Preparation method of battery cathode material with surface coated with composite oxides

A composite oxide and surface coating technology, which is applied in the field of lithium-ion battery materials and materials science, can solve problems such as poor cycle performance and storage performance, restrictions on the application of lithium manganate batteries, and capacity decay during storage to achieve high thermodynamic stability Good reactivity and reducing properties, and improved high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

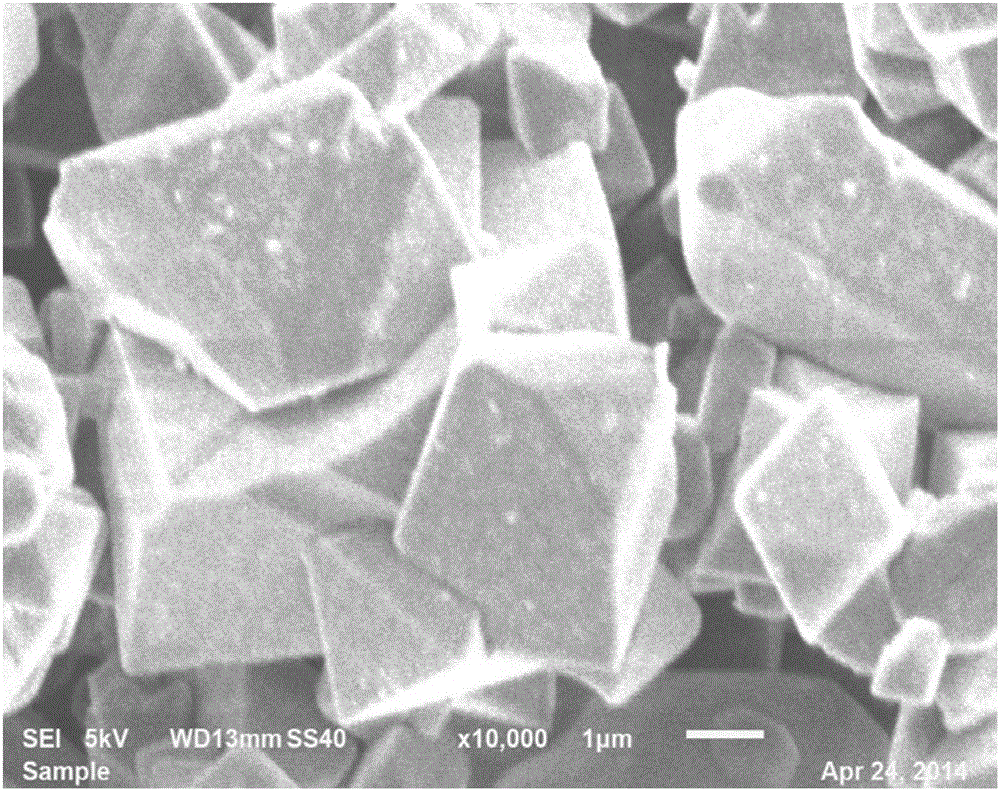

[0033] A preparation method of composite oxide surface-coated battery cathode material, comprising the following steps in turn: (1) dissolving 45.39g of aluminum isopropoxide and 47.10g of lanthanum chloride hexahydrate in 3000ml of absolute ethanol, and Add 4ml of acetylacetone, under stirring, quickly add 3000g of the pre-prepared parent material into it, and add 85g of urea, after stirring evenly, the temperature rises to 75°C, and 100 ℃ water vapor, stop after 40min, keep stirring until dry at this temperature, put it in an oven at 100℃ for drying. (2) The dried samples were sintered in an air atmosphere, the sintering temperature was 500° C., and the sintering time was 8 hours. (3) Pulverize and sieve the sintered sample to obtain the composite oxide surface-coated battery positive electrode material.

