Testing device for simulating concrete test piece hydraulic fracture under multi-field coupling condition

A technology for concrete specimens and test devices, which is applied in the direction of testing the strength of materials by applying stable tension/compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

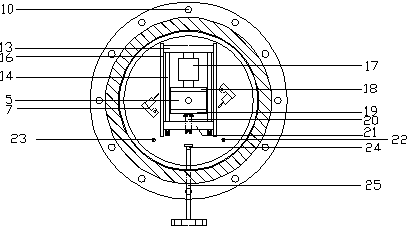

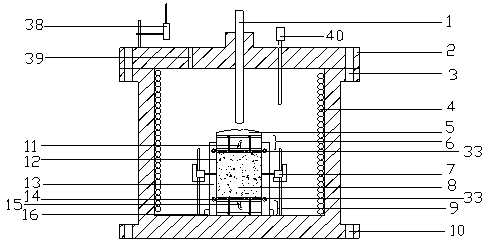

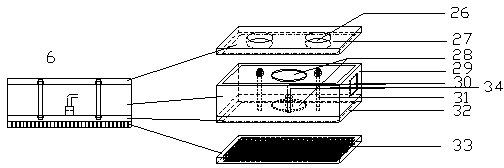

Embodiment Construction

[0022] 1) Use and age-appropriate concrete specimen (8) with a length, width, and height of 100mm×50mm×100mm, and put it into the rubber sleeve (12). The opening (34) of the opening (34) is inserted into the water-permeable copper plate (33) with dense 1.0mm diameter holes respectively on both sides. The specification is 100mm×50mm×5mm. The steel sets (6), (9) are symmetrically installed on the outside of the permeable copper plate to provide space for the water inlet and outlet pipes and to transmit axial force. The upper steel set (6) is the water outlet (11), and the lower steel set (9) is For water inlet (15). The installation of the above steel kit (6) is an example: the upper steel kit is divided into the upper block (27) with a specification of 100mm×50mm×5mm, the middle block (29) with a specification of 100mm×50mm×25mm, and the lower block (32) with a specification of 100mm×50mm× 5mm. Open a small opening in the middle of the lower block, install the water outlet jo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com