Water-based synchronous registering and over-embossing decorative film production process

A production process and decorative film technology, which is applied in the field of water-based synchronous overprinting and overlay decorative film production process, can solve problems such as defective rate, avoid all uncertain factors and defective rate of coating, and improve the effect of coating compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

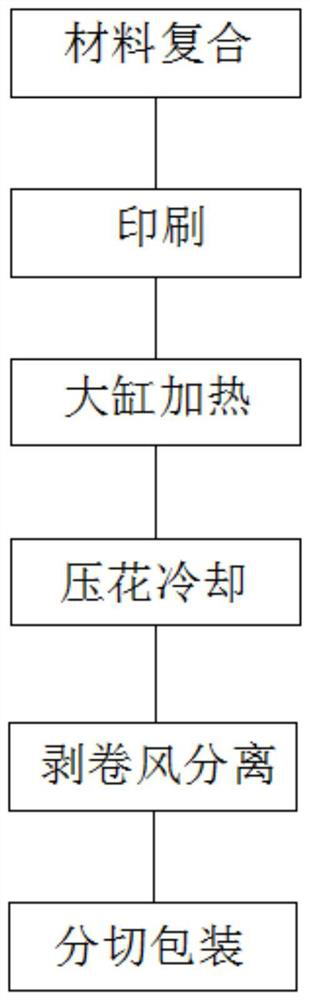

[0020] refer to figure 1 The embodiment of the production process of a water-based synchronous overprint overprint decorative film of the present invention will be further described.

[0021] A water-based synchronous overprinting and overprinting decorative film production process, including the following steps, compounding: the material is PET film, PVC calendering film, the thickness of the PET film is 1.5-3 wires, the role of PET is to assist in completing the entire production process, and the PVC calendering film is based on The product needs to use 10-25 wire thickness. The lamination is completed by passing the two materials through three continuous heating rollers. The whole process does not require the use of adhesives. The heating temperature is 80-120°, PVC will soften in this temperature range and it is easier to bond with the PET film. Extrude the residual air through the rubber roller and the heating roller, and the compound is completed. Printing: gravure, rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com