Method and apparatus for producing a structured surface on an embossing steel roll

A technology of steel rolls and embossing, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem of no disclosure of embossing rolls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

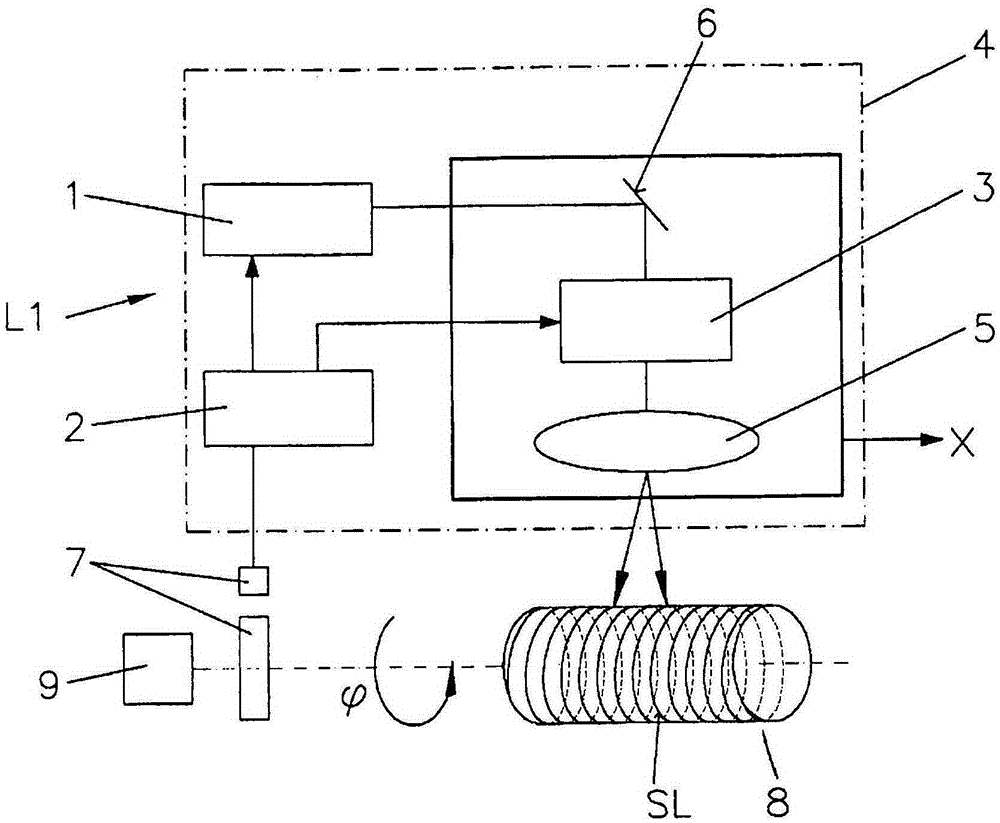

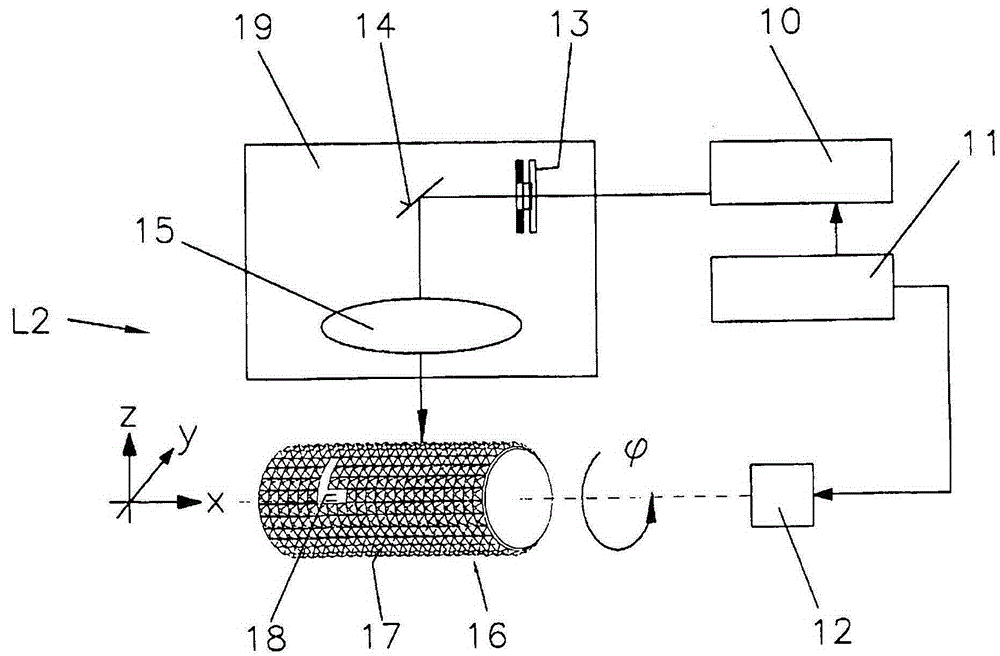

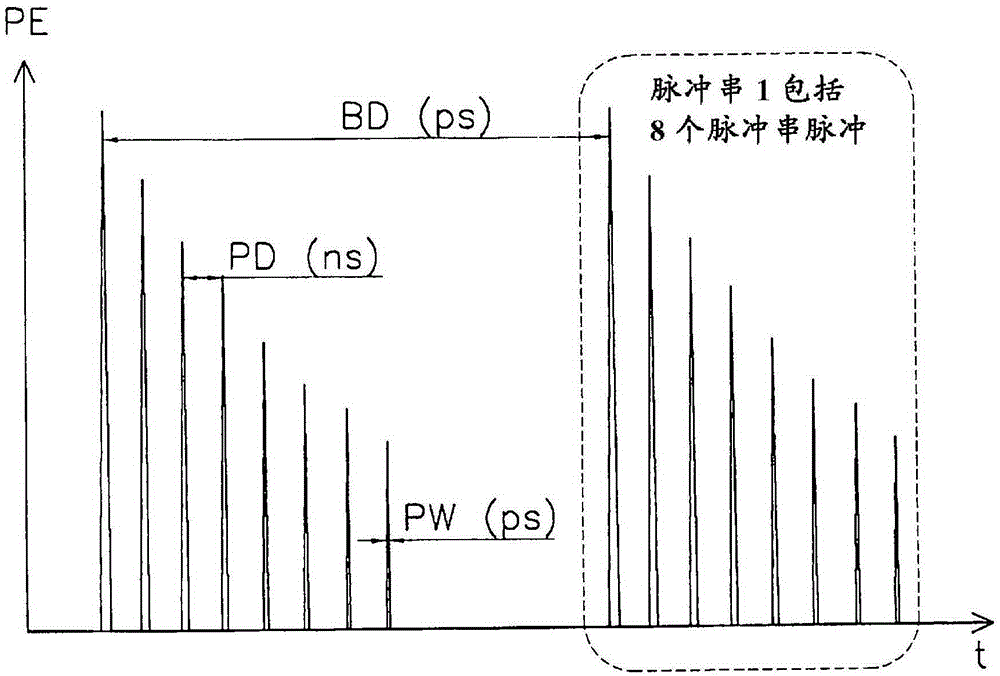

Method used

Image

Examples

Embodiment Construction

[0023] A fundamental novelty of the described method consists in providing modern materials with the possibility of engraving macroscopic-dimensional surface structures with dimensions exceeding 20 μm, and more precisely over 70 μm, and engraving depths up to 400 μm, which is not possible with conventional laser processing methods accomplish. In macroscopic technology, it is also highly desirable to be able to generate structures on the surface of inhomogeneous high-alloy iron-based materials, which is becoming increasingly important in fabrication technologies concerning surface structures. The heterogeneous structural composition of these materials is essential for the specific properties required of the roll surface.

[0024] However, these different structural phases have very different physical properties, leading to corresponding differences in local macroscopic behavior during laser processing. So far, these materials have not been able to be macrostructured economical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com