Analytical method for rapidly evaluating barrier property of inner liner for cigarettes

A technology of lining paper and barrier performance for cigarettes, which is applied in the fields of permeability/surface area analysis, suspension and porous material analysis, and measurement devices, which can solve the problems of long measurement time, poor applicability, and poor repeatability, and achieve instrument stability sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] 1. Sample preparation

[0070] Select three samples of cigarette lining paper: sample A, sample B, and sample C. Among them, samples A, B, and C are samples of different types of aluminum-free lining paper that are normally produced in the workshop and meet the standards.

[0071] 2. Measure the samples and record the results

[0072] Using a TQY500 paper air permeability measuring instrument, four different test pressures of 500Pa, 1000Pa, 1500Pa, and 2000Pa were selected to test the air permeability values of the inner lining paper samples under different test pressures. The test range of air permeability is 0~40000CU, and the resolution is 0.5CU.

[0073] Divide the lining paper patterns A, B, and C into three parts, and number them respectively as paper patterns A1~3, B1~3, and C1~3. Among them, the paper samples A1, B1, and C1 are measured on the front side first and then on the back side, and the other paper samples are measured on the back side first and the...

Embodiment 2

[0081] 1. Sample preparation

[0082] Select two samples of cigarette lining paper: sample D and sample E. Among them, samples D and E are the normal production of the workshop and meet the standard lining paper samples. Among them, sample D is vacuum direct plating lining paper, and sample E is vacuum transfer aluminized lining paper. Embossing was performed on sample D, and the embossing pressure was set to 8 gradients (0, 1, 1.4, 2, 2.6, 3, 3.6, 4 Bar), and sample E was embossed, and the embossing pressure was set to 11 Gradients (2, 2.2, 2.4, 2.6, 2.8, 3, 3.2, 3.4, 3.6, 3.8, 4Bar).

