Full-automatic pipe penetrating equipment for inserting copper pipes into condenser fins and pipe penetrating technology

A condenser and fully automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low production efficiency and high labor cost, and achieve the effect of improving production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

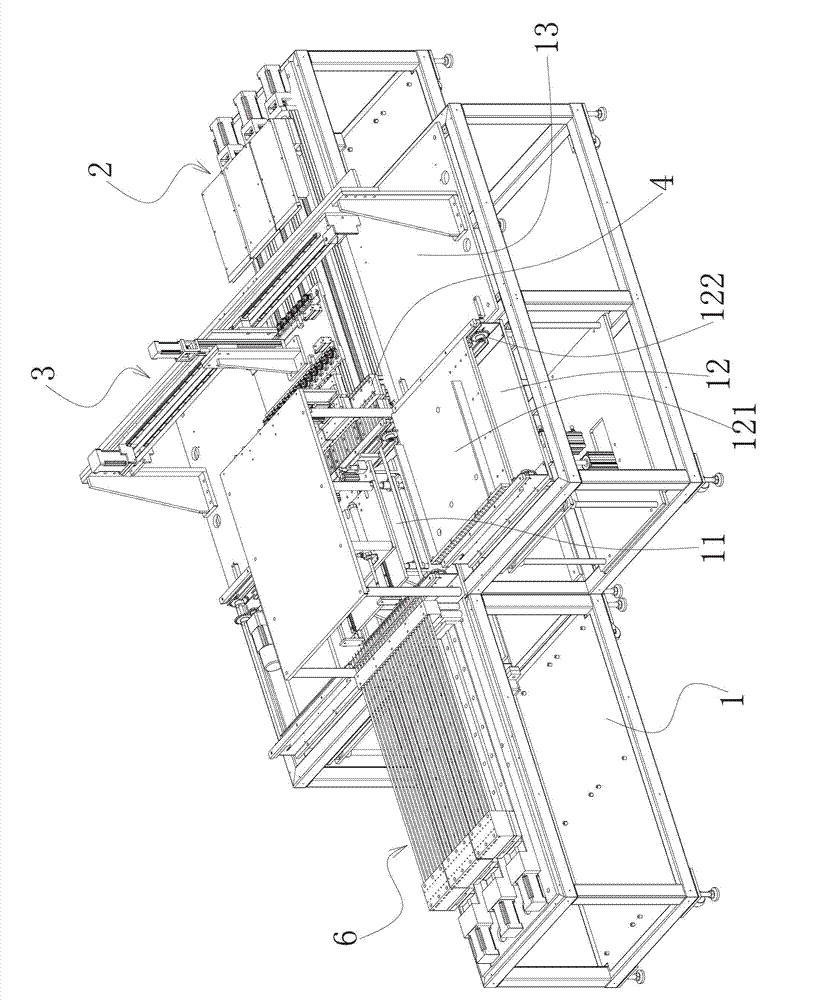

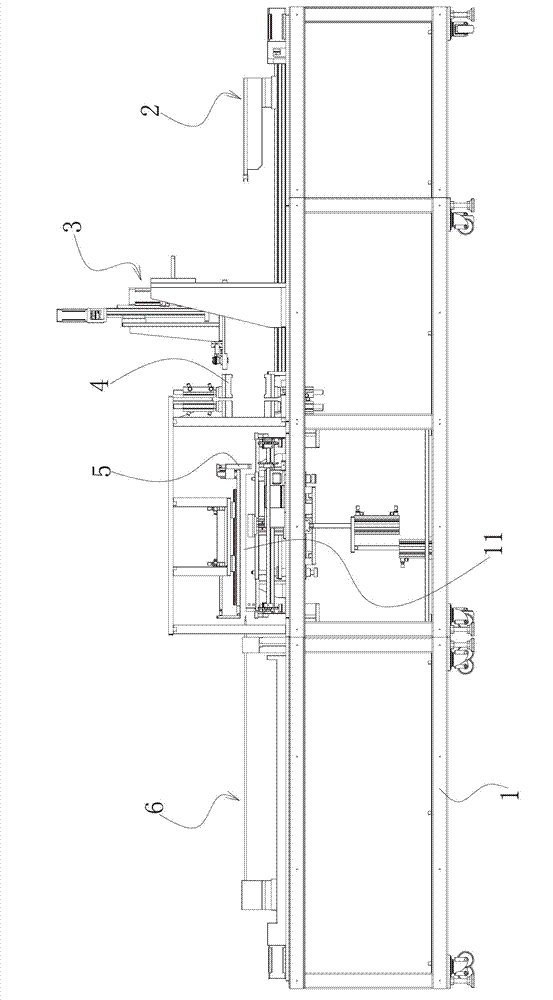

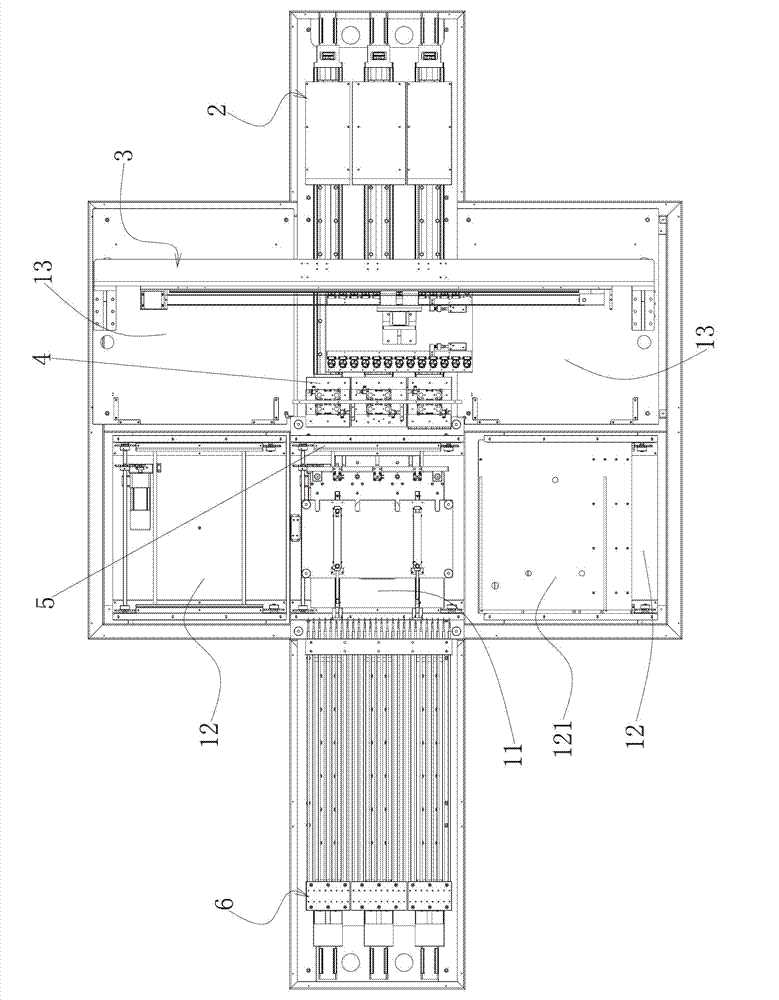

[0033] A fully automatic pipe threading device for inserting copper pipes into condenser fins, including a frame 1, a copper pipe pushing and inserting mechanism 2 imitated from right to left on the frame, a manipulator 3, and a guide mold 4 , the guide rake 5, and the traction mechanism 6, the frame 1 is provided with a pipe-passing work area 11 between the guide rake 5 and the traction mechanism 6, and the front and rear sides of the pipe-pass work area 11 are respectively provided with fin placement areas 12. The fin placement area 12 is provided with a fin tray 121 and a tray transfer device 122 , and the position corresponding to the manipulator 3 on the frame 1 is provided with a discharge area 13 for placing copper pipes.

[0034] The copper pipe pushing and inserting mechanism 2 at least includes a pushing block 21 and its driving device 22, and the pushing block 21 can insert the copper pipe 01 into the end of the following draw bar 61 under the drive of its driving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com