Roller compacted concrete full package chute vertical conveying technology

A technology of roller compacted concrete and concrete, which is used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., to achieve the effect of small loss of VC value, low cost and strong continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

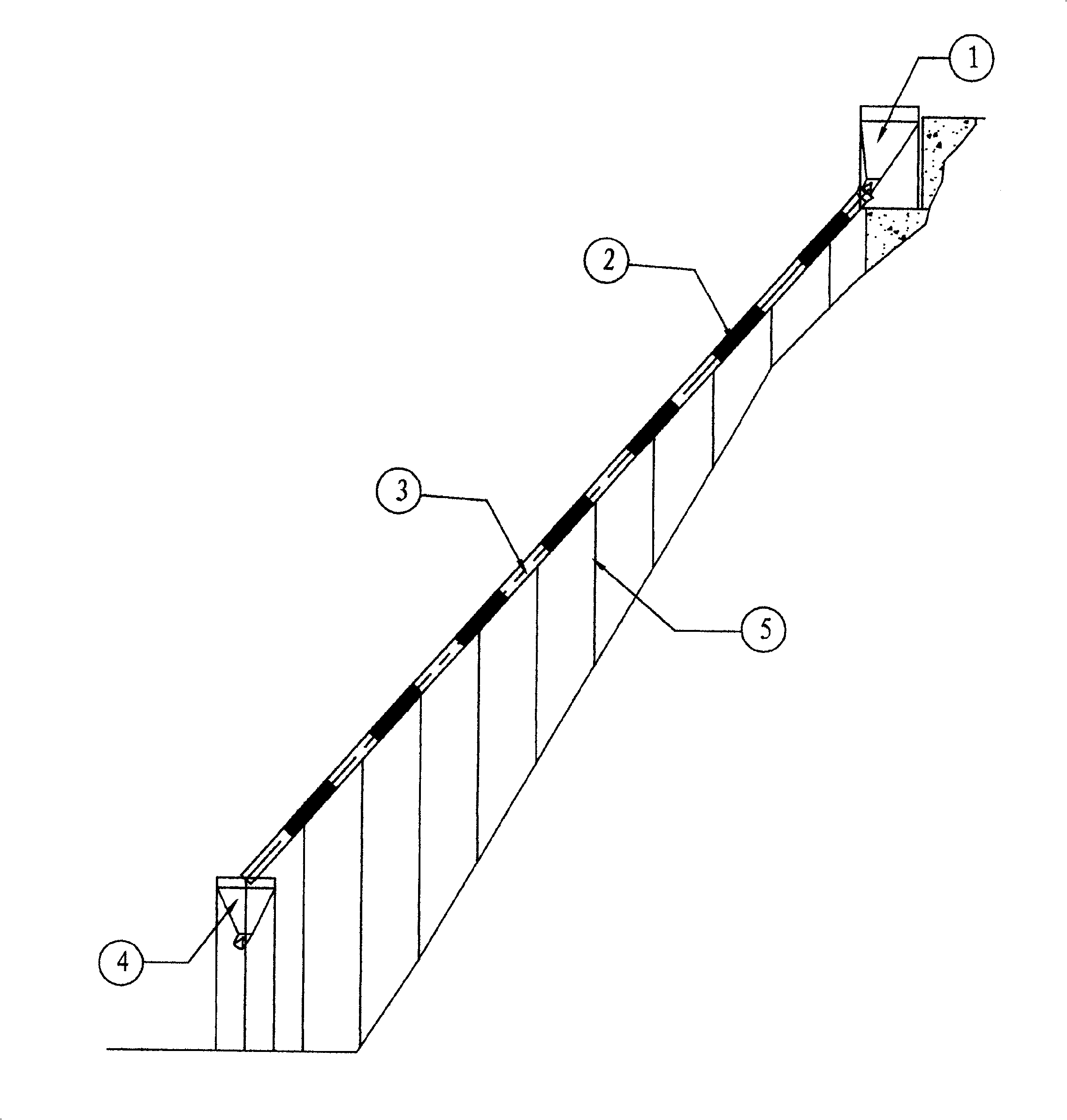

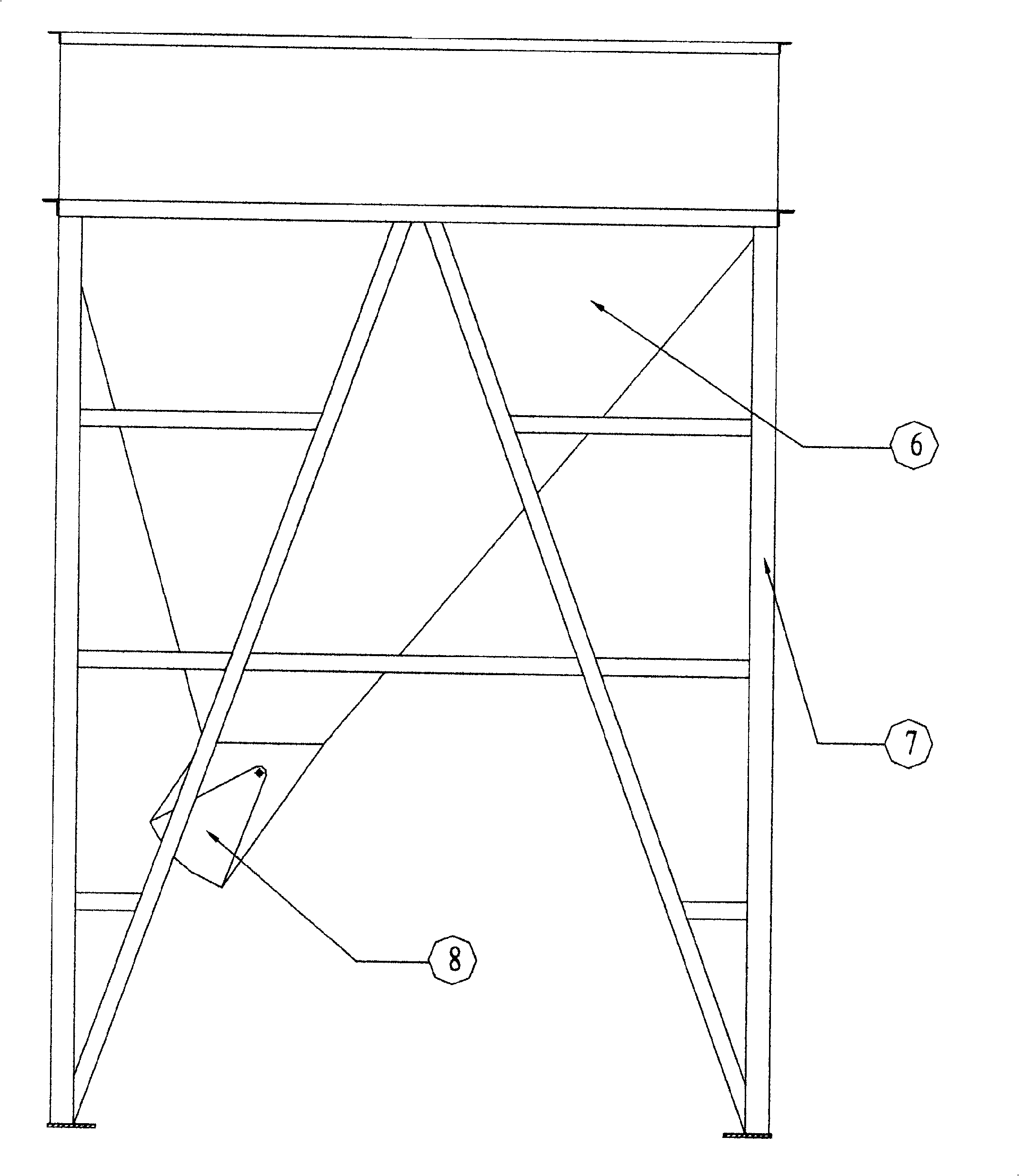

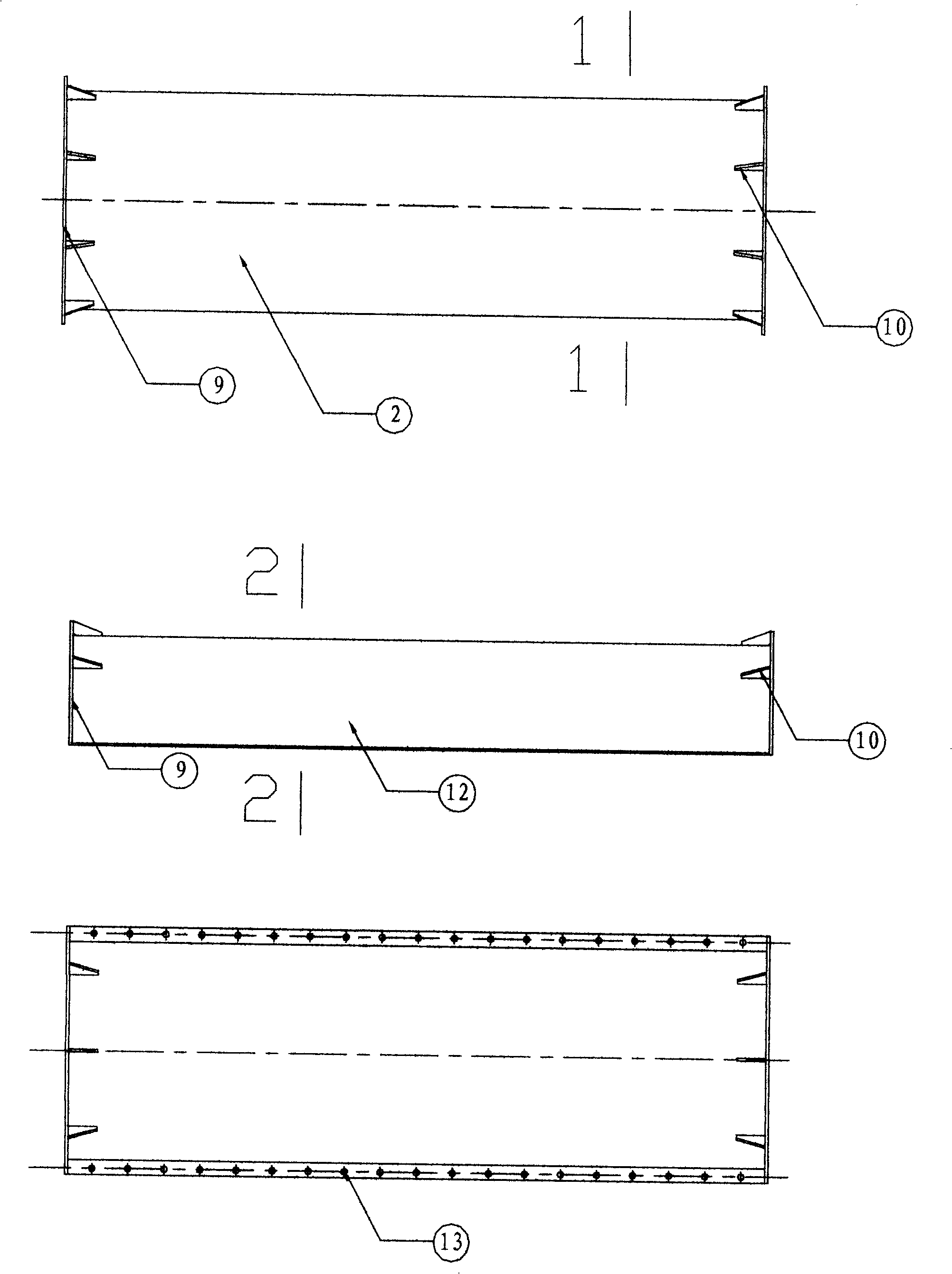

[0013] like figure 1 The volume of the upper storage box 1 shown is 8.6m 3 ; The diameter of the full-pipe chute full cylinder 2 and the full-pipe chute maintenance cylinder 3 is D = 600mm, which is a circular cross section, and the length of a single section is 1950mm / section, and two sections are removed for every 3.0m increase in the pouring height; the lower storage Box 4 volume is 3.6m 3 The support frame 5 is a 2-inch steel pipe; the receiving hopper 6 is a 6mm steel plate; the receiving hopper support frame 7 is ∠100×10 steel; the inlet and outlet arc door 8 is a pneumatic arc door; the connecting plate 9 is a 6mm steel plate; the rib plate 10 is 6mm Steel plate; bolt hole 11 is φ170; semicircular inspection cylinder 12 is composed of two R=300mm semi-cylinders; bolt hole 13 is φ170.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com