Sealed UV curable aqueous polyurethane resin and preparation method thereof

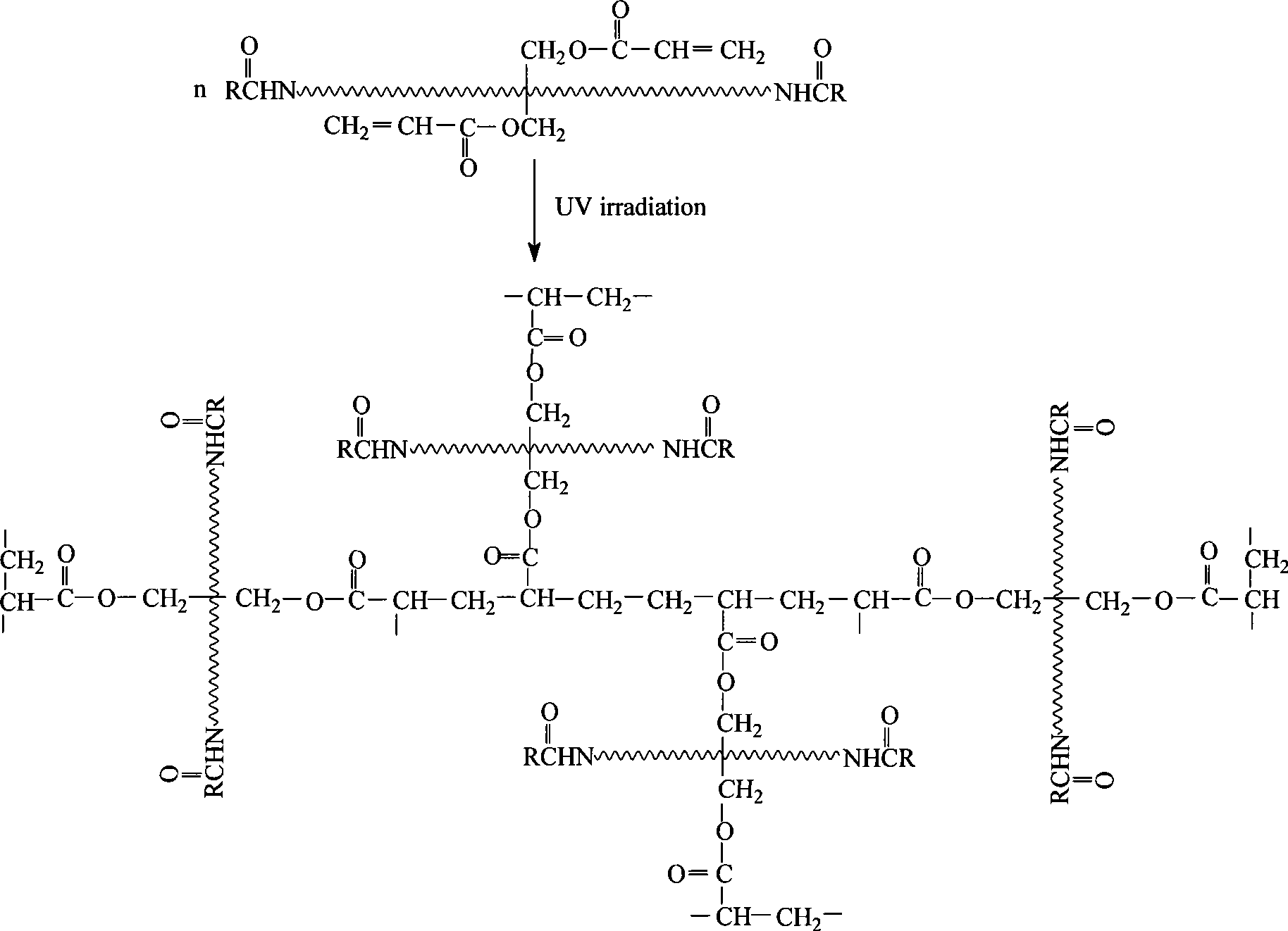

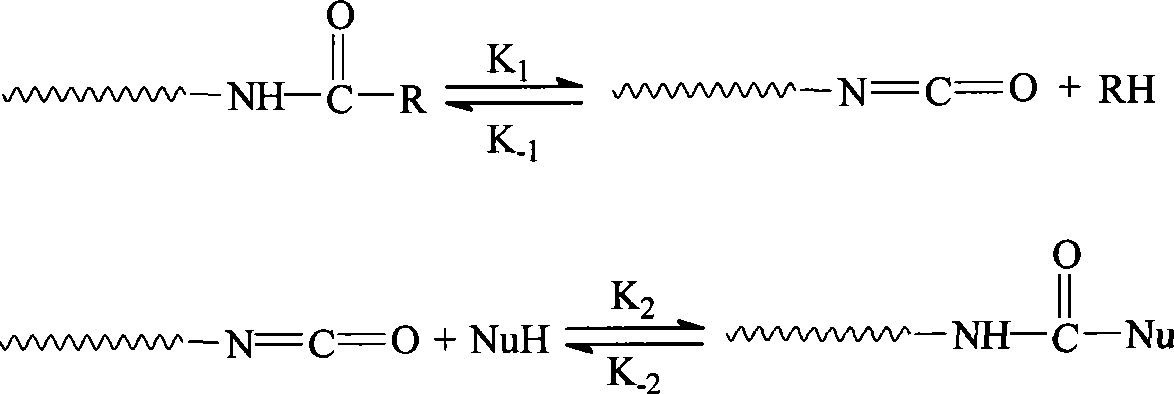

A technology of waterborne polyurethane and ultraviolet light, which is applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, adhesive types, etc. Large shrinkage and other problems, to achieve the effect of improving the degree of curing and adhesion, high hardness after curing, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Put 36.7 grams of PTMG in a 500ml three-necked flask, after dehydration at 100°C for 1.5 hours, add 47.9 grams of IPDI, stir and react at 100°C for 2 hours, then add 6.5 grams of hydrophilic chain extender DA, and stir at 90°C After reacting for 2 hours, add 22 grams of acetone, 45 grams of DPETA, 2.8 grams of p-methoxyphenol and 0.073 grams of dibutyltin dilaurate. After stirring at 80°C for 2 hours, add 4.5 grams of DAM and stir at 65°C. After 1.5 hours of reaction, transfer the reaction product to a high-speed shearing disperser, add 5 grams of triethylamine at 800 rpm and 40°C, react for 1 minute, then add 272 grams of water, and the UV can be obtained after 5 minutes Light-curable water-based polyurethane resin emulsion; transferred to a rotary evaporator, and acetone was removed under vacuum conditions of 40°C and 0.08MPa to obtain a closed UV-curable water-based polyurethane resin.

Embodiment 2

