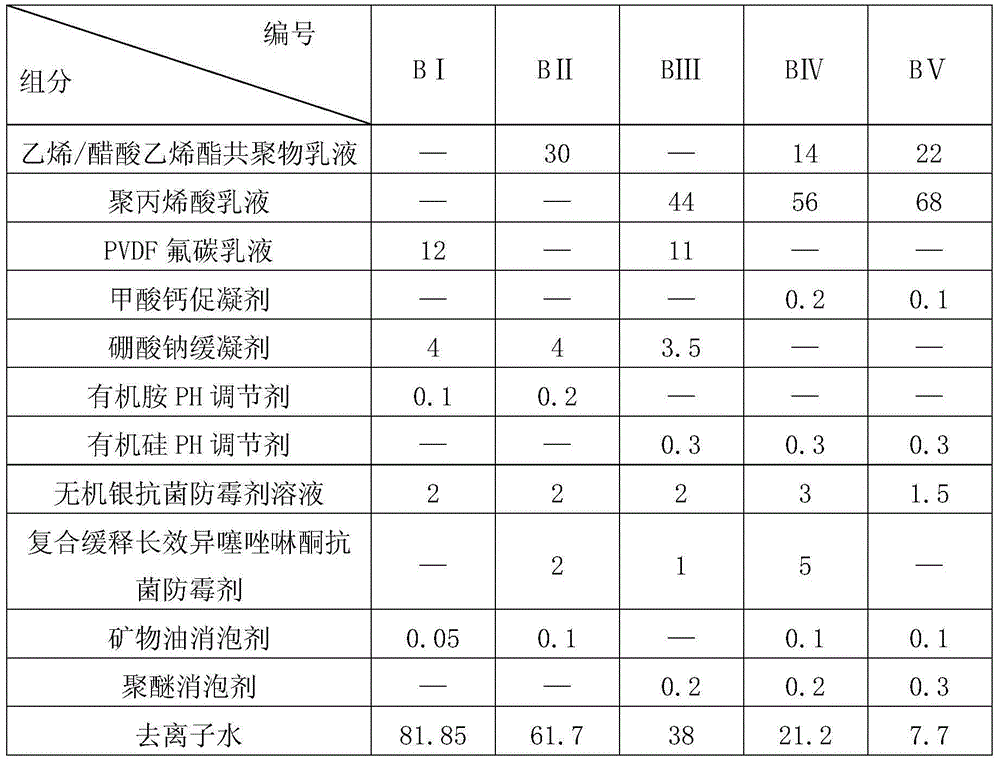

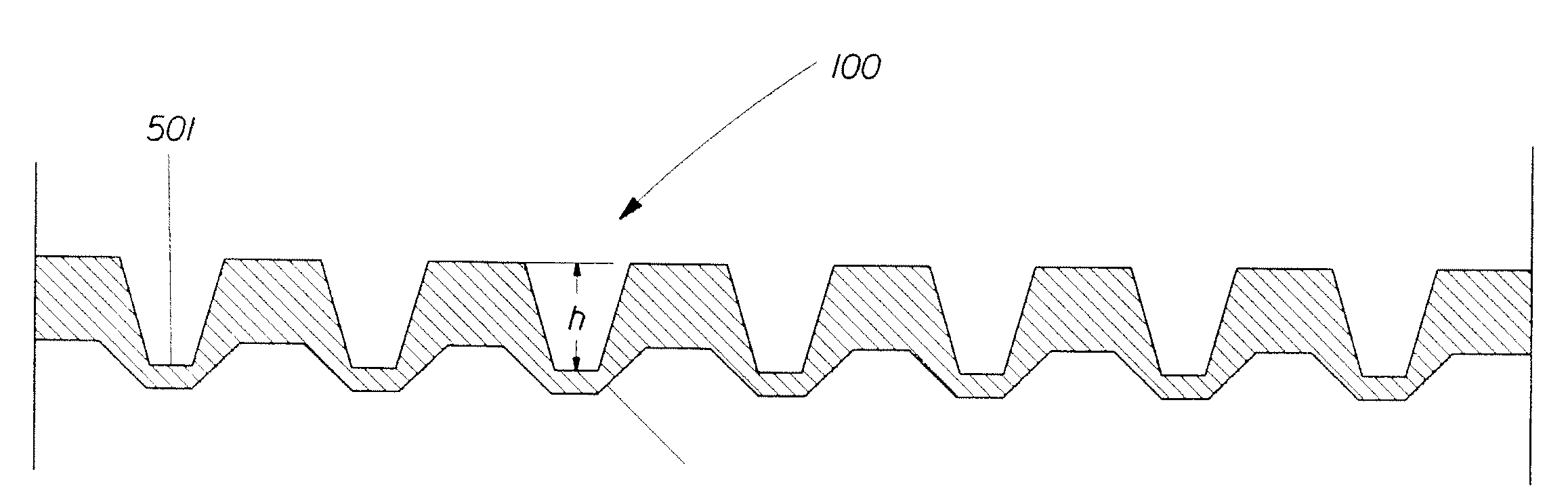

Decorative coating materials for embossing and production method and construction method thereof

ActiveCN104860715AImprove comfortImprove performanceCovering/liningsDecorative surface effectsWater basedEmulsion

The invention discloses decorative coating materials for embossing and a production method and a construction method thereof. According to the decorative coating materials, expanding glass beads serve as aggregates, organic elastic expansion hollow microspheres or flexible silica aerogel micro powder serve or serves as fluffy foaming packing, sulphate aluminum cement serves as inorganic gels, a water-based polymer emulsion or re-dispersible emulsion powder serves as organic gels, the optimized selection is performed on multiple accessories and functional additives, and accordingly the performance of the decorative coating materials for the embossing is effectively improved, the plasticity is high particularly, and the decorative coating materials are suitable for the delicate texture embossing operation and texture fabrics comprising three-dimensional concave and convex texture on the market are directly utilized to produce embossed decorative wall bodies and plates on the basis of the application of the decorative coating materials and accordingly the problems of various defects and application limits of the existing embossing process are well solved, the development investment and production and manufacturing on mechanical equipment such as embossing dies are avoided, and the production cost is saved.

Owner:昆山创石集工艺材料有限公司

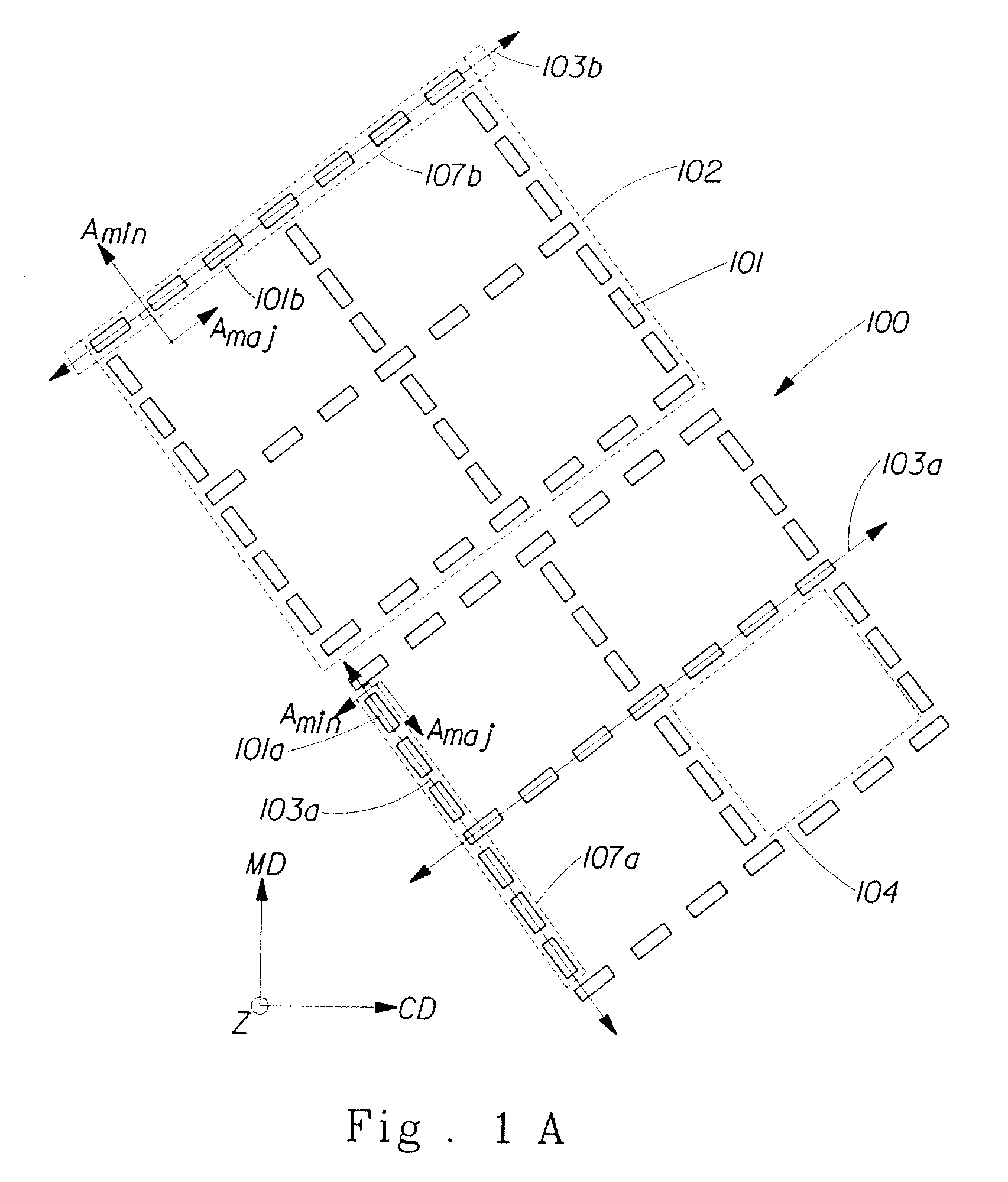

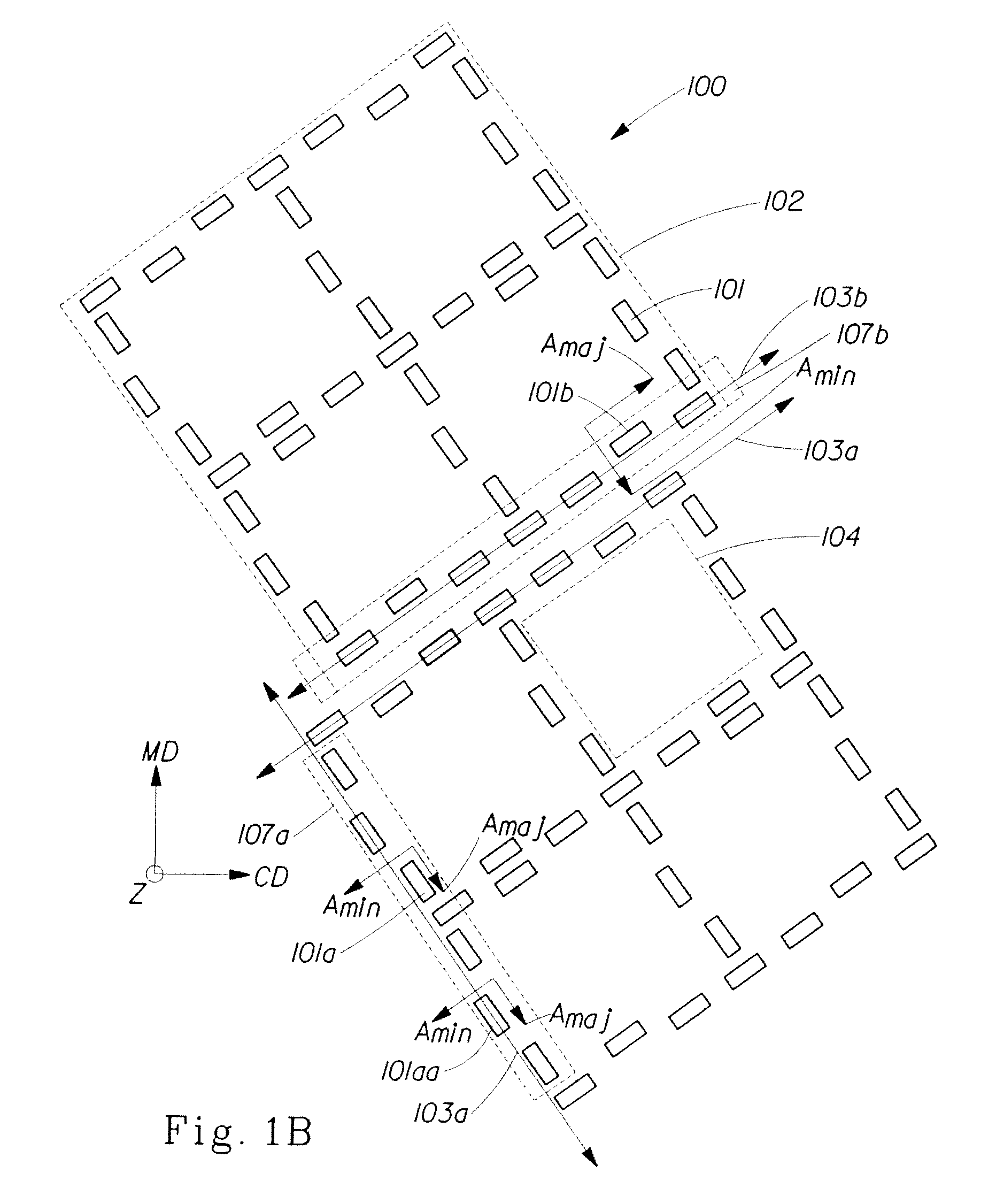

Paper product with enhanced emboss and background pattern contrast

A ply of cellulosic fibrous structure product having a repeating pattern such that the repeating pattern contains one or more master patterns. A first one or more master pattern has: a first individual embossment having a major axis and a minor axis, a first line segment axis parallel to the major axis of the first individual embossment, and at least one individual embossment adjacent to the first individual embossment. The individual embossment adjacent to the first individual embossment has a major axis and a minor axis such that the major axis of the individual embossment adjacent to the first individual embossment and the first line segment axis form an angle of from about 0° to about 20°. The master pattern also has a second individual embossment having a major axis and a minor axis, a second line segment axis parallel to the major axis of the second individual embossment, and at least one individual embossment adjacent to the second individual embossment, wherein the individual embossment adjacent to the second individual embossment has a major axis and a minor axis such that the major axis of the individual embossment adjacent to the second individual embossment and the second line segment axis form an angle of from about 0° to about 20°. The first line segment axis and the second line segment axis intersect. The product also has a background pattern having one or more features forming a base pattern. The repeat frequency by which the base pattern is repeated within a certain area is greater than about 1.5 times by which a master pattern is repeated within the same area.

Owner:THE PROCTER & GAMBLE COMPANY

Embossed reflective laminates

InactiveCN1625468AReduce energy transmittanceVisible light reflectance minimizedLamination ancillary operationsSynthetic resin layered productsInfraredMetal coating

