Embossing device for use on paper towel processing equipment and embossing production technology thereof

A processing equipment and embossing technology, applied in the direction of machining/deformation, etc., can solve the problems of difficulty in ensuring the consistency of line pressure during embossing of multi-layer paper towels, failure to meet product processing requirements, and high difficulty in heat treatment, reducing replacement The effect of cost, good product quality and easy control of line pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

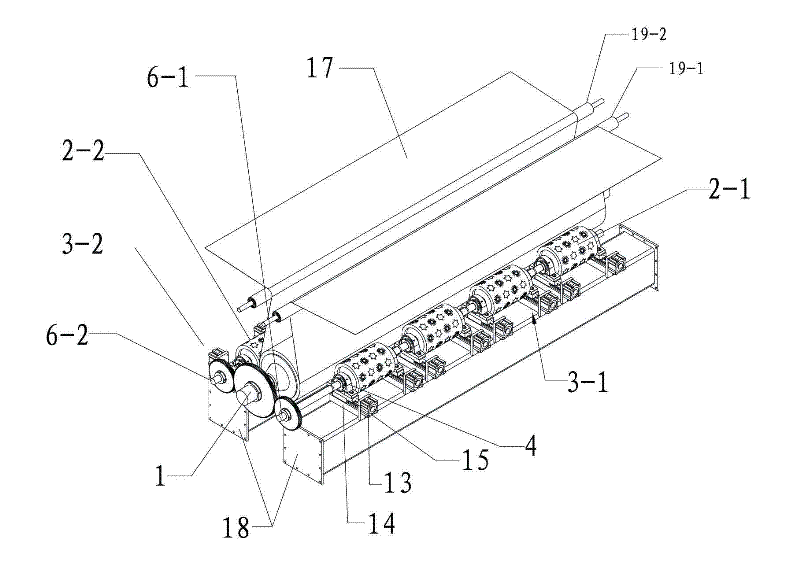

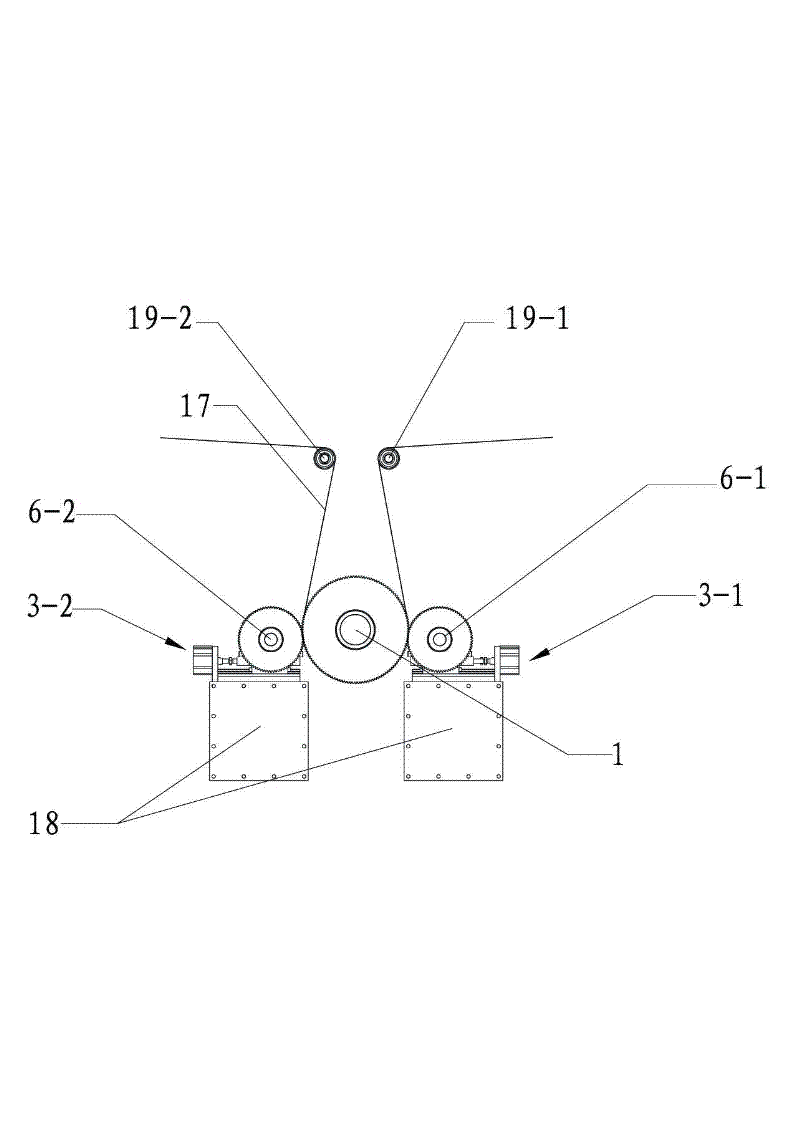

[0025] Embodiment 1: according to the appended figure 1 And attached figure 2 As shown, the embossing device used on the paper towel processing equipment described in this embodiment includes a bottom roller 1 driven by a power source, wherein, on both sides of the bottom roller 1 along the axial direction of the bottom roller 1 Two sets of embossing rollers acting on the surface of the bottom roller 1 are respectively arranged; one set of embossing rollers is composed of multi-stage embossing roller assembly 2-1, and the other embossing roller group is composed of multi-stage embossing roller assembly 2-1 -2, each section of the embossing roller assembly 2-1, 2-2 is pressurized by an independent presser 3-1, 3-2, and the presser 3-1, 3-2 is fixed Installed on the frame beam 18 of the paper towel processing equipment; in order to meet the embossing spacing requirements required by paper towels of different specifications, the interval between the multi-section embossing roll...

