Fibrous product and method and device for manufacturing such a fibrous product

A technology of fiber products and products, applied in the direction of textiles and papermaking, transportation and packaging, papermaking, etc., can solve problems such as not looking, bulking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In the drawings, the same elements are denoted by the same reference numerals.

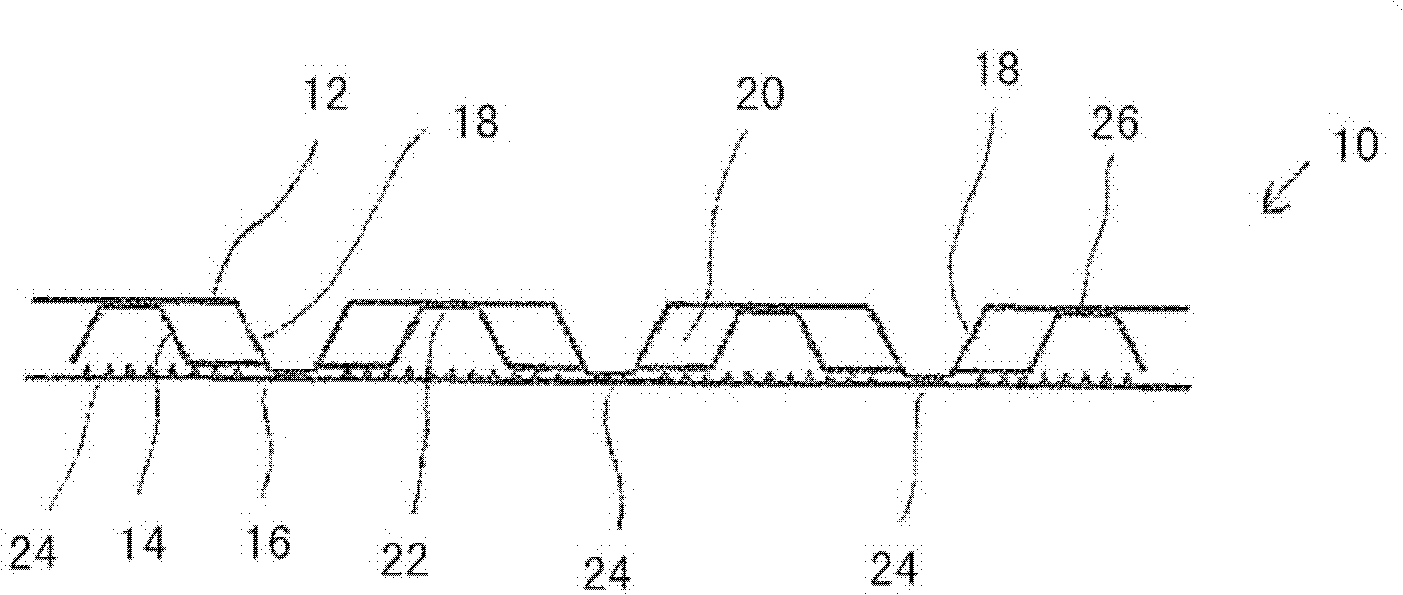

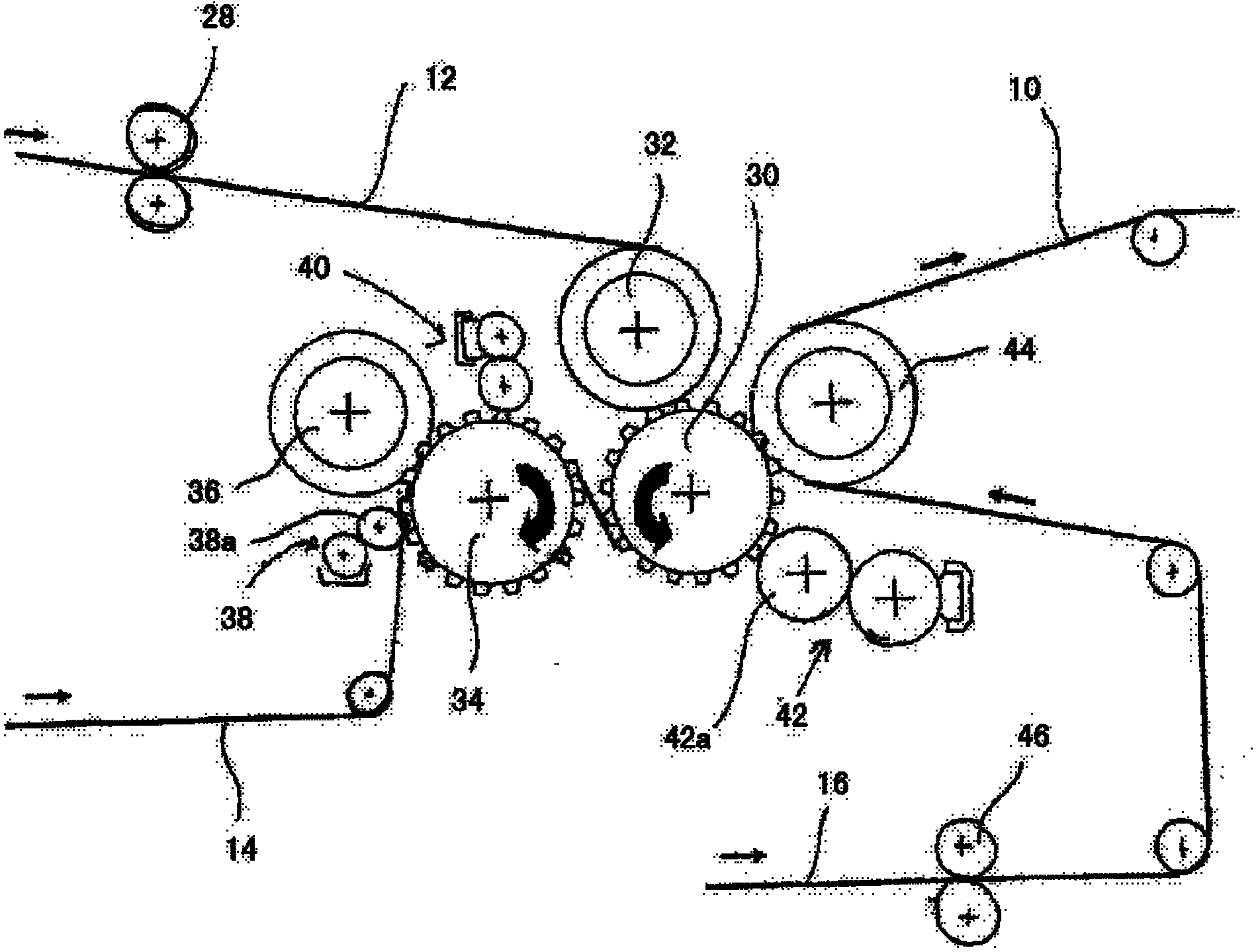

[0067] figure 1 The illustrated fibrous product of the present invention is generally designated by the reference numeral 10 . It consists of a top layer 12 , a middle layer 14 and a bottom