Owner:SOLUTIA INC

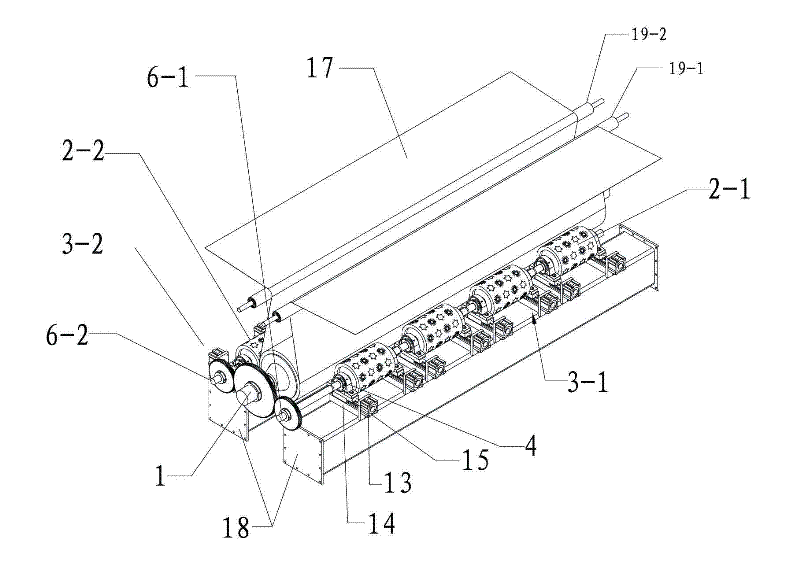

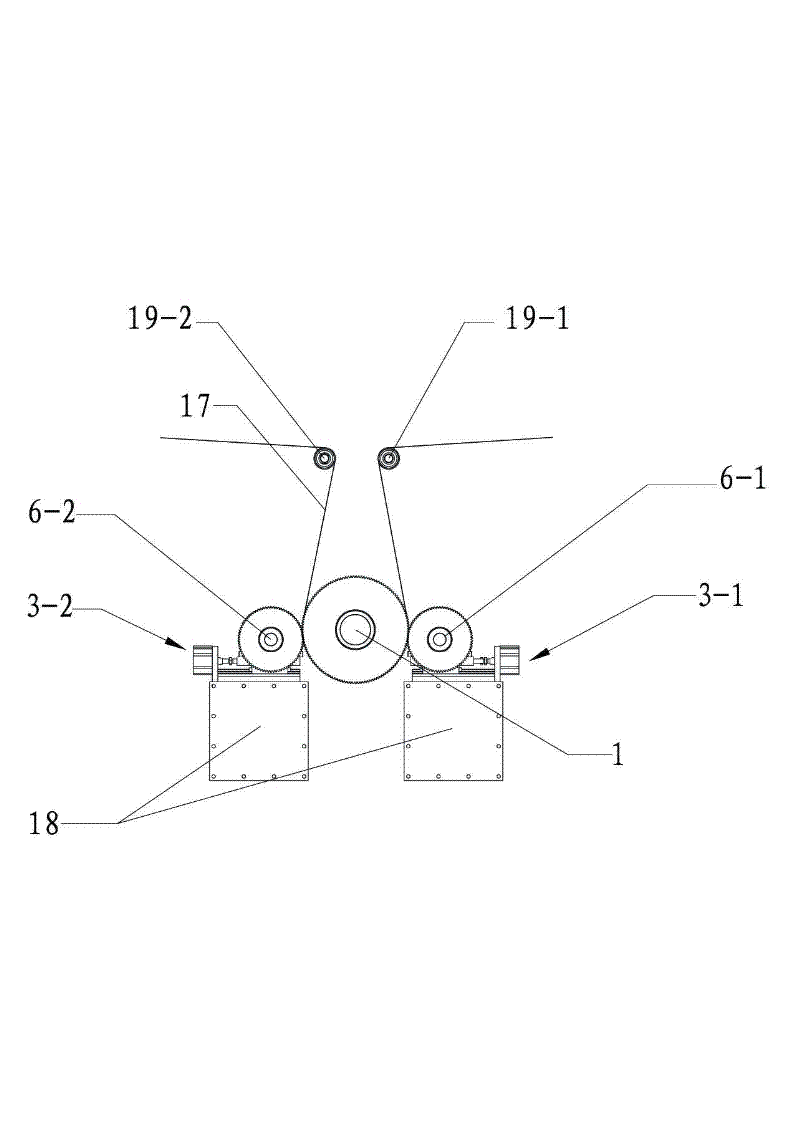

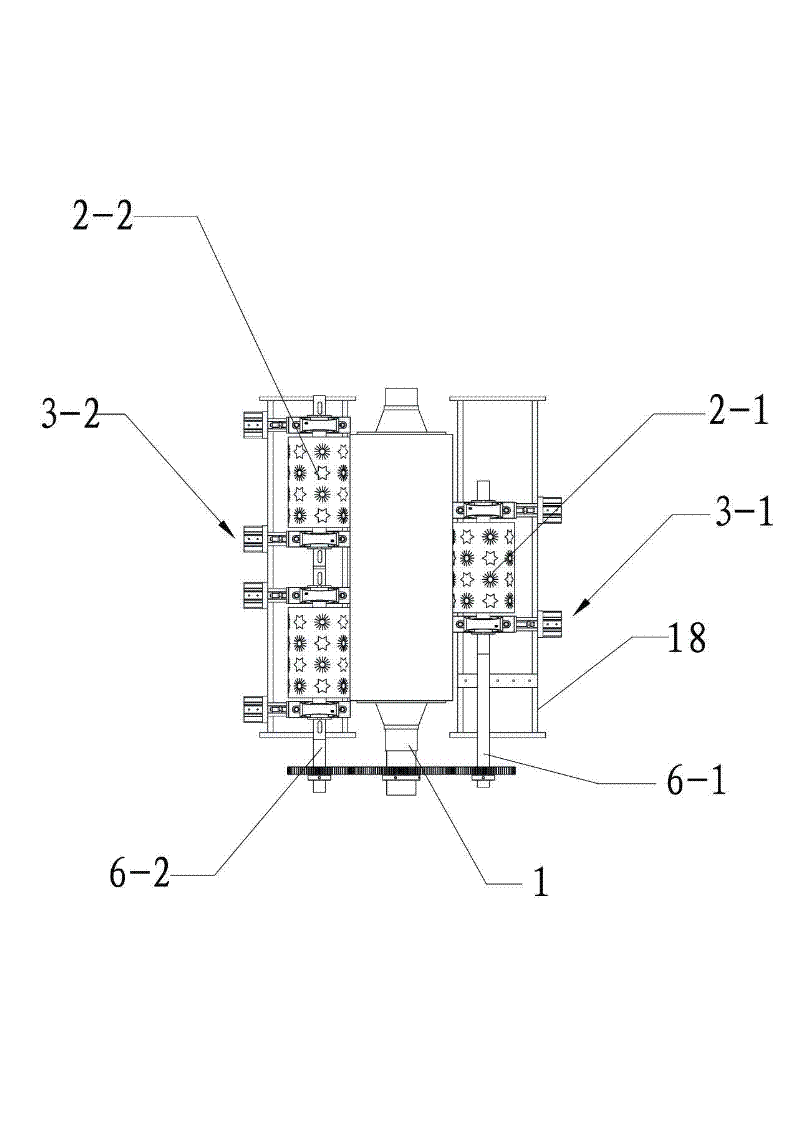

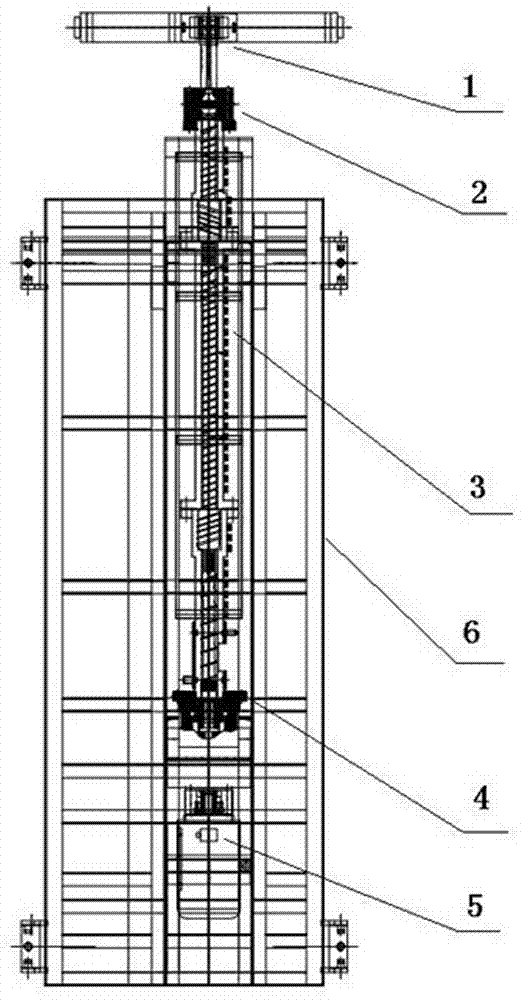

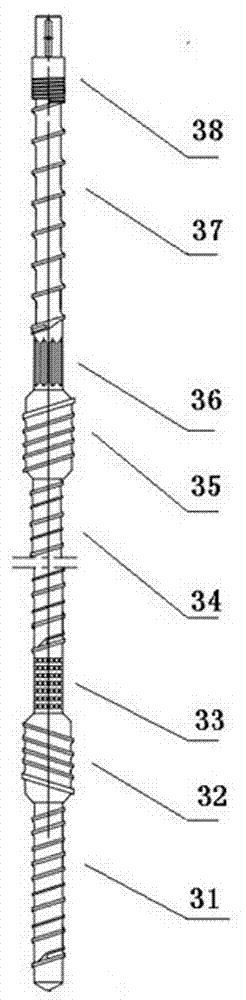

Embossing device for use on paper towel processing equipment and embossing production technology thereof

ActiveCN102407614AEasy to controlImprove product qualityMechanical working/deformationPaper towelEngineering

The invention provides an embossing device for use on paper towel processing equipment and an embossing production technology thereof. The device comprises a bottom roller; at least two embossing roller sets acted on the surface of the bottom roller are arranged along the axial direction of the bottom roller at the two sides of the bottom roller respectively; one embossing roller set is composed of one or more embossing roller assemblies, while the other embossing roller set is composed of two or more embossing roller assemblies; each embossing roller assembly is pressurized with an independent pressurizer respectively; and the embossing roller assembly at one side and the embossing roller assembly at the other side rotate by working with each other to form mutual complementation of embossed patterns. The segmented embossing is used, so that the line pressure in the embossing process is easy to control and convenient to adjust, and the embossed paper towel has better product quality and better effect; and more importantly, the diameter of the embossing roller assembly is much smaller than that of the integrated roller design in the prior art, so that the cost of manufacturing the embossing roller assembly and the cost of engraving flower patterns are also greatly reduced.

Owner:FOSHAN NANHAI DECHANGYU PAPER MASCH MFG CO LTD

Polyurethane coated resilient surface covering having improved fidelity of texture and process of manufacture

Owner:TARKETT INC

High molecular leather release paper producing process

InactiveCN103938490AStrong oxidation resistanceStrong embossed layeringSpecial paperPaper/cardboardPolymer scienceMolecular materials

The invention relates to a high molecular leather release paper producing process capable of effectively improving the production efficiency of leather products. The process comprises the following steps: coating the back surface of body paper with oxidation-resistant liquid glue, drying by using hot air at an instantaneous high temperature, carrying out ultraviolet (UV) curing processing, conveying the processed body paper to a composite embossing unit, pushing multilayer high molecular resin to a high-temperature high-pressure clearance type current reducing spray head through a hot reflux high speed smelting pushing device, uniformly spraying the multilayer high molecular resin on the front surface of the body paper to form half-soakage combination with the body paper, carrying out mechanical embossing at the same time, combining the high molecular material with the body paper to form leather patterns, trimming and rolling to obtain the high molecular leather release paper.

Owner:青岛鼎立强包装机械有限公司

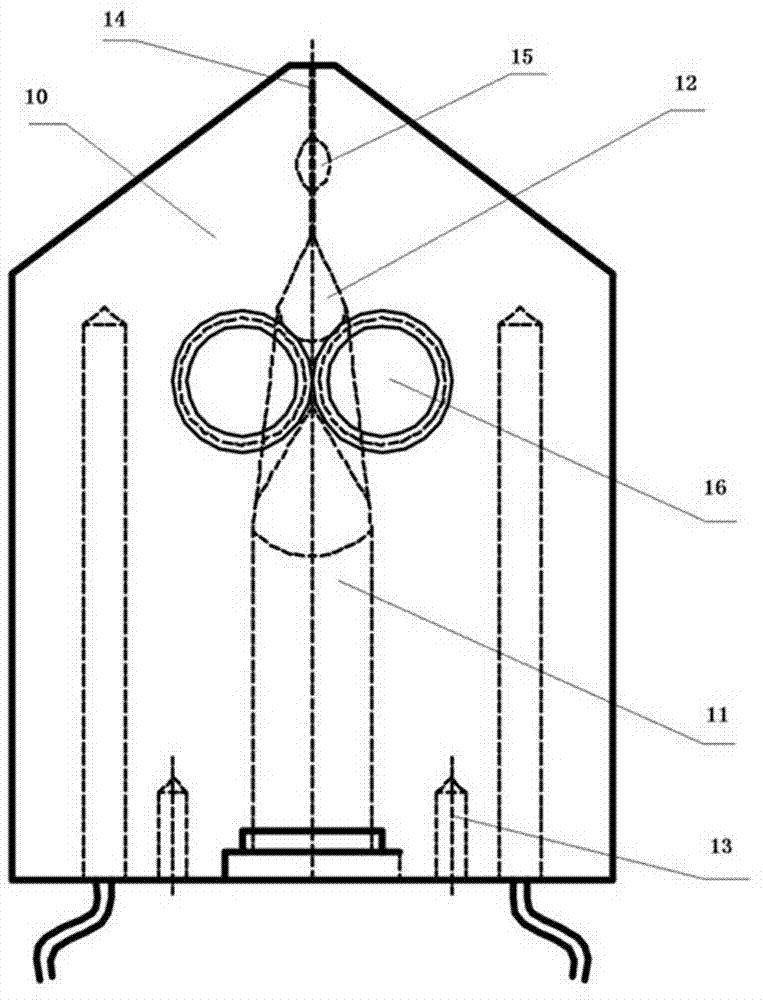

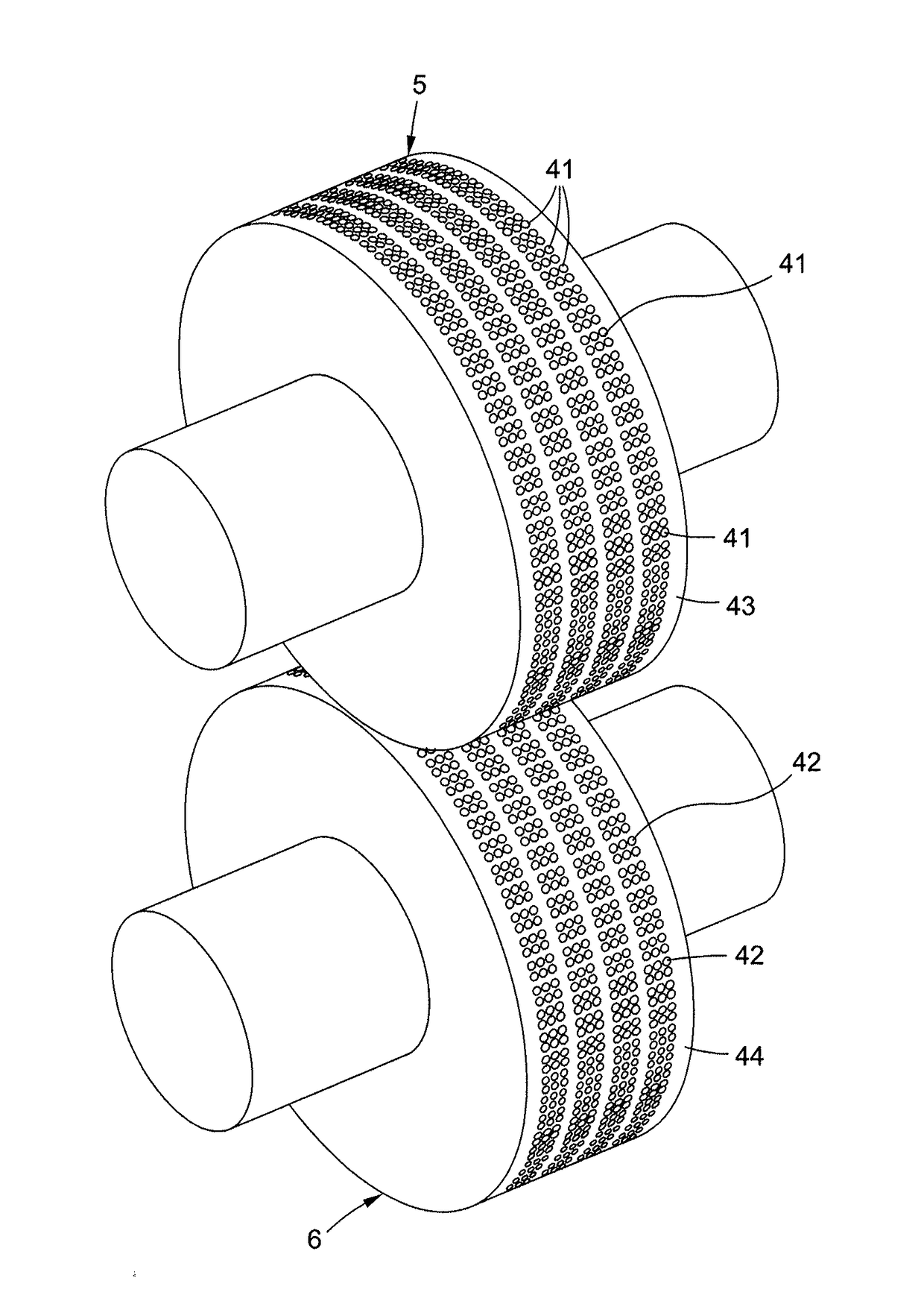

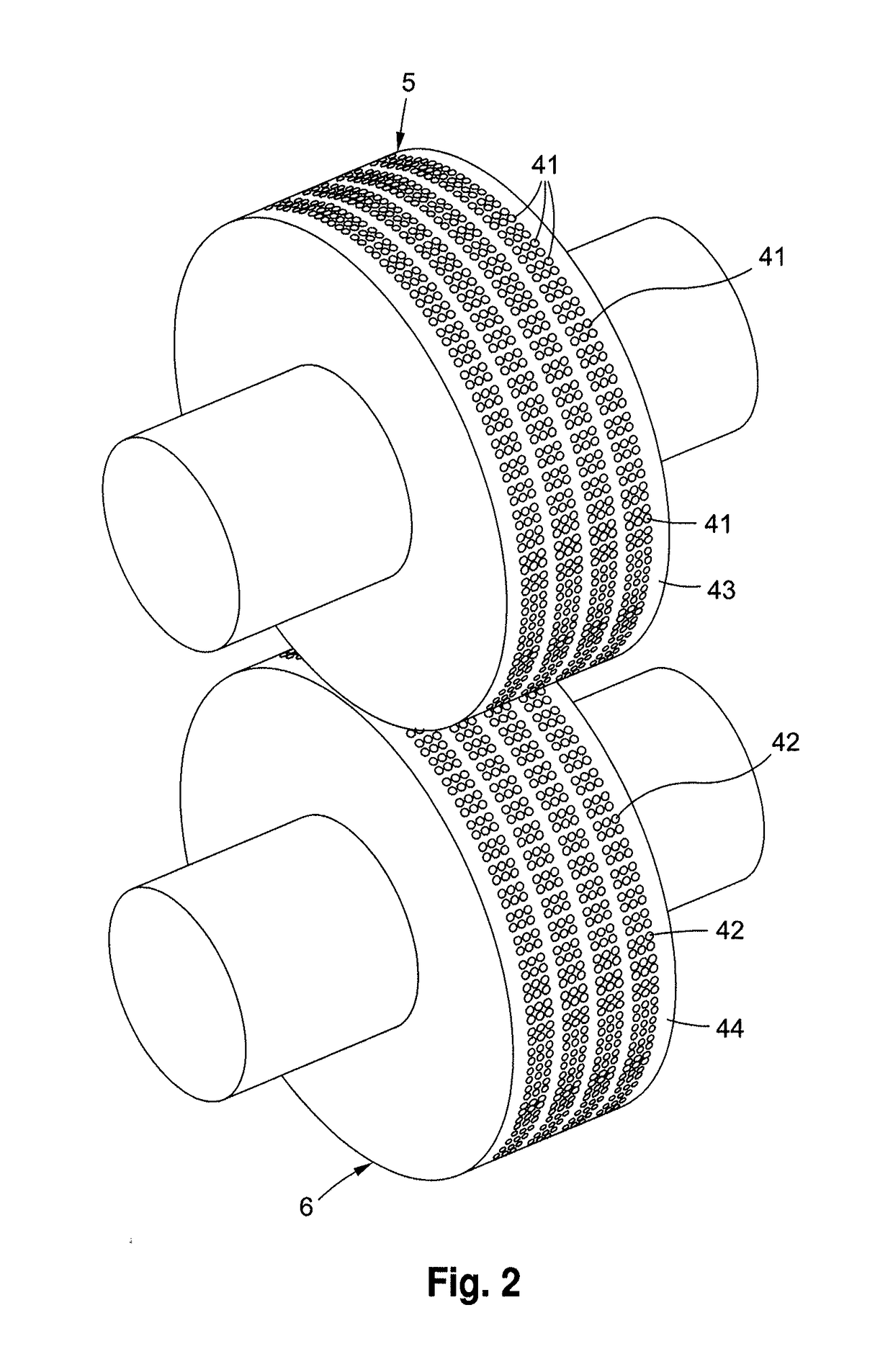

Method and device for producing a printed and embossed web

InactiveCN101873927AIncrease embossing thicknessMechanical working/deformationAdhesivesTextile printerAdhesive

Method and device for producing a printed and embossed multi-ply web (3) of tissue paper or nonwoven having a good visual appearance. A first web-shaped material (1) is embossed in a nip (6) between a first embossing roll (4) and a counter roll (5), thereby creating a set of embossments. A first ink with a first colour is applied to a first subset of said set of embossments of said first web-shaped material while the material still resides on said first embossing roll. Thereafter an adhesive is applied to a second subset of said set of embossments of said first web-shaped material (1) while the material still resides on said first embossing roll (4). After that, said first web-shaped material is combined with a second web-shaped material (2) to form a multi-ply web (3). There is also provided a printed and embossed multi-ply web (3).

