High molecular leather release paper producing process

A production process and technology of release paper, applied in the field of material processing, to achieve strong oxidation resistance, strong embossing layering, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A production process of polymer leather release paper, comprising the steps of:

[0043] 1) Put the base paper into the paper unloading unit in the production line, and the vector frequency conversion drive system will transport the base paper to the back glue unit, during which the tension control is automatically calculated by the fully automatic tension balance PLC system.

[0044] 2) The base paper is coated with glue on the back of the base paper, and the oxidation-resistant liquid glue is coated on the back of the base paper through mesh roll coating, and then dried at high temperature and hot air for instant UV curing treatment, and the ultraviolet irradiation intensity is 40μW / cm 2 .

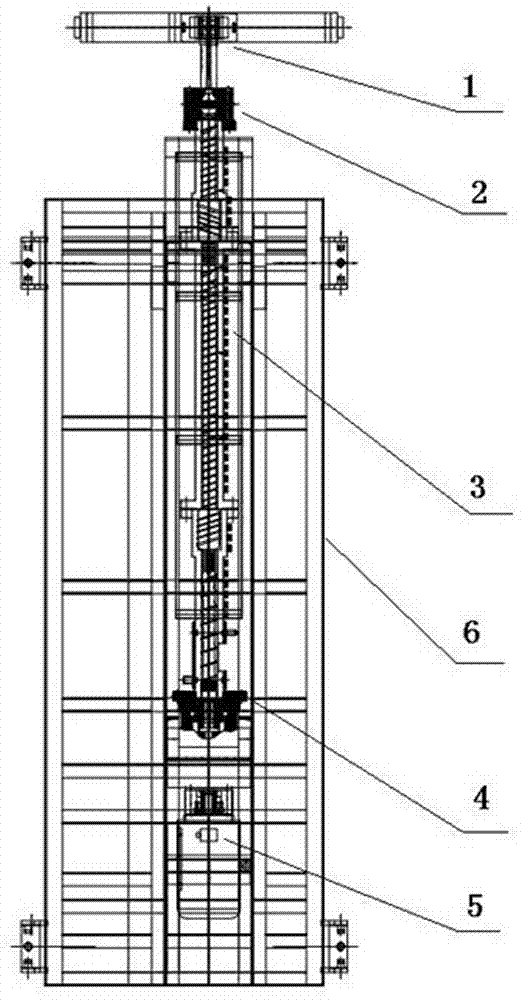

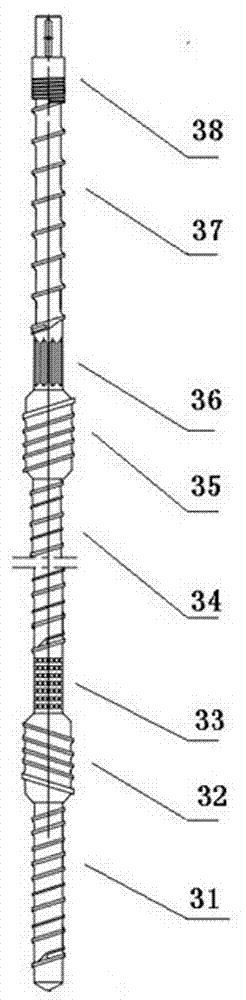

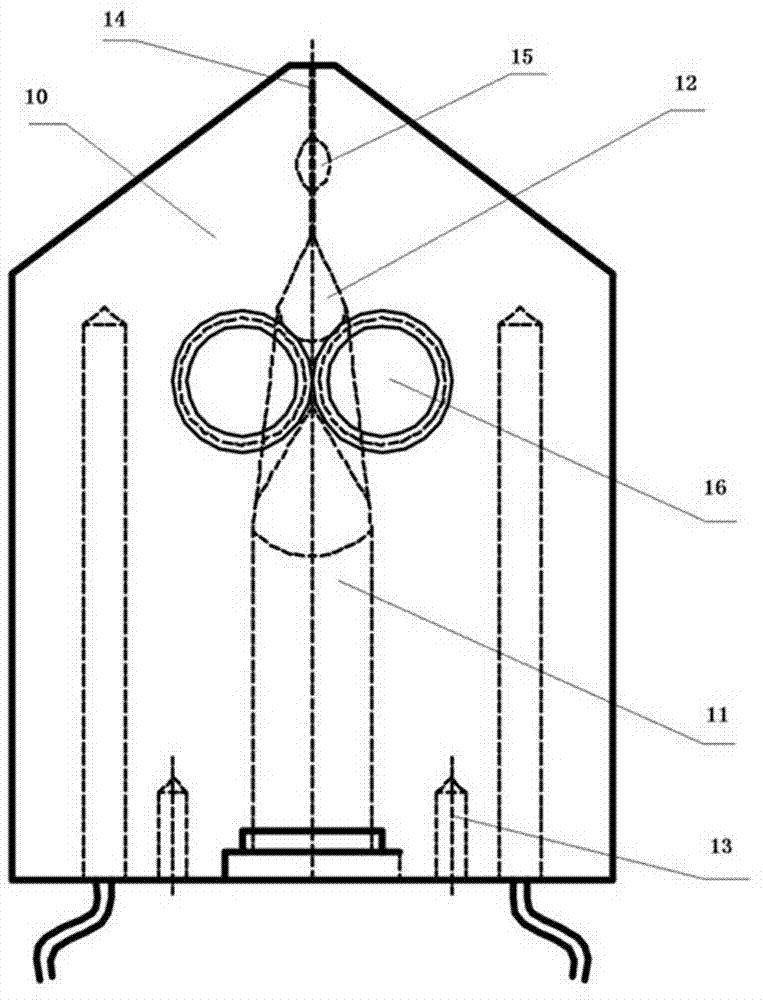

[0045] 3) The back-coated base paper is transported to the composite embossing unit by the servo motor through the motion controller, and the multi-layer polymer resin is pushed to the high-temperature, high-pressure gap-type flow-reducing nozzle through the heat-reflow high-speed...

Embodiment 2

[0048] A production process of polymer leather release paper, comprising the steps of:

[0049] 1) Put the base paper into the paper unloading unit in the production line, and the vector frequency conversion drive system will transport the base paper to the back glue unit, during which the tension control is automatically calculated by the fully automatic tension balance PLC system.

[0050] 2) The base paper is coated with glue on the back of the base paper, and the oxidation-resistant liquid glue is coated on the back of the base paper through mesh roll coating, and then dried at high temperature and hot air for instant UV curing treatment, and the ultraviolet irradiation intensity is 80μW / cm 2 .

[0051] 3) The back-coated base paper is transported to the composite embossing unit by the servo motor through the motion controller, and the multi-layer polymer resin is pushed to the high-temperature, high-pressure gap-type flow-reducing nozzle through the heat-reflow high-speed...

Embodiment 3

[0054] A production process of polymer leather release paper, comprising the steps of:

[0055] 1) Put the base paper into the paper unloading unit in the production line, and the vector frequency conversion drive system will transport the base paper to the back glue unit, during which the tension control is automatically calculated by the fully automatic tension balance PLC system.

[0056] 2) The base paper is coated with glue on the back of the base paper, and the oxidation-resistant liquid glue is coated on the back of the base paper through mesh roll coating, and the high temperature is instantaneously dried with hot air, and ultraviolet UV curing is carried out. The ultraviolet irradiation intensity is 120μW / cm 2 .

[0057] 3) The back-coated base paper is transported to the composite embossing unit by the servo motor through the motion controller, and the multi-layer polymer resin is pushed to the high-temperature, high-pressure gap-type flow-reducing nozzle through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com