Recyclable Single Polymer Floorcovering Article

a single-layer, polymer technology, applied in the field of tufted floorcovering articles, can solve the problems of increasing the number and increasing the cost of tufted carpet tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

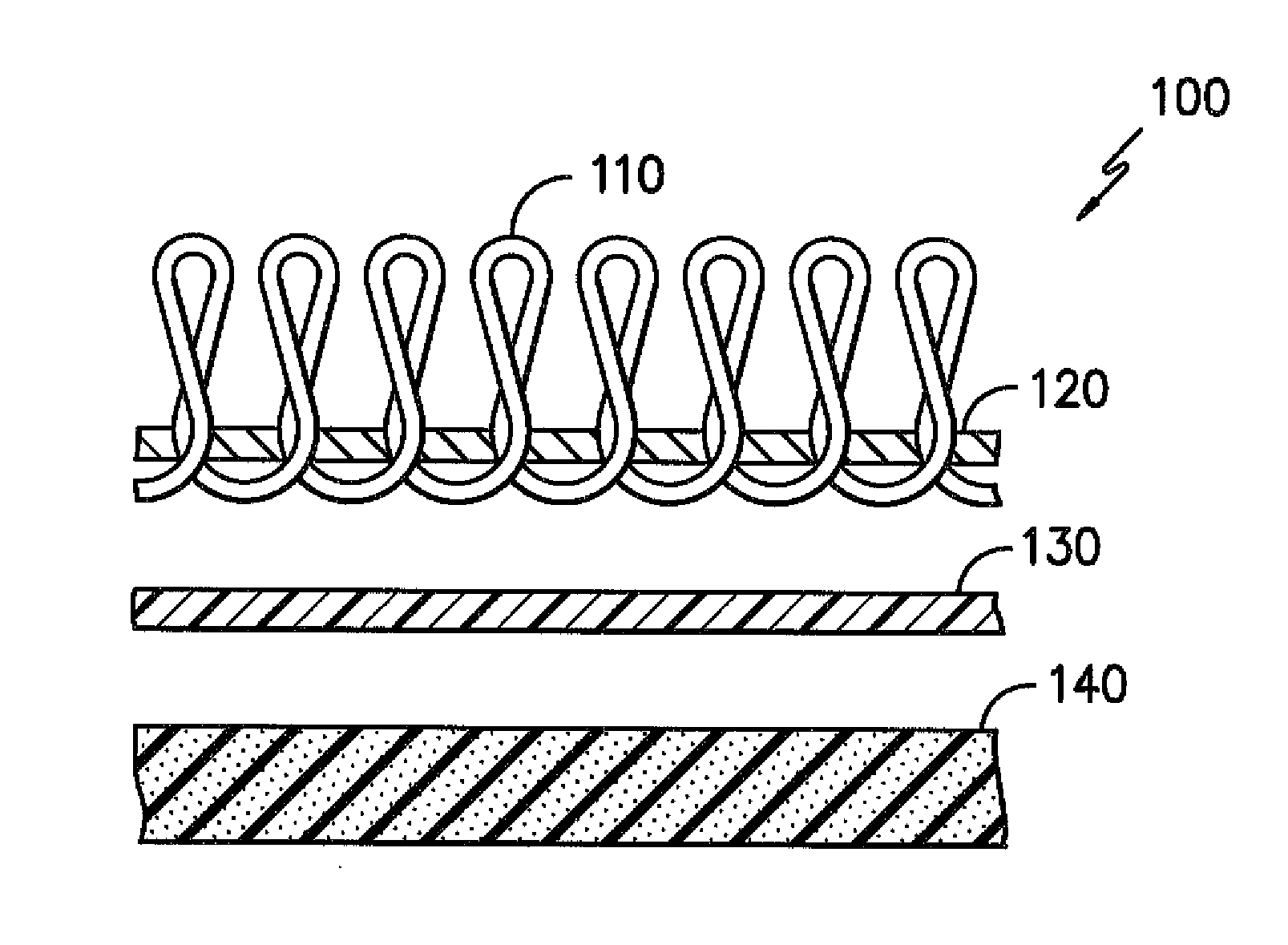

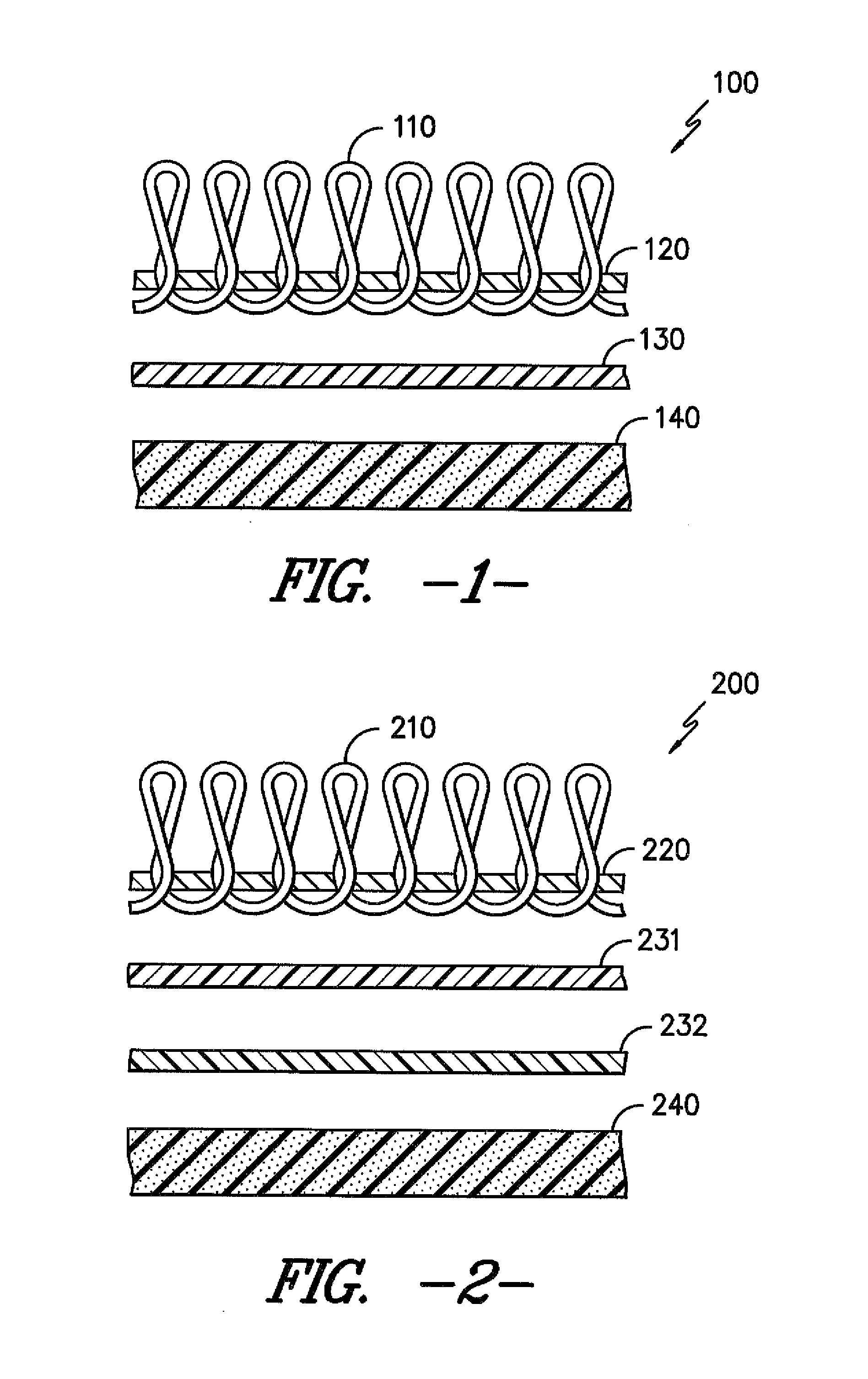

[0076]A floorcovering article comprised substantially of 100% polyester material was prepared as follows:

[0077]A base substrate was constructed of 40 oz / yd2 tufted polyester loop carpet containing a combination of semi-dull and bright yarns. The yarns were tufted through a 130 gsm polyester nonwoven primary backing layer from Freudenberg. The semi-dull yarn was 55% of the tufted face weight and the bright yarn was 45% of the tufted face weight. The yarns were arranged in alternating rows. The semi-dull yarn was a 2 ply, 2 ends per tufting needle, available from Pharr. The bright yarn was a 2 ply, 2 ends per tufting needle, available from Pharr. All yarn was in an undyed state. However, it should be noted that solution dyed yarn may optionally be used.

[0078]The tufted primary backing was scatter coated with EMS Griltex D1539 copolyester hot melt adhesive powder (melt viscosity of 100,000 cps at 160° C. measured per ISO 1133) from EMS Chemie of Domat, Switzerland. 5.8 oz / yd2 of adhesi...

example 2

[0079]The tufted primary backing used in Example 1 was scatter coated with EMS Griltex D1539 copolyester hot melt adhesive powder. 10 oz / yd2 of adhesive was applied. The sample was placed under an IR heater to sinter the adhesive. The carpet composite had good tuft bind (greater than 8 lbs). The Velcro roller fuzzing resistance was less than 2.

example 3

[0080]The tufted primary backing of Example 1 was scatter coated with EMS Griltex D1539 copolyester hot melt adhesive powder. 16 oz / yd2 of adhesive was applied. The sample was placed under an IR heater to sinter the adhesive. The carpet composite had good tuft bind (greater than 8 lbs). The Velcro roller fuzzing resistance was 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com