Owner:SCA卫生产品有限责任公司

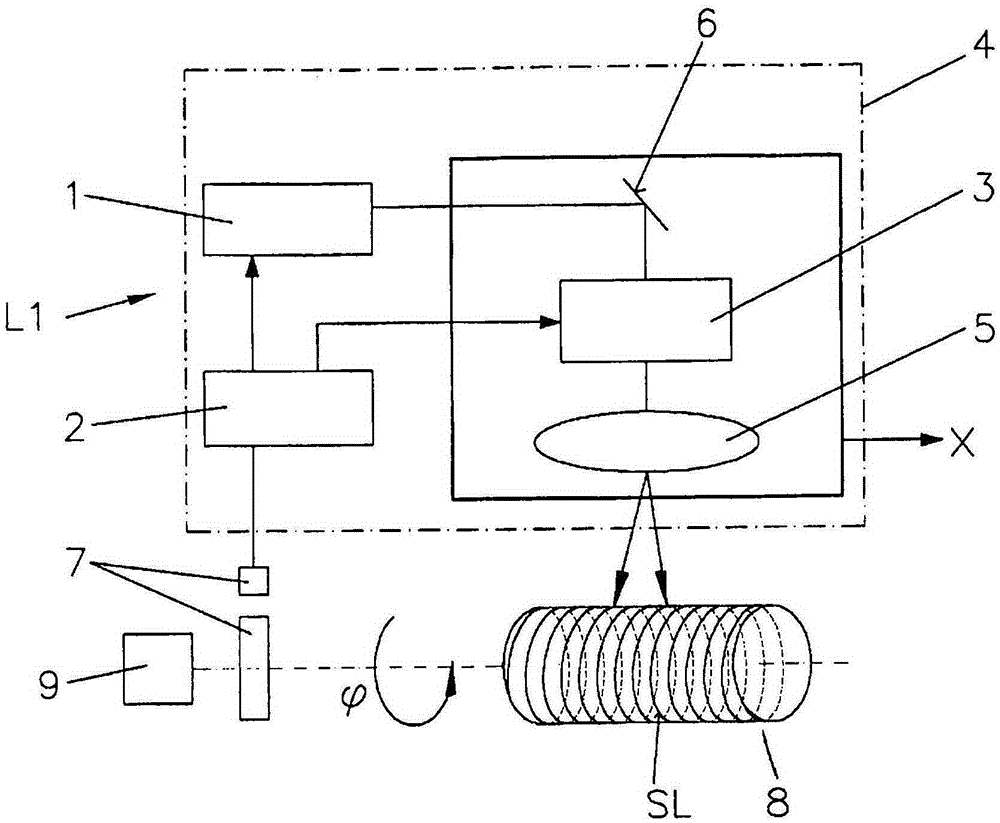

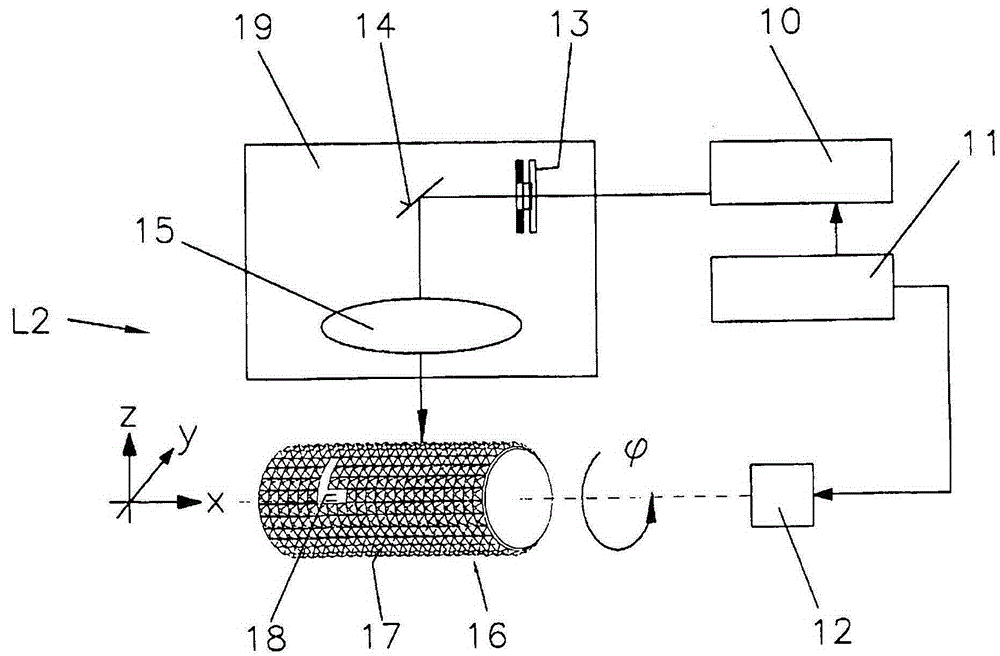

Method for producing an embossing roller from silicone rubber for the continuous embossing of the surface of a thermoplastic film

InactiveUS20020124954A1Not require much timeSimple casting processMechanical working/deformationLamination ancillary operationsEngineeringSurface structure

Method for producing an embossing roller from silicone rubber for the continuous embossing of the surface of a thermoplastic film, with the embossing surface having a negative form of a surface structure to be embossed. An auxiliary roller is provided which is plastic, at least in the region of its circumferential surface. A laser beam is directed onto the circumferential surface and controlled for defining a real imaginary pattern in such a way that a surface structure of the pattern is created as a positive form on the surface. A layer of silicone rubber provided on the surface produces an embossing matrix which is pulled off the surface, turned inside out, and adhered to a surface of an embossing roller, with the negatively structured embossing surface facing outward. Thus, multiple embossing matrices can be created after a one-time structuring of the surface of an auxiliary roller, using a casting process.

Owner:BENECKE-KALIKO

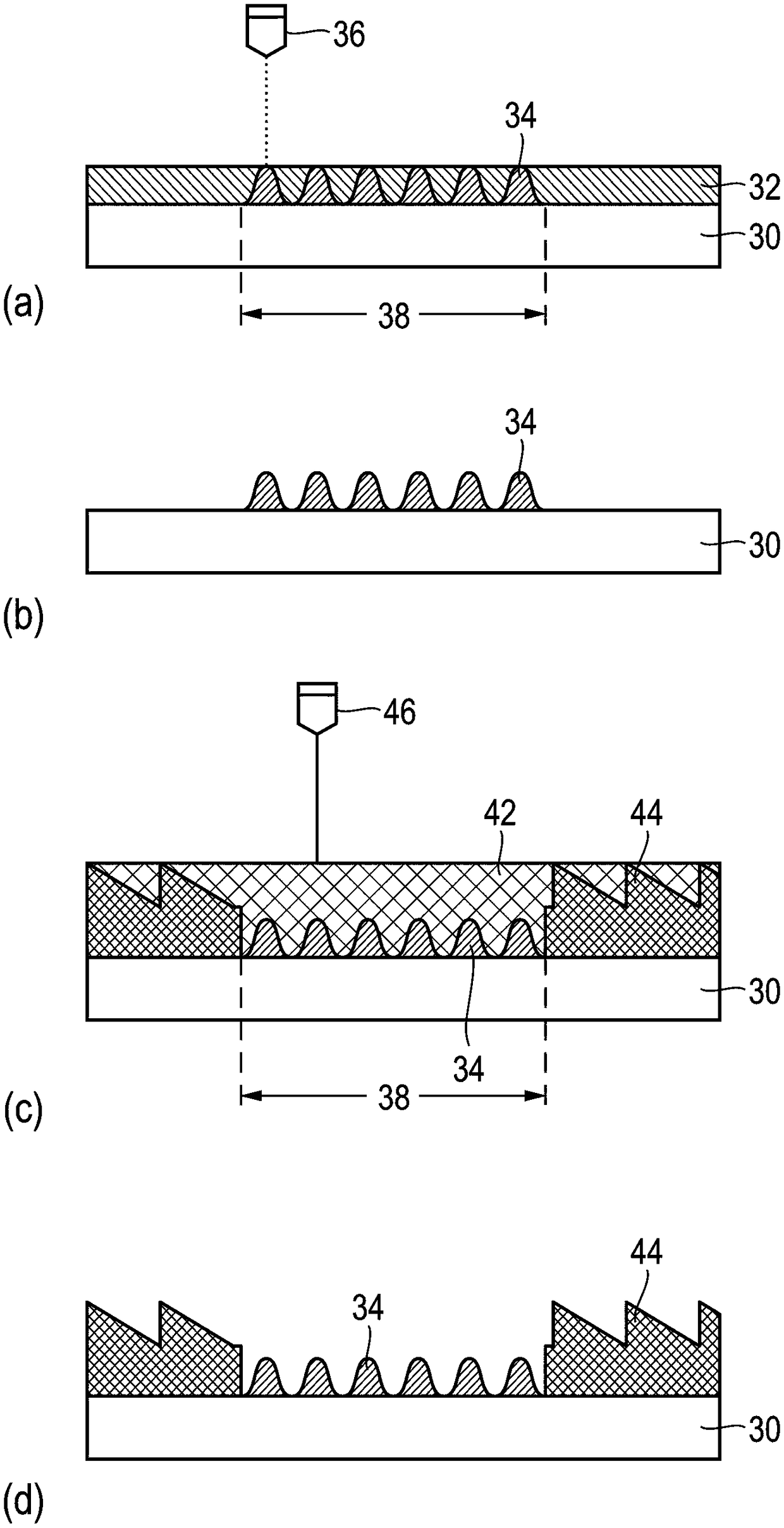

Method for production of a female embossing tool, a female embossing tool, and an embossing module equipped therewith

ActiveUS20170313018A1Increase flexibilityObstruction is producedEnvelopes/bags making machineryMechanical working/deformationMemory typeMechanical engineering

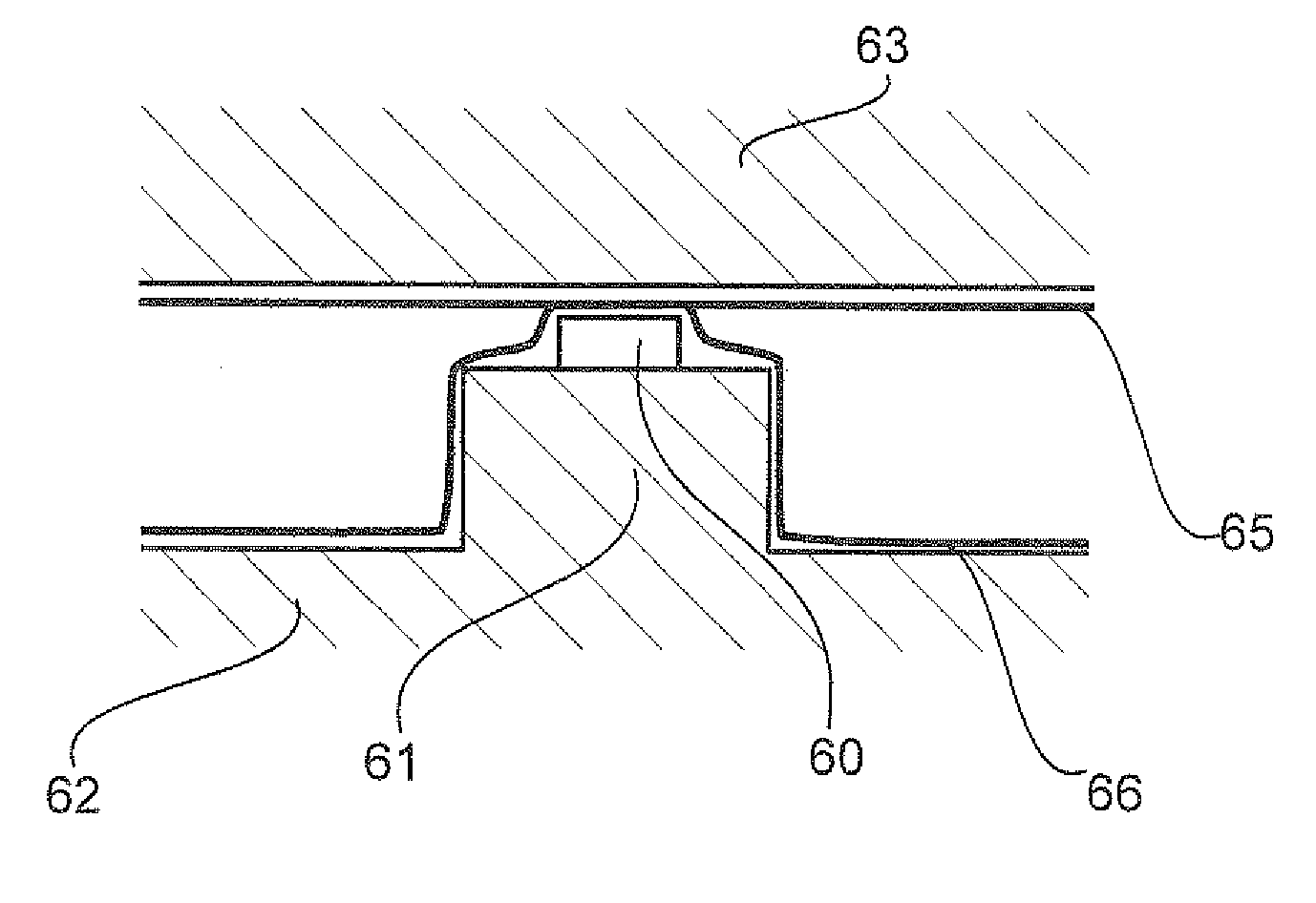

A method for production of a female embossing tool (6) intended for embossing a sheet element (60): provide a female embossing tool (6) with an outer layer (44) made of a material with shape-memory type properties, and the outer face of the layer has no recesses; provide a male embossing tool (5, 5′) with an outer face with at least one protuberance corresponding to at least one desired embossing relief that is to be formed on the sheet element (60) after embossing; and cooperation of the male embossing tool (5, 5′) with the female embossing tool (6) such that the outer layer (44) of the female embossing tool (6) undergoes a plastic deformation which creates at least one recess (42, 42′) of a shape complementary to the protuberance(s) (41, 41′) of the male embossing tool (5, 5′).