Embodiment 2

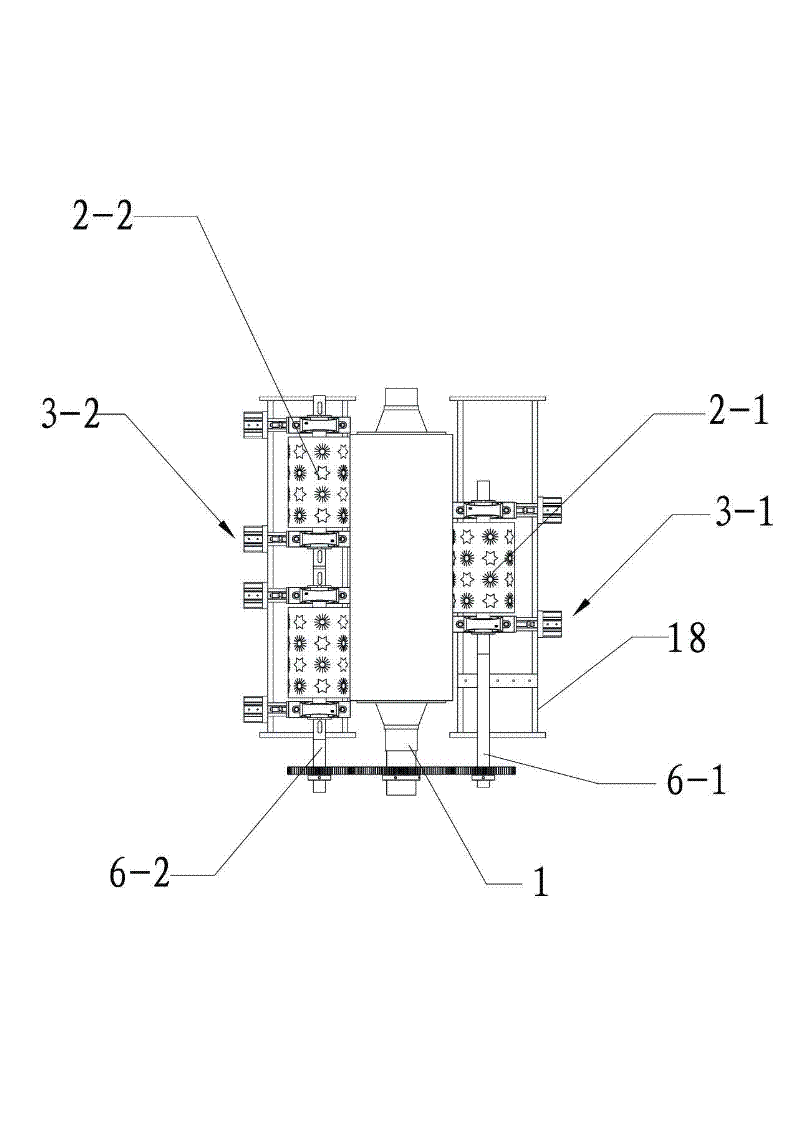

[0026] Embodiment 2: According to the attached image 3 And attached Figure 4 As shown, the difference from Embodiment 1 is that one set of embossing rollers in this embodiment consists of one section of embossing roller assembly 2-1, and the other embossing roller set consists of two sections of embossing roller assembly 2-2.

Embodiment 3

[0027] Embodiment 3: according to the appended Figure 5 And attached Figure 6 As shown, the difference from embodiment 2 is that the embossing roller assemblies on the same side of this embodiment are not on the same axis, and each section of embossing roller assemblies 2-1, 2-2 of this embodiment is movably installed on their corresponding swinging Frames 5-1, 5-2 are driven to rotate by the same transmission shaft 11-1, 11-2 on the same side through respective synchronous pulleys, and each swing frame 5-1, 5-2 of the present embodiment simultaneously Pressurized by two cylinders 12 connected to its rocker arm 9, and the swing frame 5-1, 5-2 includes a base 7, a rocker arm shaft 8, a rocker arm 9, and a bearing block 10, wherein , the rocker arm shaft 8 is installed on the base 7 through the bearing housing 10, and at the same time, two ends of the rocker arm shaft 8 are respectively connected with a rocker arm 9, and the two rocker arms 9 are connected through an embossin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com