Very-high performance concrete prefabricated assembled pipe gallery and construction method

An ultra-high-performance, prefabricated assembly technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., to achieve the effects of good durability, material saving, and convenient hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

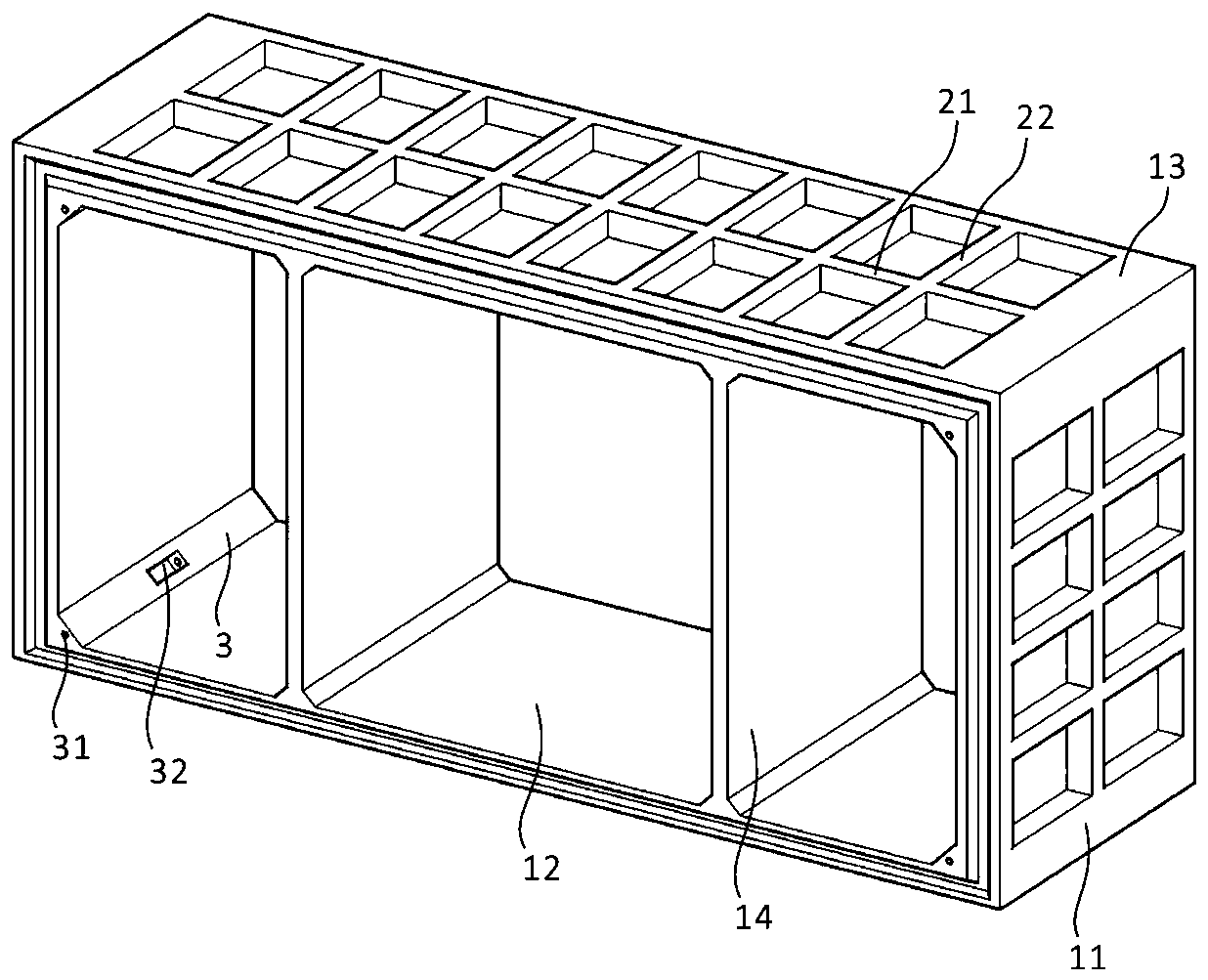

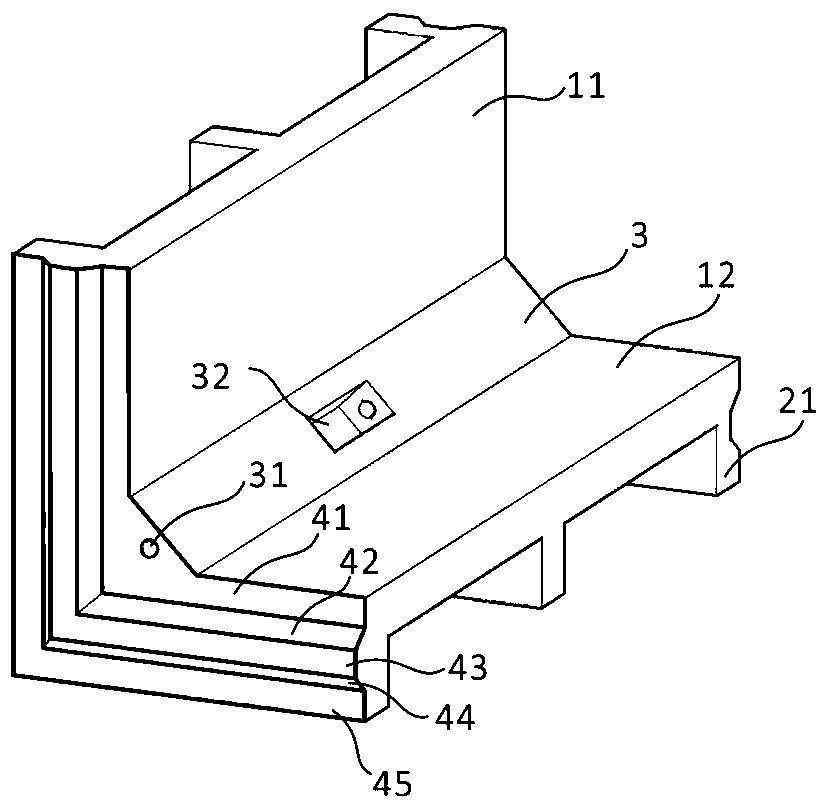

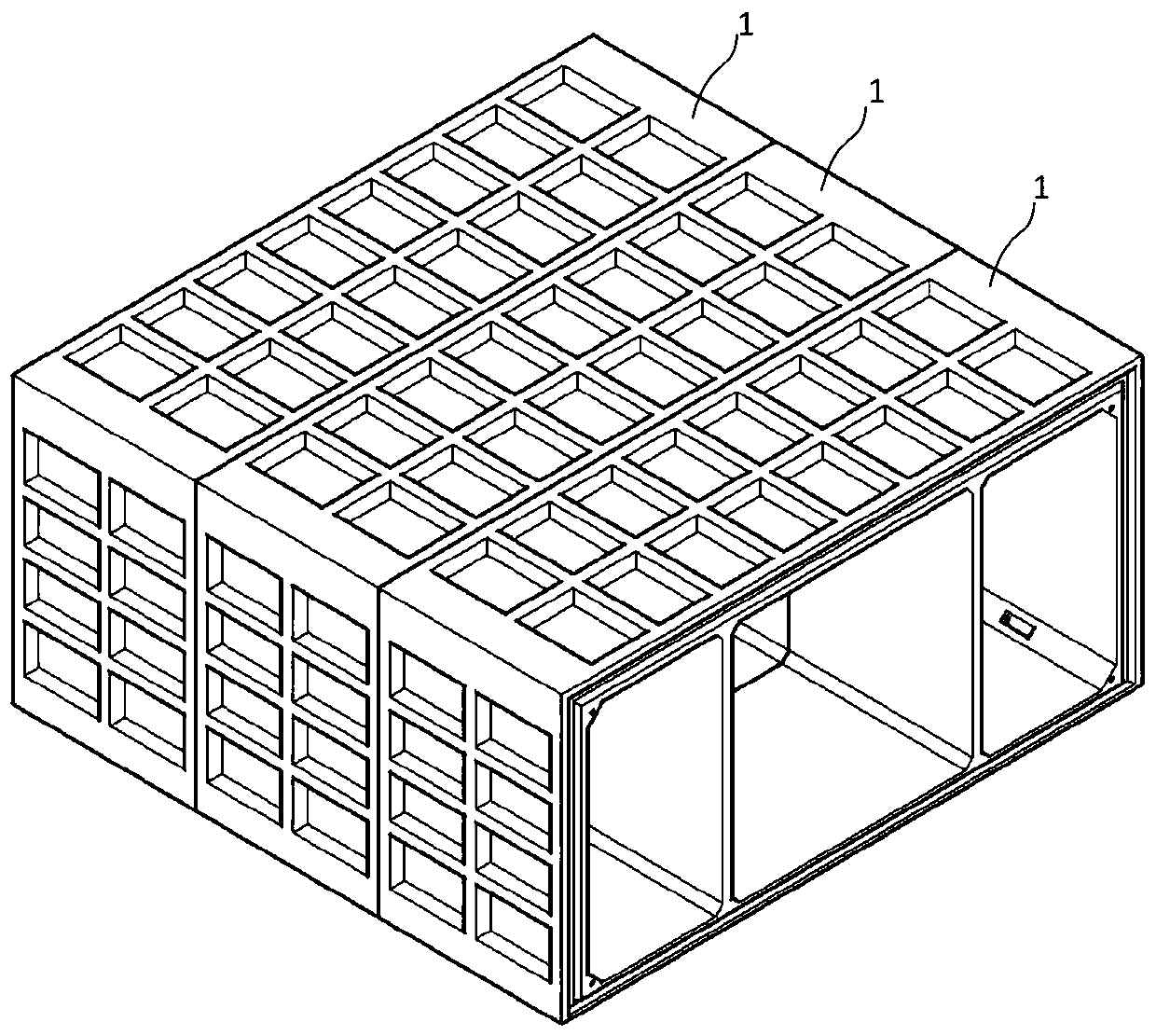

[0036] Such as figure 1 , figure 2 , image 3 As shown, an ultra-high-performance concrete prefabricated integrated pipe gallery is assembled from several ultra-high-performance concrete integrally formed rectangular culvert units 1 with front and rear sockets; the rectangular culvert unit 1 includes side plates 11 and bottom plates 12 , top plate 13 and partition 14; side plate 11 is set to a thickness of 0.10m to 0.35m, bottom plate 12 is set to a thickness of 0.15m to 0.40m, top plate 13 is set to a thickness of 0.10m to 0.35m, and partition 14 is set to a thickness of 0.10m ~0.30m.

[0037] The outer surfaces of the side plates 11 and the top plate 13 are provided with reinforcing rib structures, the reinforcing rib structures include transverse stiffeners 21 and longitudinal stiffeners 22, and the transverse stiffeners 21 and longitudinal stiffeners 22 are set to be 0.10m-0.30m wide and 0.10m high. m ~ 0.30m, spacing 0.50m ~ 2.50m.

[0038] The side plate 11 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com