Owner:BOBST MEX SA

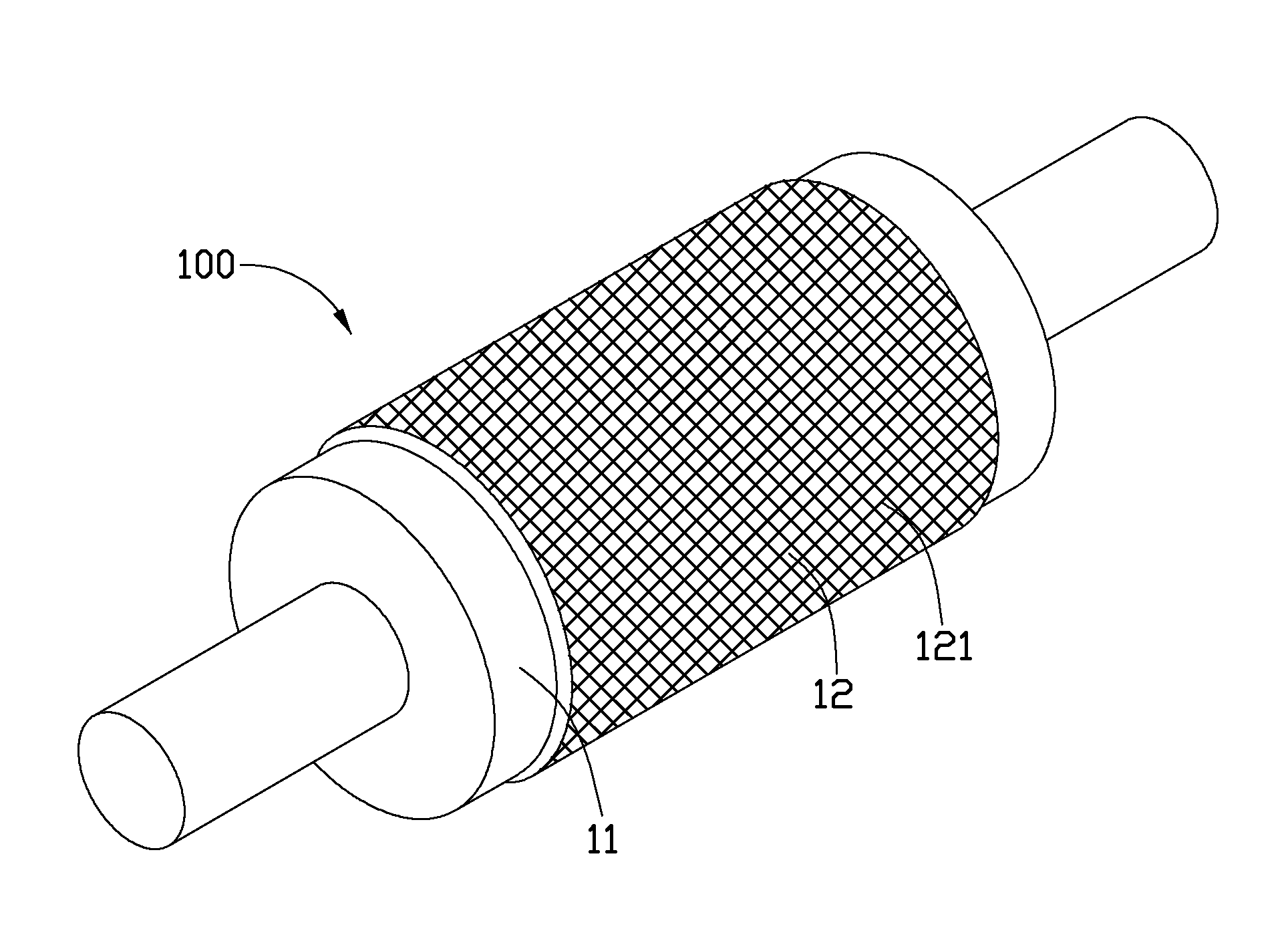

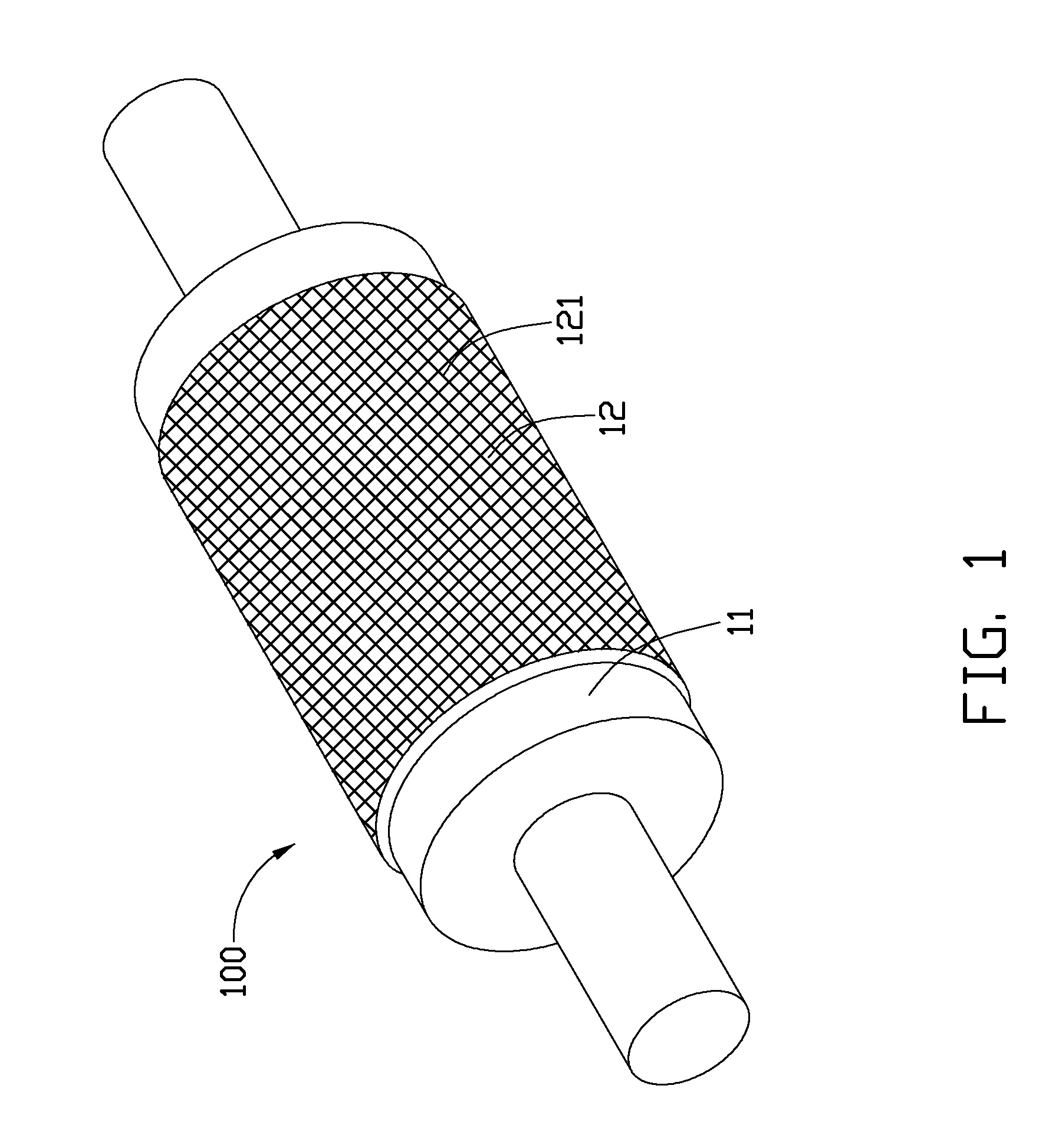

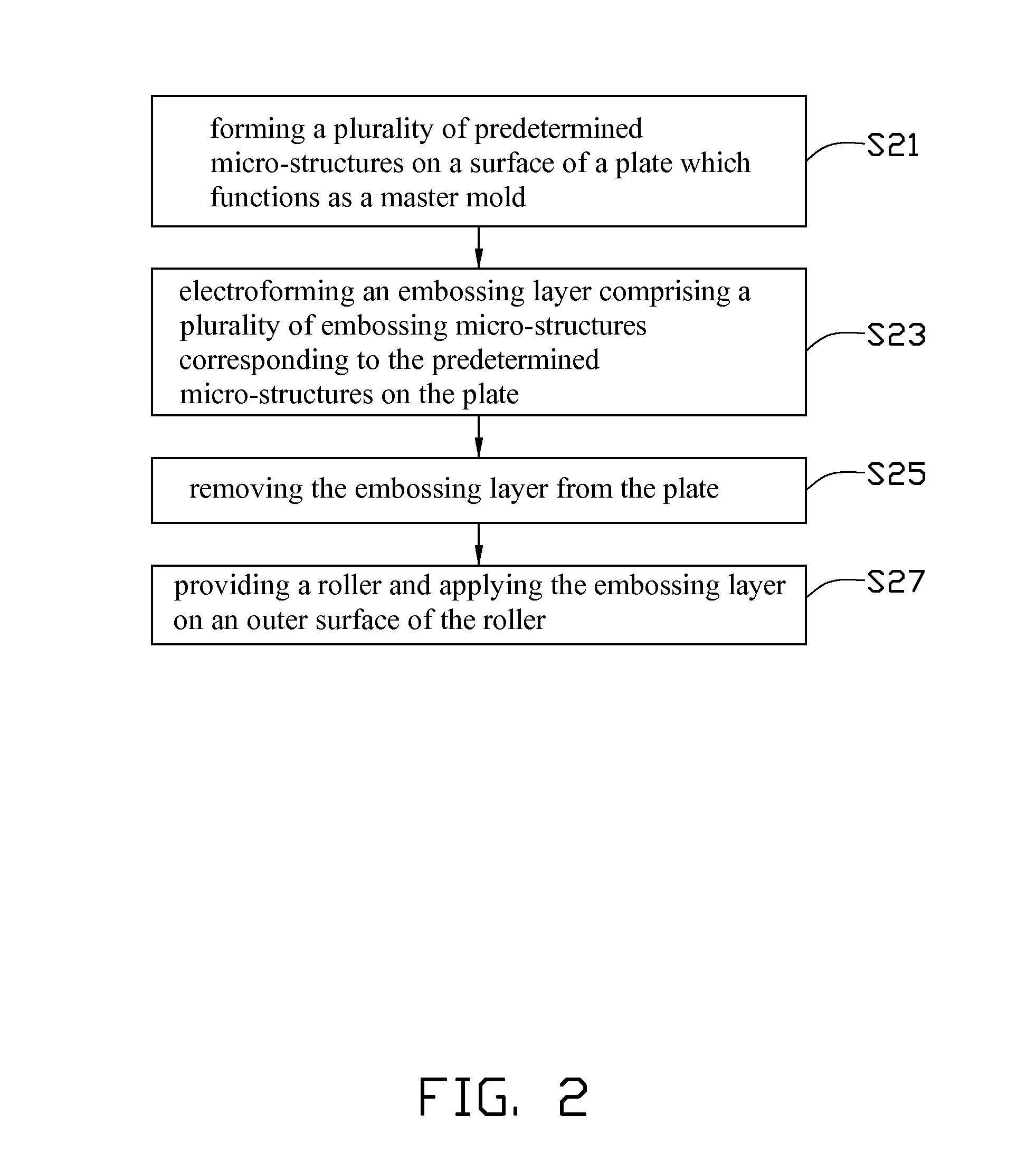

Embossing assembly, manufacturing method thereof, and embossing method using the same

A light guide plate is manufactured by applying an embossing assembly. The embossing assembly includes a roller and an embossing layer applied on the roller. The embossing assembly is formed by electroforming embossing micro-structures on the outer surface of the embossing layer to an embossing substrate and embossing micro-structures on a surface thereof.

Owner:HON HAI PRECISION IND CO LTD

Method for producing an embossing roller from silicone rubber for the continuous embossing of the surface of a thermoplastic film

InactiveUS6962640B2Easy to manufactureLamination ancillary operationsOrnamental structuresEngineeringSurface structure

Method for producing an embossing roller from silicone rubber for the continuous embossing of the surface of a thermoplastic film, with the embossing surface having a negative form of a surface structure to be embossed. An auxiliary roller is provided which is plastic, at least in the region of its circumferential surface. A laser beam is directed onto the circumferential surface and controlled for defining a real imaginary pattern in such a way that a surface structure of the pattern is created as a positive form on the surface. A layer of silicone rubber provided on the surface produces an embossing matrix which is pulled off the surface, turned inside out, and adhered to a surface of an embossing roller, with the negatively structured embossing surface facing outward. Thus, multiple embossing matrices can be created after a one-time structuring of the surface of an auxiliary roller, using a casting process.

Owner:BENECKE-KALIKO

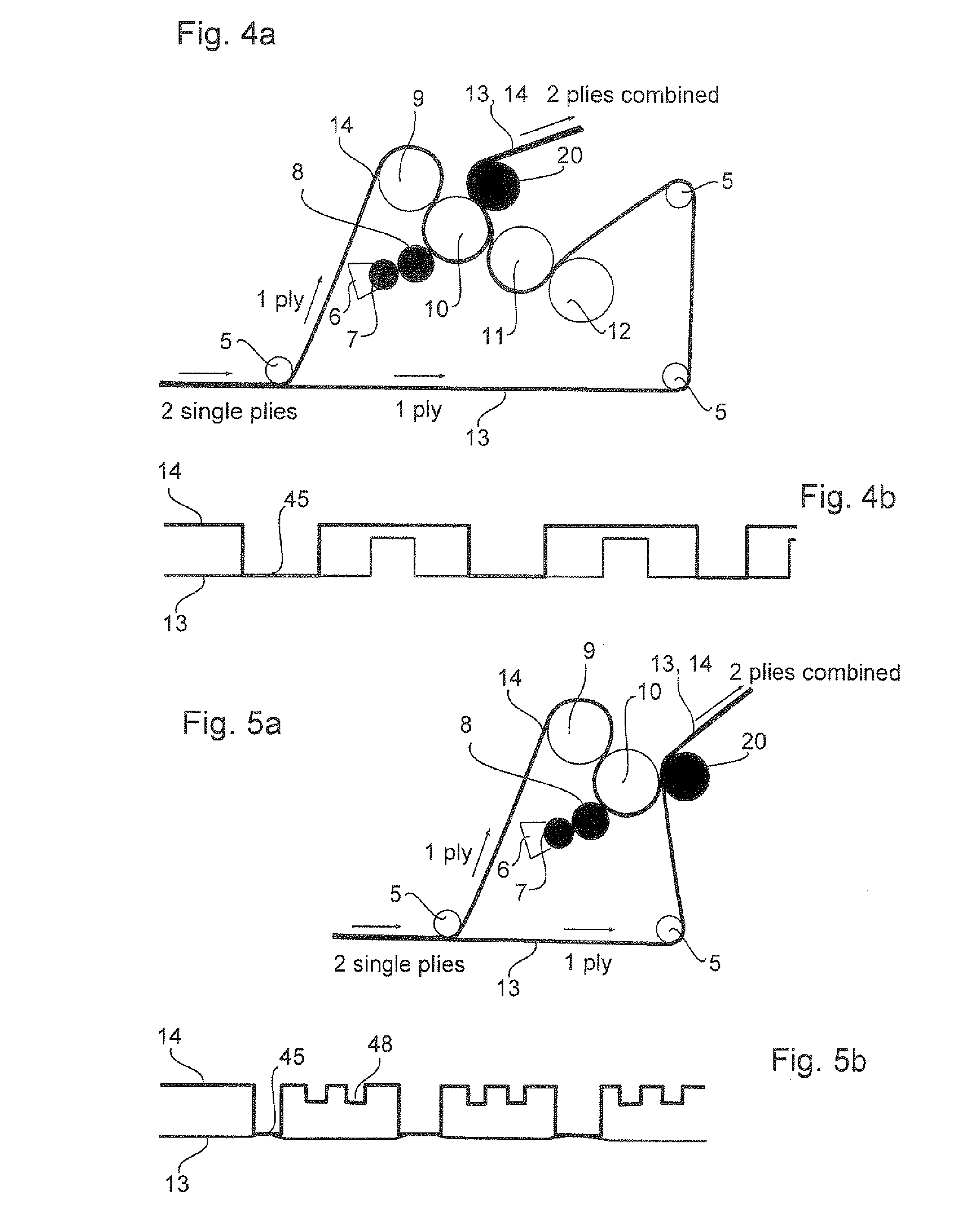

Apparatus and method for ply bonding as well as multi-ply product

InactiveUS20110111180A1Good lookingLow costMechanical working/deformationLayered productsMechanical engineeringComposite material

Apparatus for bonding at least two plies of a fibrous web, includes: a first roller having an outer periphery, at least one embossing protuberance provided on the outer periphery; and a second roller having an outer periphery and being elastic at least in a radial direction, the second roller including at least an inner layer and an outer layer that is harder than the inner layer, the second roller together with the first roller forming a nip through which the two plies are to be fed, wherein an embossing element is located on top of at least one of the embossing protuberance(s), an embossing area of each embossing element being smaller than an embossing area of the corresponding embossing protuberance(s) so that the two plies are bonded at discrete locations corresponding to the first and second embossing elements. Multi-ply product including the bonded plies and corresponding method are also described.

Owner:SCA HYGIENE PROD AB

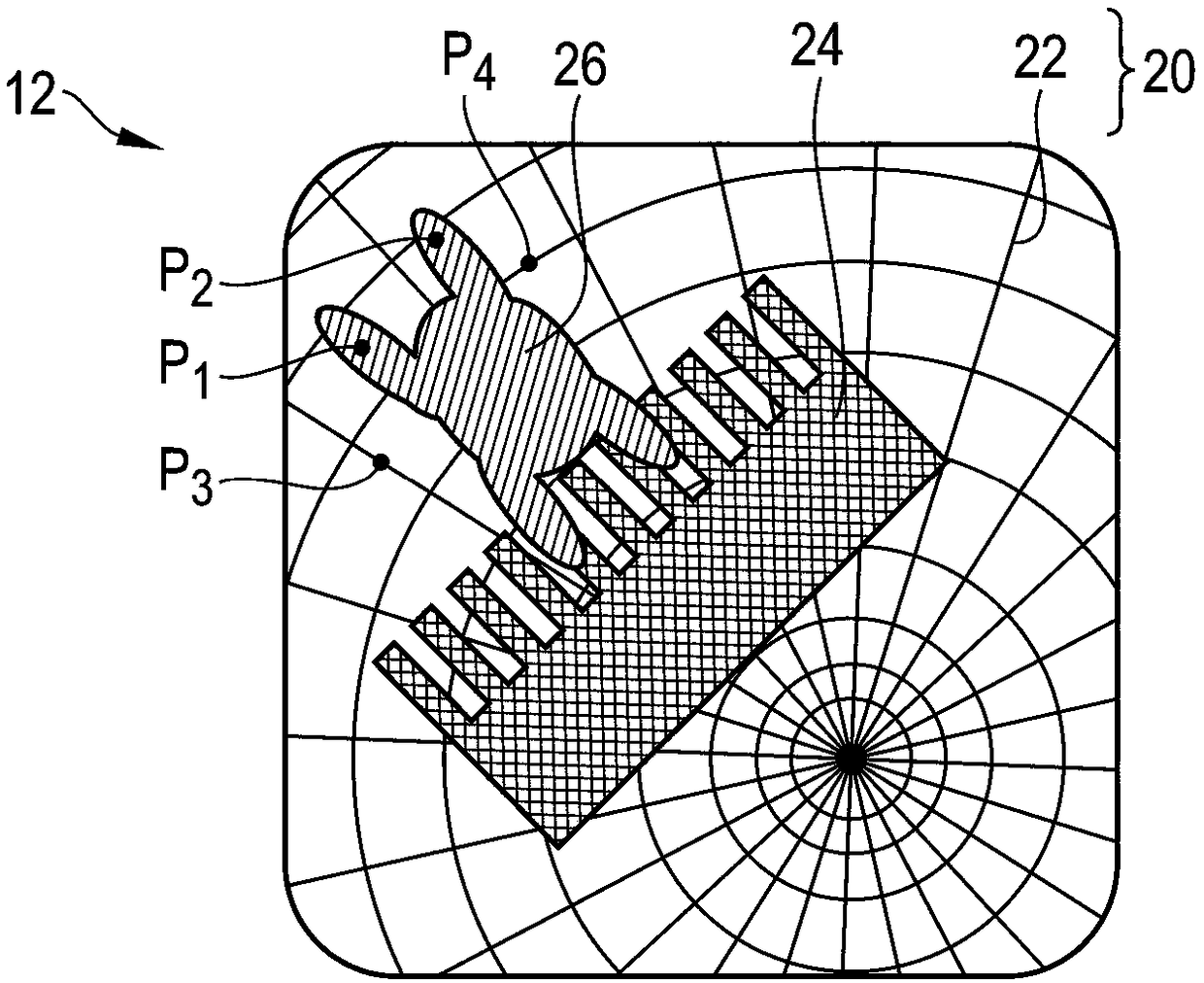

Embossing plate, production method, and embossed security element

The invention relates to an embossing plate (110) for embossing a desired motif, which contains at least two sub-areas having different optical appearance, into an embossing substrate. According to the invention, the embossing plate (110) is provided with an embossing relief (112) in the form of the inverted desired motif and the embossing relief (112) contains at least two sub-areas (114, 116) arranged in precise register in relation to each other in pairs, wherein in each sub-area (114, 116) the embossing relief (112) consists of a plurality of embossing elements (120, 122) having a characteristic structure size, and the characteristic structure sizes of the embossing elements (120, 122) of two sub-areas (114, 116) differ in pairs by at least a factor of 1.5.

