Suction duct of air conditioner compressor and fabricating and connecting method thereof

An air-conditioning compressor and connection method technology, which is applied to manufacturing tools, welding equipment, mechanical equipment, etc., can solve the problems of high welding defect rate and leakage defect rate, rising prices of brazing materials, and rising prices of copper pipes, etc. Achieve the effect of enhancing product competitiveness, reducing usage, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

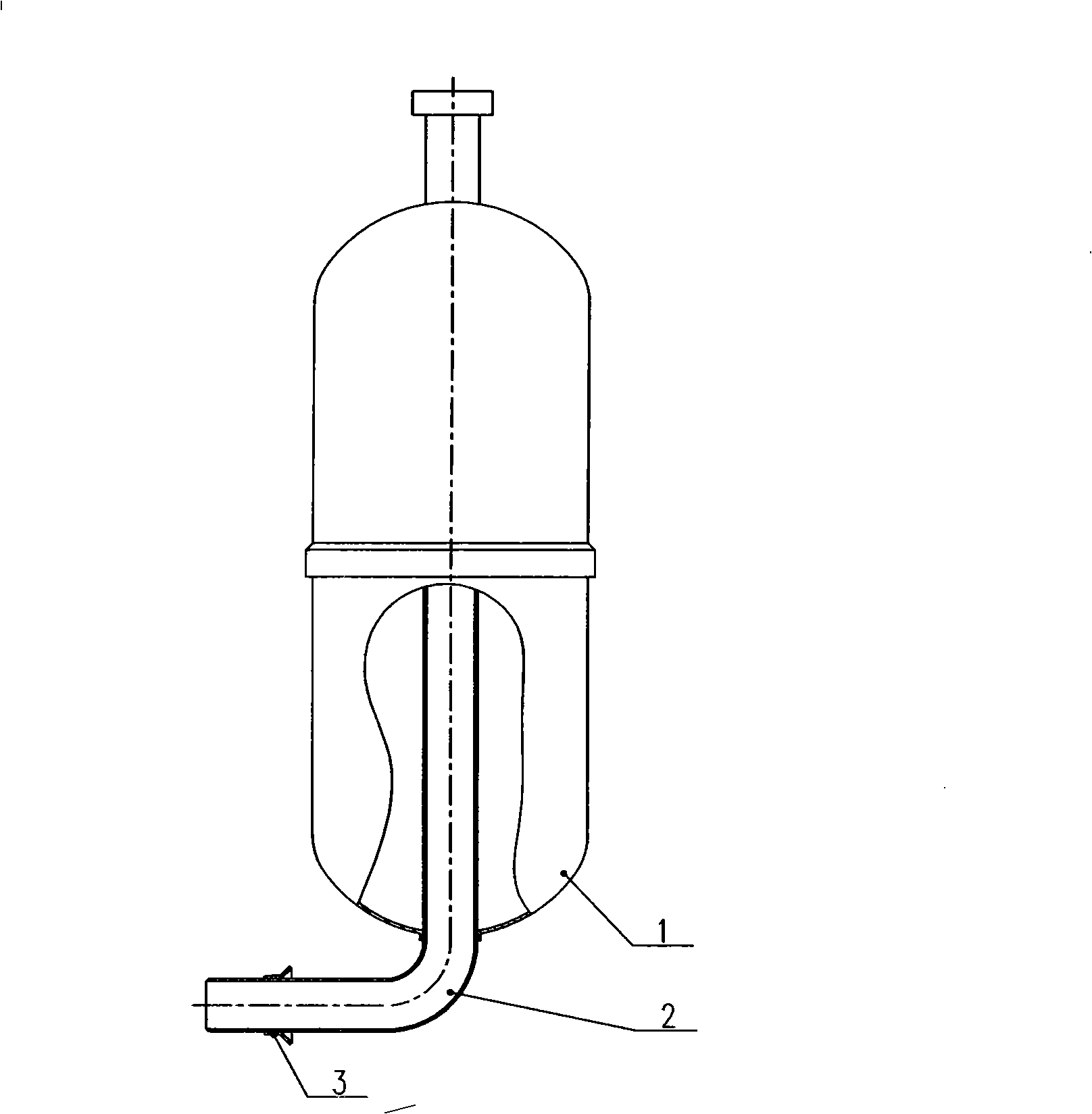

