Coordinated control method of cooling-heating-power cogeneration system of micro gas turbine

A micro gas turbine, combined cooling, heating and power technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as controlled quantity constraint and large inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

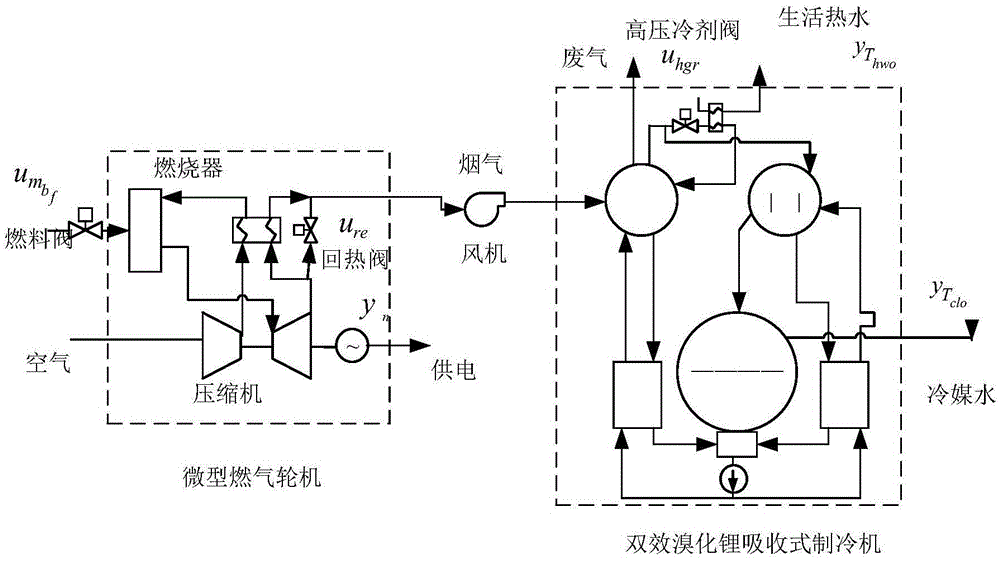

[0067] The control method of the present invention is applied to the simulation model of the MGT-CCHP system that a 80kW heat recovery micro gas turbine and a 425kW double-effect lithium bromide absorption refrigerator form, such as figure 1 shown. This triple power supply system can output electric energy, and at the same time provide domestic hot water at 60-80°C and refrigerant water at 7-12°C (for cooling). The control goal is to achieve good tracking of power supply, heating and cooling loads on the user side

[0068] The invention proposes a coordinated predictive control method for a micro gas turbine combined cooling, heating and power supply system, which can deal with control problems such as controlled quantity constraints, large delays, and multivariable systems, and can further improve the response speed to user loads and reduce dynamics. Deviation, thereby improving the quality of power supply, heating and cooling. Including the following steps:

[0069] (1) O...

Embodiment 2

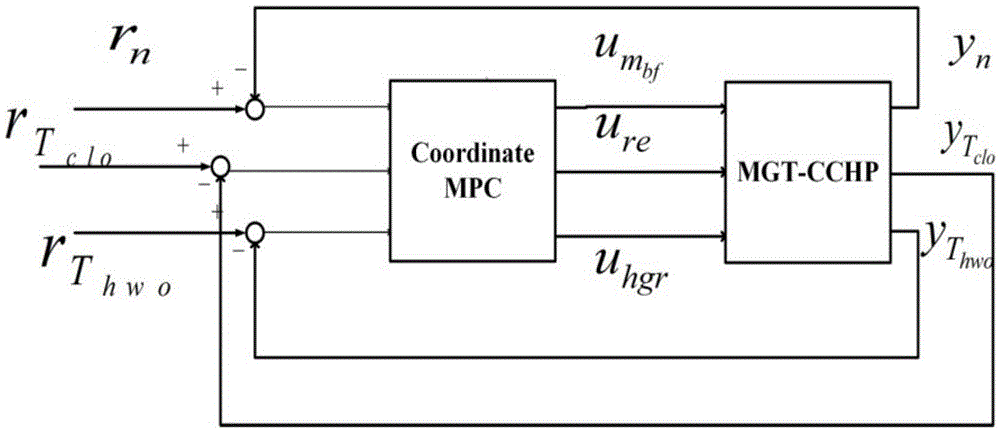

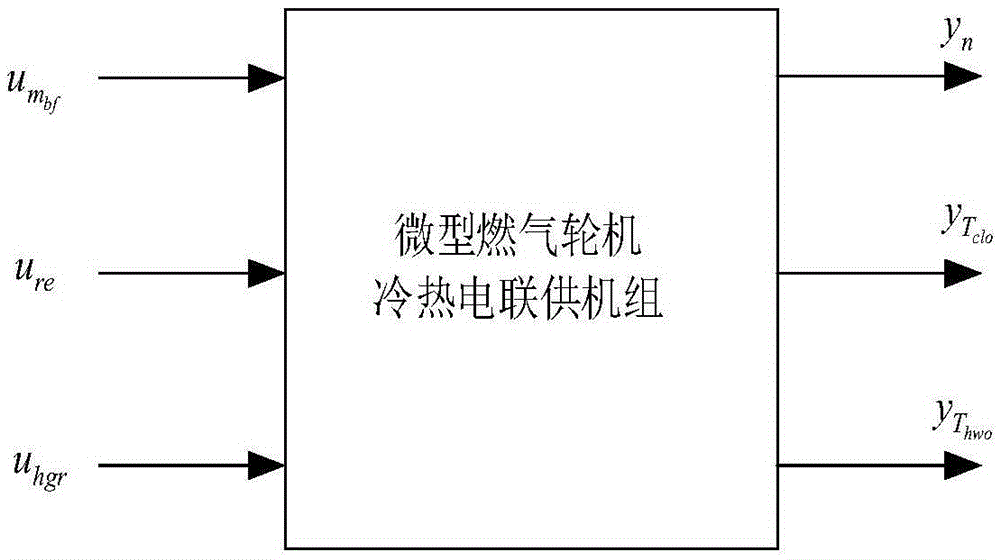

[0091] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. Aiming at the simulation model of the MGT-CCHP system composed of an 80kW regenerative micro gas turbine and a 425kW double-effect lithium bromide absorption refrigerator, the present invention designs a three-input and three-output coordinated predictive control system, so that the fuel on the side of the micro gas turbine flow control valveu mbf and the reheat valve opening u on the side of the double-effect LiBr absorption chiller re , high pressure refrigerant valve opening u hgr Able to work in harmony while efficiently handling the large inertia on the chiller side, making the three output variables (turbine speed y n (r / min), refrigerant water temperature y Tclo (°C) and domestic hot water temperature y Thwo (°C)) can well track the load command on the user side and improve the adjustment quality.

[0092] The control block diagram o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com