Ultraviolet curing paint and preparation method and application thereof

A technology for curing coatings and ultraviolet light, applied in the direction of polyester coatings, polyether coatings, epoxy resin coatings, etc. Incompatibility, light transmittance drop and other problems, to achieve the effect of high hardness, high wear resistance, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

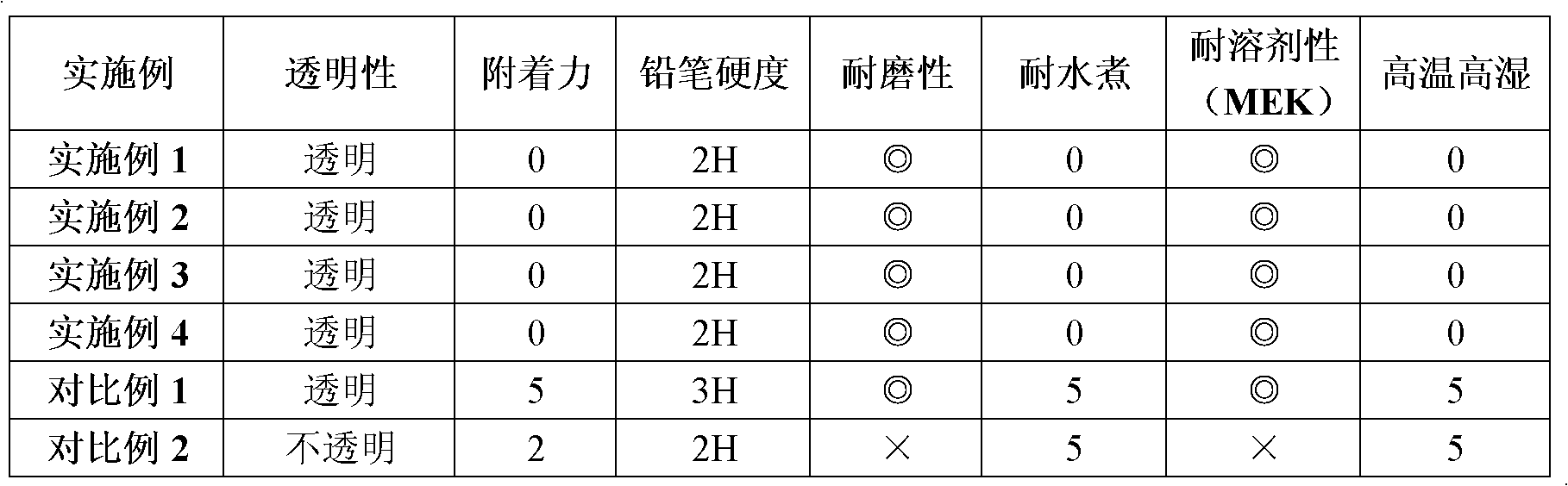

Examples

Embodiment 1

[0033] 100g SiO 2 Put the sol (30% solid content, pH=3) into a four-necked flask and stir at a constant speed, heat to 50°C, slowly add 20g of γ-methacryloxypropyltrimethoxysilane dropwise, keep warm for 5hr after the dropwise addition, and cool down to 20°C to obtain modified SiO 2 Sol.

[0034] Take 50g modified SiO 2 Sol, add 15g of water-soluble polyurethane acrylate, 25g of deionized water, 8g of ethylene glycol butyl ether, 0.1g of leveling agent BYK333 (produced by Germany BYK) under stirring, mix for 10min, then add 2g of 2-hydroxy-2 -Methyl-1-phenyl-1-propanone, stirred for 5 minutes to obtain a UV-curable coating.

Embodiment 2

[0036] 100g SiO 2 Put the sol (solid content 30%, pH=2) into a four-neck flask and stir at a constant speed, heat to 60°C, slowly add 20g of vinyltrimethoxysilane dropwise, keep warm for 3hr after the dropwise addition, and cool down to 24°C to obtain modified SiO 2 Sol.

[0037] Take 80g modified SiO 2 Sol, add 10g water-soluble epoxy acrylate, 5g absolute ethanol, 2g propylene glycol methyl ether, 0.1g leveling agent BYK333 (produced by German BYK company) under stirring, mix for 10min, then add 2g 1-hydroxyl-cyclohexyl Benzophenone was stirred for 5 minutes to obtain a UV-curable coating.

Embodiment 3

[0039] 120g SiO 2Put the sol (solid content 25%, pH=4) into a four-necked flask and stir at a constant speed, heat it to 40°C, slowly add 10g of vinyltriethoxysilane dropwise, keep it warm for 6hrs after the dropwise addition, and cool down to 26°C to obtain modification SiO 2 Sol.

[0040] Take 50g modified SiO 2 Sol, add 15g of water-soluble polyether acrylate, 25g of methanol, 8g of isopropanol, 0.1g of leveling agent BYK333 (produced by German BYK company) under stirring, mix for 10min, then add 2g of 2,4,6-trimethyl Benzoyl diphenylphosphorus oxide was stirred for 5 minutes to obtain a UV-curable coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com