Owner:GIESECKE & DEVRIENT CURRENCY TECHNOLOGY GMBH

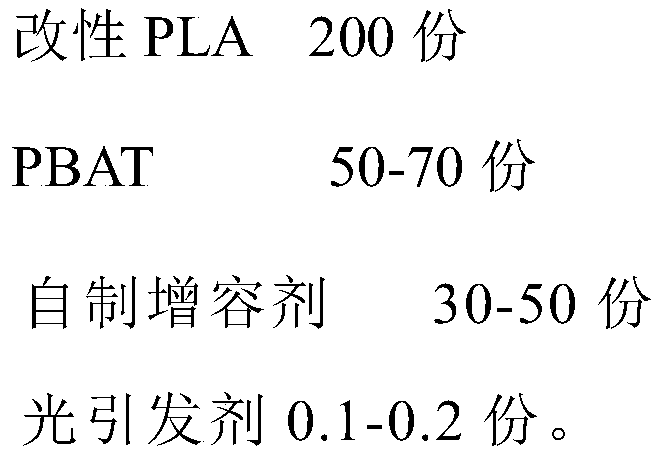

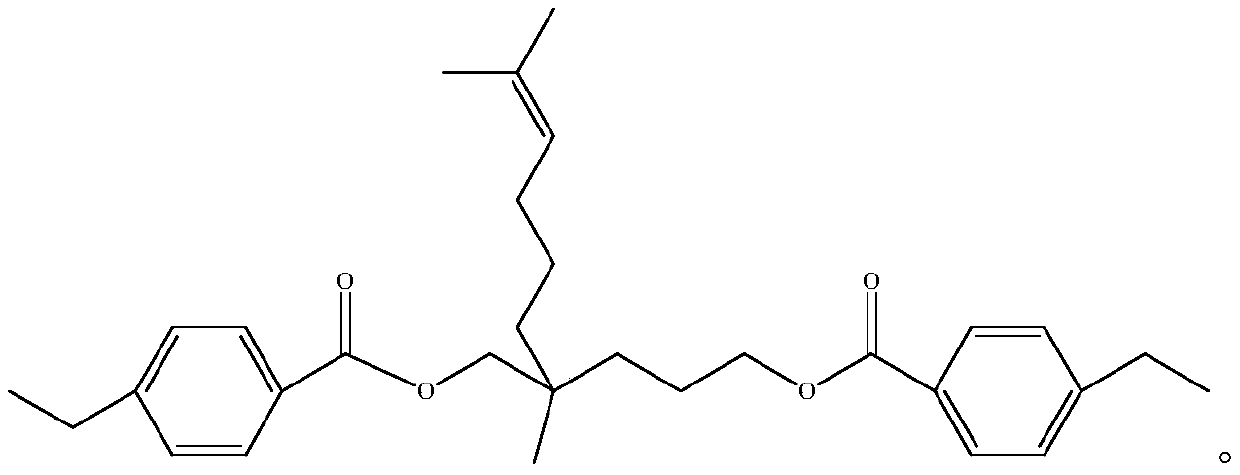

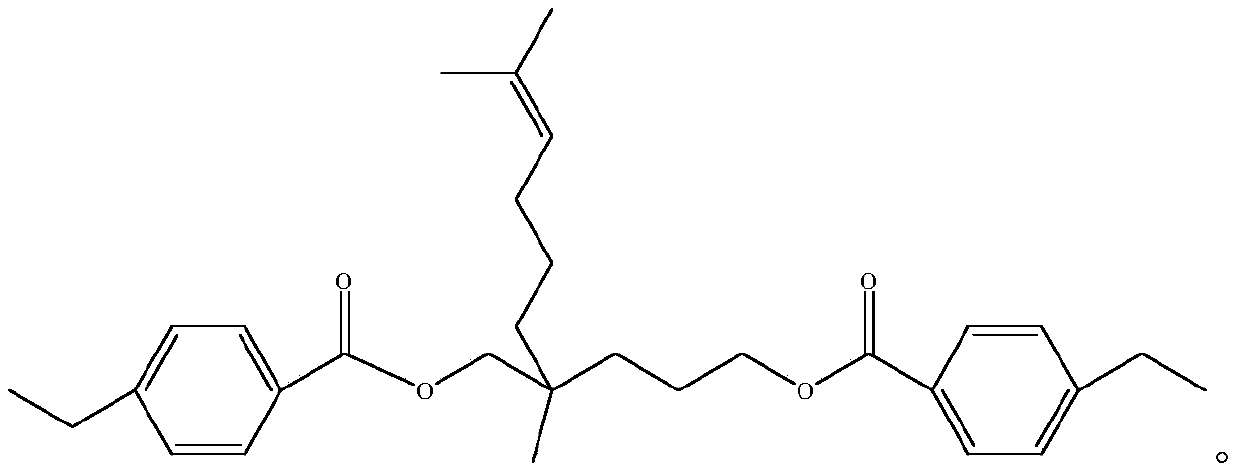

Biodegradable PLA embossed film and preparation method thereof

The invention relates to the technical field of high polymer materials, and in particular, relates to a biodegradable PLA embossed film and a preparation method thereof. Embossing on the surface of aPLA film is achieved, and the PLA embossed film is enabled to have relatively high stiffness; the invention provides the biodegradable PLA embossed film which is composed of the following components in parts by weight: 200 parts of modified PLA, 50 to 70 parts of PBAT, 30 to 50 parts of a self-made compatibilizer and 0.1 to 0.2 part of a photoinitiator. The method disclosed by the invention can realize embossing on the PLA film smoothly; the molecular structure of the self-made compatibilizer provided by the invention contains double bonds; under the action of illumination and a photoinitiator, self-made compatibilizer molecules are subjected to self-polymerization in a PLA embossed film system and also subjected to a photopolymerization reaction with unsaturated double bonds on a polylactic acid molecular structure, the elongation at break and the tensile strength of the PLA embossed film can be reduced to a certain extent through the reaction, and the stiffness of the PLA film is improved.

