Multifunctional coffee grounds composite rattan-imitating material and application thereof

A coffee grounds, multi-functional technology, applied in the field of coffee grounds composite rattan-like materials, can solve the problems of waste of resources, environmental pollution, etc., achieve good heat resistance, improve flame retardancy, and tightly bonded effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of multifunctional coffee grounds composite imitation rattan material of the present invention is as follows:

[0026] (1) Treatment of coffee grounds: wash the coffee grounds with distilled water, filter and dry; place the dried coffee grounds in a grinder for grinding to obtain coffee grounds powder with a particle size of 1 to 5 microns;

[0027] (2) Preparation of coffee charcoal: Take a certain amount of coffee grounds powder obtained in step (1) and heat it at 50°C min under a nitrogen atmosphere. -1 Heating to 460°C at a high speed, roasting for 2 hours to obtain coffee charcoal, and putting the coffee charcoal in a grinder for grinding to obtain a powder with a particle size of nanometer scale;

[0028] (3) Mixing of coffee grounds and coffee charcoal: the coffee charcoal powder obtained in step (2) is soaked in a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, heated by microwave at 30...

Embodiment 1-16

[0033] The following examples adopt the above method to prepare rattan-like materials.

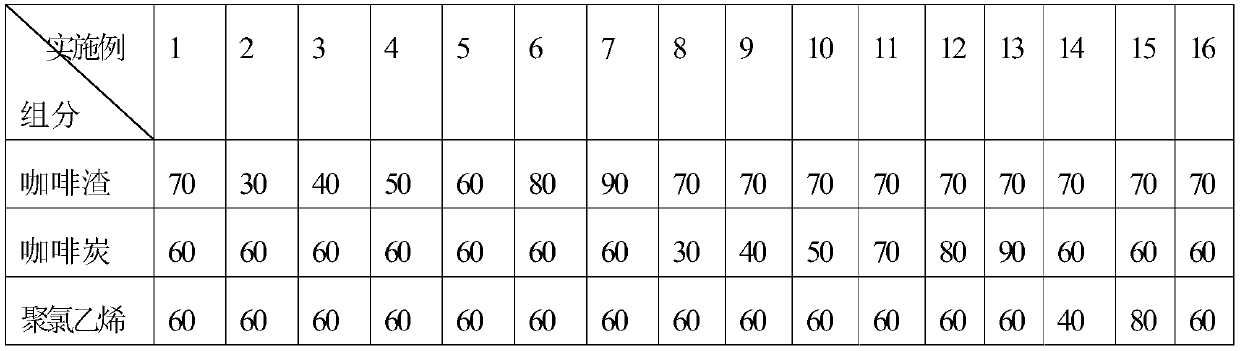

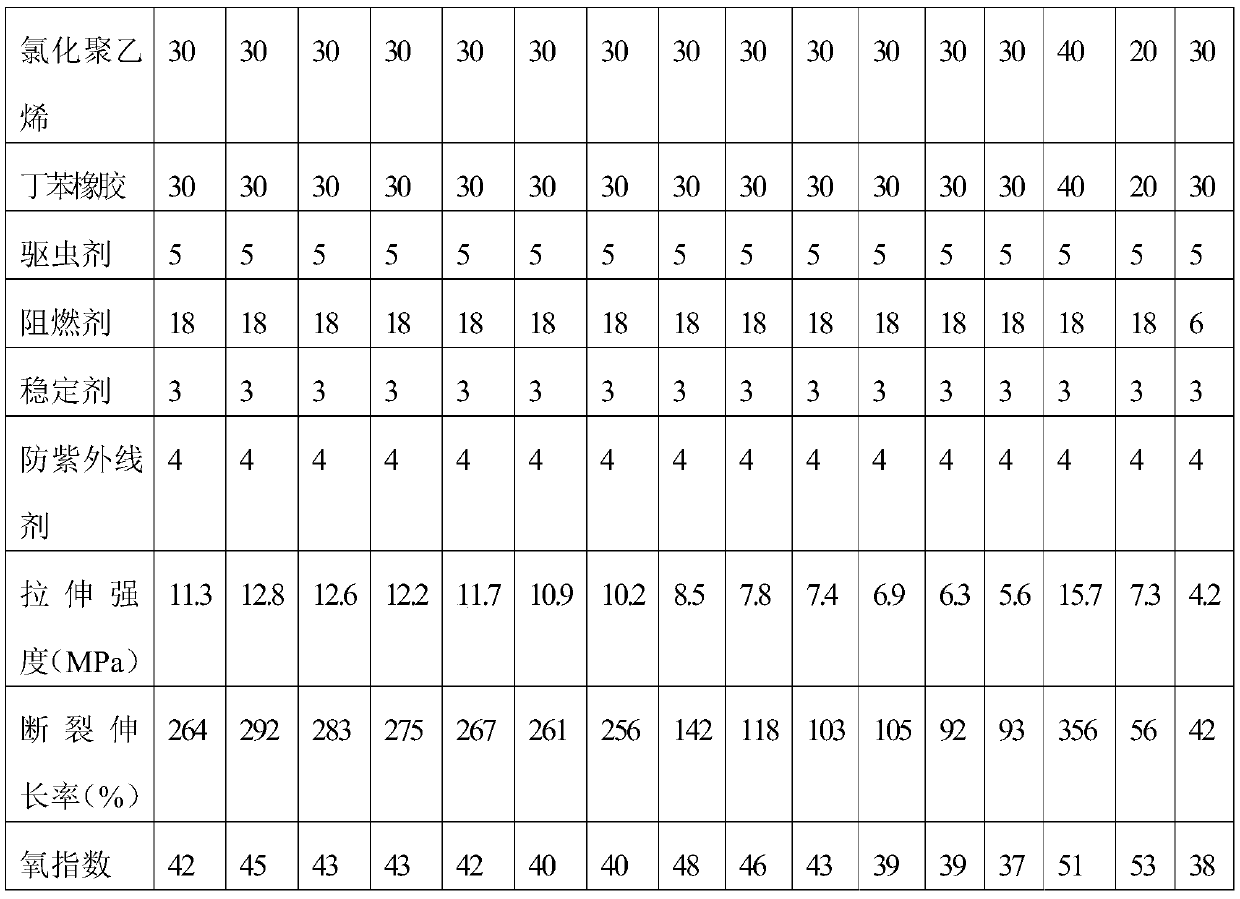

[0034] Its mass ratio and rattan-like material performance test are as follows:

[0035] Table 1

[0036]

[0037]

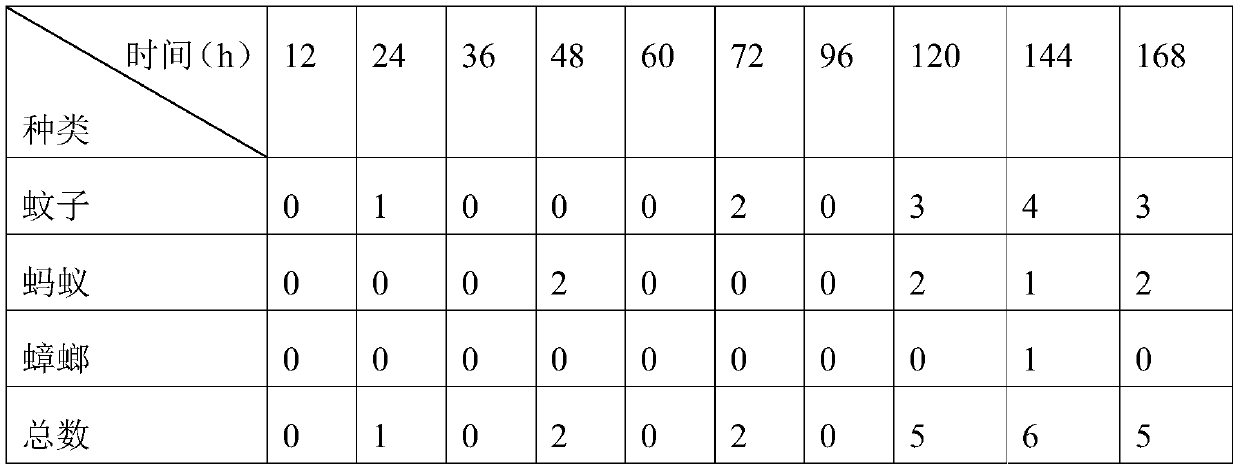

[0038] Result: From the analysis in Table 1, it can be seen from Examples 2 to 13 that with the increase of the added amount of coffee grounds and coffee charcoal, the tensile strength and elongation at break of the product all decreased; With the increase of ethylene and styrene-butadiene rubber proportion, the tensile strength and elongation at break of the product all increase thereupon, and the flame retardancy also increases thereupon; wherein, in embodiment 14 and embodiment 15, the tensile strength of the product and There is an obvious positive correlation between the elongation at break and the change of the styrene-butadiene rubber content; in Example 16, the flame retardant is reduced, and the flame retardant performance of the product is also reduced. Whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com