Method for preparing cross section transmission electron microscope sample

A transmission electron microscope sample and cross-section technology, which is applied in the preparation of test samples, etc., can solve the problems of complex preparation process, large mechanical damage of samples, easy breakage of samples, etc., and achieve simple overall process, simplified operation steps, The effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

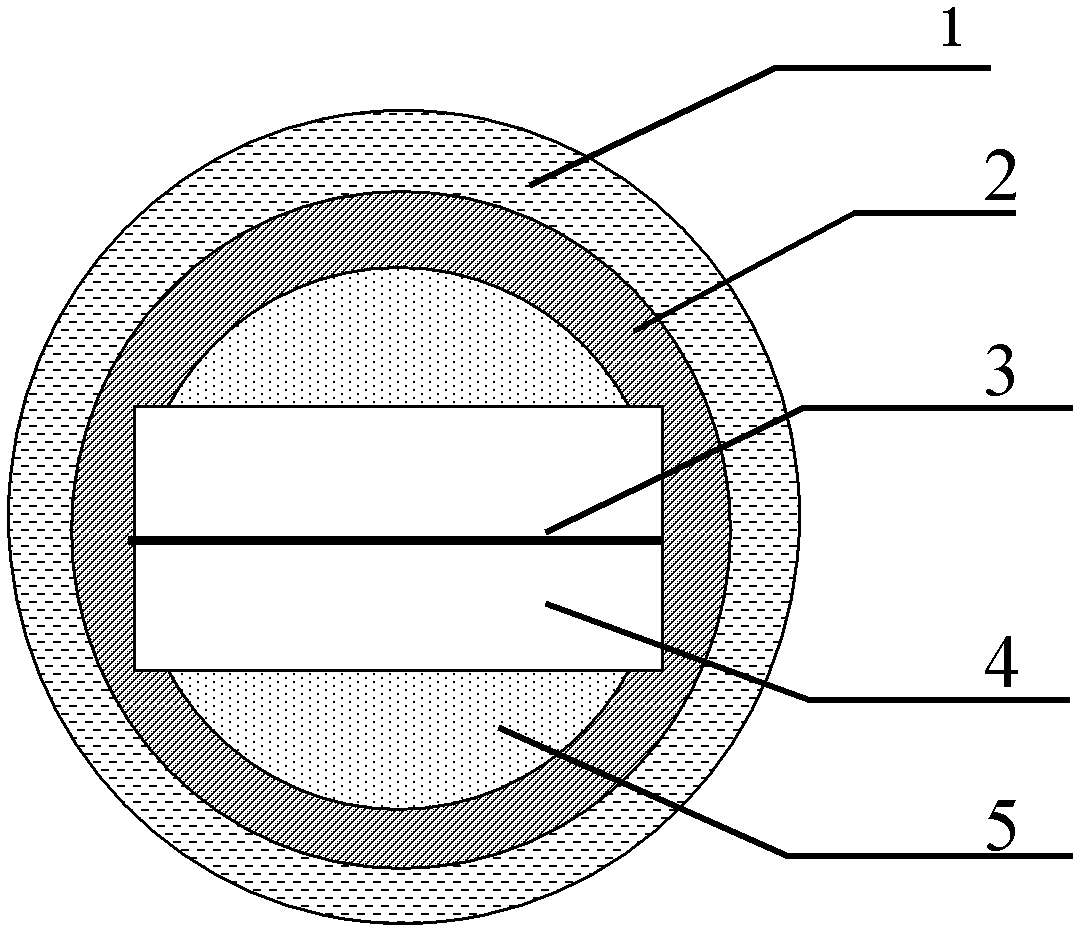

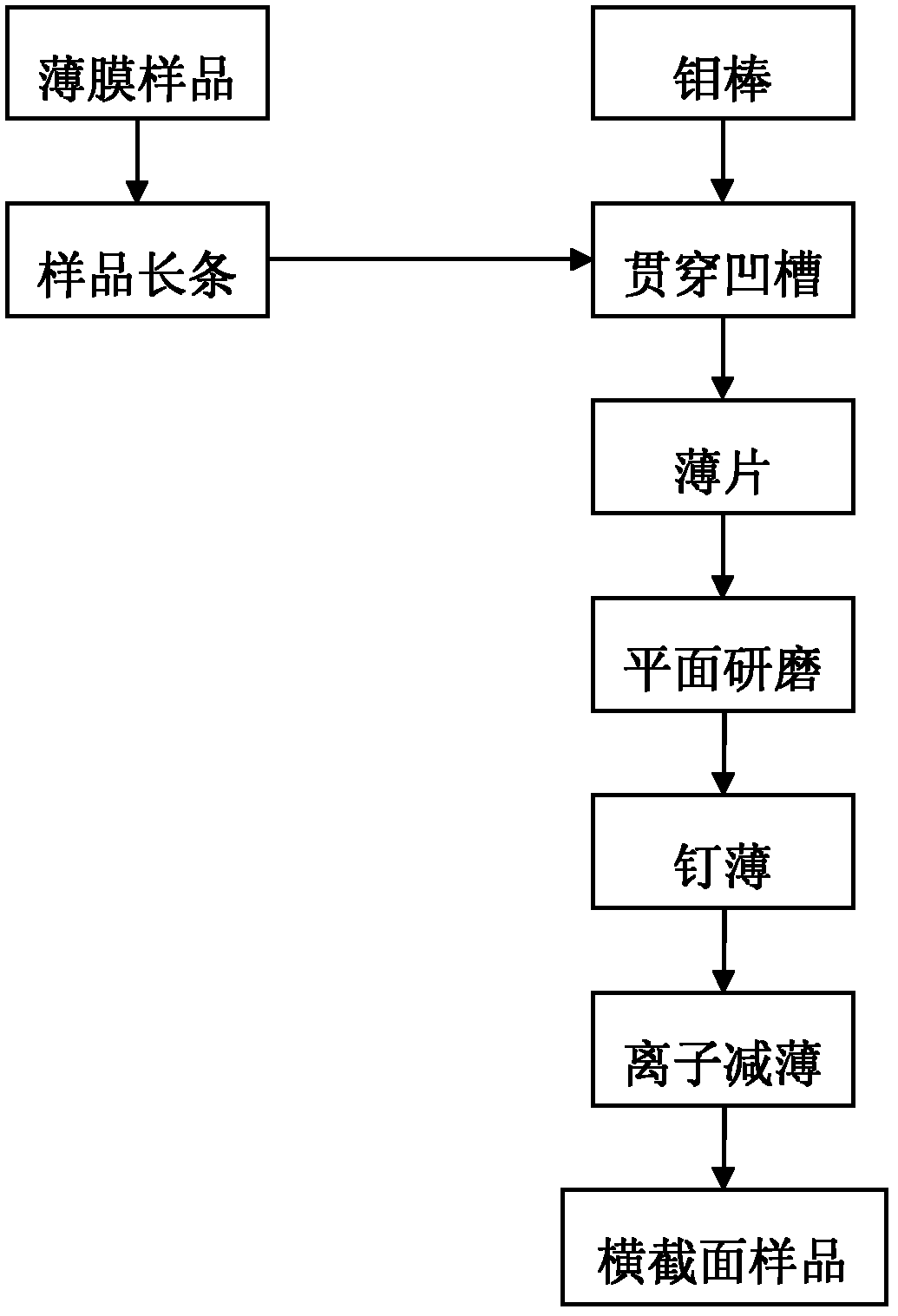

