Detection device for detecting curing degree of optical fiber coloring printing ink

A coloring ink and detection device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems affecting the stripping and splicing of optical fiber ribbons, the color falling off of the surface of optical fibers, and poor coloring and curing of optical fibers, etc., to achieve accurate data The effect of reliability, reliable detection effect, and improvement of detection accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

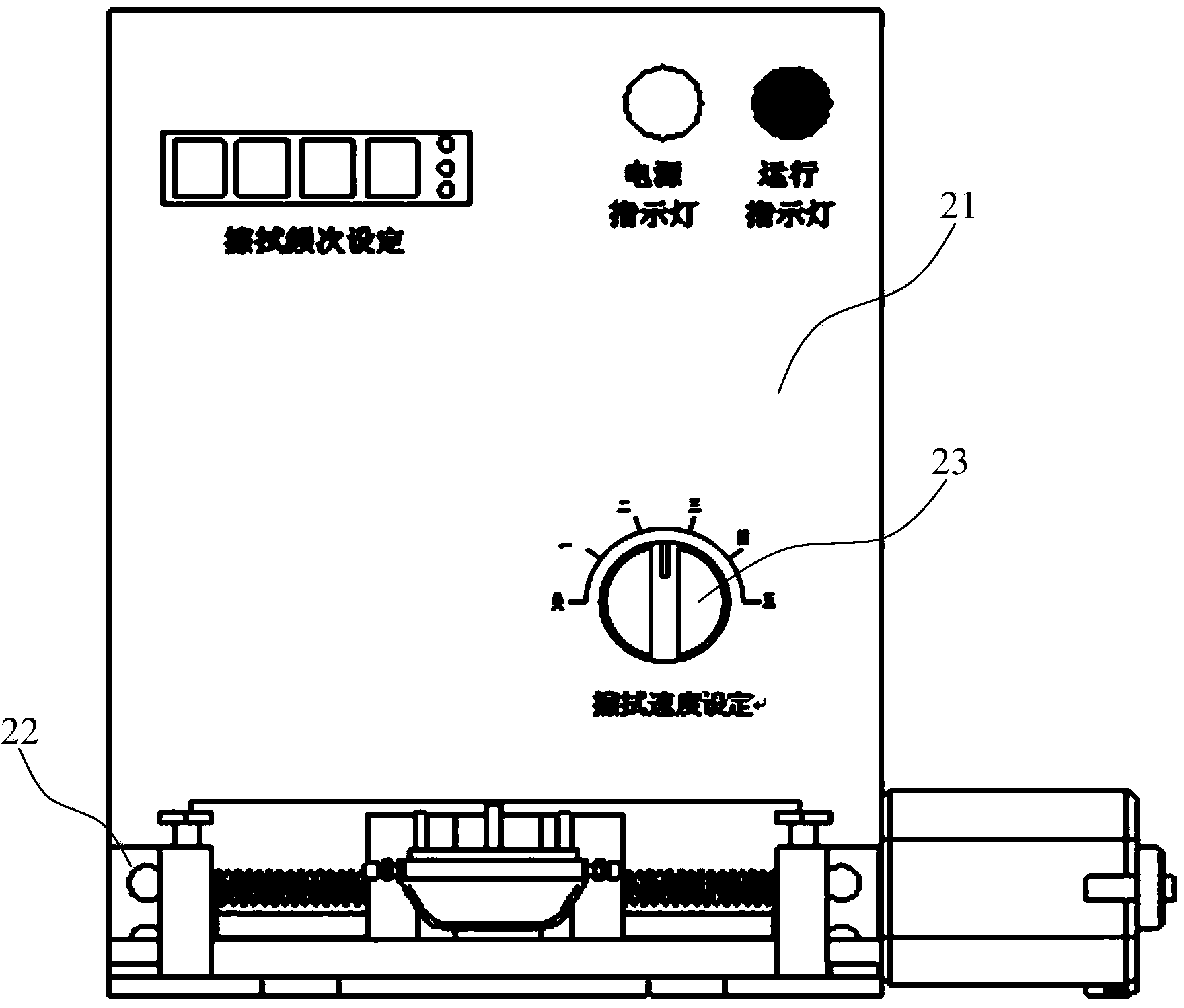

