High-speed cross-belt sorting and conveying machine control system

A cross-belt sorting and control system technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., to achieve the effect of optimizing the electrical installation structure, improving maintainability, control performance and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

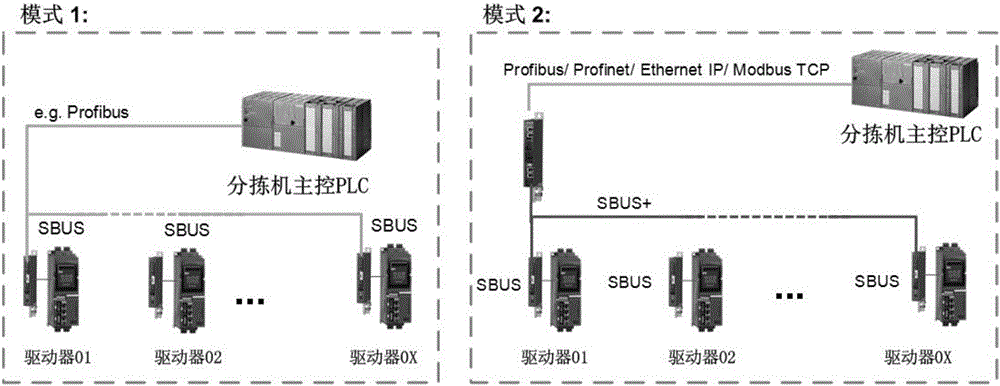

Method used

Image

Examples

Embodiment Construction

[0025] In order to better describe the above purpose and features of the present invention, the following drawings will further elaborate the present invention in detail.

[0026] In the following description, some specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways than those described here, therefore, the present invention is not limited to the specific examples disclosed below.

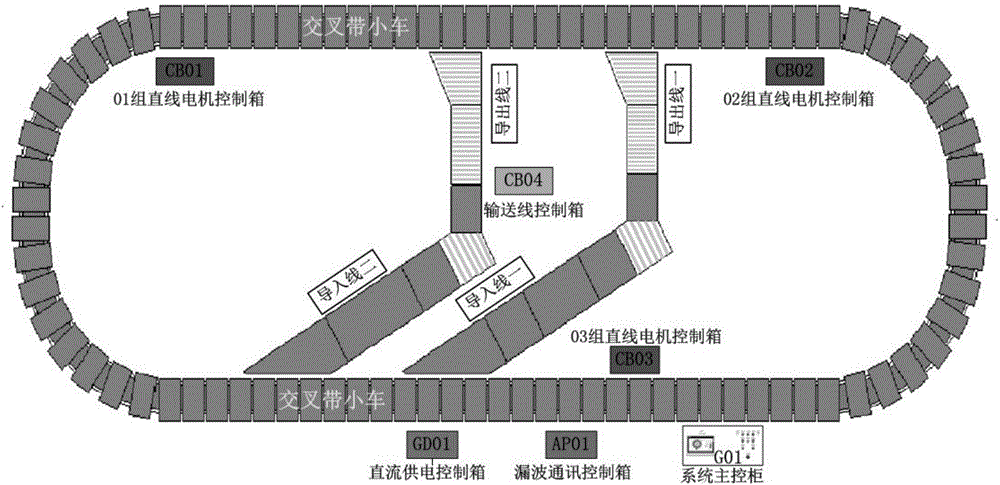

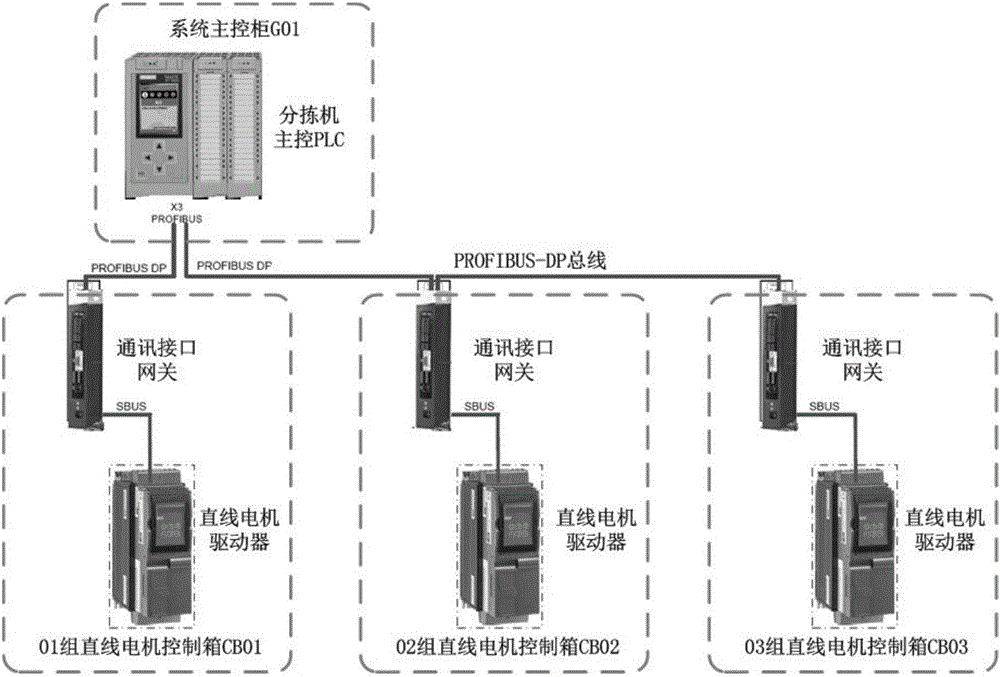

[0027] refer to figure 2 , the example of this invention is a set of cross-belt sorting and conveying system consisting of 90 cross-belt trolleys, 2 sets of import and export conveyor lines, 3 sets of SLC synchronous linear motors and several control cabinets. The structure includes: as the main control The system main control cabinet G01 of the unit, the DC power supply control box GD01 used to provide the power of the trolley, the leaky wave communication control box AP01 used to provide the leaky wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com