Blast furnace big data application system

An application system and big data technology, applied in data processing applications, special data processing applications, blast furnaces, etc., can solve the problems of underutilization of ironmaking data, blanks in intelligent manufacturing, etc., to improve effectiveness and practicability, improve Effectiveness of mastery, improved operations and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

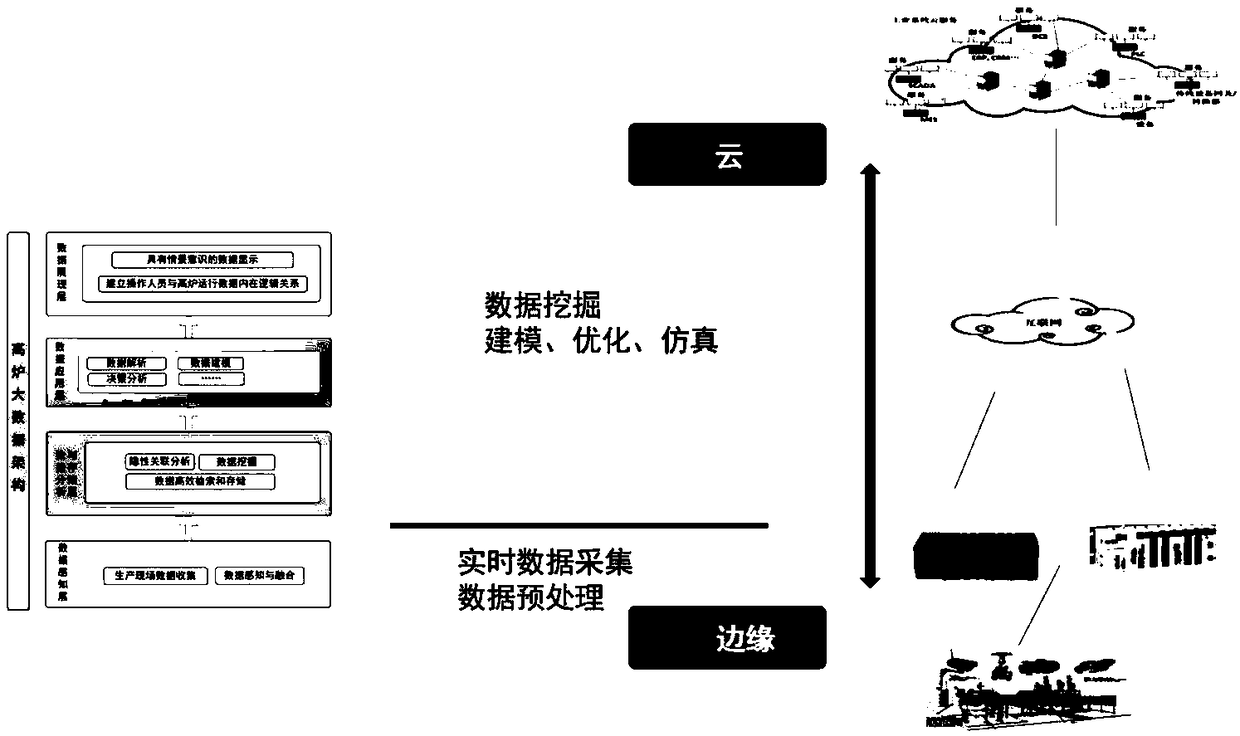

[0033] Such as Figure 1A with Figure 1B as shown, Figure 1B for Figure 1A In the enlarged schematic diagram on the left side, the network architecture of the blast furnace big data application system in this embodiment is based on the edge computer-blast furnace private cloud. Real-time data collection and data preprocessing of blast furnace production are completed by the edge computer, and blast furnace big data analysis and mining, blast furnace mechanism modeling and digital simulation, blast furnace process analysis and prediction, and autonomous learning are performed on the blast furnace private cloud.