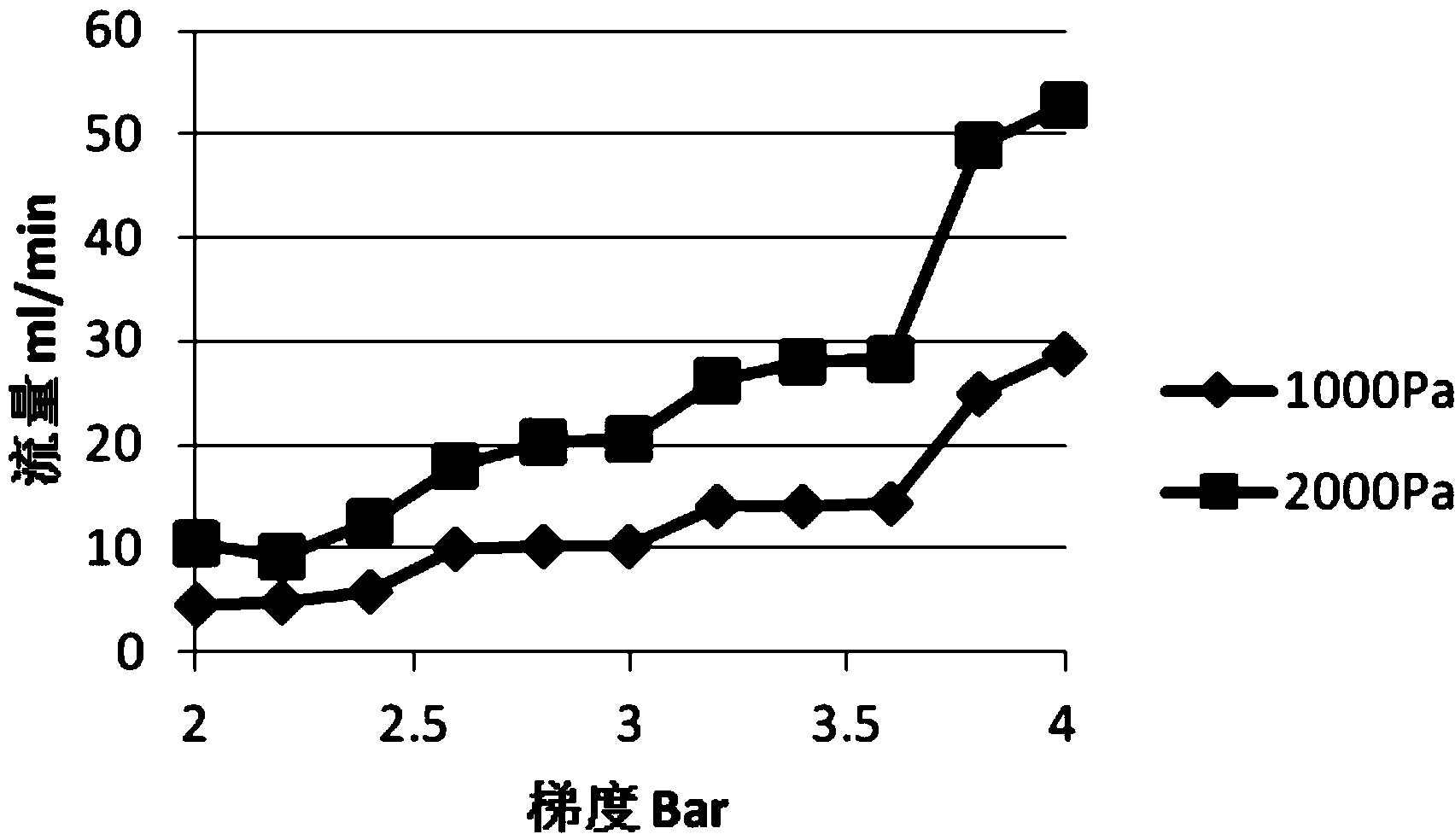

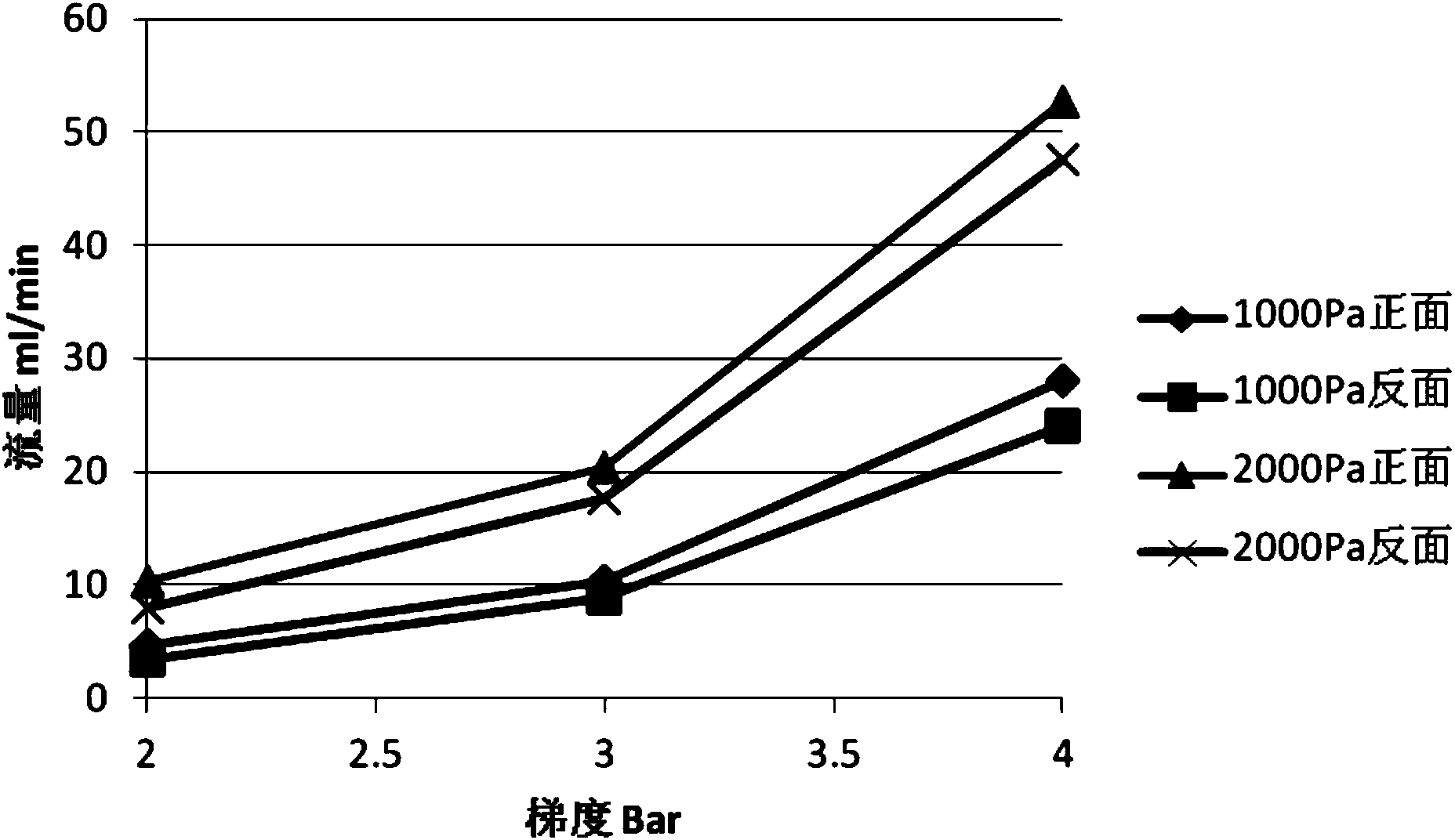

[0083] 2. Measure samples, record results and analyze

[0084] Use TQY500 paper air permeability measuring instrument, select two different test pressures of 1000Pa and 2000Pa, test the air permeability flow value of the inner lining paper samples D and E, and draw the standard working curve.

