Flame-burning-through-resistant machine and flame-burning-through-resistant floor used for flame-burning-through-resistant machine

A floor and flame technology, applied in aircraft floors, fuselage insulation, aircraft accessories, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical contents and technical effects of the present invention will be further illustrated by describing the embodiments below in conjunction with the accompanying drawings.

[0019] Explanation of technical terms:

[0020] The direction along the front and back of the aircraft is called "longitudinal"; the direction along the left and right of the aircraft is called "transverse"; taking the body as the reference, the outside and the bottom are the same side, and the inside and the top are the same side.

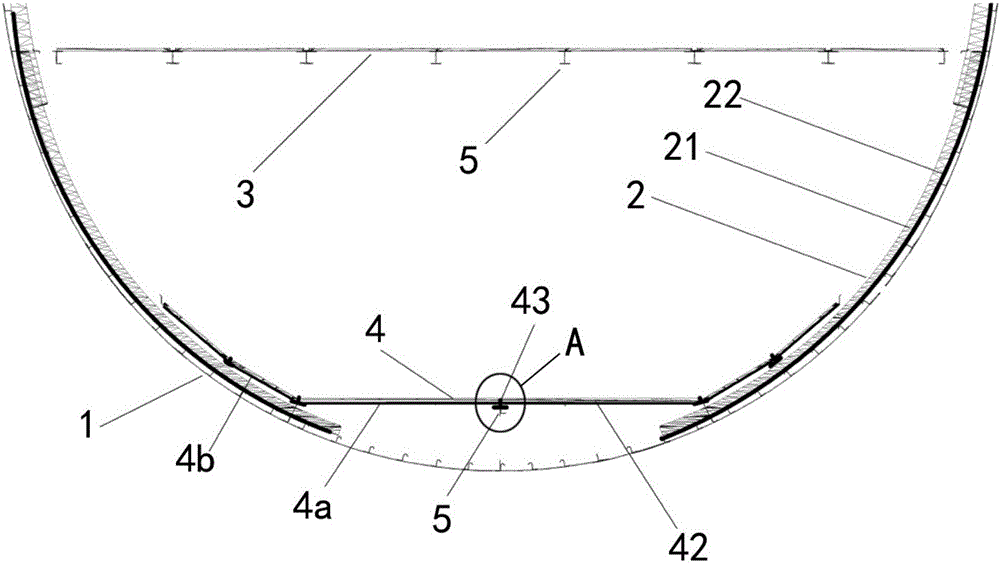

[0021] figure 1 The illustrated embodiment comprises a longitudinally extending passenger compartment floor 3 and a cargo compartment floor 4, which are of the same material and of the same construction, combined below figure 2 Taking the cargo compartment floor 4 as an example to describe the structure of the anti-flame burn-through floor adopted in the present invention.

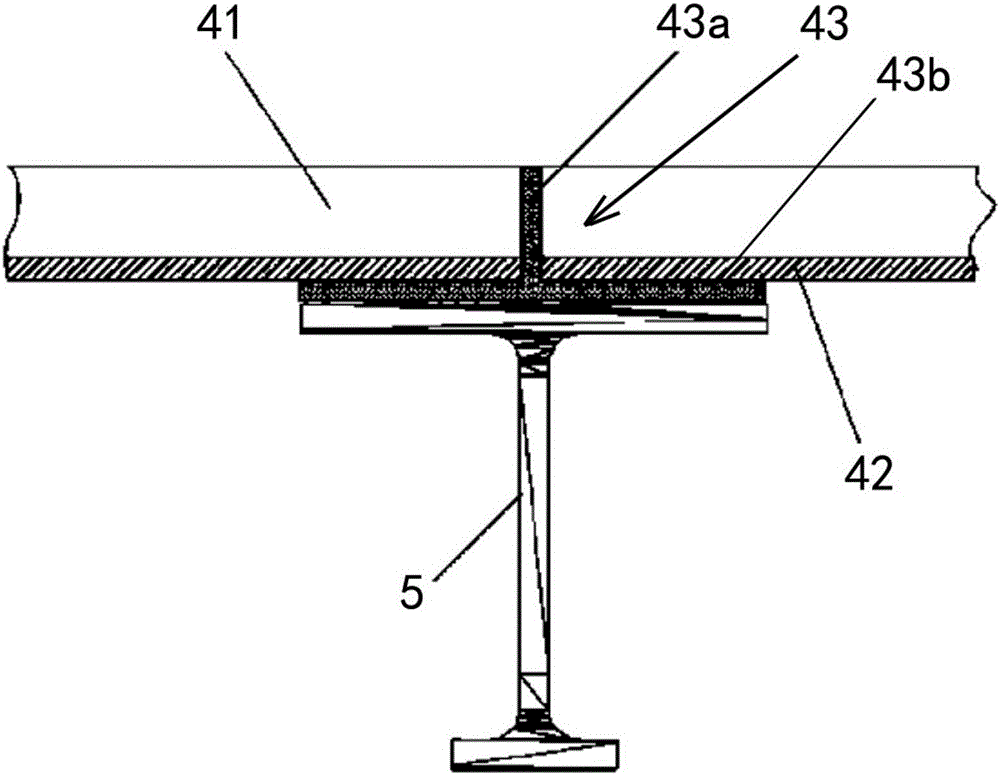

[0022] like figure 2 As shown, the cargo floor 4 extends longitudinally of the fus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com