Decorative coating materials for embossing and production method and construction method thereof

A coating material and embossing technology, which is applied in the field of decorative coating materials for embossing and its preparation, can solve the problems of high manufacturing cost of embossing special machinery and equipment, high development cost, hardness and softness, lack of flexibility, etc. Development investment and manufacturing, the surface texture is mild and delicate, and the effect of overcoming application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

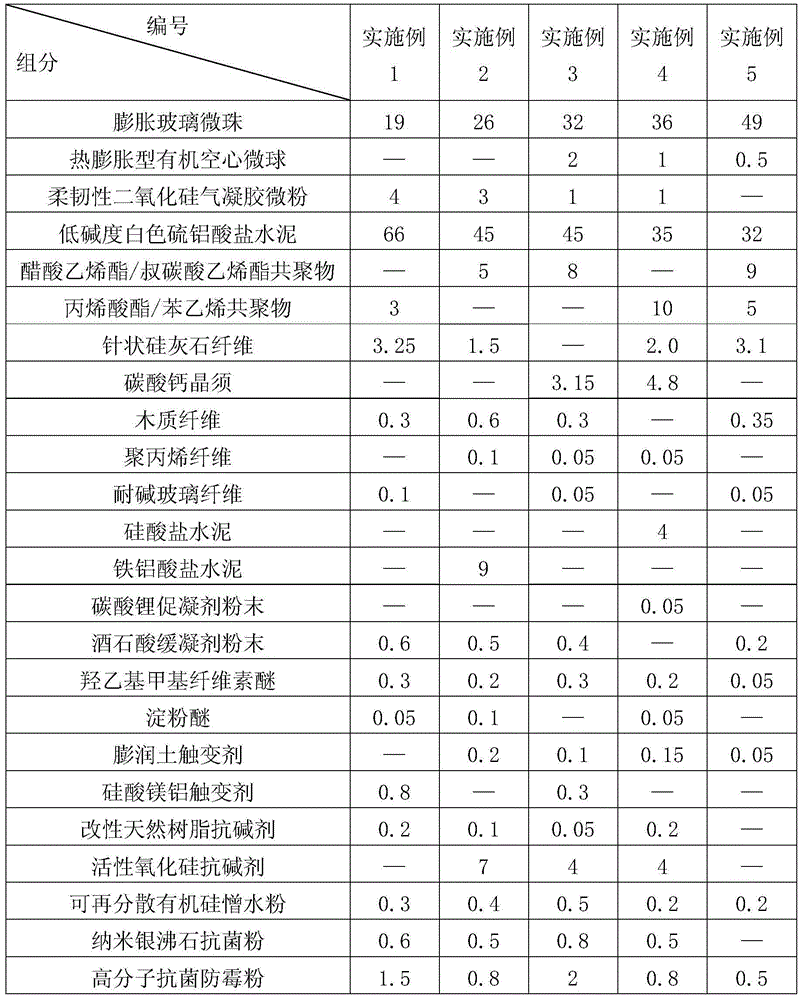

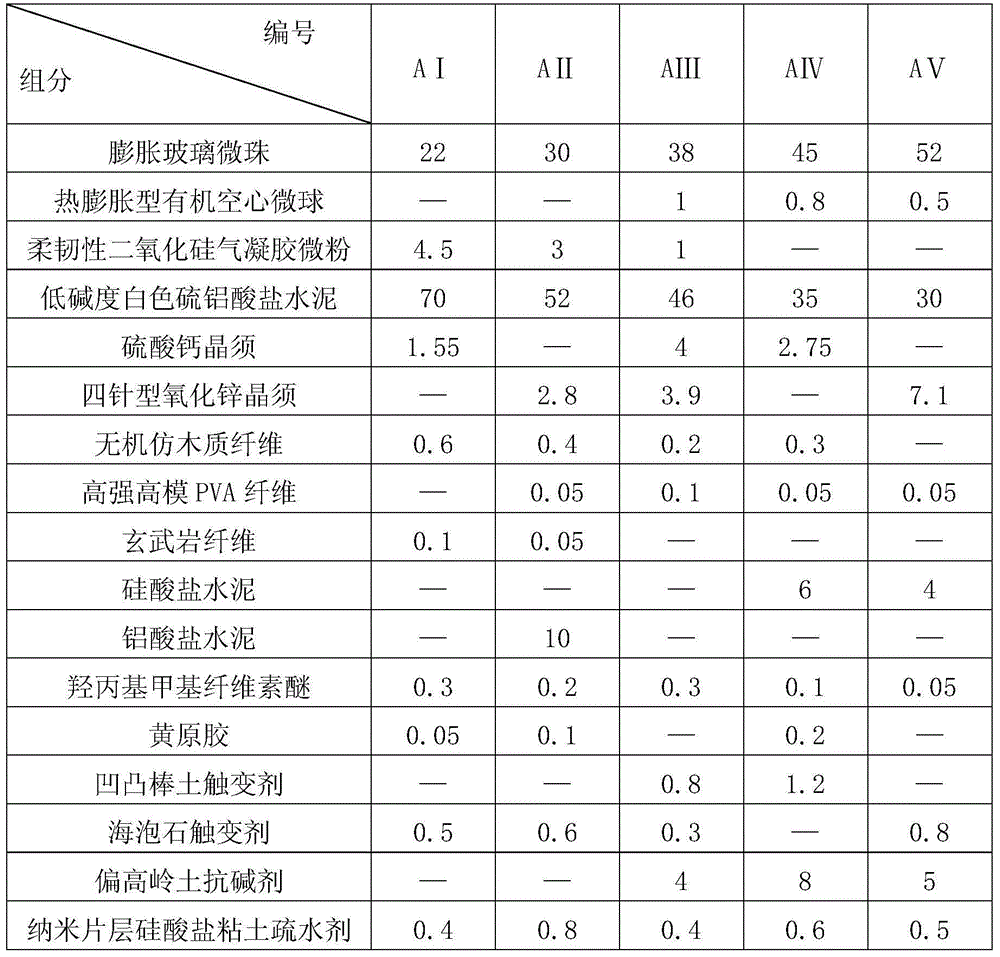

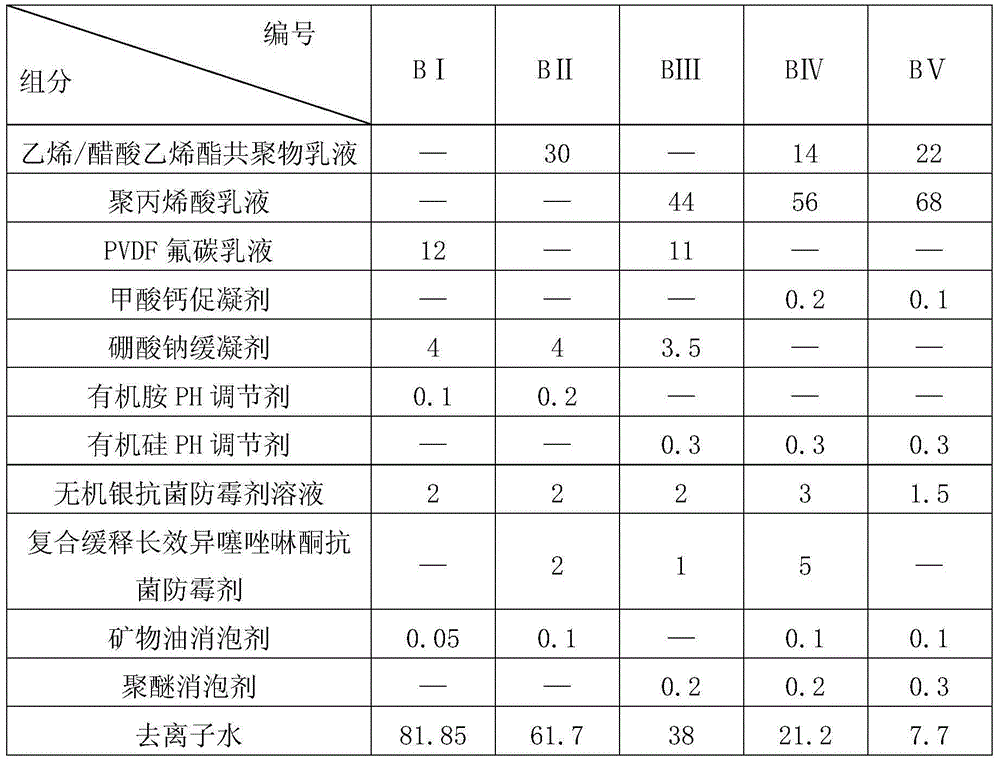

Method used

Image

Examples

Embodiment 11

[0065] In this embodiment, a section of 3-meter-high and 5-meter-wide cement concrete structure wall is used as the blank to be decorated. Set the decoration requirements as "integral molding from top to bottom, no transverse seams in the horizontal direction, and 5mm wide vertical seams". The specific construction method is as follows:

[0066] Step 1) Select a washable fabric (washable texture fabric) with "crumpled organza embroidery with irregular flowers", and cut the fabric to a width of 1.25 meters and a height of 3.2 meters according to the wall specifications. spare;

[0067] Step 2) Using the decorative coating material for embossing prepared in Example 3, add water and mix the decorative coating material for embossing, and stir until it is evenly mixed to obtain an embossing slurry with a suitable viscosity, and set aside In addition, coloring pigments or coloring pastes can also be added to the embossing slurry according to actual needs;

[0068] Step 3) Emboss ...

Embodiment 12

