Fibrous product, embossing roll for producing such fibrous product, and device and method for producing such fibrous product

A technology for fiber products and embossing rolls, which is applied in the field of fiber products and can solve problems such as correlation not necessarily applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] In the following description of the preferred embodiment, the same basic elements will be denoted by the same reference numerals, but the details of the basic elements will vary in different embodiments.

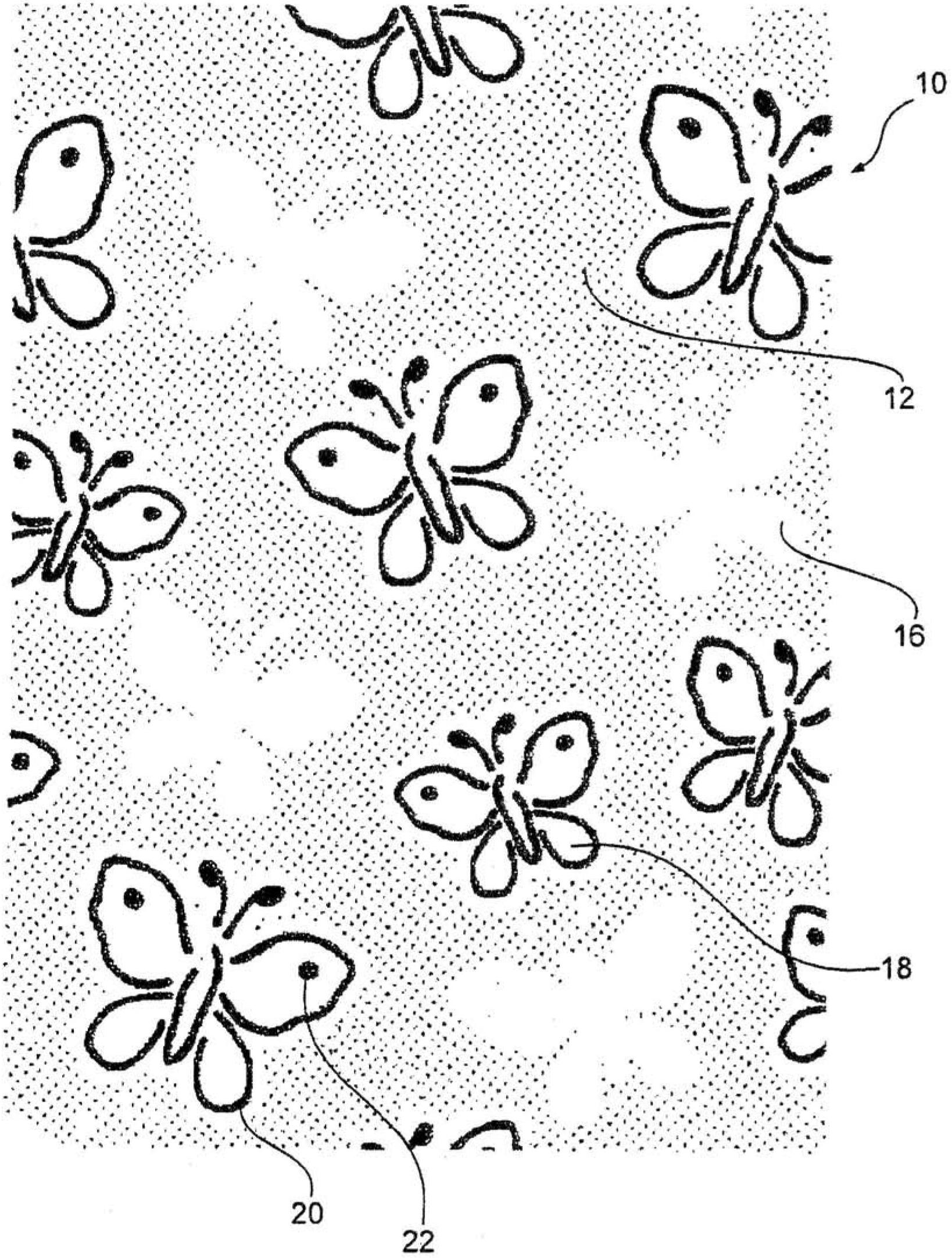

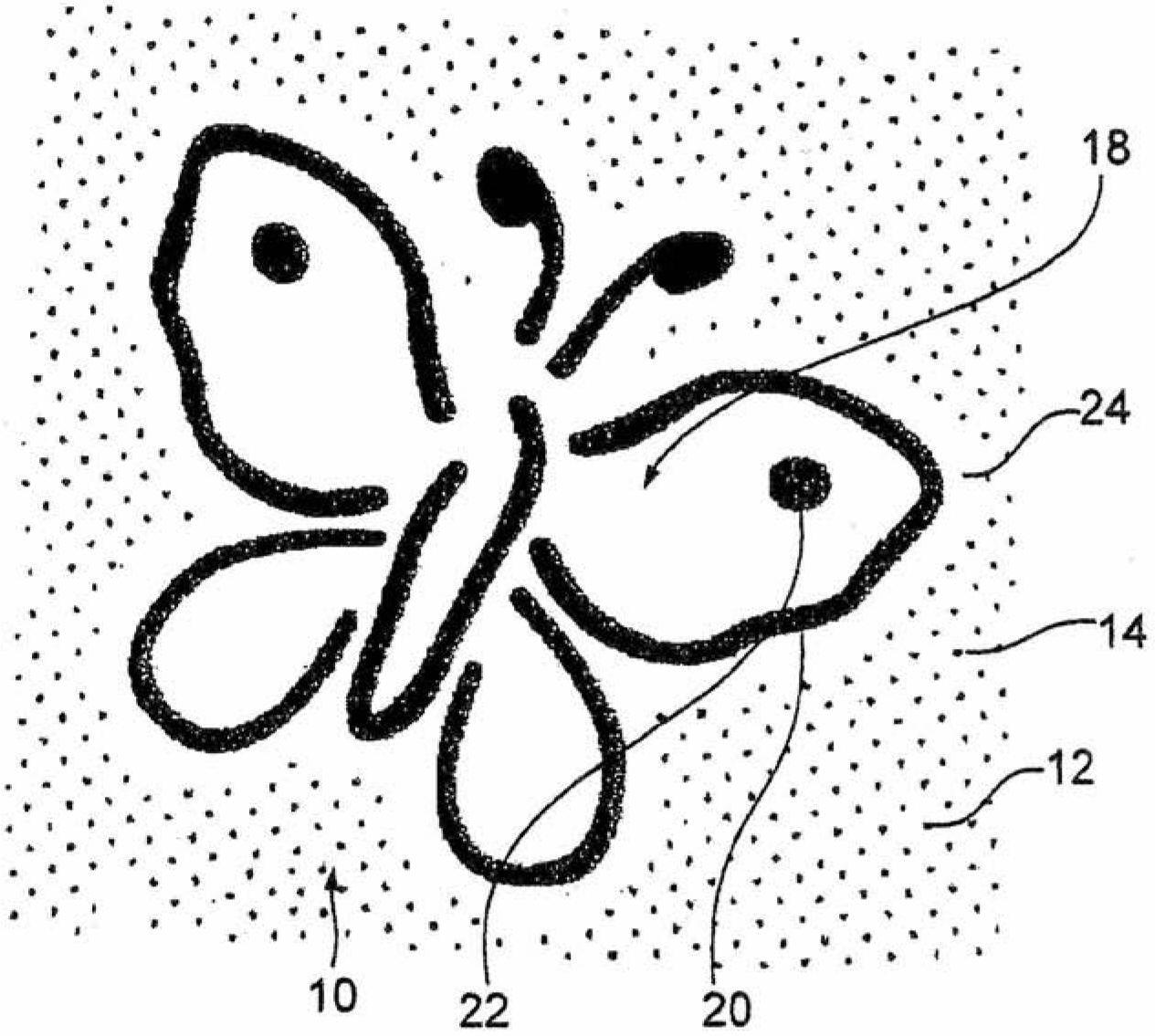

[0088] figure 1 A plan view showing the major surfaces of the top layer of the fibrous article of the present invention. Products can have the same bottom layer, so for simplicity figure 1 The view considered to be the top level of the product.