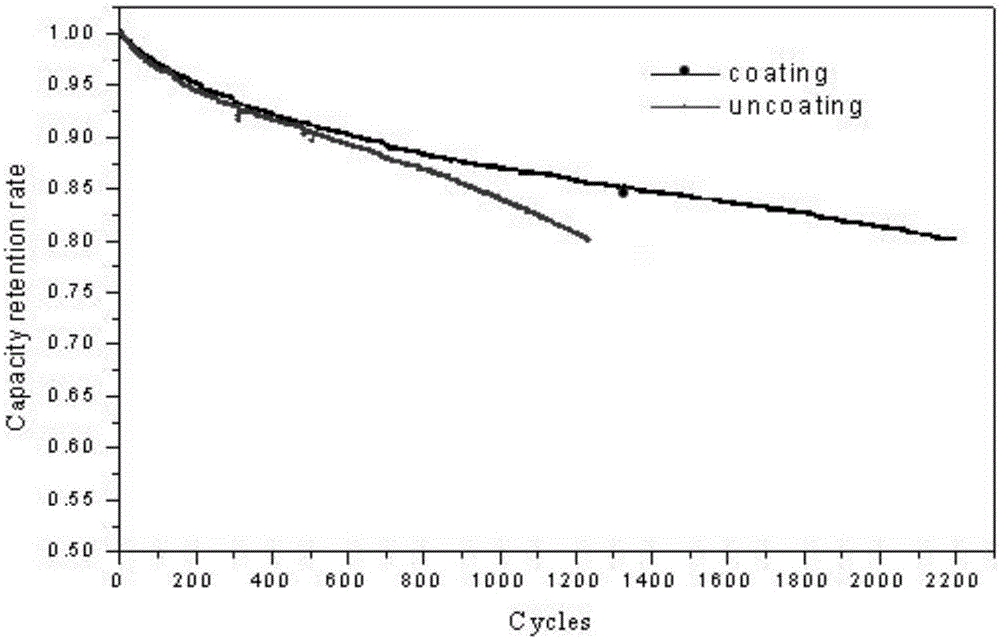

[0034] Such as figure 1 At room temperature, the battery positive electrode material after coating cycled for 2201 cycles with a capacity retention rate of 80%, while th...

Embodiment 2

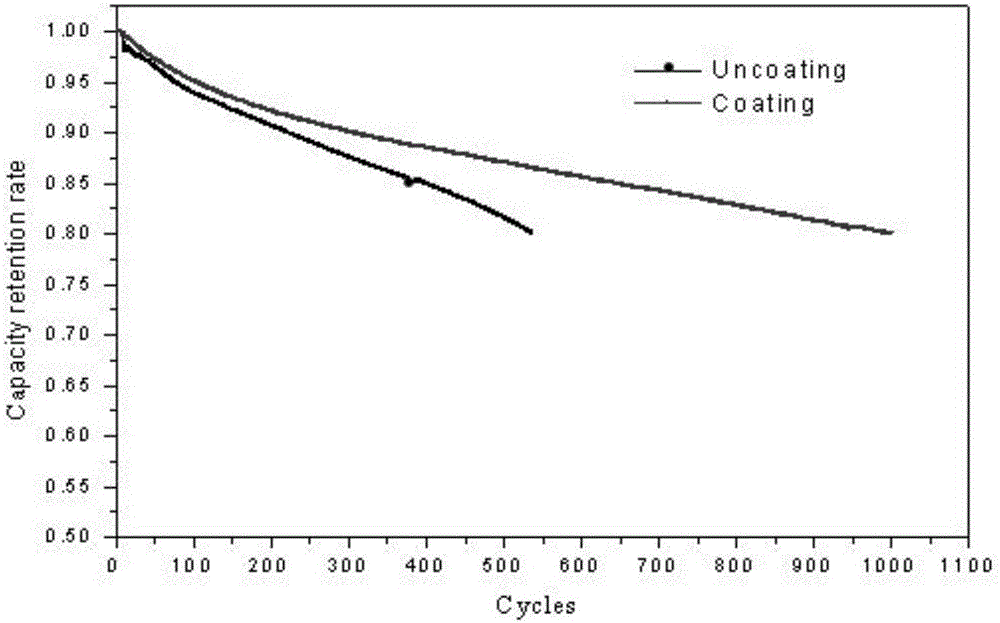

[0037] A method for preparing a composite oxide surface-coated positive electrode material for a battery, comprising the following steps in sequence: (1) dissolving 8.90 g of aluminum isopropoxide and 85.32 g of tetrabutyl titanate in 3000 ml of absolute ethanol, and Add 6ml of acetylacetone, and under stirring, quickly add 3000g of the pre-prepared lithium manganate parent material into it, and add 55g of urea. After stirring evenly, the temperature rises to 70°C. From the bottom of the feed liquid at a speed of 5g / min Introduce water vapor at 90°C, stop after 30 minutes, keep stirring until dry at this temperature, and put it in an oven for drying at 100°C. (2) The dried samples were sintered in an air atmosphere, the sintering temperature was 450°C, and the sintering time was 8h. (3) Pulverize and sieve the sintered sample to obtain the positive electrode material of the composite oxide surface-coated lithium manganate battery.

Embodiment 3

[0039] A preparation method for a composite oxide surface-coated battery positive electrode material, comprising the following steps in turn: (1) 31.77g of aluminum isopropoxide and 15.81g of magnesium chloride hexahydrate are dissolved in 2500ml of dehydrated ethanol, and 2.5 ml of acetylacetone, under stirring, quickly add 3000g of the pre-prepared lithium manganate matrix material into it, and add 55g of urea, after stirring evenly, the temperature rises to 80°C, and passes through the bottom of the feed liquid at a speed of 5g / min Inject water vapor at 100°C, stop it after 30 minutes, keep stirring until dry at this temperature, and put it in an oven for drying at 100°C. (2) The dried samples were sintered in an air atmosphere, the sintering temperature was 450°C, and the sintering time was 8h. (3) Pulverize and sieve the sintered sample to obtain the positive electrode material of the composite oxide surface-coated lithium manganate battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com