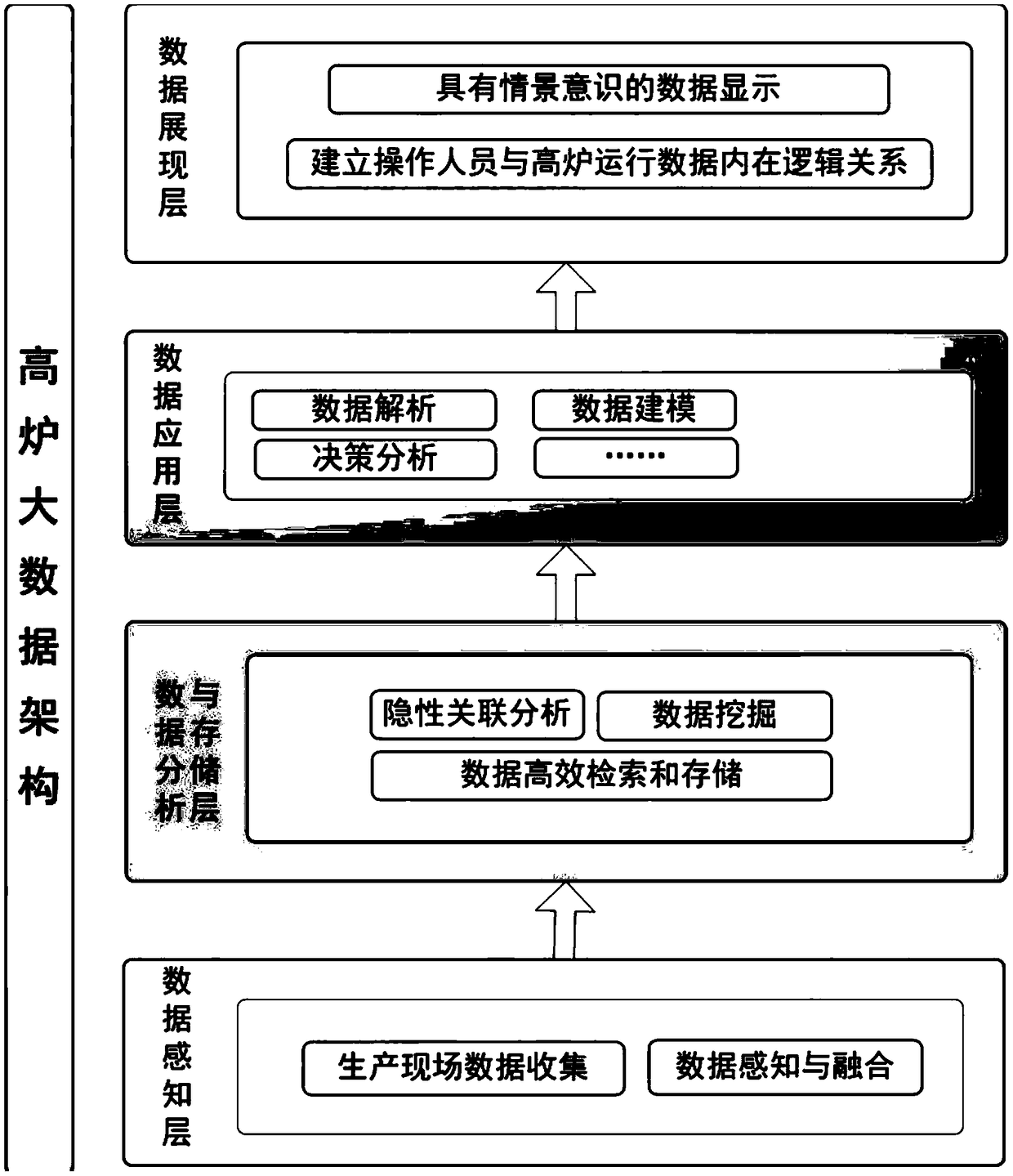

[0034] In terms of layer data analysis, the business architecture of the blast furnace big data application system in this embodiment can be composed of a data perception layer, a data analysis and storage layer, a data application layer, and a data presentation layer. Among them, the data perception layer obtains the data obtained by the edge computer in a two-way...

Embodiment 2

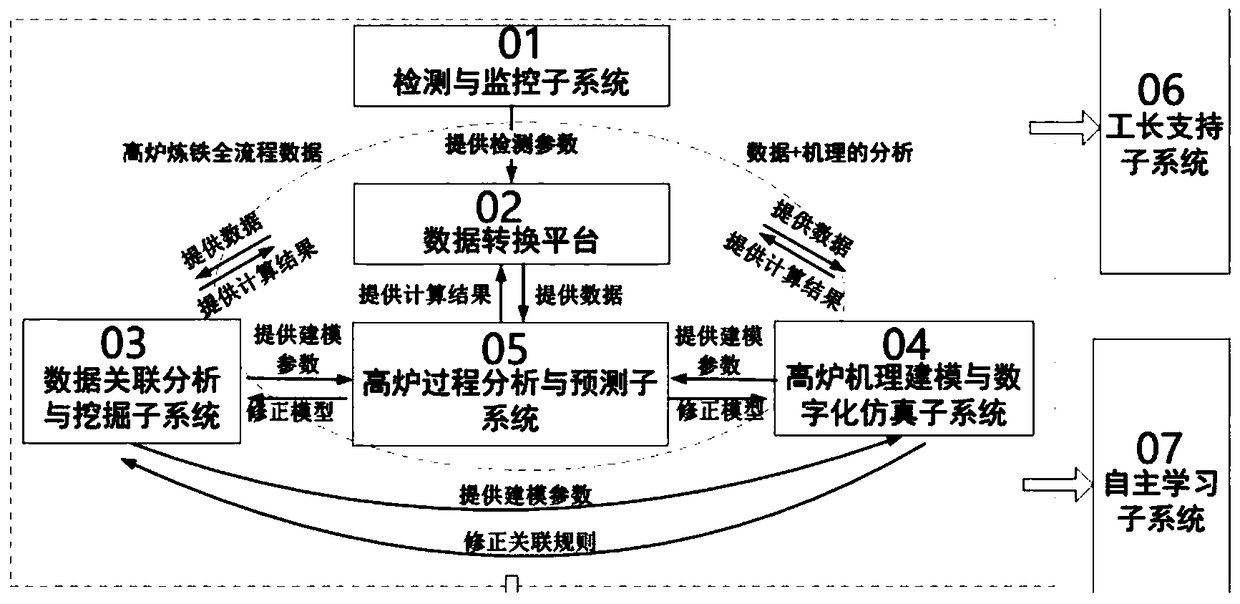

[0053] Such as figure 2 As shown, the blast furnace big data application system includes: detection and monitoring subsystem 01, data conversion platform 02, data association analysis and mining subsystem 03, blast furnace mechanism modeling and digital simulation subsystem 04, blast furnace process analysis and prediction subsystem 05 , Foreman support subsystem 06, data-based autonomous learning subsystem 07.

[0054] Among the above subsystems, detection and monitoring subsystem 01 and data-based autonomous learning subsystem 07 are implemented by edge computers, data association analysis and mining subsystem 03, blast furnace mechanism modeling and digital simulation subsystem 04, blast furnace process analysis and prediction Subsystem 05 is deployed in the blast furnace private cloud.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com