Transparent anti-ultraviolet heat insulating compound film and method for preparing the same

An anti-ultraviolet and composite film technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of high cost and poor quality of transparent film and glass surface film forming technology, and achieve good light transmission The effect of high efficiency, uniform film formation, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

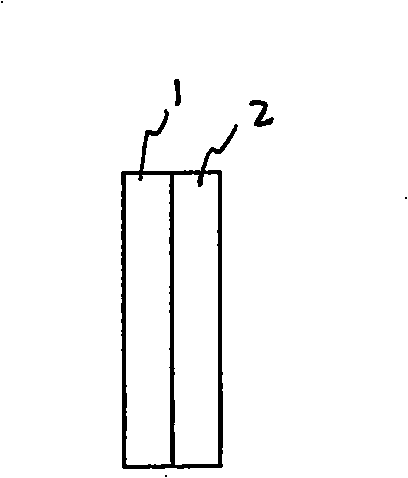

[0028] Example 1: PET-based transparent heat insulation film, refer to figure 1 , It is composed of a transparent film substrate 2 and a nano-transparent heat-insulating functional light-curing coating 1, and the thickness of the coating is 10 μm. The composition and structure of the heat insulation film are shown in Table 1:

[0029]

[0030] First, the above raw materials are defoamed and stirred by a vacuum stirrer, and then sanded and dispersed by a sand mill for use. Then the PET film is unwinded and tensioned by a special optical film coating machine, dust is removed, static electricity is removed and corona treated, and then passed through the net Grain roller transfer coating: apply the transparent heat-insulating coating on the surface of the PET substrate, preheat it in a segmented oven at 100°C for 1 min, and then cure it by an ultraviolet curing device for 1-30 seconds to form a nano transparent heat-insulating functional light-curing film on the PET substrate , Thi...

example 2

[0031] Example 2: PVC-based transparent insulation film, refer to figure 1 , It is composed of a transparent film substrate 2 and a nano-transparent heat-insulating functional light-curing coating 1, and the thickness of the coating is 10 μm. The composition and structure of the heat insulation film are shown in the following table 2:

[0032]

[0033]First, the above raw materials are defoamed and stirred by a vacuum stirrer, and then sanded and dispersed by a sand mill for use. Then, the PVC film is unwinded and tensioned by a special optical film coating machine, dust is removed, static electricity is removed and corona treated, and then passed through the net Grain roller transfer coating applies the transparent heat-insulating coating on the surface of the PVC substrate, preheating it in a segmented oven at 100°C for 1.5 minutes, and then curing it by an ultraviolet curing device for 15 seconds to form a nano-transparent heat-insulating functional light-curing film on the ...

example 3

[0034] Example 3: OPP-based transparent insulation film, refer to figure 1 , It is composed of a transparent film substrate 2 and a nano-transparent heat-insulating functional light-curing coating 1, and the thickness of the coating is 5 μm. The composition and structure of the heat insulation film are shown in Table 3 below:

[0035]

[0036]

[0037] First, the above raw materials are defoamed and stirred by a vacuum stirrer, and then sanded and dispersed by a sand mill for use. Then, the OPP film is unwinded and tensioned by a special optical film coating machine, dust is removed, static electricity is removed, and corona is treated. Grain roller transfer coating applies the transparent heat-insulating coating to the surface of the OPP substrate, preheating it in a segmented oven at 100°C for 1.3 minutes, and then curing it by an ultraviolet curing device for 30 seconds to form a nano-transparent heat-insulating functional light-curing film on the PET substrate. This kind ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com