End socket structure of copper and steel bimetallic pipe and seal welding method thereof

A technology of bimetallic pipes and copper pipes, applied in welding equipment, metal processing equipment, non-detachable pipe connections, etc., can solve the problems of unreliable sealing, poor weldability, and easy cracks in welds, etc., and achieve simple process, Reliable welding seal, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

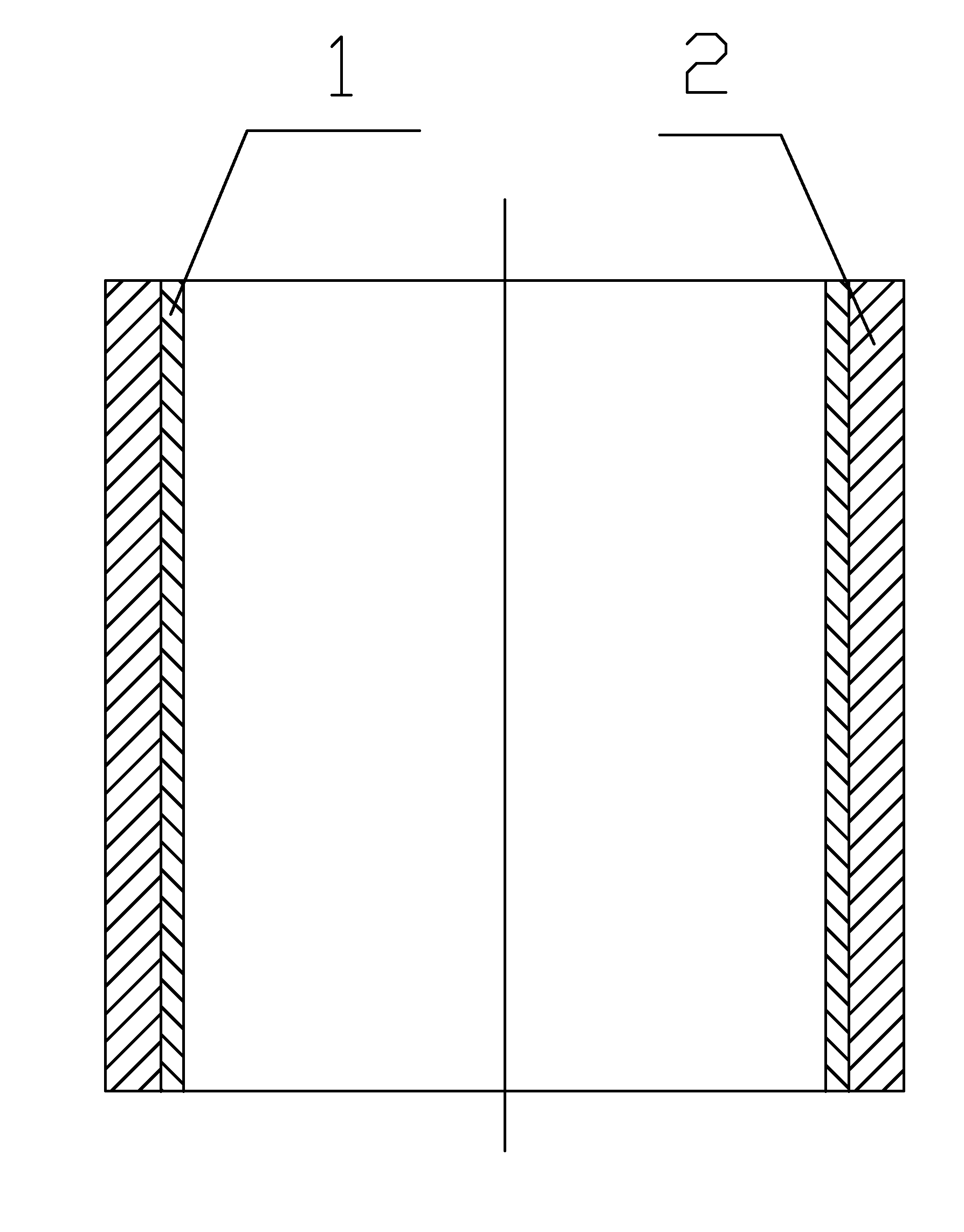

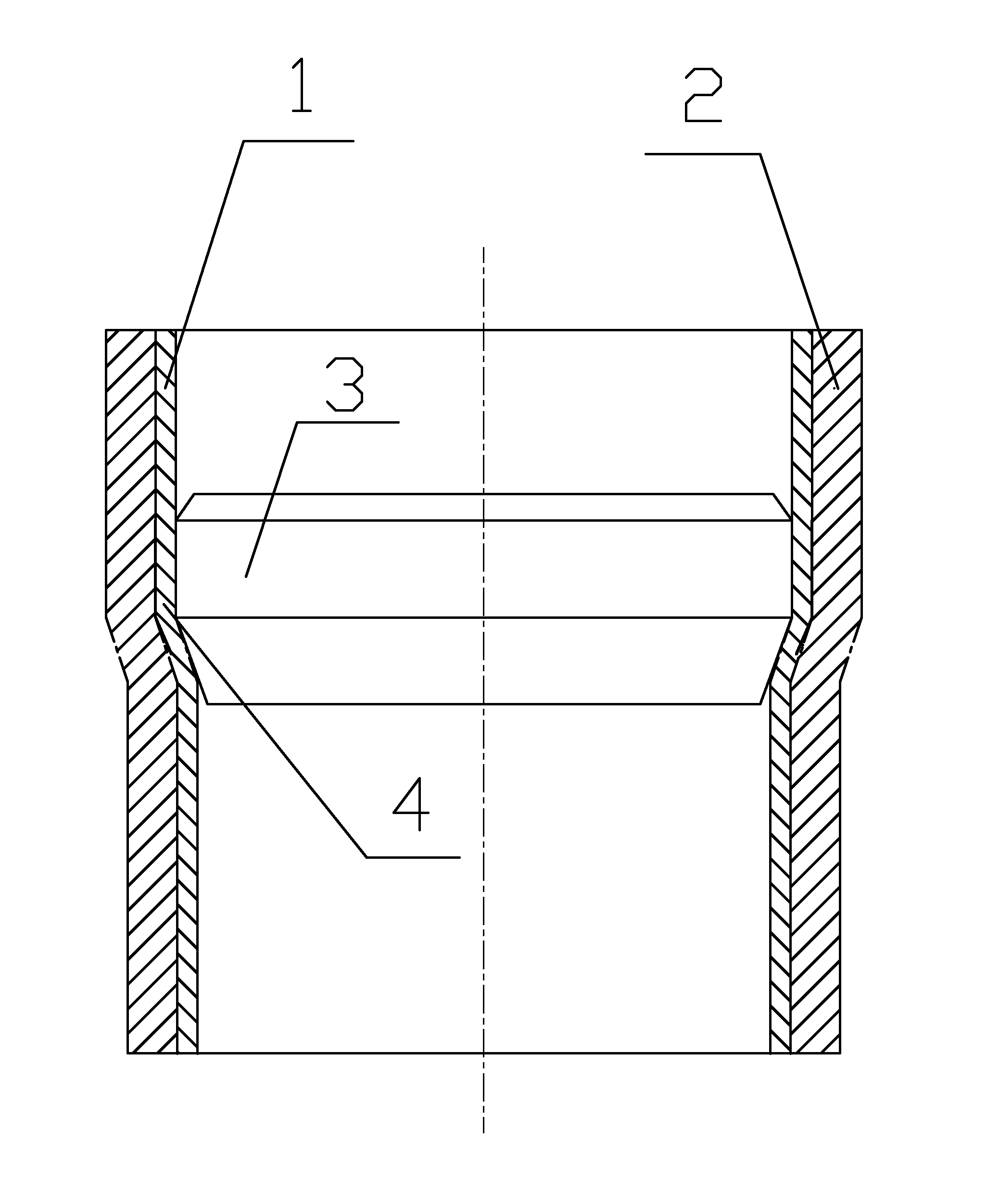

