Method and device for producing a printed and embossed web

An embossing and printing technology, which is applied in the field of printing and embossing multi-layer webs for the manufacture of tissue paper or non-woven materials, and can solve problems such as deformation of the printed area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

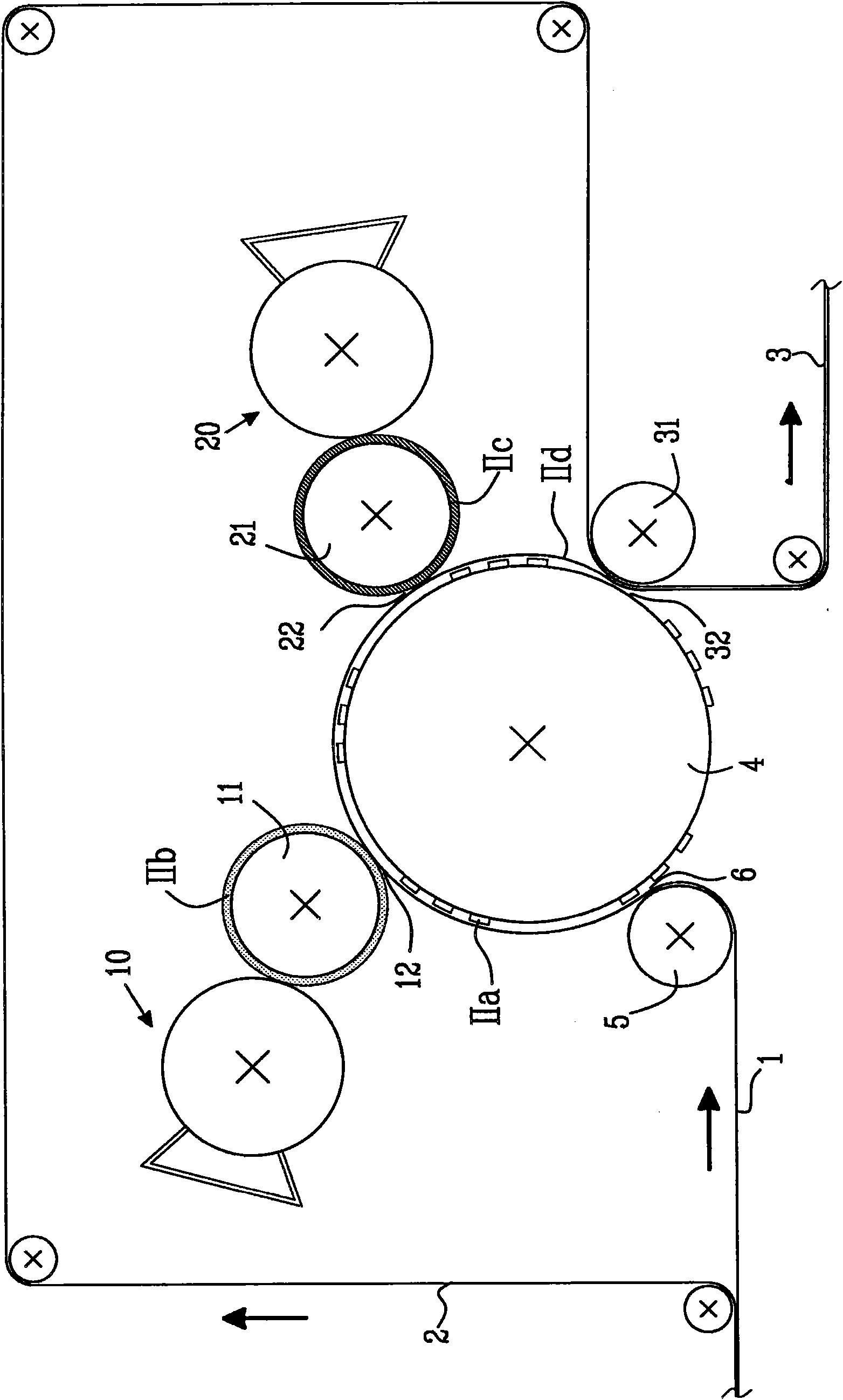

[0070] figure 1 Denotes an apparatus for the manufacture of printed and embossed webs of tissue paper or nonwoven material. The first web material 1 is transported through the nip 6 between the first embossing roll 4 and the counter roll 5 . The first embossing roll has protrusions corresponding to the desired embossing on the web material. A common material for embossing rolls may be steel, which may have a chrome plating. Alternatively, the embossing roll may be made of a polymer such as hard rubber, hard glue or plastic. If the embossing pattern needs to be changed frequently, a system with quick exchange of embossing rolls is preferred, eg with embossing sleeves, embossing plates or the unit can be easily opened and the embossing rolls can be lifted out.

[0071] The counter roller 5 can be made of eg rubber, steel or paper. If the material is steel or paper, the circumferences of the counter roll 5 and the first embossing roll 4 should preferably be equal or approxima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com