Design and construction method of rigid-flexible composite anti-seepage recoverable supporting structure

A support structure, rigid-flexible composite technology, applied in infrastructure engineering, excavation, construction, etc., to achieve the effect of high recycling value, easy recycling, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

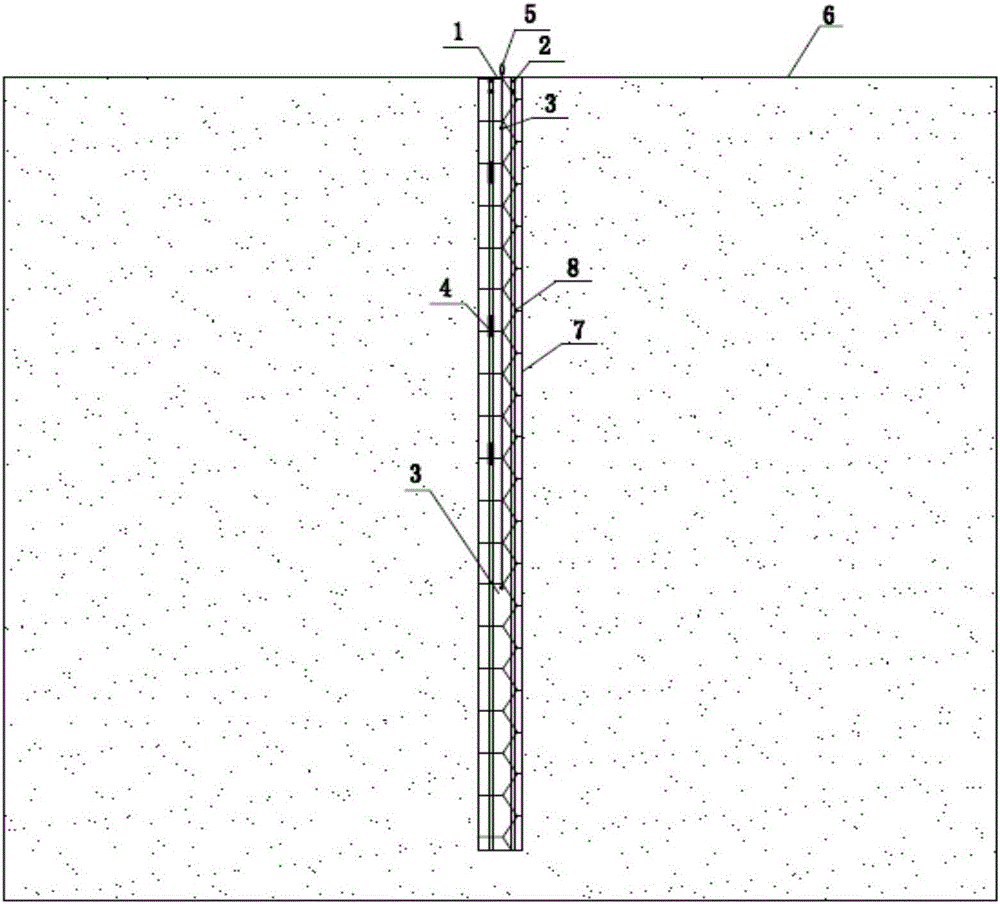

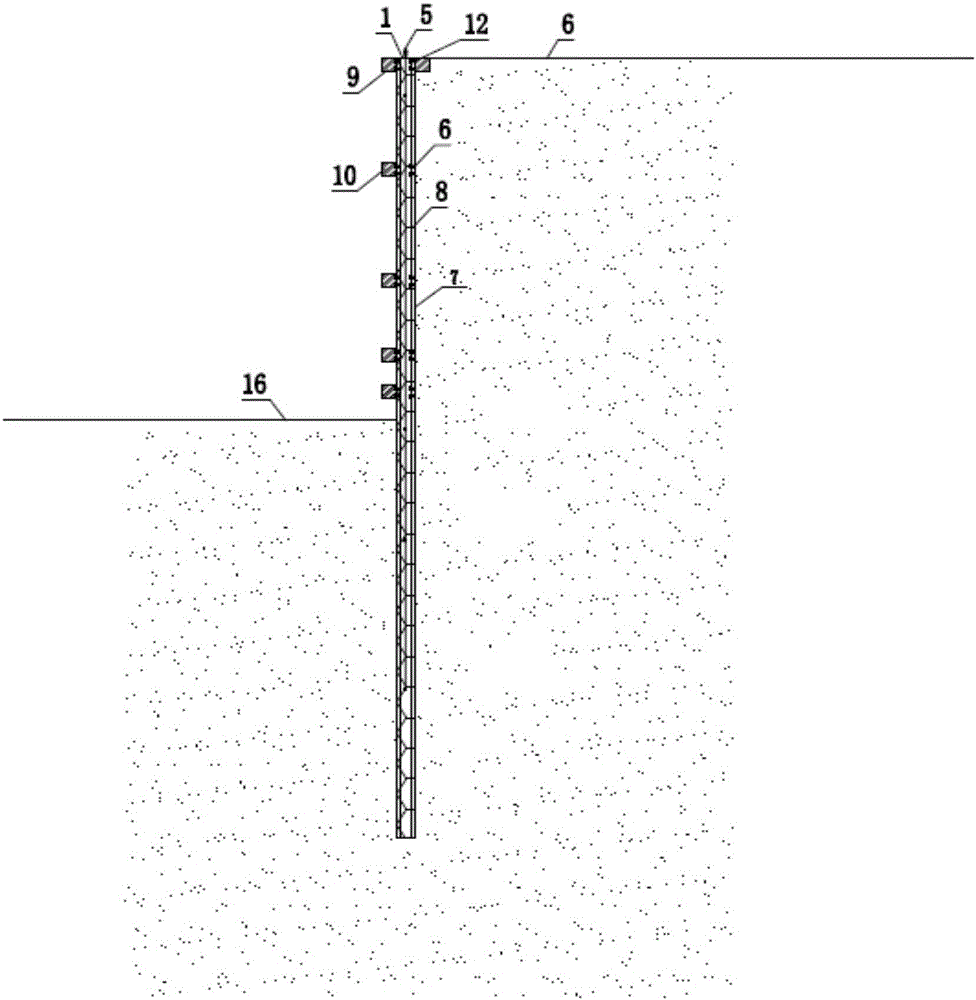

[0049] The present invention will be further described below in conjunction with accompanying drawing.

[0050] A design and construction method for a rigid-flexible composite anti-seepage recyclable support structure, characterized in that, in the foundation pit support structure, the concept of mechanical manufacturing