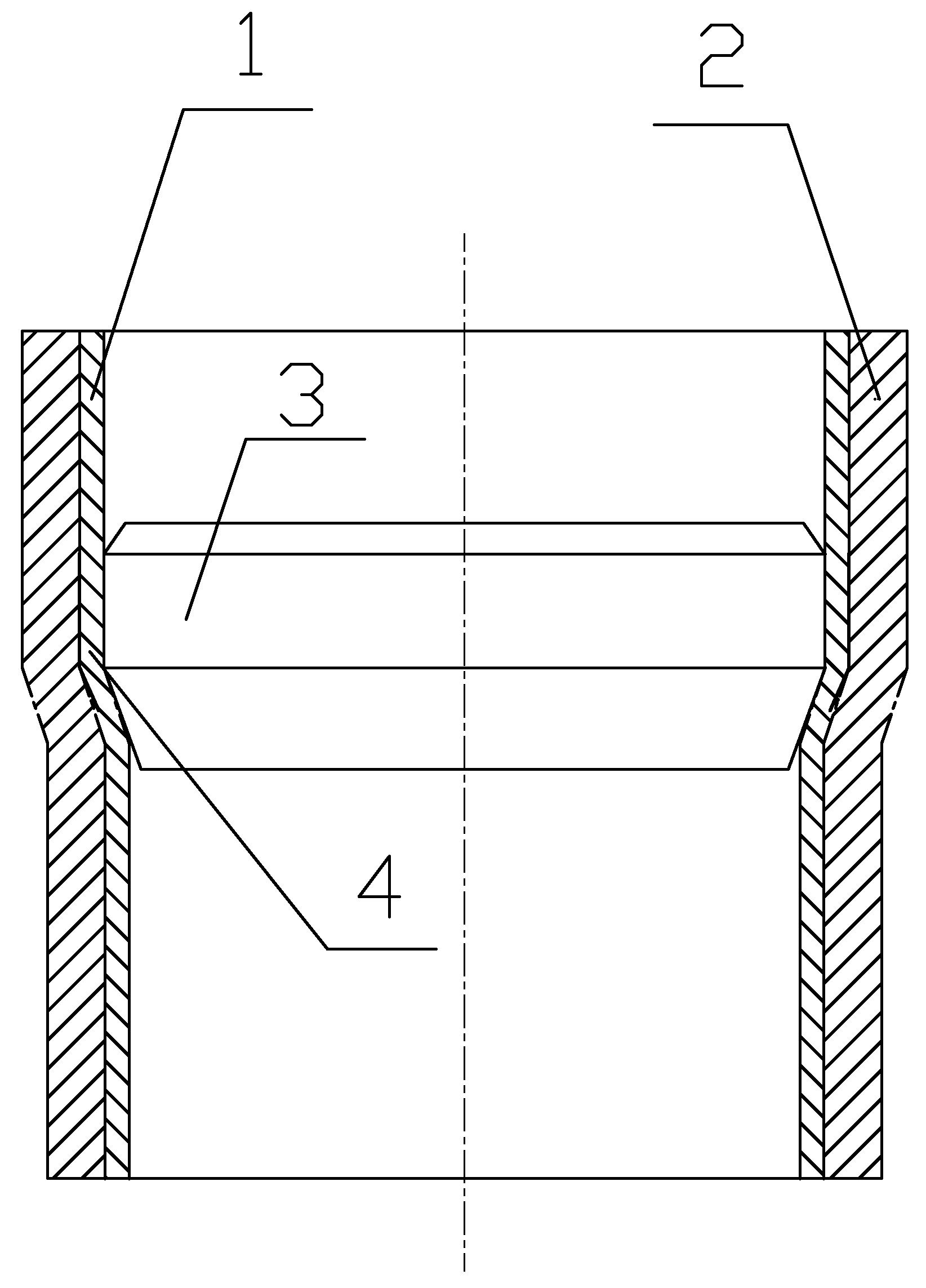

[0028] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, a copper-steel bimetallic pipe end structure includes a copper pipe 1 and a steel pipe 2, and the copper pipe 1 and the steel pipe 2 are connected by a diffusion welding bonding layer 4 at the junction of the ends.

[0029] A sealing welding method for a copper-steel bimetallic pipe end structure, comprising the following steps:

[0030] A. Clean the surface to be joined at the end of copper pipe 1 and steel pipe 2, use copper pipe 1 as the inner pipe and steel pipe 2 as the outer pipe, and use mechanical deformation to make the joint surface of copper pipe 1 and steel pipe 2 pre-laminated together;

[0031] B. Press the bulging plug 3 into the inner hole of the end of the copper pipe 1, so that the diameter of the end of the copper pipe 1 and the steel pipe 2 is enlarged and deformed, and an interference fit is maintained between the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com