[0072] In this embodiment, a wall body with a height of 4 meters and a width of 4 meters and a vertical wavy arc shape structure is used as the blank to be decorated. Set the decoration requirement as "the whole wall is completely free of seams". The specific construction method is as follows:

[0073] Step 1) Select a non-washable PU artificial leather (non-washable texture cloth, hereinafter referred to as PU leather) with "irregular deep embossed zebra pattern effect", and cut the PU leather to a width of 1.45 meters according to the wall specifications , with a height of 4.2 meters, spare; in addition, in practical applications, the back of the two sides of the PU leather is often wrapped and fixed with a cylindrical long strip of sponge with a diameter of about 5 cm, as a control position for operation, and also Avoid leaving linear marks on the embossing slurry on both sides of the texture cloth during embossing to affect the appearance; after curling, the effective wid...

Embodiment 13

[0080] In this embodiment, the fiber-reinforced cement pressure plate commonly used in the market is used as the decorative plate. The size of the fiber-reinforced cement pressure plate is 2440*1220mm, and the required size for decoration is 1200*800mm. Therefore, before construction, the fiber reinforced cement pressure plate needs to be cut into a decorative substrate of 1220*810mm. In addition, in order to prevent the decorative substrate from warping and deforming in the future, it is usually necessary to weld and make a metal keel rectangle with a length*width of 1150*750mm. The frame (the material can be galvanized steel square tube or stainless steel square tube, etc.), is also provided with one or more reinforcing crosspieces on the frame, and the decorative substrate is fixed to the frame with countersunk drill screws, the frame and Adhesive glue is applied between the contact surfaces of the decorative substrate to assist in anchoring. After the above preparatory wor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com