and standardized production is introduced for the first time. construction of the supporting structure. The construction process specifically includes the following steps:

[0051] (1) Construction of section steel slope protection piles, the specific steps are as follows:

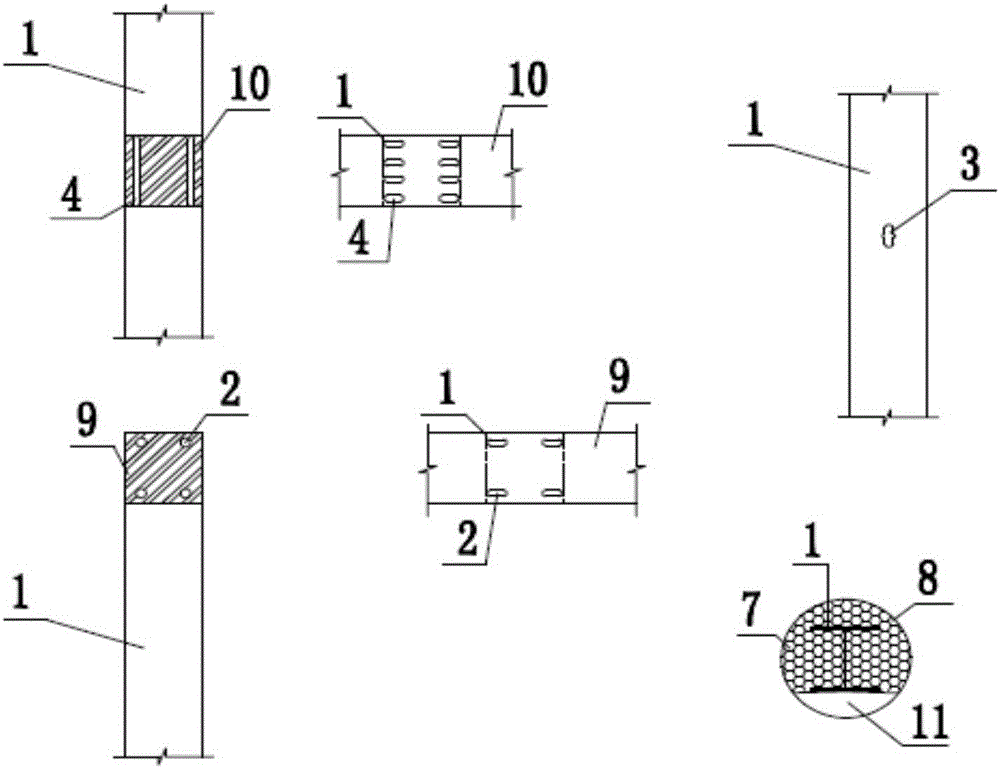

[0052] (1) Processing of section steel slope protection piles: According to the design requirements, the crown beam installation hole 2 and the waist beam installation hole 4 are processed on the top of the section steel pile 1 and the corresponding position of the waist beam, and the hoisting hole 3 for later recovery is processed and penetrated Recovery steel cable 5, such as figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com