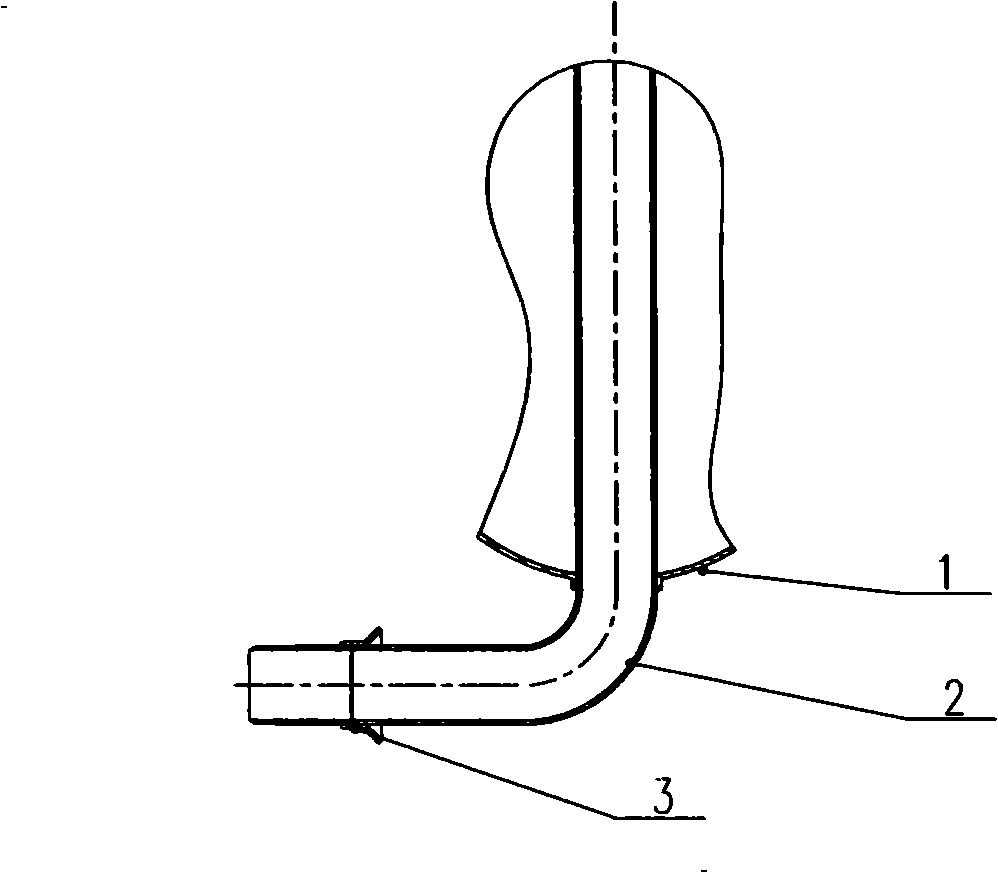

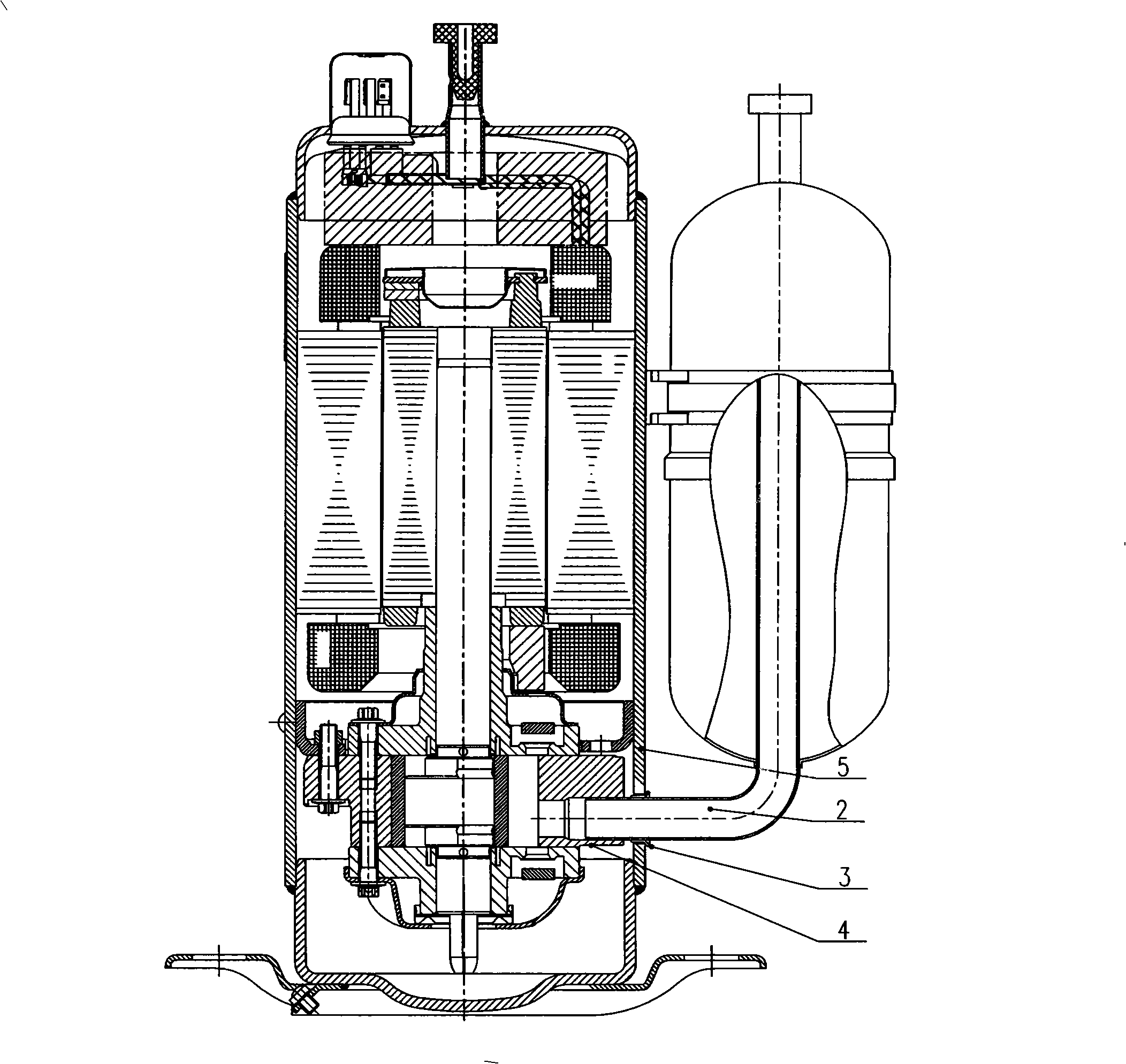

[0031] like figure 1 , figure 2 As shown, it is an accumulator for an air-conditioning compressor, which includes an accumulator body 1 and other internal structures. The body 1 is connected with a suction pipe composed of an integrated steel elbow 2 and a straw hat-shaped iron ring 3. The iron ring 3 is set on the horizontal section of the elbow (i.e. the extended end, when using figure 2 During the mode, the horizontal straight pipe section and the tapered pipe section that the elbow 2 protrudes are simultaneously set in the hoop 3, and the iron hoop 3 and the elbow 2 are fixed together by welding.

[0032] In this embodiment, the elbow 2 is integrally bent from a steel pipe of equal outer diameter, and the extended end is longer than the connecting pipe of the conventional liquid reservoir to replace the conventional conduit and connecting pipe. One end of the iron ring 3 is a pipe string, and the other end is a bell mouth. The inner diameter of the iron ring 3 pipe str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com