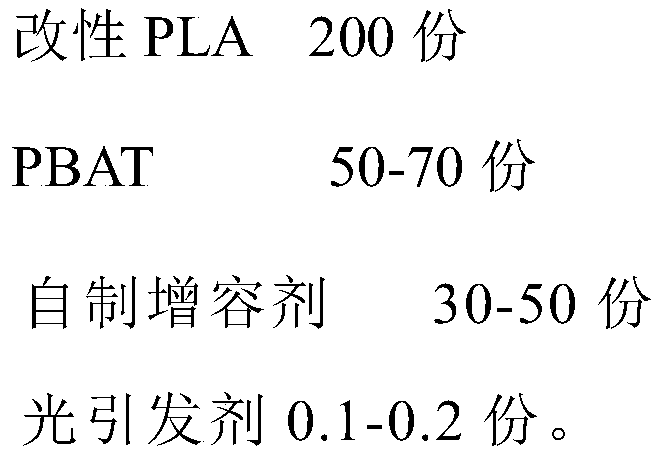

Biodegradable PLA embossed film and preparation method thereof

A biological and embossing technology, applied in the field of biodegradable PLA embossed film and its preparation, can solve the problems of PLA film stiffness reduction, and achieve the effect of reducing elongation at break and tensile strength, and increasing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail now in conjunction with embodiment.

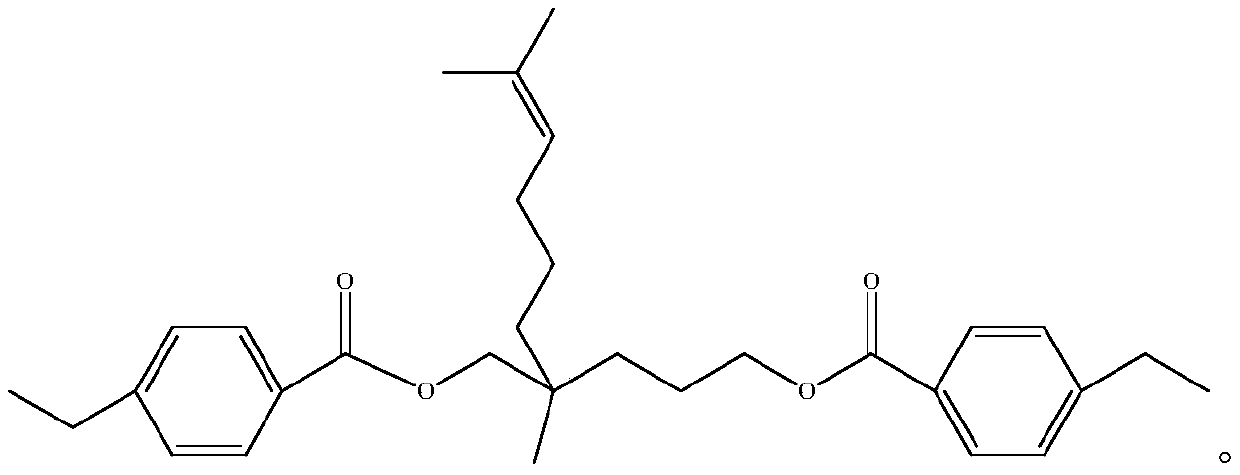

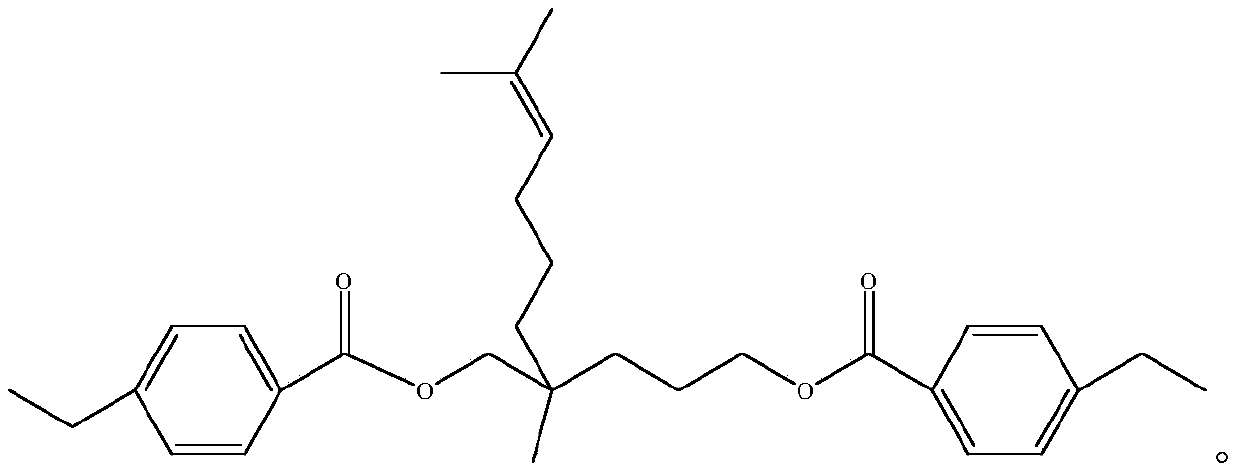

[0037] The preparation embodiment of self-made compatibilizer:

[0038] (1) Add 1g of p-toluenesulfonic acid into a 250mL three-necked flask, add 5g of 4,9-dimethyl-4-hydroxymethyl-8-decen-1-ol, and heat to a reaction temperature of 120°C;

[0039] (2) Add 7.5g p-ethylbenzoic acid in the above-mentioned reaction system, continue heating, the reaction system is in the reflux water separation state, and the -OH peak in the infrared detection reaction system disappears, then the reaction ends;

[0040] (3) the mixed solution in the there-necked flask is washed with sodium carbonate solution and water respectively, after drying, carry out distillation to remove catalyzer, p-ethylbenzoic acid, promptly obtain self-made compatibilizer, its 1 HNMR (400MHz, DMSO-d6): δ (ppm) : 0.89(s, 3H, -C-CH 3 ), 1.13(t, 4H, -C-CH 2 -), 1.18(t, 6H, -CH 3 ), 1.31 (m, 2H, -CH 2 -), 1.70-1.82 (m, 6H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com