Waterborne wear-resisting ultraviolet-cured glazing oil and preparation method thereof

An ultraviolet light, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of slow drying speed, poor surface adhesion of printed matter, poor water resistance, etc., to improve work efficiency, enhance initial viscosity, and increase water resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

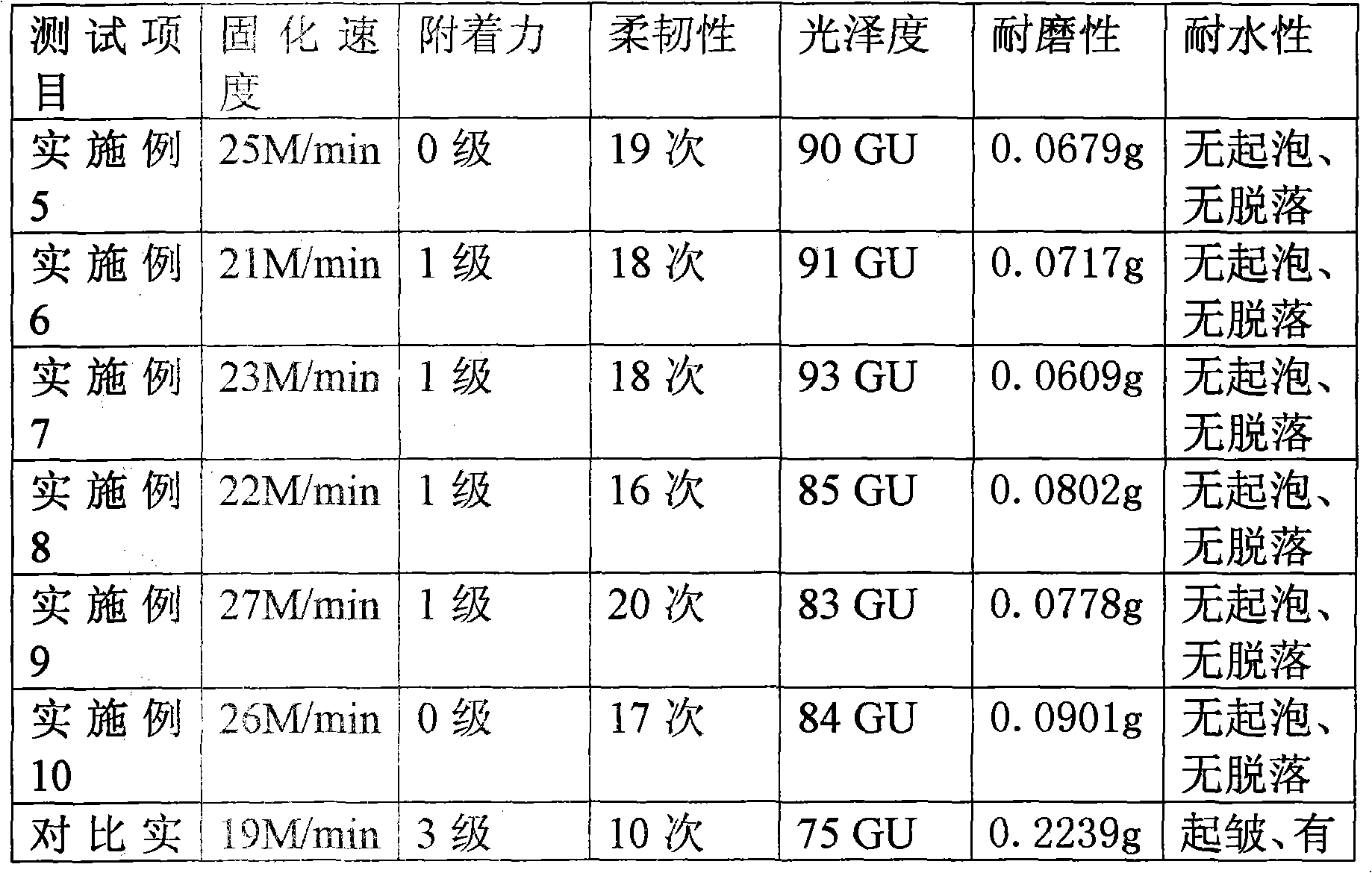

Examples

Embodiment 1

[0039] Embodiment 1: Preparation of modified polyurethane acrylate anionic waterborne resin

[0040] Under the protection of dry nitrogen, add 0.8 mol of KH-550 and 0.7 mol of epoxy resin E51 into a four-neck flask, mix well, and react at 25°C for 3 hours. Then, under the protection of nitrogen, add 4.5mol of isophorone diisocyanate, 0.35mol of vacuum dehydrated polybutylene adipate diol (molecular weight is 1000), dimethylolpropionic acid of 1.8mol, 0.0003mol Dibutyltin dilaurate and 3mol butanone, react for 2 hours, heat up to 75°C, add 0.45mol of diethylene glycol and 0.35mol of trimethylolpropane, react for 1.5 hours, add 0.7mol of hydroxyethyl acrylate Ester, 0.4mol pentaerythritol triacrylate and 0.002mol p-hydroxyanisole were reacted for 2 hours, cooled to 45°C, added 1.4mol triethylamine, stirred for 20min, butanone was removed under reduced pressure, and the material was discharged. The modified polyurethane acrylate anionic water-based resin is obtained.

Embodiment 2

[0041] Embodiment 2: Preparation of modified polyurethane acrylate anionic waterborne resin

[0042]Under the protection of dry nitrogen, 1.2 mol of KH-602 and 1.1 mol of epoxy resin E44 were added into a four-neck flask, mixed evenly, and reacted at 25°C for 3 hours. Then, under the protection of nitrogen, add 3.5 mol of isophorone diisocyanate, 2 mol of 2,4-xylene diisocyanate, 0.5 mol of polypropylene glycol (molecular weight is 2000) of vacuum dehydration, 2.2 mol of dimethylol butyric acid , 0.0005mol dibutyltin dilaurate and 5mol butanone, react for 2 hours, heat up to 75°C, add 0.5mol triethylene glycol and 0.45mol pentaerythritol, react for 1.5 hours, add 1.1mol hydroxyethyl acrylate React with 0.5mol pentaerythritol triacrylate and 0.005mol p-hydroxyanisole for 2 hours, cool down to 45°C, add 1.8mol dimethylethanolamine, stir for 20min, remove methyl ethyl ketone under reduced pressure, and discharge. The modified polyurethane acrylate anionic water-based resin is ob...

Embodiment 3

[0043] Example 3: Preparation of modified polyurethane acrylate cationic water-based resin. Under the protection of dry nitrogen, add 0.3 mol of KH-902, 0.7 mol of KH-113 and 0.9 mol of epoxy resin E51 into a four-necked bottle, and mix well , reacted at 25°C for 3 hours. Then, under nitrogen protection, add 2mol methylcyclohexyl diisocyanate, 3mol isophorone diisocyanate, 0.4mol polyethylene adipate diol (molecular weight is 1800) of vacuum dehydration, 2mol N-methyl Diethanolamine, 0.0003mol dibutyltin dilaurate and 6mol butanone were reacted for 2 hours, the temperature was raised to 75°C, 0.18mol of 1,2-propanediol, 0.3mol of neopentyl glycol and 0.4mol of trihydroxypropane were added, and the reaction After 1.5 hours, add 1.0mol of hydroxyethyl acrylate, 0.45mol of pentaerythritol triacrylate and 0.004mol of p-hydroxyanisole, react for 2 hours, cool down to 40°C, add 1.6mol of glycolic acid, stir for 30min, remove butanone under reduced pressure ,Discharge. The modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com