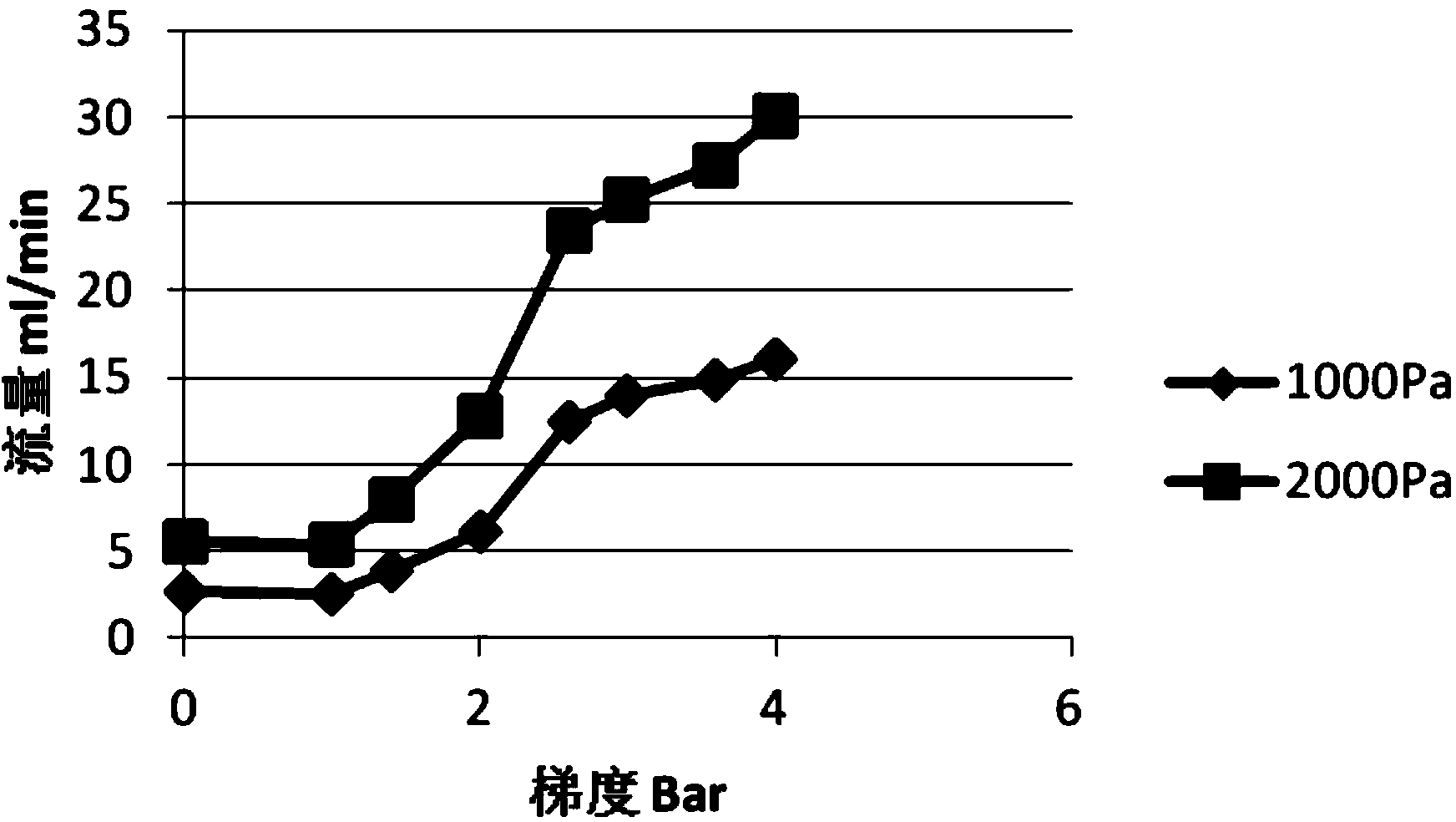

[0085] 1) Air permeability test results and analysis of D-sample lining paper

[0086] The air p...

Embodiment 3

[0103] 1. Sample preparation

[0104] Two samples of cigarette lining paper were selected: sample F and sample G. Among them, samples F and G are the normal production of the workshop and meet the standard lining paper samples. Among them, the F sample is the vacuum direct plating lining paper, and the G sample is the vacuum transfer aluminized lining paper.

[0105] 2. Measure samples, record results and analyze

[0106] Table 5F, G sample air permeability repeatability test results

[0107]

[0108] Adopt TQY500 type paper air permeability measuring instrument, set the test pressure to 2000Pa, and the test area is 2cm 2 , the air permeability value test range is 0 ~ 40000CU, and the resolution is 0.5CU.

[0109] Select a paper sample for the lining paper samples F and G respectively, select 3 measurement point positions on each paper sample, and measure the number of times for each position 5 times, and investigate the repeatability of the test results of the air perme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com