Owner:常州绿之源高分子材料有限公司

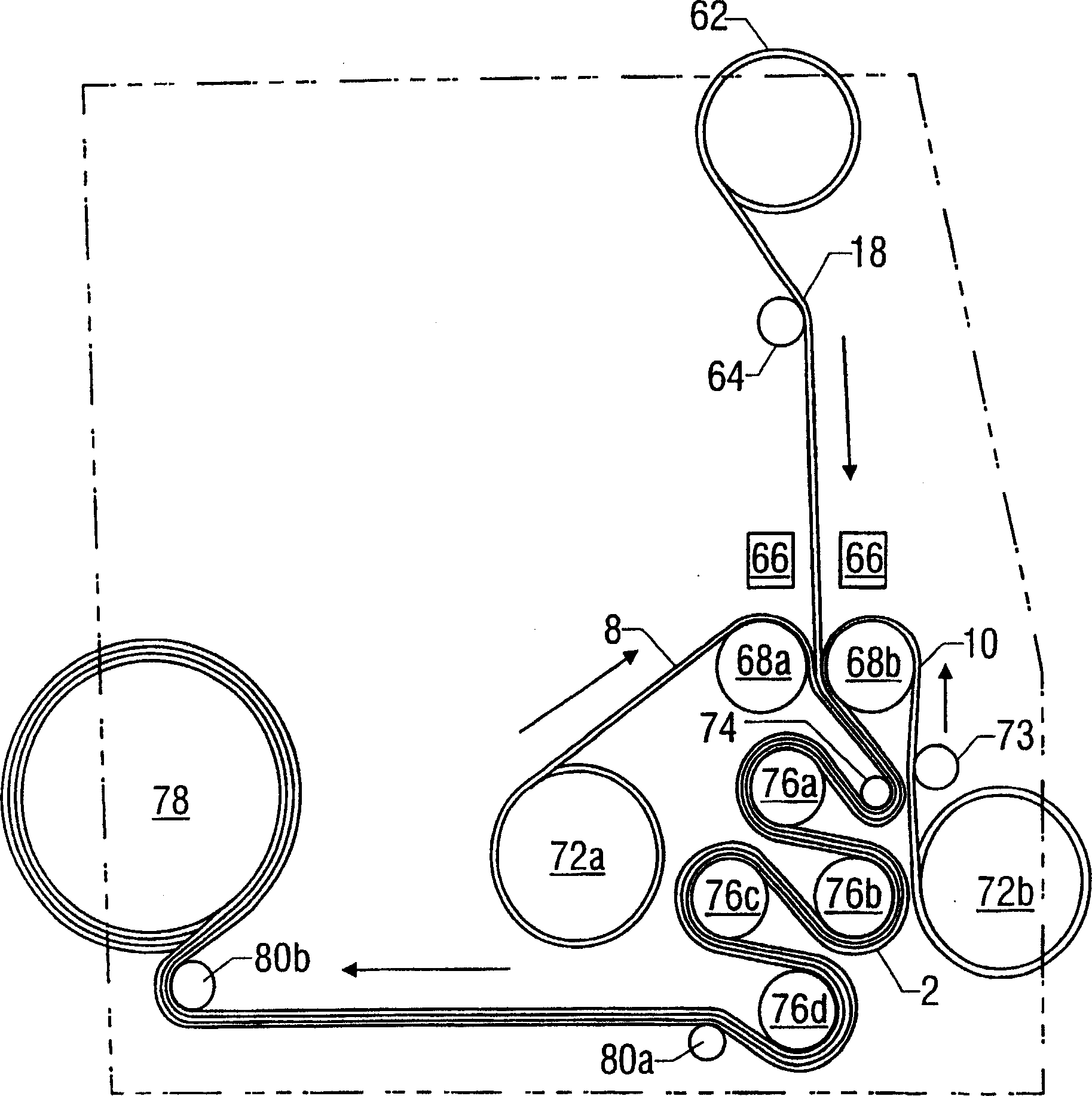

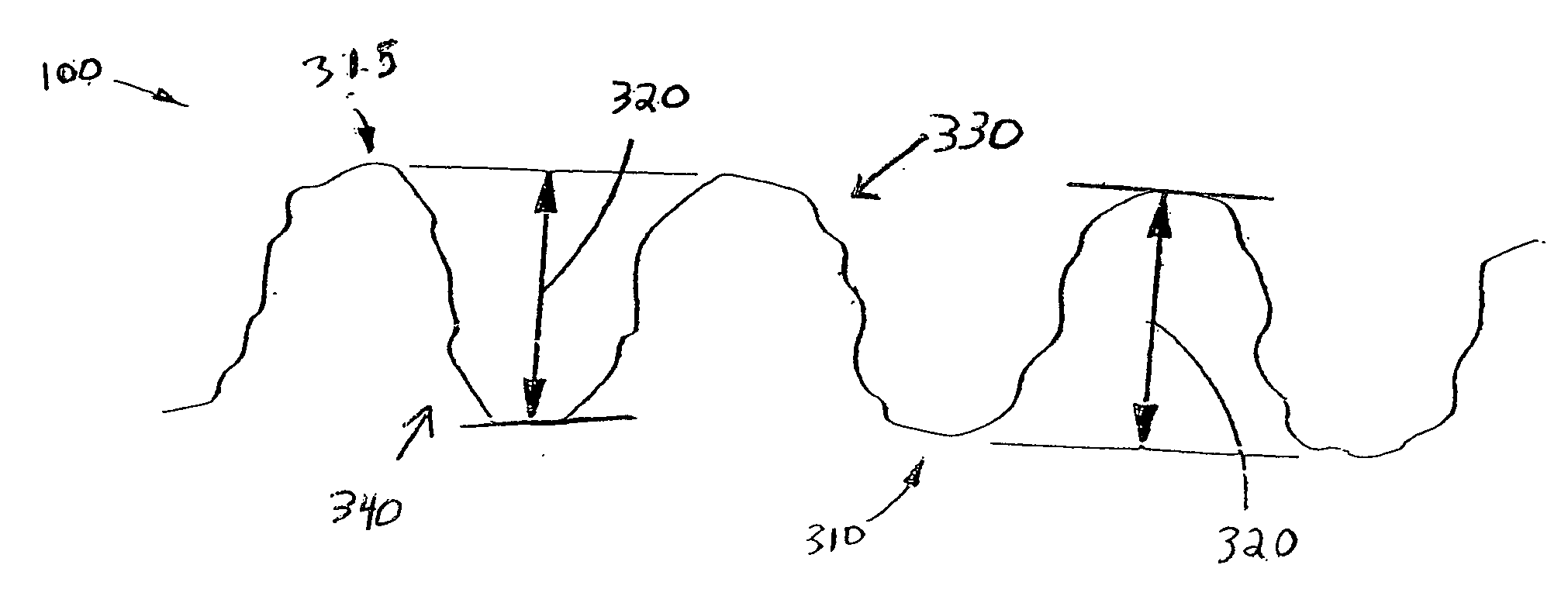

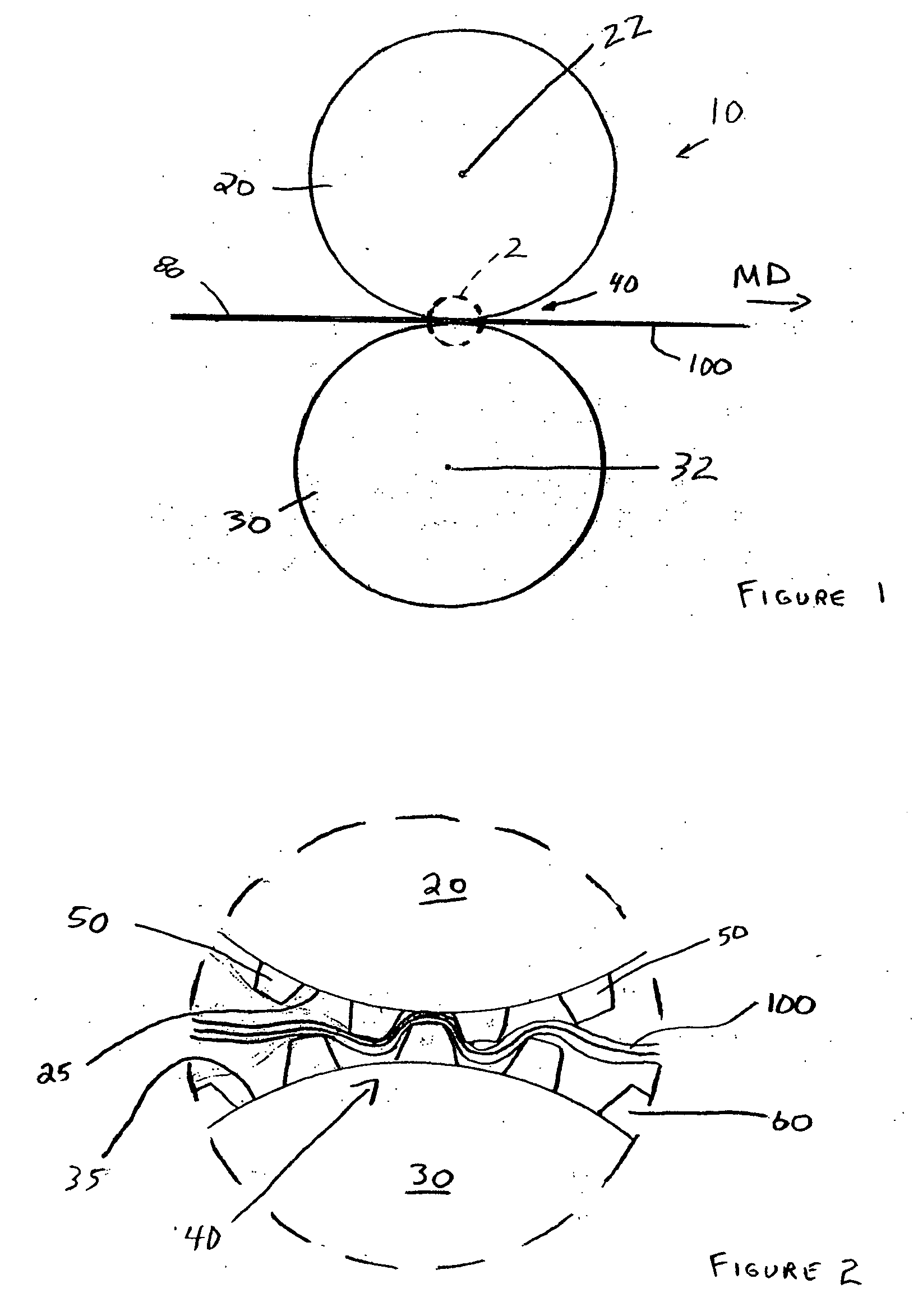

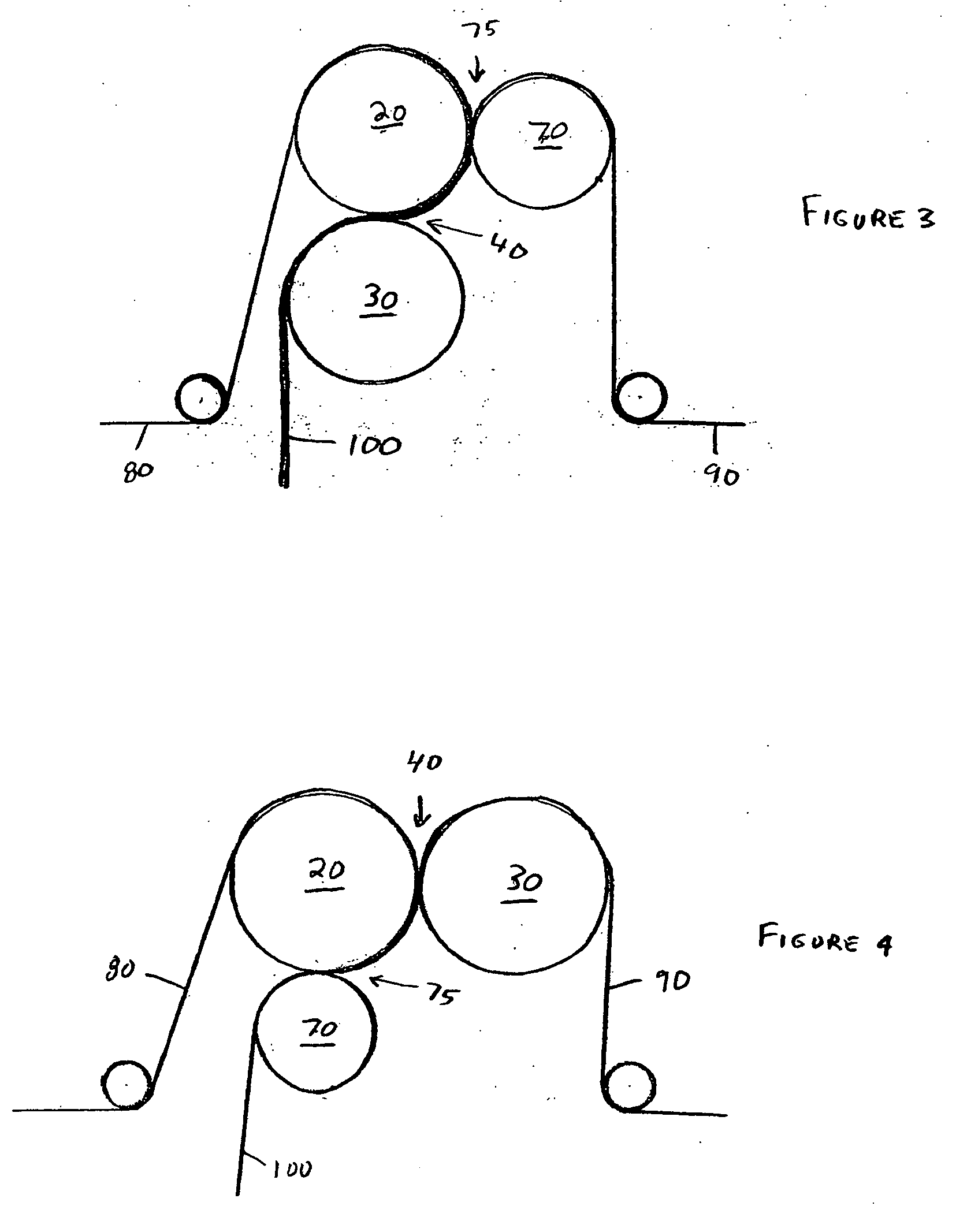

Process for high engagement embossing on substrate having non-uniform stretch characteristics

ActiveUS20070059495A1Improve featuresLocalize stressNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringPaper sheet

The present invention provides a process for producing a deep-nested embossed paper product comprising the steps of delivering one or more plies of paper to an embossing apparatus and embossing the one or more plies of the paper between two opposed embossing cylinders. The one or more plies of paper have a first direction and a second direction that is perpendicular to the first direction where both the first and second directions are in the plane of the paper and the one or more plies of paper have a stretch characteristic in the first direction that is higher than the stretch characteristic in the second direction. Each of the embossing cylinders having a plurality of protrusions, each of which have a height, where the embossing protrusions are disposed in an overall non-random pattern where the respective overall non-random patterns on the cylinders are coordinated to each other and the two embossing cylinders are aligned such that the respective coordinated overall non-random patterns of embossing protrusions nest together such that the protrusions engage each other to a depth of greater than about 1.016 mm. The overall non-random pattern of protrusions comprises a plurality of emboss regions where each of the emboss regions comprising a fraction of the total number of protrusions in the overall non-random pattern. All of the protrusions within an embossing region have about the same height and the pattern of protrusions within an emboss region creates a localized primary line of stress on the paper as the plies of paper are embossed where the line of stress has a component in the first direction and a component in the second direction. The height of the protrusions within an embossing region having a higher line of stress component in the first direction is greater than the height of the protrusions in an embossing region having a lower line of stress component in the first direction.