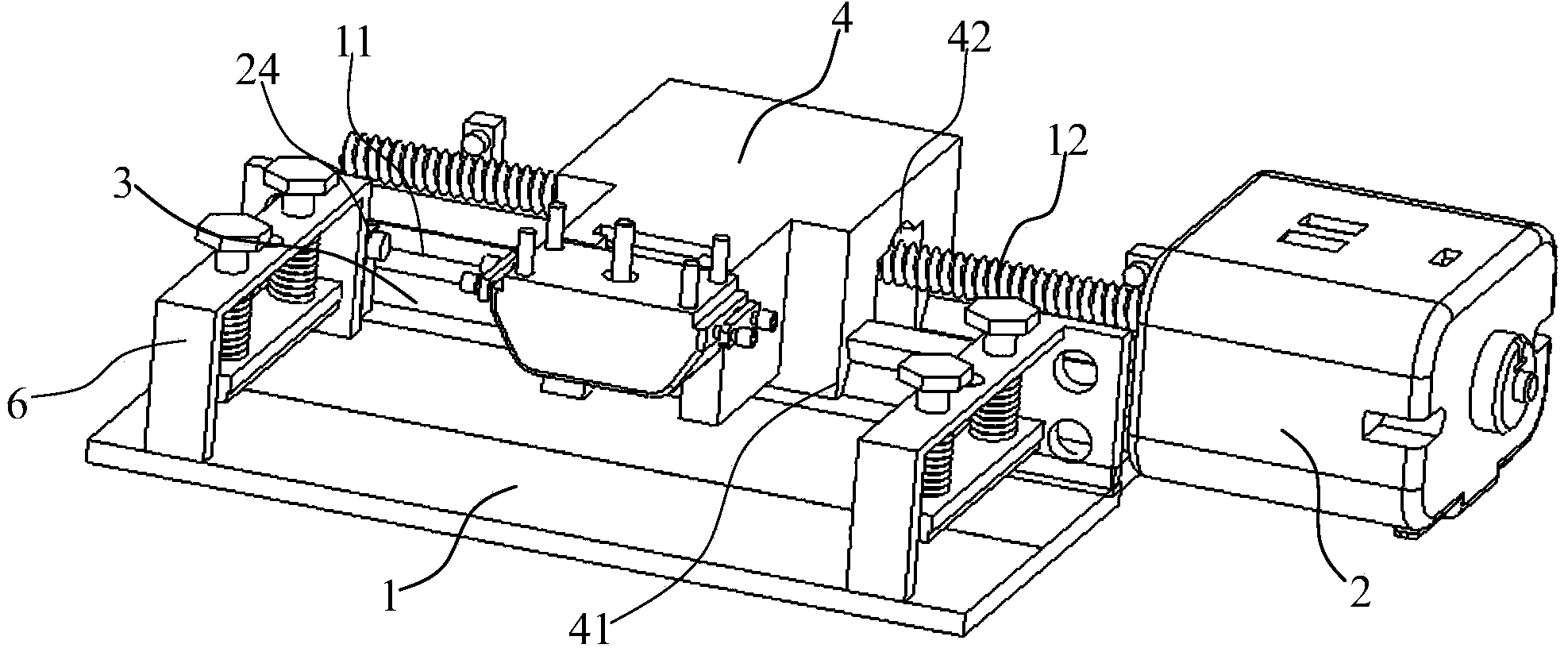

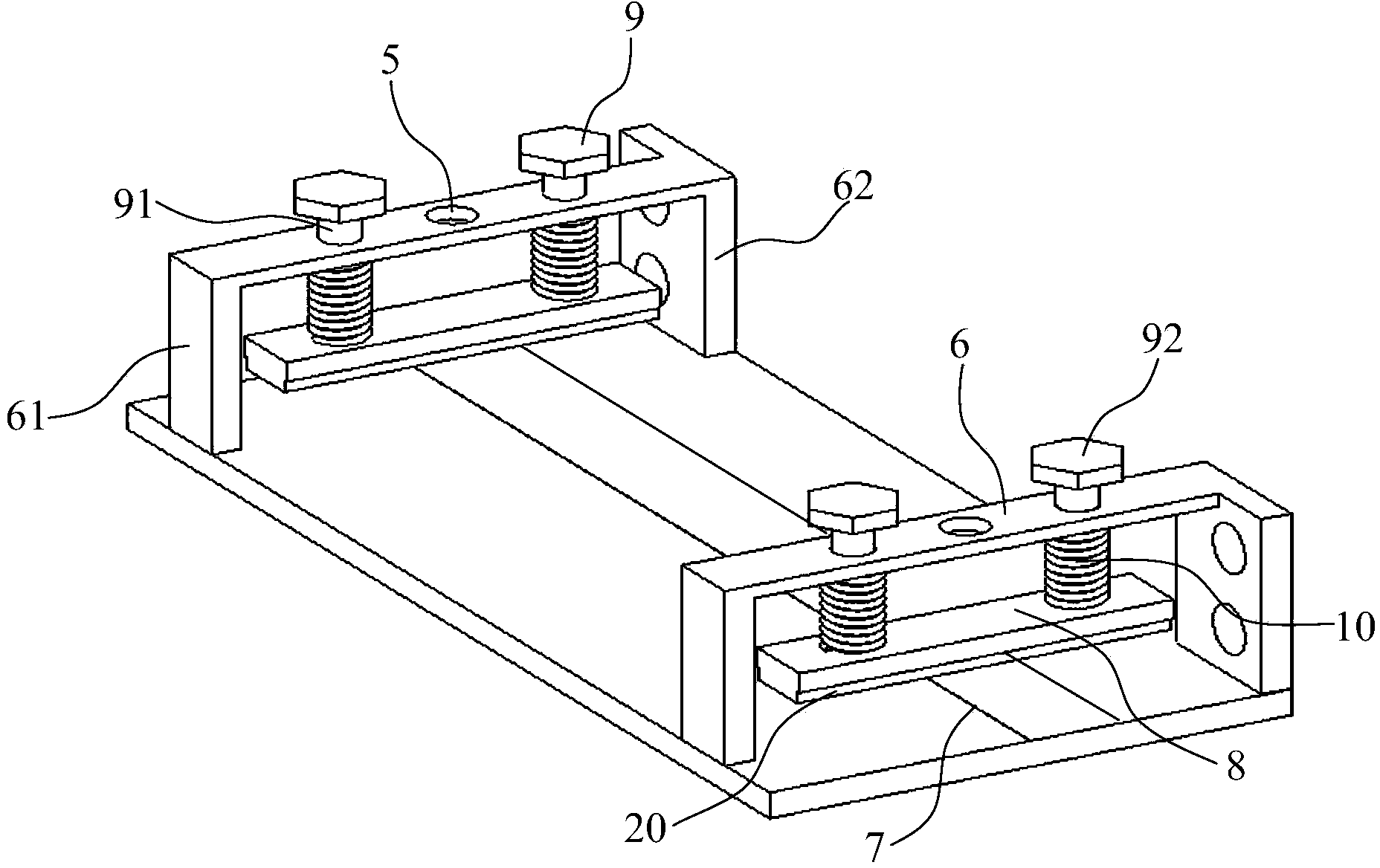

[0024] Embodiment: A detection device for detecting the curing degree of optical fiber coloring ink, including a loading platform 1, a frequency conversion motor 2, a base 3, a transmission block 4 and a frame 21 between the loading platform 1 and the base 3 , two brackets 6 with at least two through holes 5 on the upper surface are respectively fixed on the two ends of the loading platform 1, and the upper surface of the loading platform 1 is provided with several Vs for placing colored optical fibers in parallel and alternately. Shaped groove 7, this V-shaped groove 7 is positioned between two brackets 6, and described bracket 6 is made up of cross bar 61, front support bar 62 and rear support bar 63 that are respectively fixed on the two ends of cross bar 61, after this support bar 63 all A counting induction probe 24 is arranged near the base and inside;

[0025] There is a strip pressing piece 8 directly below the cross bar 61 of the support 6, and a connecting bolt 9 com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com