Method for harmlessness treatment of waste mineral oil by blast furnace injection mode

A technology for waste mineral oil and waste disposal. It is applied in blast furnace, hydrocarbon oil treatment, blast furnace details, etc. It can solve the problems of ineffective treatment of residues, environmental pollution and air pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

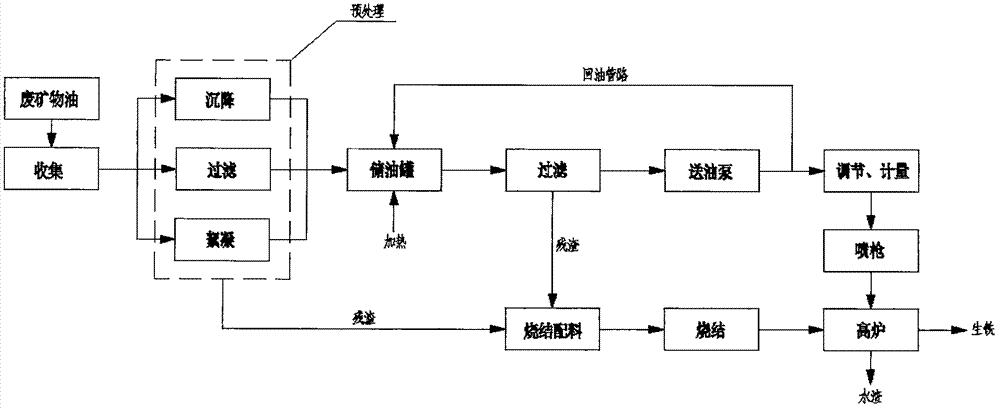

[0019] The method for the harmless disposal of waste mineral oil by means of blast furnace injection is described in detail below in conjunction with the accompanying drawings:

[0020] As shown in the attached figure: Firstly, the waste mineral oil is classified and collected, and then the collected waste mineral oil is pretreated. According to the actual situation of the waste mineral oil, one or several methods of sedimentation, filtration and flocculation are used in combination. Pretreat the waste mineral oil; the pretreated waste mineral oil is sent to the blast furnace oil storage tank by tank truck or pipeline; the oil storage tank has a heating device to heat the waste mineral oil to 90-100 °C. When the blast furnace is blown, the oil delivery pump pumps the waste mineral oil out of the oil storage tank and pressurizes it. Before the waste mineral oil is pressurized, it is filtered again to ensure that the pipeline and nozzle will not be blocked. The pressurized waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com