Owner:THE PROCTER & GAMBLE COMPANY

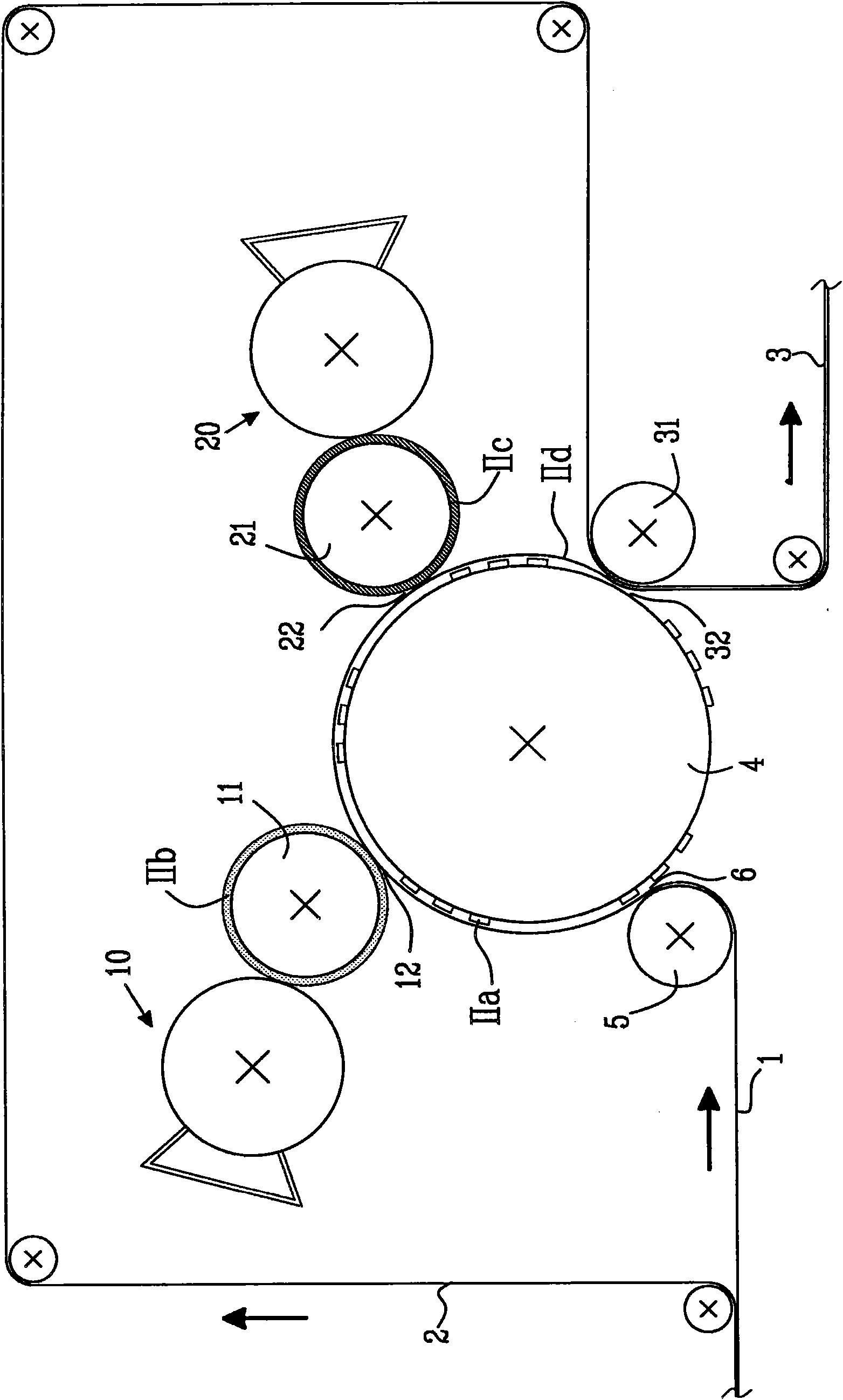

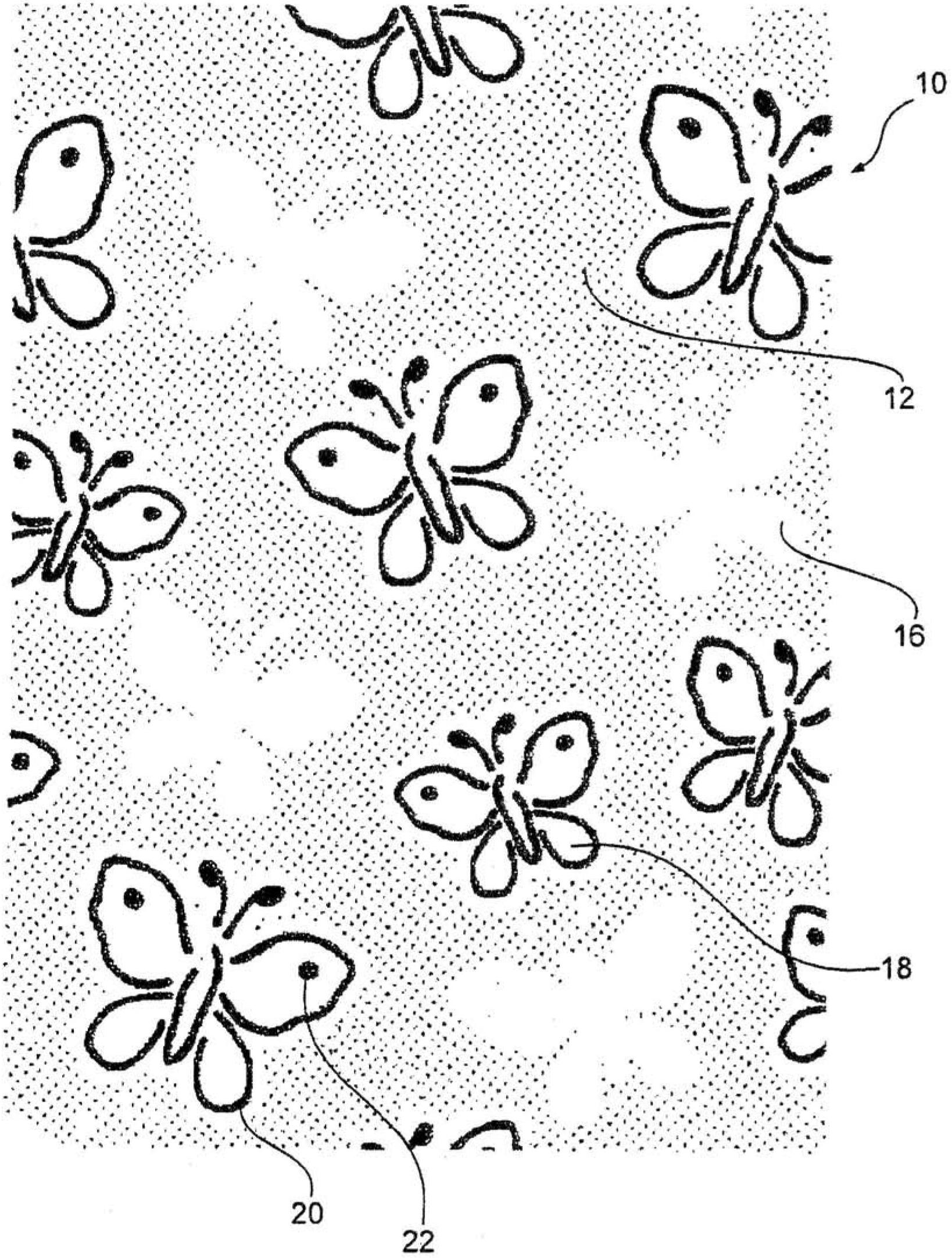

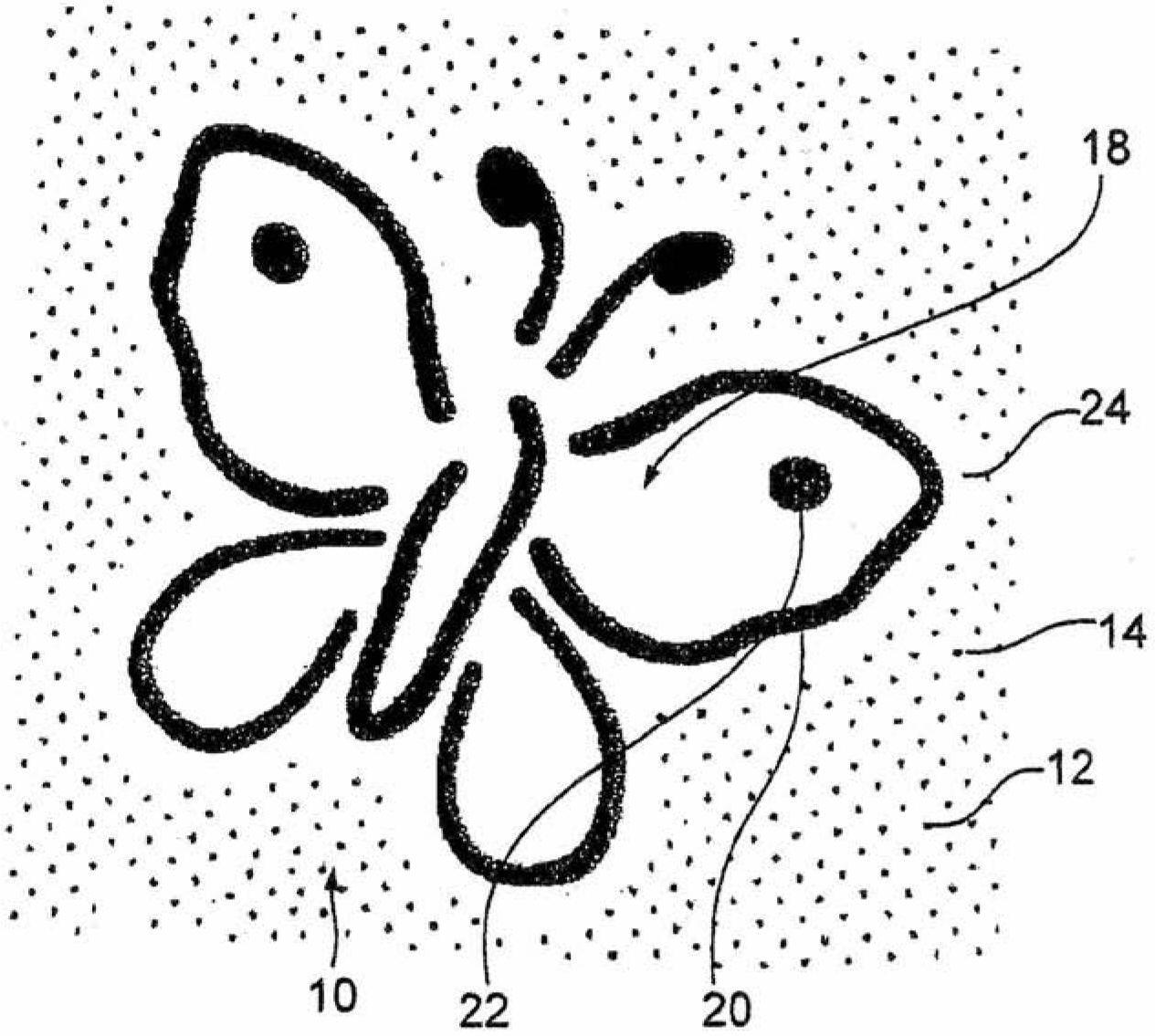

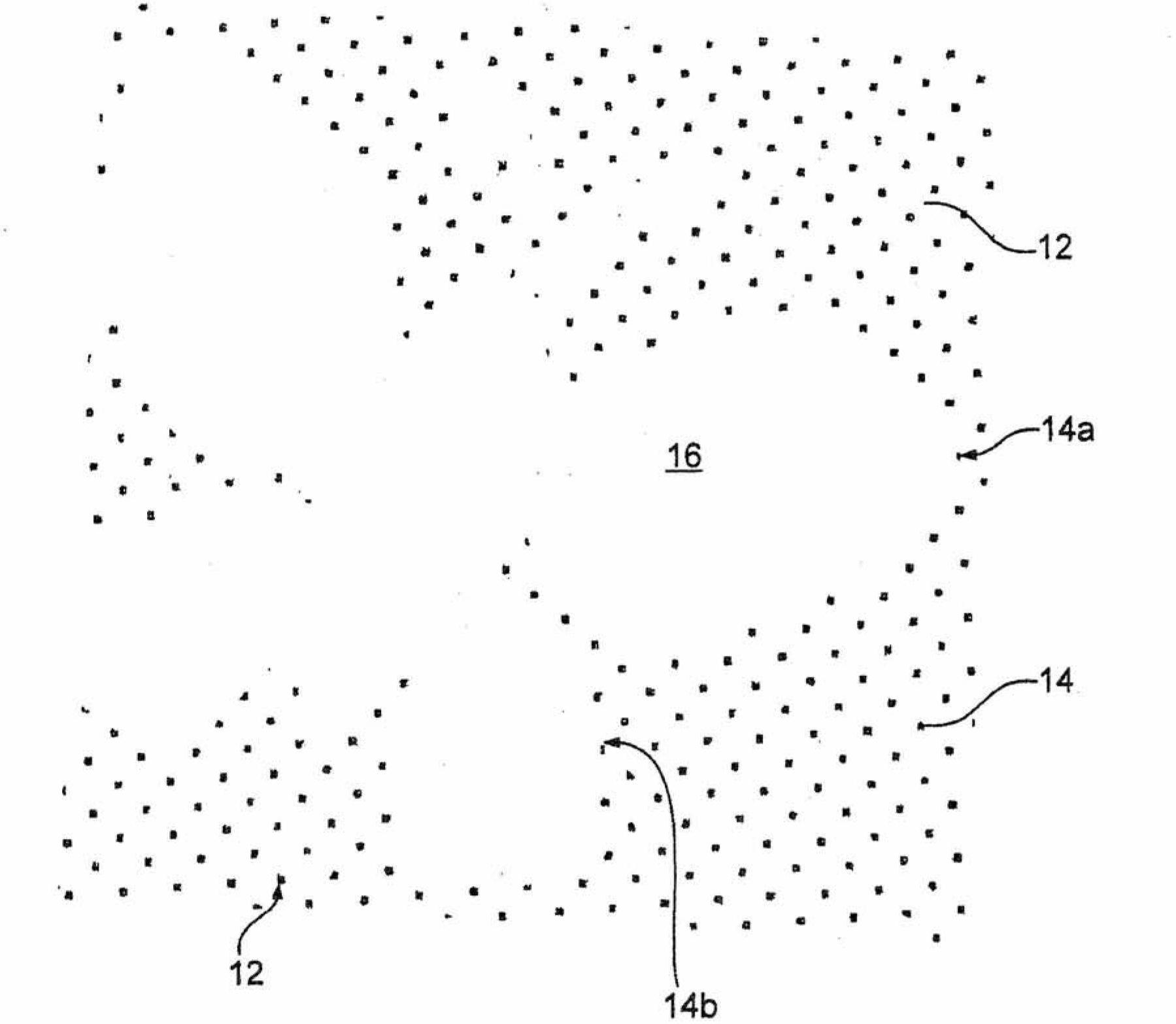

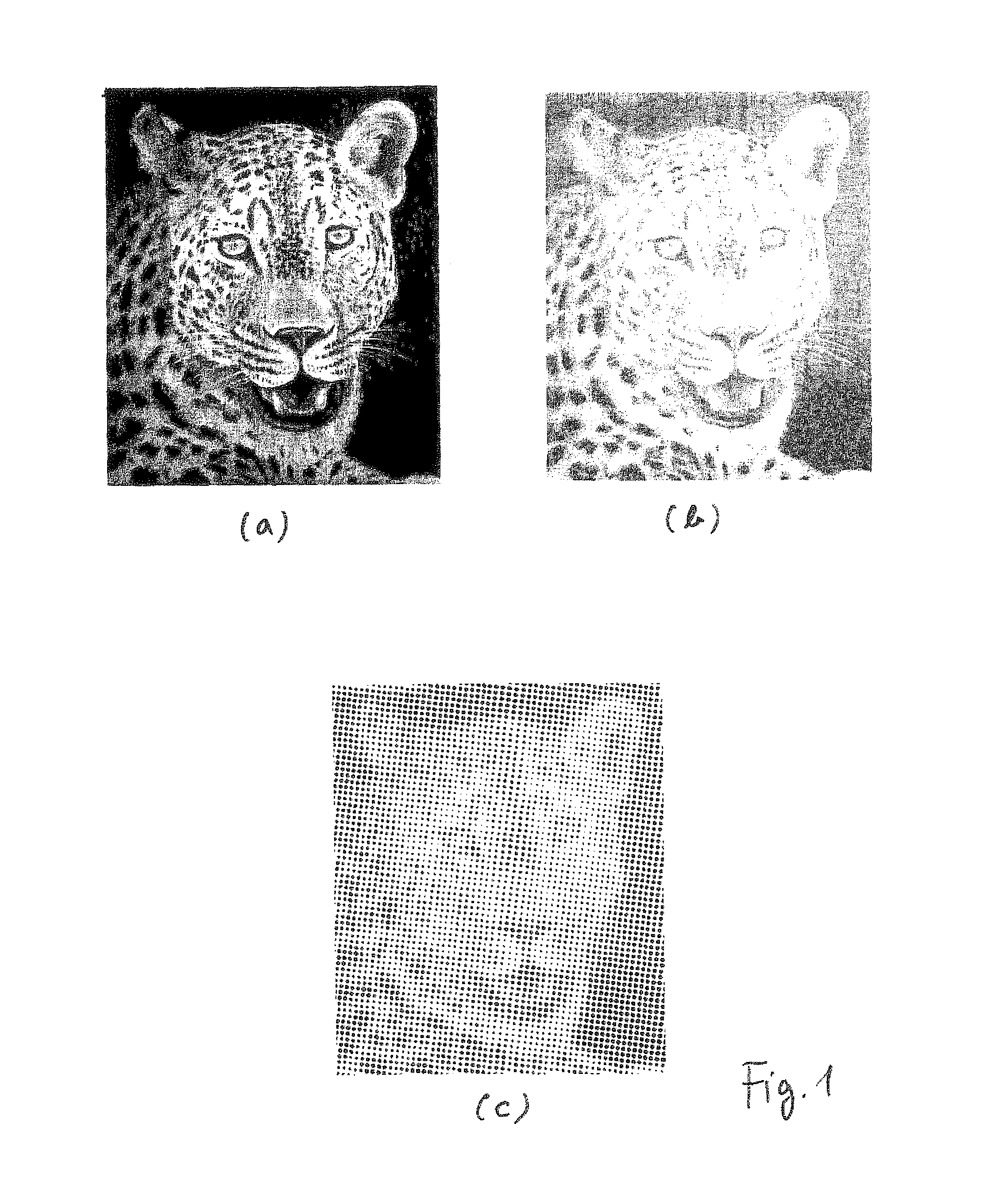

Fibrous product, embossing roll for producing such fibrous product, and device and method for producing such fibrous product

A fibrous product, especially tissue paper product, non-woven product or a hybrid thereof, preferably hygiene and cleaning product, has at least one ply, the surface of which is partly covered with an embossing pattern, and is characterized in that the pattern comprises at least one first zone (12) being micro-embossed with at least 30 embossing depressions (14) per cm2, preferably 30 to 160 embossing depressions / cm2, more preferably 30 to 120 embossing depressions / cm2 and most preferably 45 to 100 depressions / cm2, forming a background embossing area, a plurality of second zones (16; 16a, 16b) being unembossed and forming a motive element and in addition to the second zones (16) at least one third zone (18) being largely surrounded by linear depressions (20). The invention also relates to an embossing roll and an embossing device including a method for manufacturing such fibrous products.

Owner:ESSITY HYGIENE & HEALTH AB

Method and apparatus for producing a structured surface on an embossing steel roll

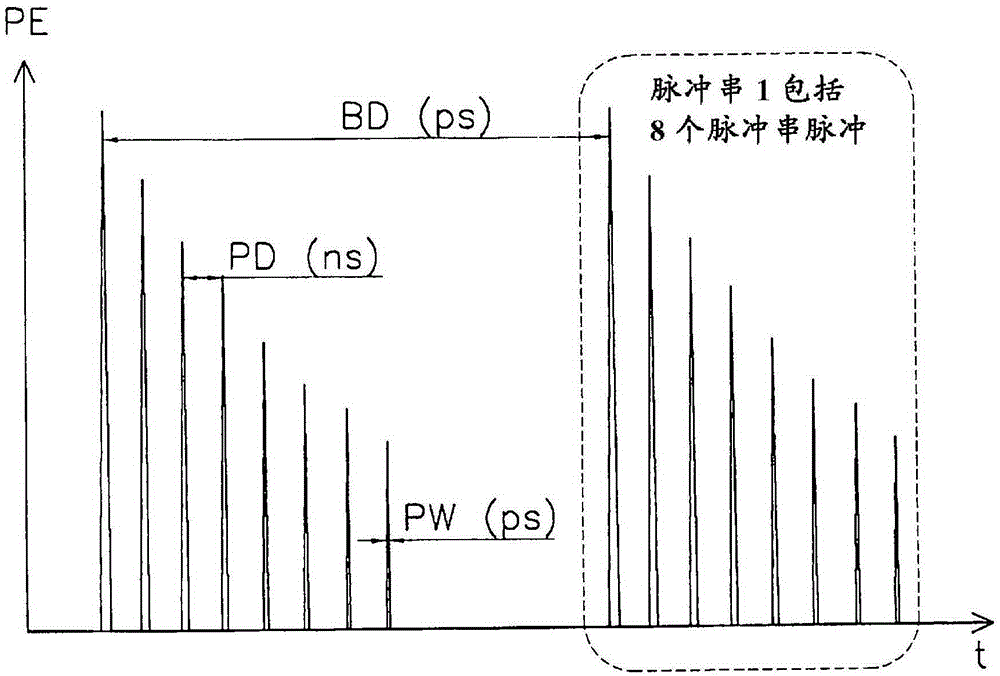

A method of forming structures on the surface of embossing steel rolls using a short-pulse laser, wherein said structures are macroscopic structures with dimensions exceeding 20 μm and depths of 150 μm and more, the structures themselves being differentiated from the following parameter combinations: a) in In single pulse operation, the fluence is in the range of 0.5J / cm2 to 3.5J / cm2, and in the burst mode, the average burst fluence is 0.5J / cm2 to 70J / cm2 per pulse, b) the wavelength is 532nm to 1064nm, c) repetition rate 1kHz to 10MHz, d) pulse-to-pulse spacing on the workpiece, 10% to 50% of beam diameter for femtosecond lasers, 10-25% of beam width and 40% for picosecond lasers -50%, e) the laser pulse position is close to the workpiece surface, and f) the deflection speed is up to 100 m / s and higher. Such a method allows the manufacture of a complete embossing roll with teeth and gaps for producing logos, the teeth having variable height, shape and spacing, for embossing eg the inner liner of a cigarette pack.

Owner:BOEGLL GRAVURES SA

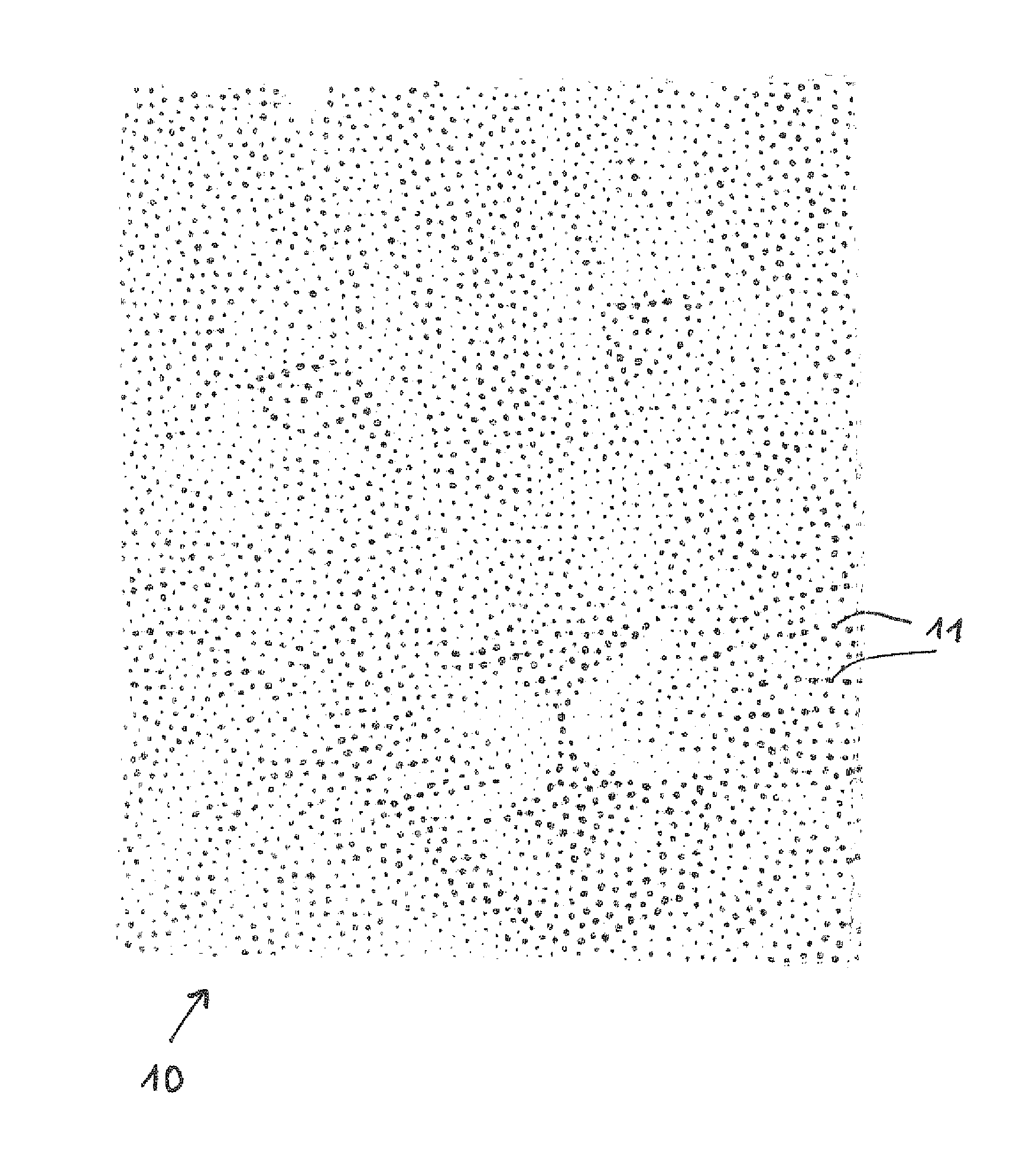

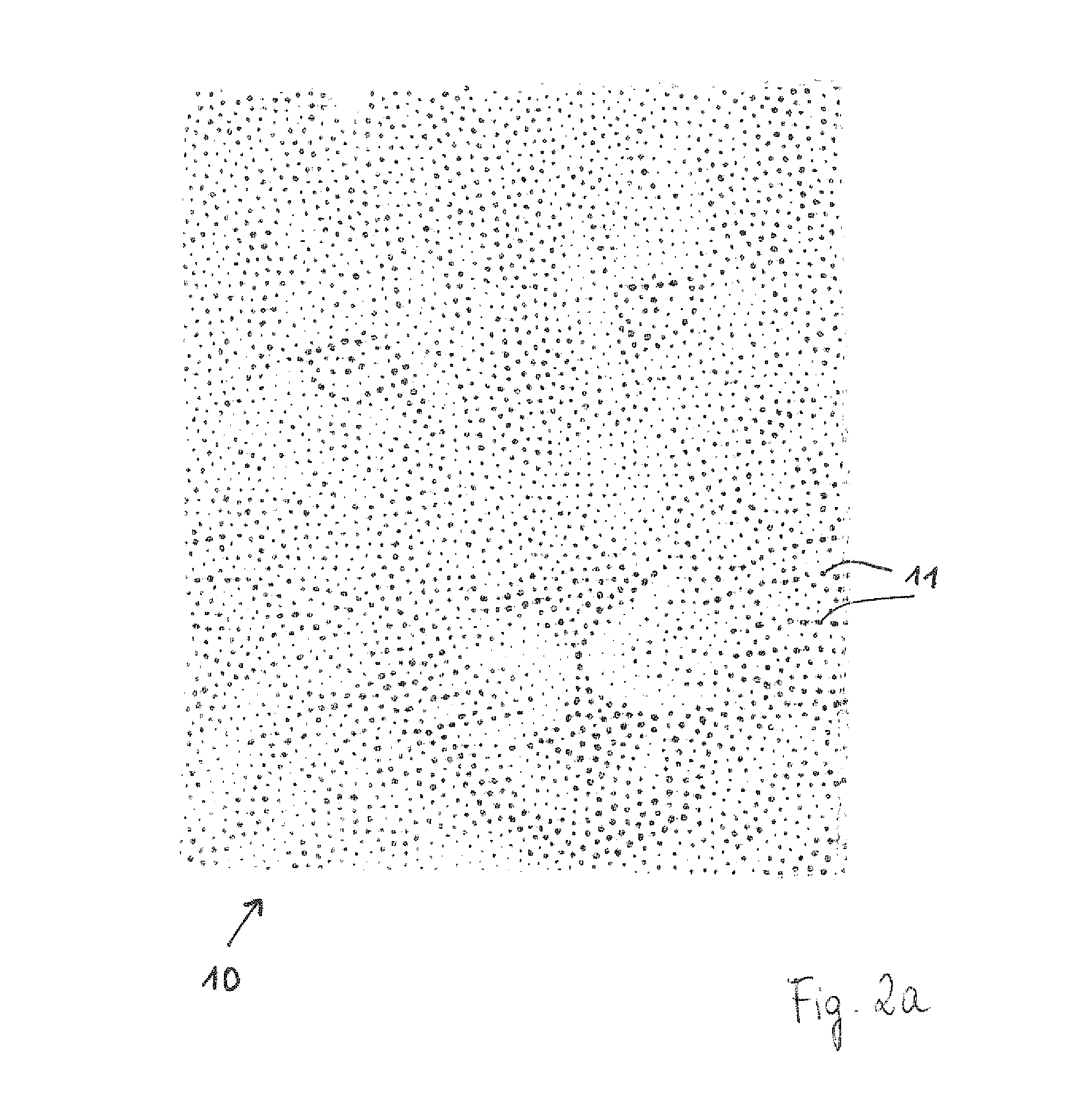

Fibrous product with a rastered embossing and method for producing same

InactiveUS8920905B2Increase visual appearanceImprove visual effectsNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceEngineering

A fibrous product (10, 20, 20b, 30), especially tissue paper product, non-woven products or a hybrid thereof, and preferably hygiene and cleaning product has at least one first ply (42; 62; 84; 104) with at least one embossing pattern including embossed depressions starting from a base plane of the ply; the embossed pattern being characterized by the following features: the embossing pattern has a minimum motive surface area of at least 3 cm×3 cm; the pattern includes a high number of embossed depressions which are sized and / or positioned such as to form a motive element covering the motive surface area; wherein at least some of the embossed depressions are sized and / or positioned such that minimum distances between pairs of consecutively arranged embossed depression vary. A method for producing such a fibrous product is also described.