layer 16 . The top layer, middle layer or bottom layer can each be a multi-layer web. However, if this is the case, these individual layers are not processed separately, which means that the double bottom layer is processed jointly in the device, as ref. figure 2 as described below.

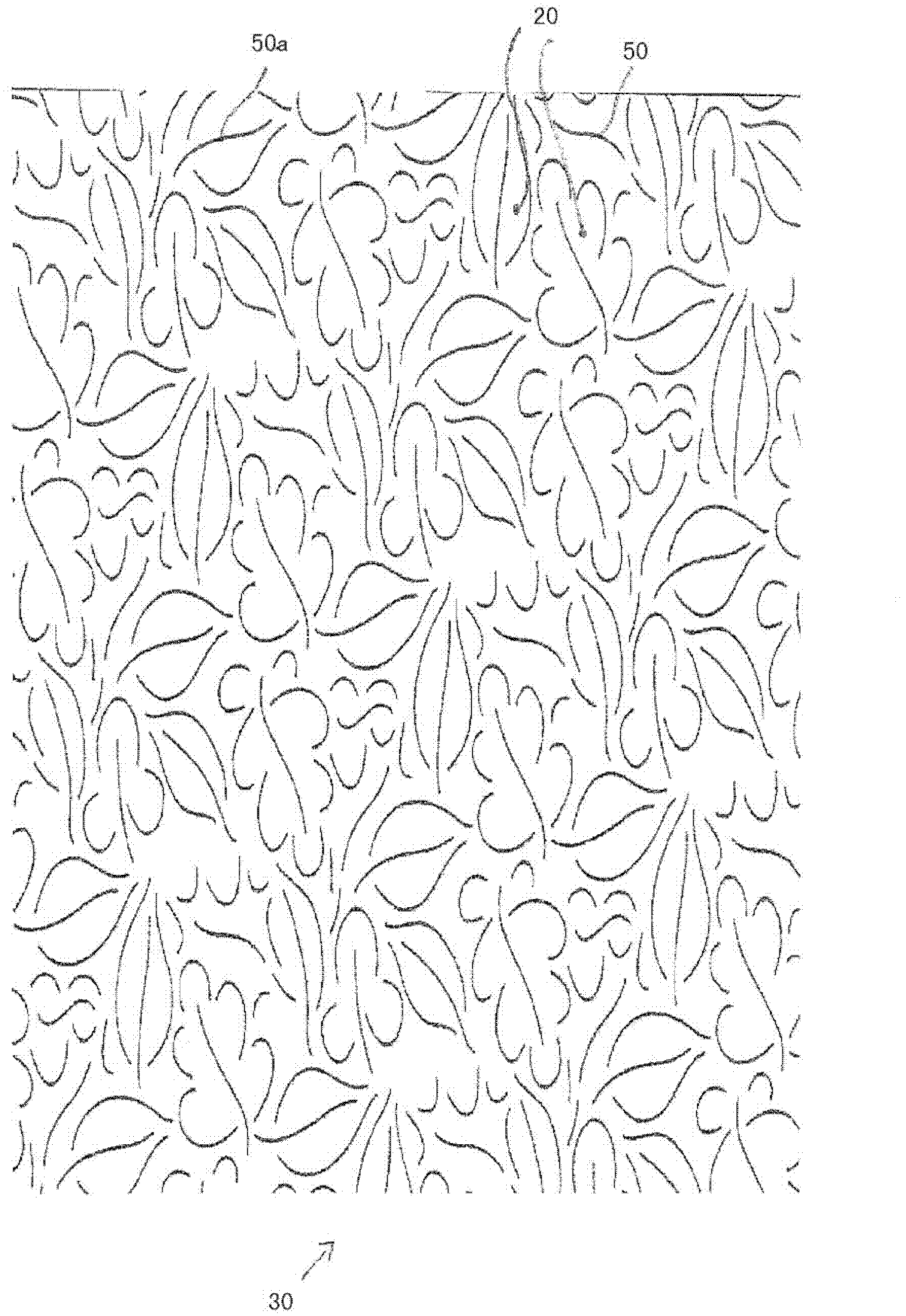

[0068] The top layer 12 has an embossed pattern forming first protrusions 18 defining pillow-like chambers 20 . The first protrusions 18 are preferably elongated, like lines which can be straight or curved and can even form closed geometric figures. However, it is preferred that each pillow chamber 20 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com