Ultra-high-performance concrete prefabricating and splicing integration pipe gallery system and construction method

An ultra-high-performance, integrated pipe gallery technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of transportation, hoisting difficulties, self-heavy unit length, short segment length, etc., and reduce comprehensive production costs. , The construction method is simple, and the effect of reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

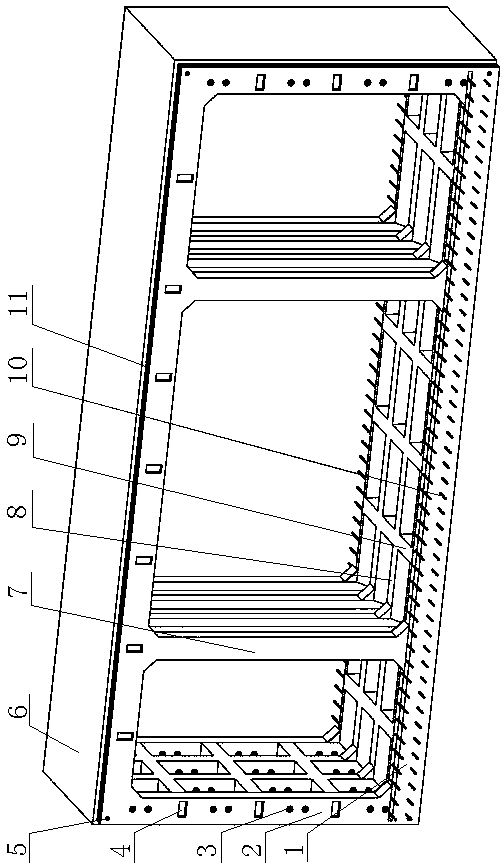

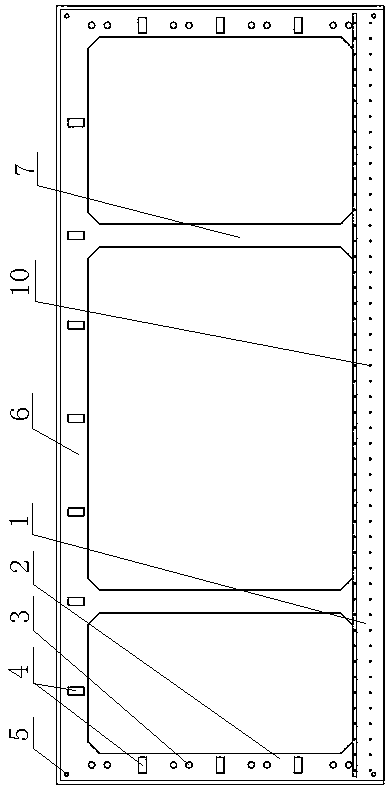

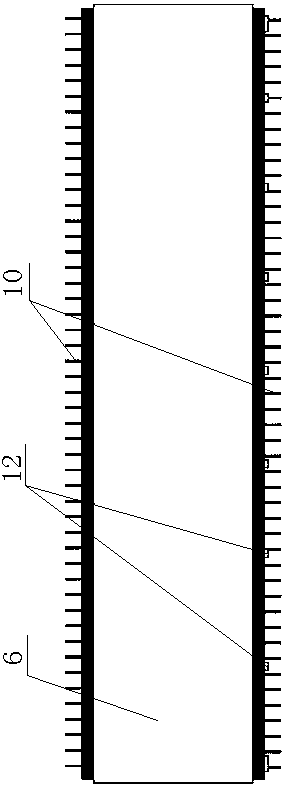

[0049] refer to Figure 1~10 Summary of the invention: A kind of ultra-high performance concrete prefabricated and assembled comprehensive pipe gallery system of the present invention is assembled by several prefabricated segments, the prefabricated segments are prepared by ultra-high performance concrete, and the prefabricated segments are composed of side plates 2 and bottom plates 1 , top plate 6 and partition plate 7, adjacent prefabricated segment connection slots are lapped with ultra-high performance concrete patch 13.

[0050] The prefabricated segment is prefabricated in the factory as a whole, the length of the prefabricated segment is 1.0m~4.5m, the inner side of the side plate 2, the bottom plate 1 and the top plate 6 are waffles composed of longitudinal ribs 9, transverse ribs 8 and plates Plate structure; the thickness of the side plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com