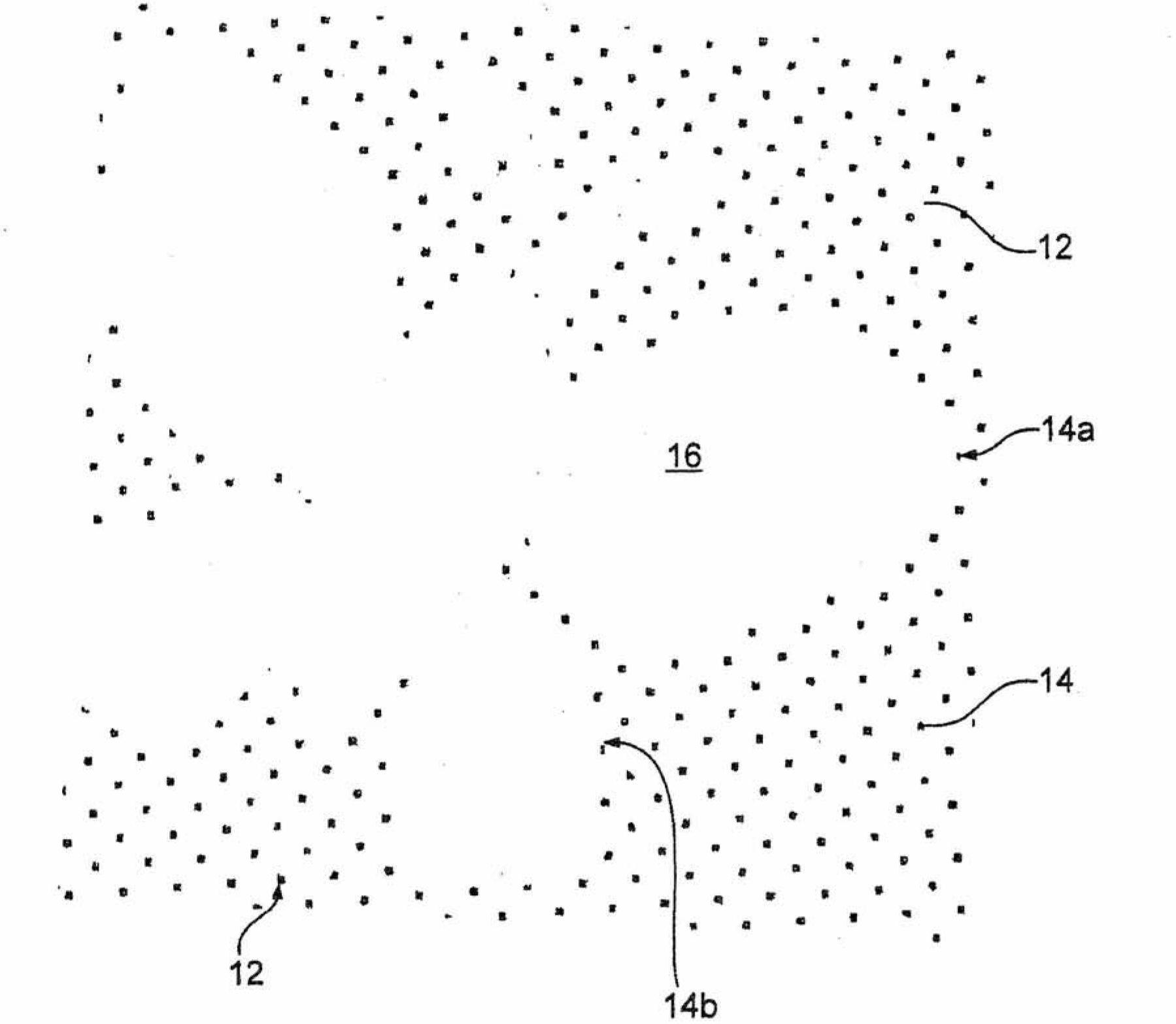

[0089] The layer 10 is partially embossed and different regions can be distinguished. Firstly, there is a continuous first region 12 provided with a micro-embossed pattern. Micro-embossing means that the average density of embossed depressions is relatively high and exceeds at least 25 embossed depressions per square centimeter. The embossed depressions can have any suitable shape commonly used for microembossed patterns. from image 3 Viewed in the extremely enlarged detail shown, it can be seen that the embossed depre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com