Owner:SCA HYGIENE PROD AB

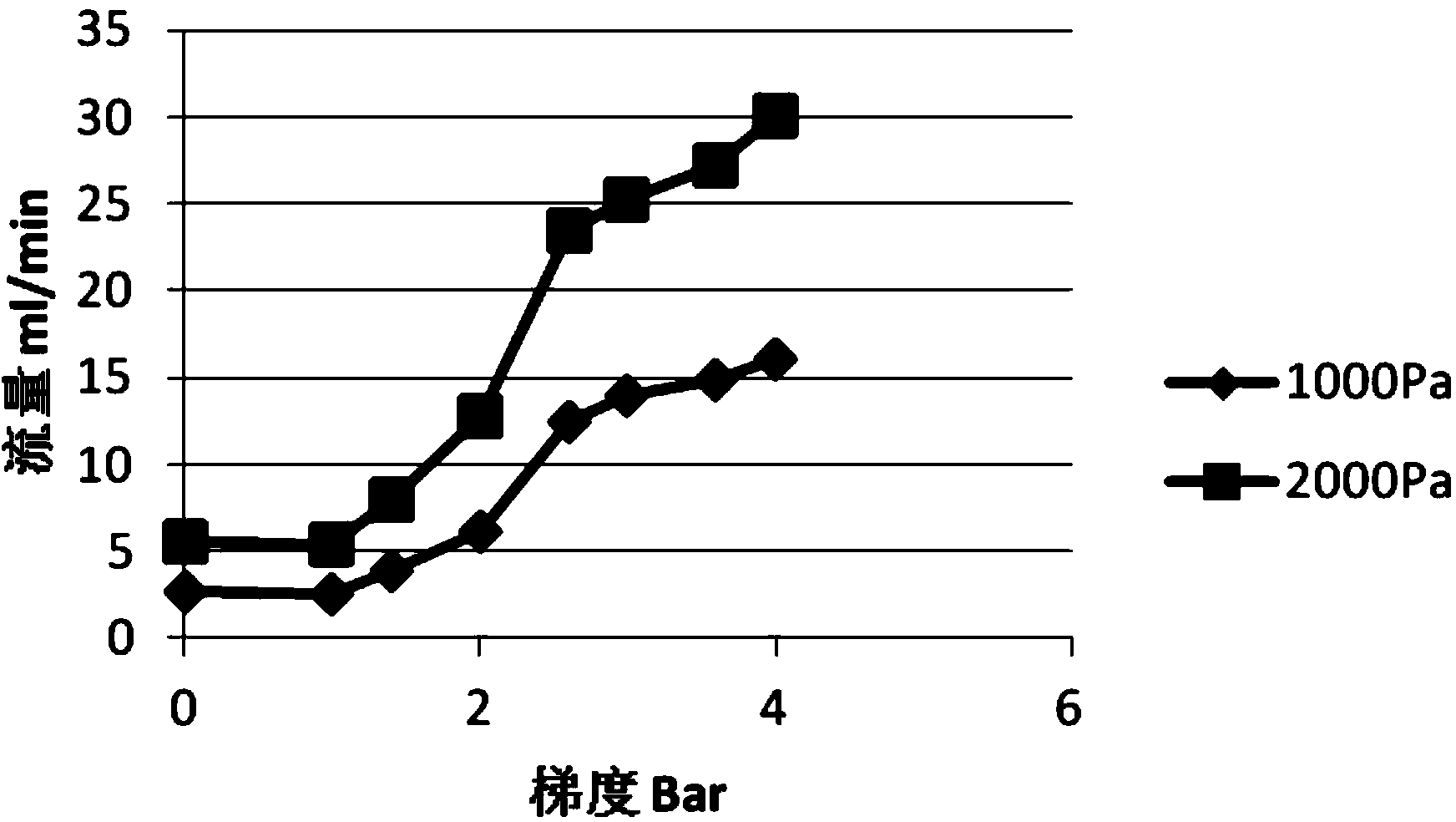

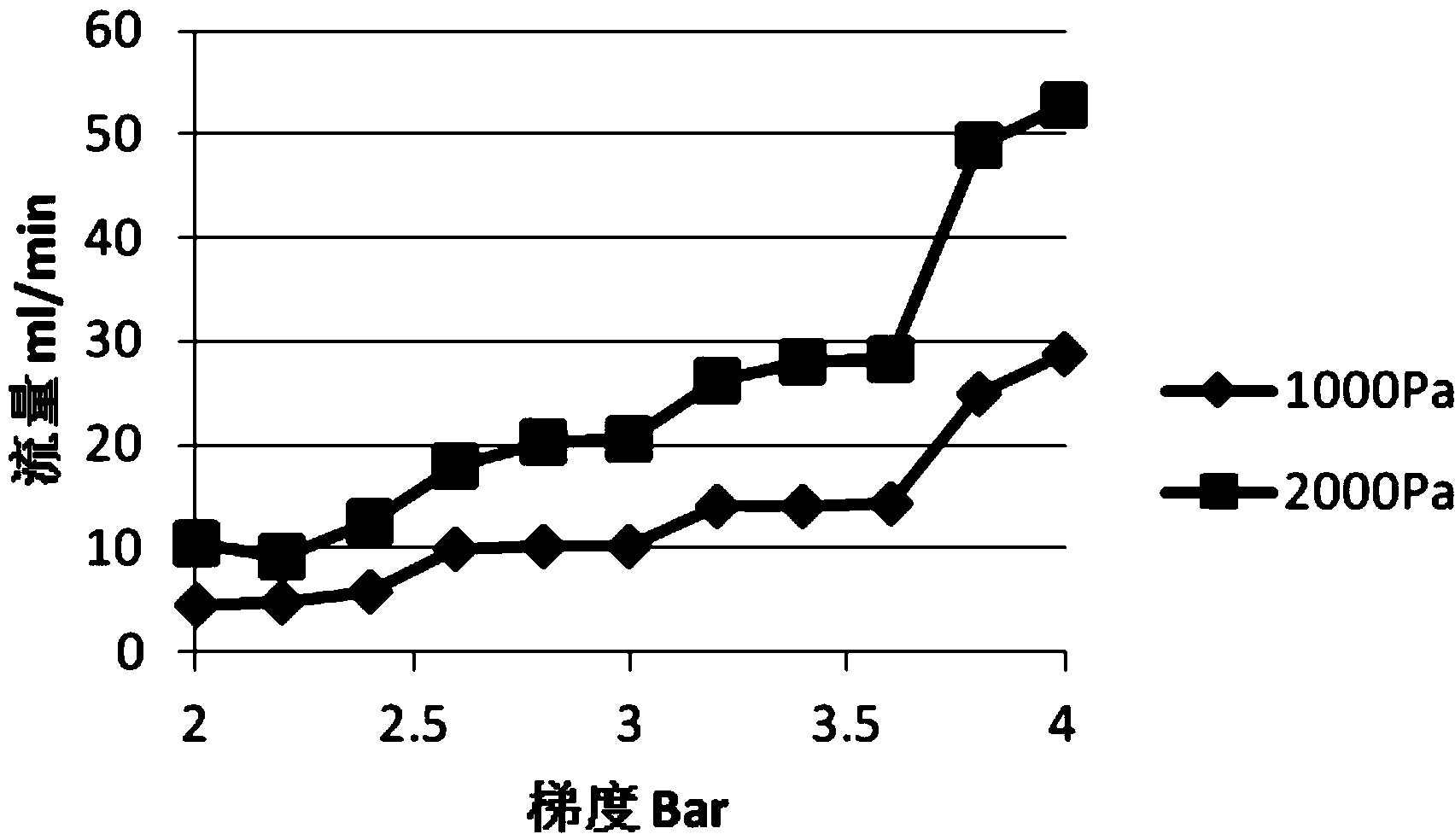

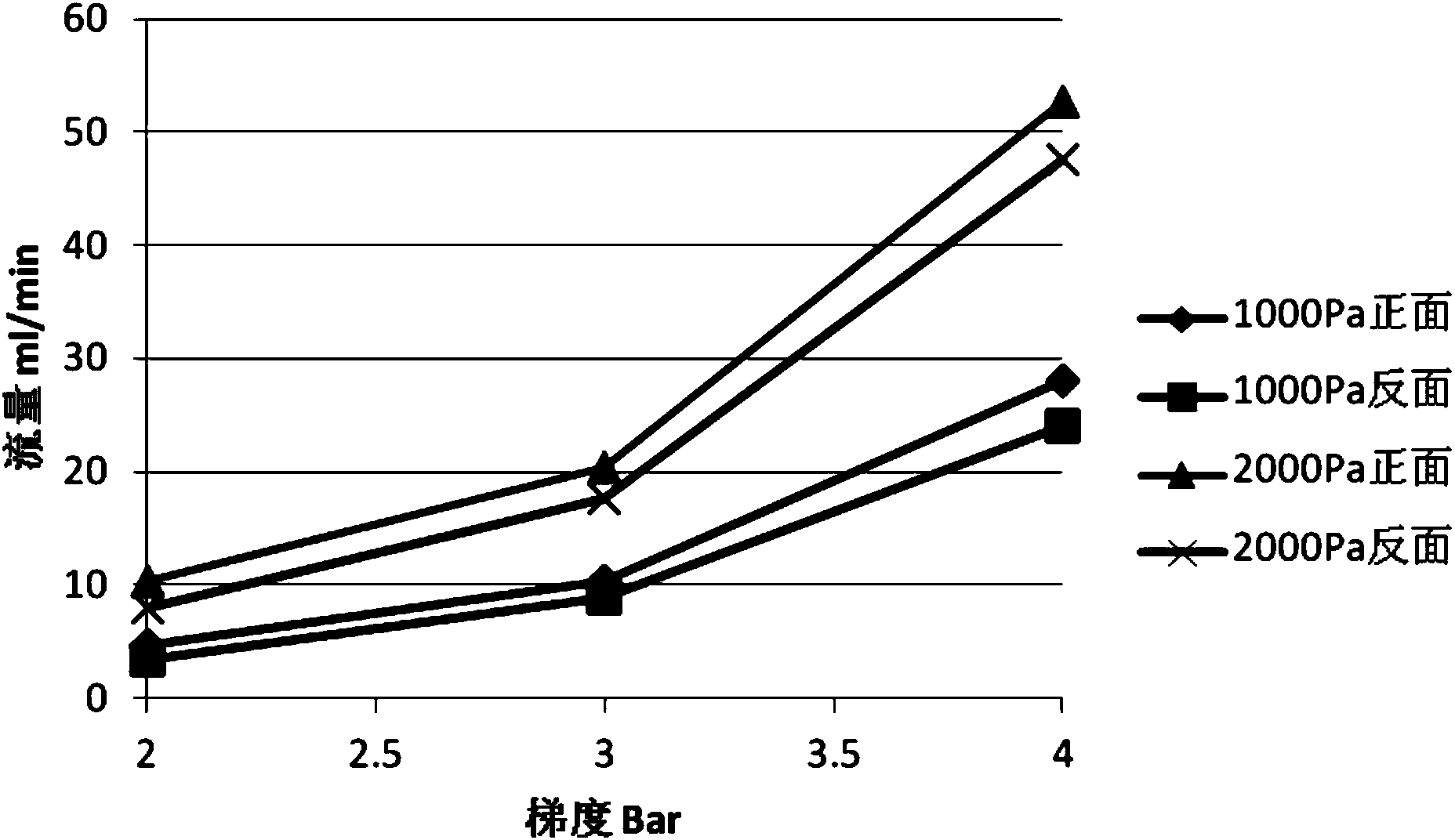

Analytical method for rapidly evaluating barrier property of inner liner for cigarettes

ActiveCN103837459AGood instrument stabilityGood experimental repeatabilityPermeability/surface area analysisTester deviceEngineering

The invention provides the determination of embossing stress on inner liner for cigarettes as well as an analytical method for rapidly evaluating of a barrier property of the inner liner for cigarettes. The analytical method comprises the following steps: putting an inner liner sample for cigarettes into an embossing flow module of a hard package cigarette packaging machine, and setting the embossing stress for embossing; then putting into an air permeability tester for determining the air permeability, drawing a standard operation curve so as to obtain the standard range of the air permeability of the inner liner; and acquiring the actual born embossing stress of the sample, and comparing with the standard range of the air permeability of the sample, thereby determining the barrier property of the inner liner sample for cigarettes. According to the analytical method for rapidly evaluating the barrier property of the inner liner for cigarettes, the measurement time for the individual inner liner sample is less than or equal to 30s; the instrument stability is favorable; the analytical method is suitable for the cigarette enterprises adopting 7*24 hour all-weather production, is good in repeatability, has the variable coefficient less than + / -4%, is high in precision, is good in field production applicability, and can guide workshops to perform relevant quality control.

Owner:SHANGHAI TOBACCO GRP CO LTD

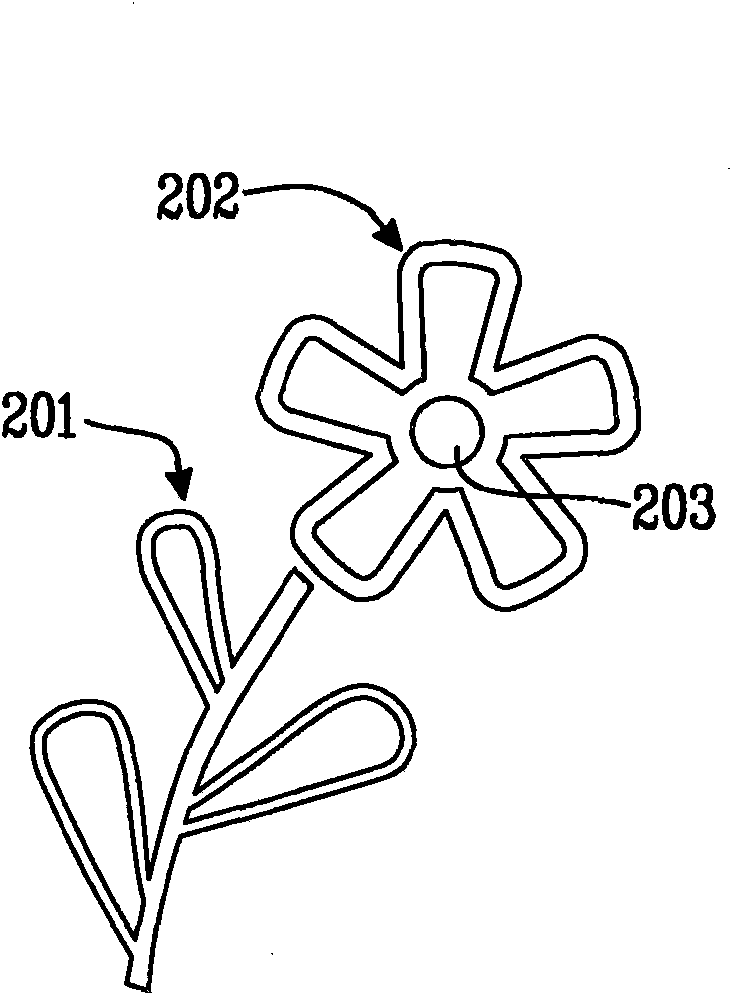

Paper-based micro-fluidic chip for multi-parameter analysis of water quality detection and manufacturing method thereof

InactiveCN111715312ALow costEasy to manufactureMaterial analysis by observing effect on chemical indicatorLaboratory glasswaresAmmoniacal nitrogenBiochemical engineering

The invention provides a novel paper-based multichannel micro-fluidic chip and a manufacturing method thereof, and belongs to the field of rapid analysis and detection. According to the paper-based micro-fluidic chip, a paper-based material is directly cut into a required shape by using an embosser, and the shape is a flower shape with six channels, a pentagram shape, a seven-channel flower shape,an eight-channel flower shape or a sun shape. The chip is manufactured by a stamping method and a laminating method, and multiple reactions of a conventional analysis and detection method can be integrated on one micro-fluidic chip by pre-loading multiple reaction reagents such as an indicator, an activator, and the like. By controlling the positions and the loading capacities of the key reagents, an operator can use simple one-step operation to realize gradual occurrence of multi-step reactions in sequence. The chip and the method can be used for rapidly and simultaneously analyzing variouswater quality detection important parameters such as pH, phosphate, ammonia nitrogen, nitrite and the like, and a detection tool, which is low in price, convenient to operate and rapid in reaction isprovided for water quality monitoring, field rapid detection and the like.

Owner:CAPITAL NORMAL UNIVERSITY

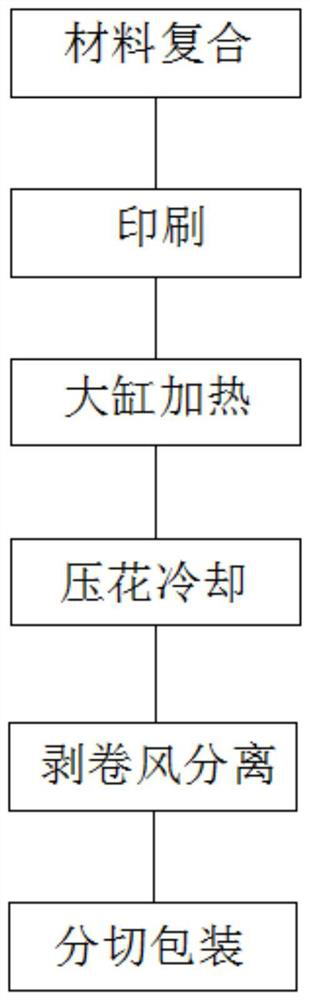

Water-based synchronous registering and over-embossing decorative film production process

InactiveCN111619146AAvoid uncertaintyAvoid yieldFlat articlesOther printing apparatusChemical reactionAdhesive glue

The invention provides a water-based synchronous registering and over-embossing decorative film production process. The water-based synchronous registering and over-embossing decorative film production process comprises the following steps of performing hot pressing on a PET film and a PVC calendering film through three continuous heating rollers at the heating temperature of 80-120 DEG C, and extruding through a rubber roller and the heating rollers to remove residual air to obtain the water-based synchronous registering and over-embossing decorative film through printing, vat heating, embossing cooling, stripping and roll dividing and slitting packaging forming. According to the water-based synchronous registering and over-embossing decorative film production process, the single PVC calendering film is adopted, compositing, printing and embossing forming are conducted in a glue-free state, all uncertain factors and the coating reject ratio generated by chemical reaction in glue in alater coating process are avoided, and the coating compatibility of a product is greatly improved.

Owner:浙江锦盛装饰材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com