Production process for improving production intensity of propionic acid

A technology of production intensity and production process, which is applied in the field of microbial fermentation to produce propionic acid, can solve problems such as regardless of product production intensity, and achieve the effects of increasing production intensity, increasing output, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] 1. Seed culture method: Inoculate the preserved glycerol tube strain: P.acidipropionici CGMCC1.2230 in an anaerobic bottle according to the inoculation amount of 1% (250 mL anaerobic bottle with 200 mL seed medium) After the anaerobic bottle was evacuated with a vacuum pump, it was placed in a 30°C incubator and incubated for 48 hours.

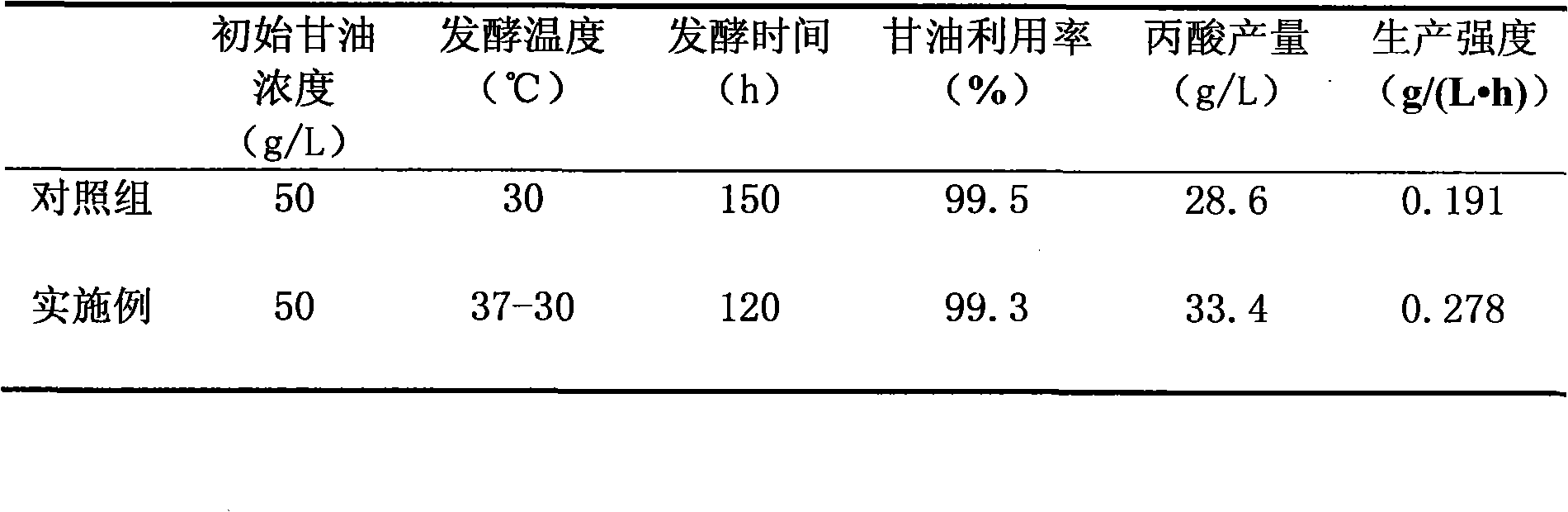

[0023] 2. Fermentation tank culture conditions: the seeds cultivated to the logarithmic phase are inoculated in a 7L fermenter (4L liquid capacity) for fermentation according to the 10% inoculum size, and 10% (w / v) Ca(OH) is added by feeding. The pH was maintained at 7.0, the stirring speed was 200rpm, and the temperature control strategy was adopted for fermentation. The temperature was controlled at 37°C for the first 72 hours, and then changed to 30°C for 72 hours. Samples were taken every 6 hours to measure the content of propionic acid, and the production intensity was calculated. Intermittent before and after each sampling Nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com