Waste-heat-drive drainage and injection type refrigerating system for refrigerator car

A refrigeration system and heat-driven technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of energy consumption, increased vehicle exhaust emissions, high evaporation pressure, etc., to reduce load, improve performance, and increase injection coefficient big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

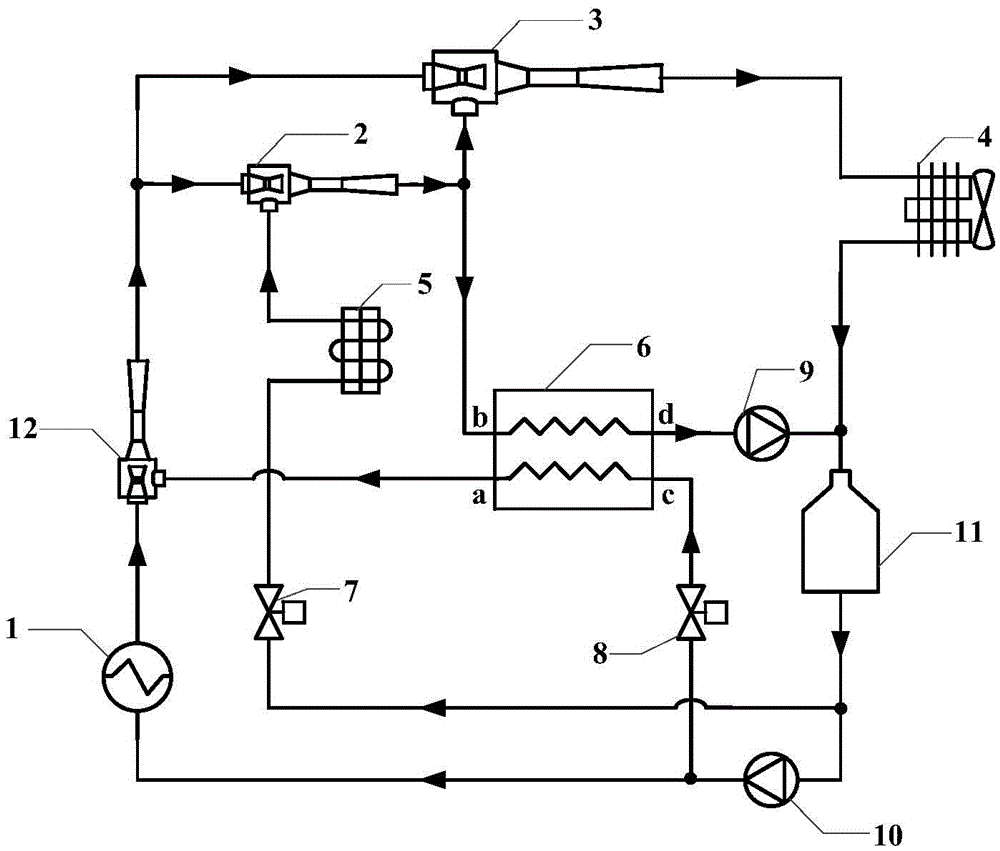

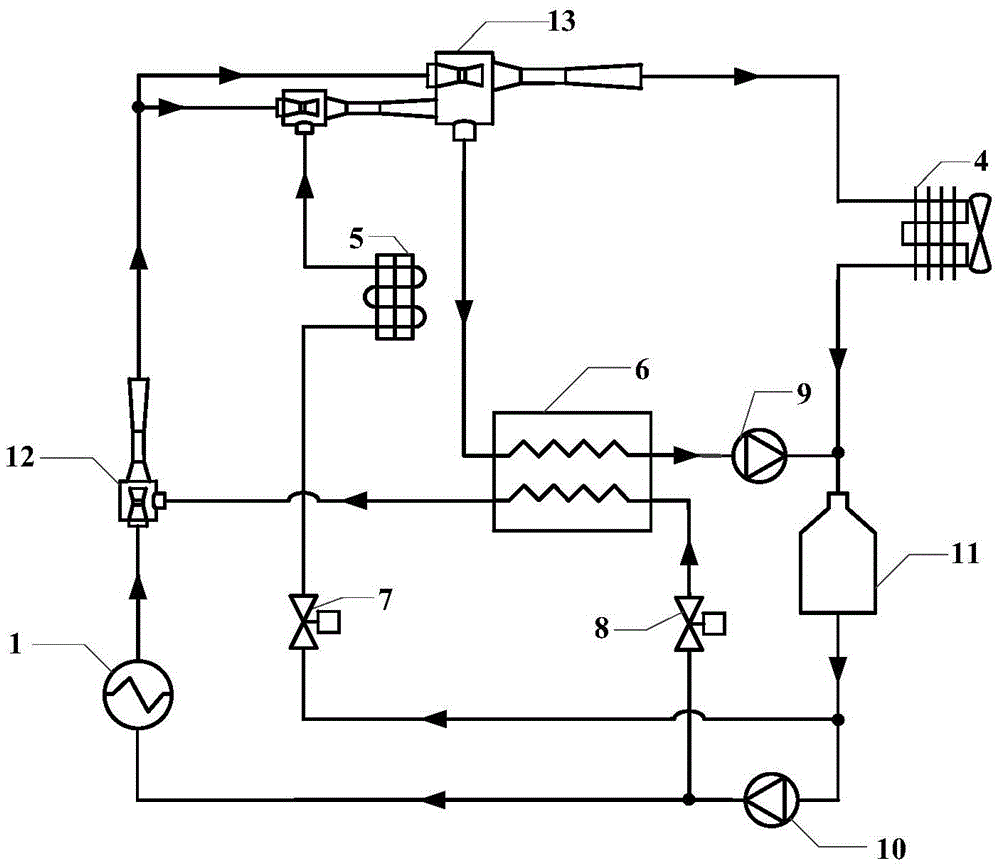

[0023] Such as figure 1 As shown, a refrigerated vehicle waste heat-driven diversion jet refrigeration system includes vehicle waste heat recovery device 1, injector I2, injector II3, condenser 4, evaporator 5, heat exchanger 6, expansion valve I7, expansion valve II8, circulation pump I9, circulation pump II10, liquid storage tank 11, injector III12, the outlet of injector III12 is respectively connected with the working fluid inlet of injector I2 and the working fluid inlet of injector II3, and the working fluid inlet of injector III12 It is connected with the first end of the automobile waste heat recovery device 1, the injection fluid inlet of the injector III12 is connected with the a end of the heat exchanger 6, the second end of the automobile waste heat recovery device 1 is connected with the first end of the circulation pump II10, the expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com