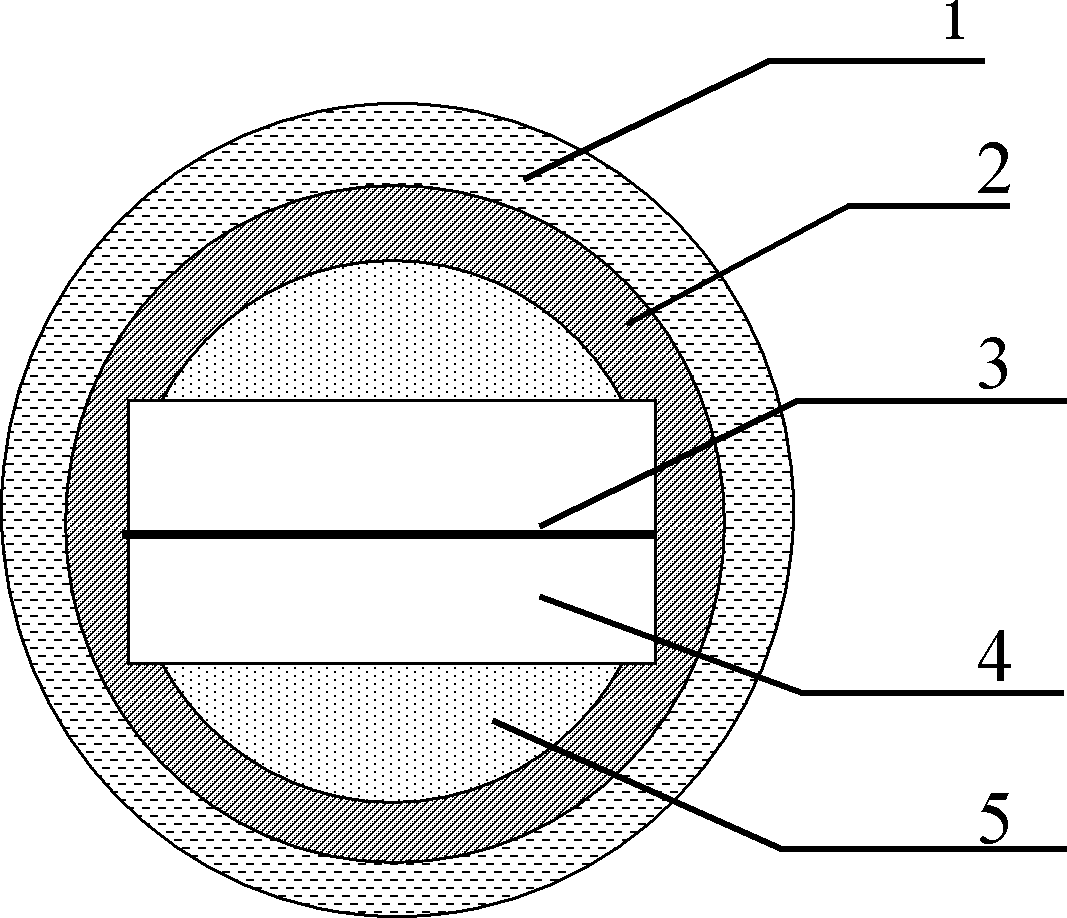

[0015] According to the attached figure 2 The preparation process shown carries out the processing of the cross-sectional transmission electron microscope sample, and its specific steps include:

[0016] (1) First cut the sample into strips with a width of 2 mm, clean the surface with acetone to remove impurities, then dry it naturally, apply a layer of curing glue evenly on the side with the film, and dry it at 130°C after bonding Cool to room temperature after heating for solidification;

[0017] (2) Cut a penetrating groove along the center at one end of a molybdenum rod with a length of 20mm and a diameter of 2mm, with a width of 1mm (the thickness of the general sample is 0.5mm), and the length should be greater than the length of the sample. Evenly coat a layer of curing glue on the outer surface of the surface and the inner surface of the groove, then put the sample into the groove to fix, heat and solidify, and cool to room temperature; if the thickness of the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com