Oxidation resistant coating and preparation method thereof

An anti-oxidation coating and coating technology, applied in the field of anti-oxidation coating and its preparation, can solve the problems of high price of rare earth elements, low natural reserves, limited technical application, etc., and achieve excellent anti-oxidation ability and take into account the anti-oxidation performance. and thermal shock resistance, the effect of reducing the rate of oxidative mass loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

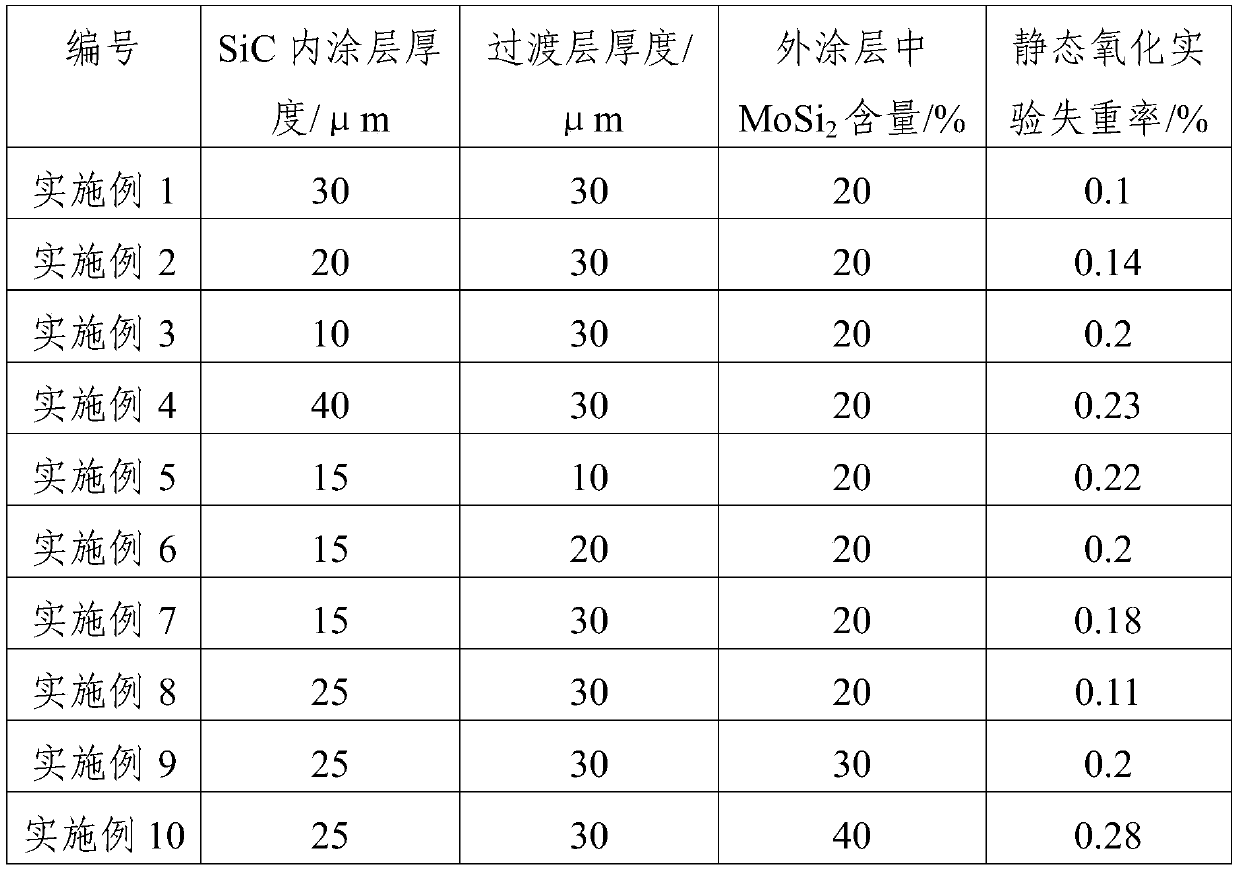

Examples

preparation example Construction

[0038] For the preparation method of the SiC inner coating, the existing chemical vapor deposition method can be used to deposit the SiC inner coating on the surface of the C / SiC composite material. The present invention does not specifically limit the specific process conditions of the chemical vapor deposition method, as long as it can produce a SiC inner coating with a thickness that meets the requirements, it can be regarded as an available chemical vapor deposition process in the present invention.

[0039] In some preferred embodiments, the SiC-ZrB 2 The thickness of the transition coating is 10-40 μm, which can be any value within this range, for example, it can be 10 μm, 15 μm, 20 μm, 25 μm, 30 μm, 35 μm, 40 μm, more preferably 20-30 μm, for example, it can be 20 μm, 21 μm , 22 μm, 23 μm, 24 μm, 25 μm, 26 μm, 27 μm, 28 μm, 29 μm, 30 μm, more preferably 30 μm.

[0040] The SiC-ZrB 2 The transition coating can be prepared as follows:

[0041] Place the C / SiC composite...

Embodiment 1

[0057] (1) The green body is chemically deposited by the CVI process to obtain a porous C / C composite material preform, which is deposited to a density of 1.0g / cm 3 , the densification process uses propylene as the carbon source gas, nitrogen as the carrier gas, and a deposition temperature of 900°C.

[0058] (2) The C / SiC composite material is prepared by a high-temperature infiltration method, the C / C composite material in step (1) is placed in a tooling, and silicon powder is added thereto. Raise the temperature of the C / C composite material to 20°C to 70°C below the melting temperature of silicon, and keep the temperature for 2 hours. Continue to heat up to the infiltration temperature, keep warm, complete the high-temperature infiltration reaction, and obtain the C / SiC composite material.

[0059] (3) The SiC inner coating is prepared by chemical vapor deposition, and the C / C composite material in step (1) is placed in a chemical vapor deposition furnace for SiC depositi...

Embodiment 2

[0066] Preparation method is basically the same as Example 1, except that:

[0067] In step (3), the SiC undercoat layer is formed with a thickness of 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com