Embossed reflective laminates

A technology of embossing and laminating glass, applied in the directions of lamination, lamination auxiliary operation, coating, etc., can solve the problem of not being able to reduce the surface defects of the infrared reflective surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

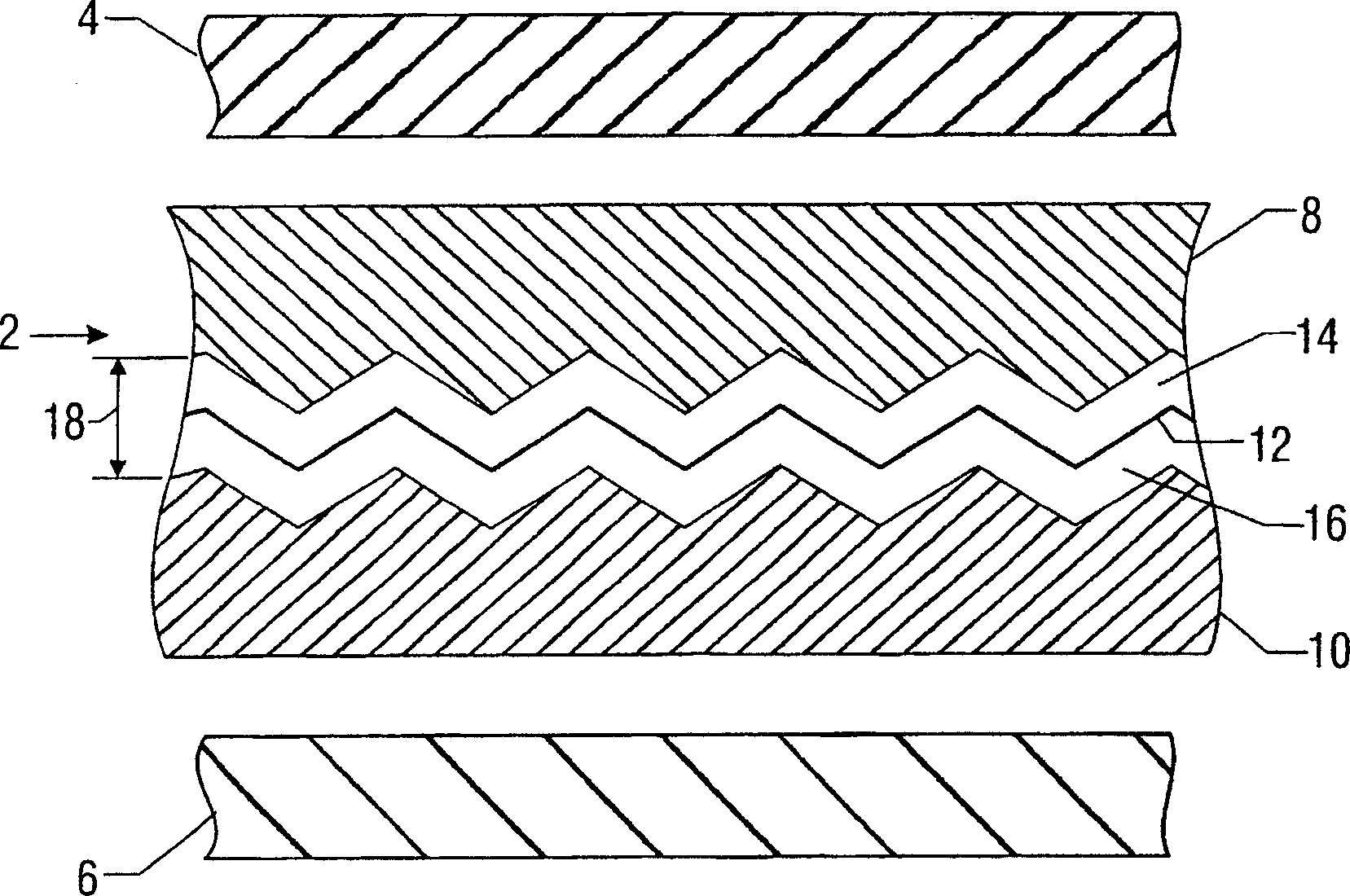

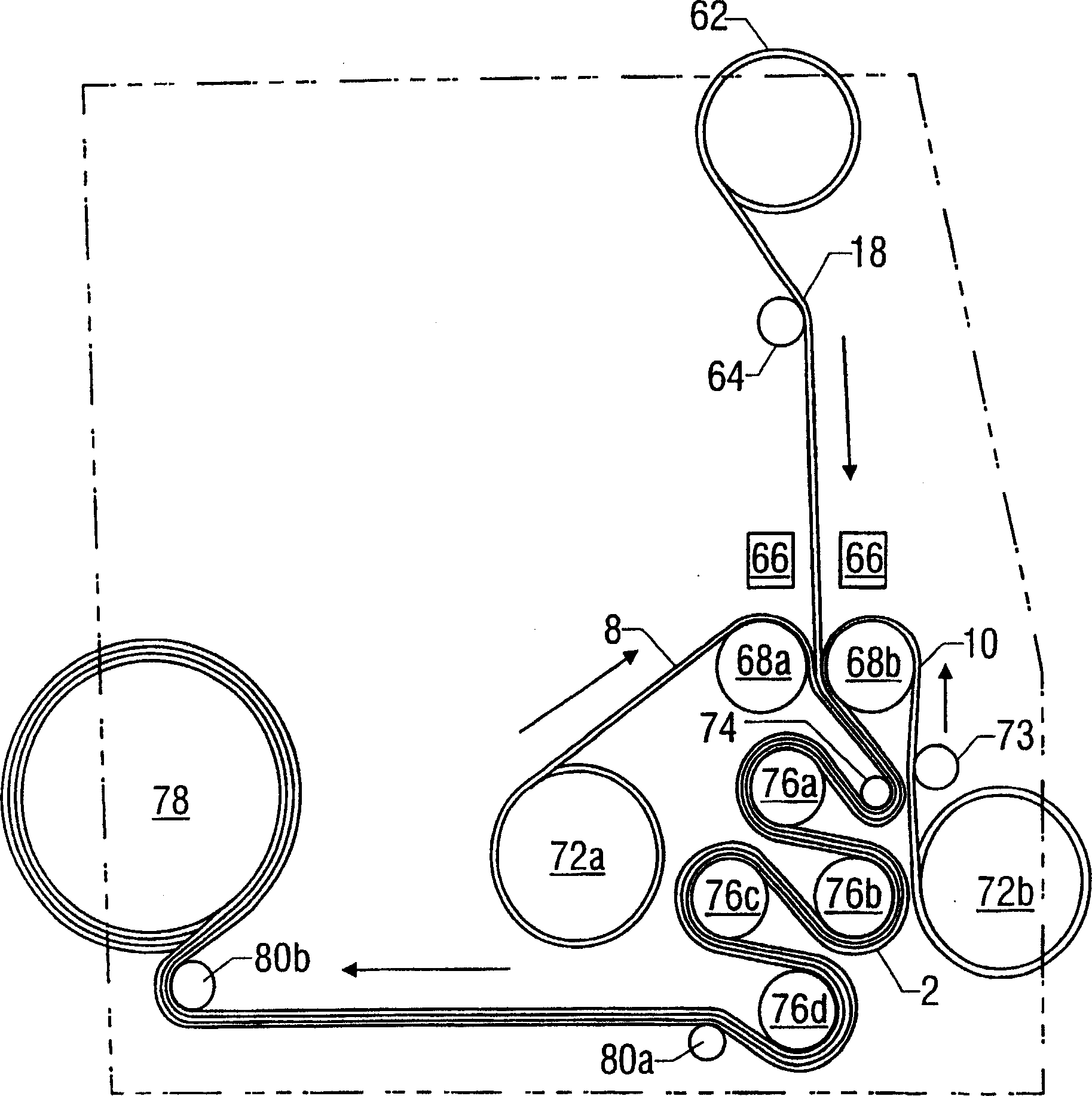

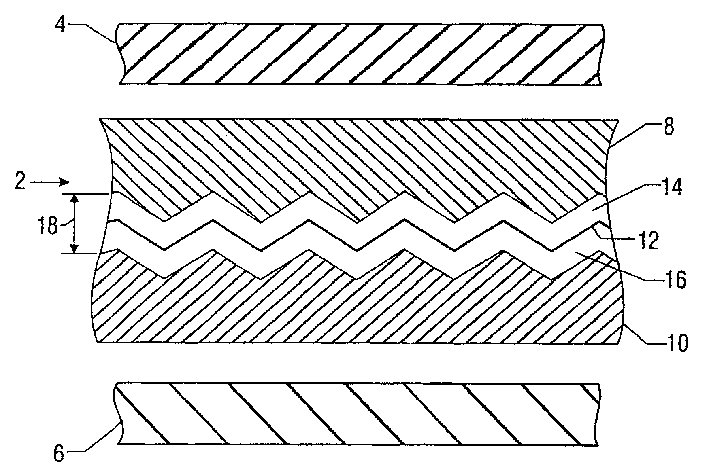

Image

Examples

Embodiment 1

[0047] Adhesive Treatment of PET Film Surface

[0048] Since PET film did not have sufficient adhesion to PVB, one surface of each of the two rolls of PET was subjected to a high vacuum "glow discharge" plasma treatment using an argon / nitrogen gas mixture to achieve an acceptable level of adhesion. The energy input and line speed in the process were chosen to maximize the adhesion of PVB to PET without appreciable yellowing of the PET film.

[0049] The 90° peel adhesion test is used to measure the bond strength between plasticized PVB and PET film. Special peel-adhesive laminates containing PET film are produced using standard lamination methods by replacing one glass sheet of a standard double-layer glass laminate with PET film.

[0050] The thickness of the plasticized PVB layer used was 0.030” (0.76mm), and it was dried at 70°C for 1 hour before use to reduce the moisture content to ensure that the adhesion of the glass / PVB interface was higher than that of the PET / PVB ...

Embodiment 2

[0054] PET film coating with aluminum

[0055] A roll of film (Example 1) that had been plasma-treated on one surface was placed in a vacuum chamber for "metallization". The pressure in the vacuum chamber was reduced by a series of vacuum pumps until it reached the evaporation pressure of aluminum (6.7 × 10 -2 Pa / 0.5 micron Hg). At this point, aluminum evaporates by resistively heating the aluminum source and deposits on the untreated PET surface. The deposition rate was controlled to obtain a coating about 50 Angstroms thick.

Embodiment 3

[0057] Lamination of metallized films (→ decorative composites)

[0058] To minimize oxidation of the aluminum surface, this roll of aluminum metallized film (Example 2) was laminated to the untreated surface of a second roll of PET film, which had previously been treated with an adhesion promoting treatment (Example 1). The decoration was obtained by bonding the aluminum coated surface of one film to the untreated surface of the other film using an isocyanate-crosslinked polyester binder system using conventional two-layer coating / dry / roll lamination methods. composite material.

[0059] The visible light transmission of the laminated film was measured with a Perkin-Elmer Lambda 900 spectrophotometer with a 150 mm diameter collecting sphere and found to be 31.4%. A D65 Illuminant at a 10° observation well was then used for the measurements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com