[0018] Put 35.8 grams of PJ in a 500ml three-necked flask, after dehydration treatment at 110°C for 1 hour, add 75.5 grams of MDI, stir and react at 80°C for 4 hours, then add 12.3 grams of hydrophilic chain extender DA, and stir at 60°C After reacting for 4 hours, add 55 g of butanone, 36.6 g of PEDA, 0.09 g of hydroquinone and 0.018 g of dibutyltin dilaurate. After stirring at 50°C for 4 hours, add 8.9 g of DMPM and stir at 50°C. After 3 hours, transfer the reaction product to a high-speed shearing disperser, add 9.5 g of triethylamine at 2000 rpm and 30°C, react for 2 minutes, then add 418 g of water, and get UV light after 1 minute Curing the water-based polyurethane resin emulsion; transfer it to a rotary evaporator, and remove butanone under vacuum conditions of 50°C and 0.08MPa to obtain a closed UV-curable water-based polyurethane resin.

Embodiment 3

[0020] Place 95 kg of PCD and HTTP mixture in any ratio in a 50L reactor. After dehydration treatment at 120°C for 0.5 hours, 64.8 kg of TDI is added. After reacting at 90°C for 3 hours, 8 kg of hydrophilic chain extension are added. Reagent DA, after reacting at 80°C for 1 hour, add 58.5 kg of acetone, 31.1 kg of TPMMA, 3 kg of BHT and 0.069 kg of dibutyltin dilaurate, stir and react at 65°C for 3 hours, then add 6.3 kg of PN After stirring and reacting at 60℃ for 2.5 hours, the reaction product was transferred to a high-speed shearing disperser, 6.5 kg of triethylamine was added at 4000 rpm and 20℃, and reacted for 3 minutes, and then 342 kg of water was added for 3 minutes Afterwards, the UV-curable waterborne polyurethane resin emulsion is obtained; the emulsion is transferred to a desolventizing kettle, and the acetone is removed under vacuum conditions of 60°C and 0.08MPa to obtain a closed UV-curable waterborne polyurethane resin.

[0021] If other conditions in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com