High strength steel plate hot stamping die for automobile parts

A technology for hot stamping dies and auto parts, which is applied in the field of hot stamping dies for high-strength steel plates for auto parts. It can solve problems such as damage to the service life and strength of the die, leakage of cooling pipe coolant, and complex design and manufacture of the die. Stability and service life, guaranteed stability, stable and reliable mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and embodiments. It should be pointed out that the examples are only used to illustrate the present invention and not to limit the scope of the present invention. In the drawings, the same reference numerals represent the same components.

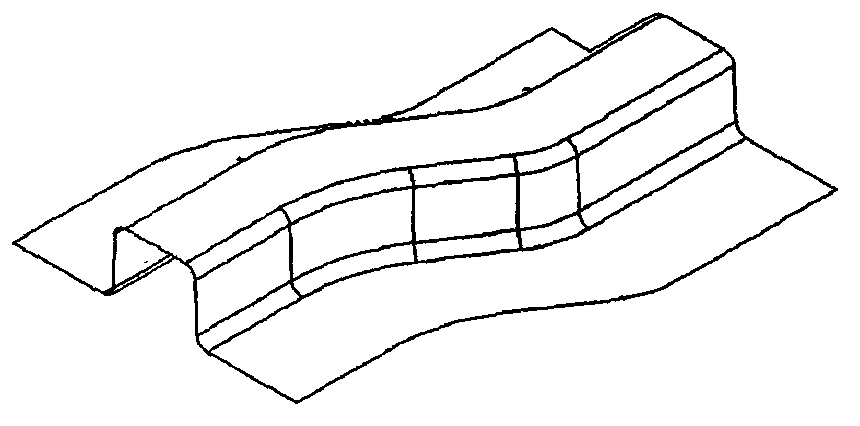

[0029] Such as figure 1 As shown, select an auto part with a U-shaped cross-section and curved surfaces both horizontally and vertically as an example.

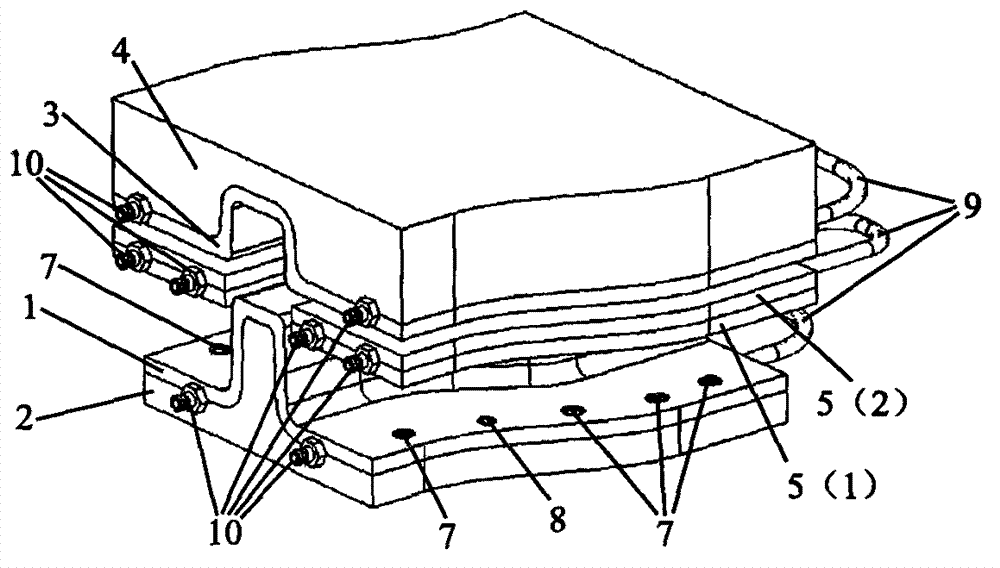

[0030] Such as figure 2 As shown, the hot stamping die for U-shaped auto parts includes a punch body (punch 1, punch connection fixing plate 2), a die body (die 3, die connection fixing plate 4), and blank holder ring plate 5 (1) and plate 5 (2), cooling pipe 6, coupling device 7, positioning device 8, U-shaped connecting hose 9, pipe joint 10.

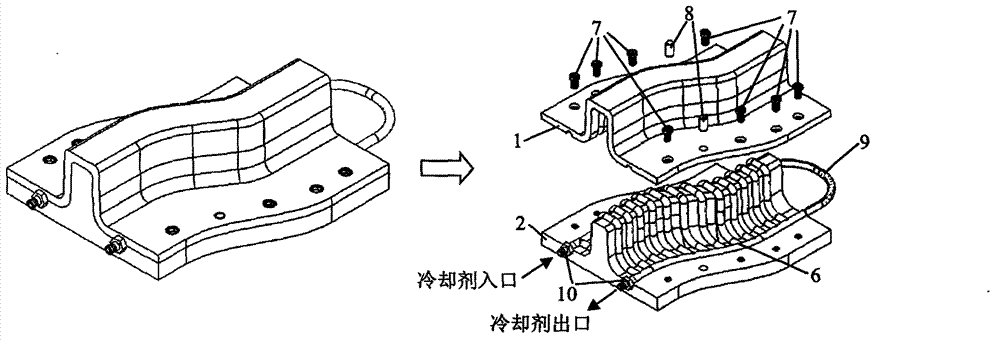

[0031] Such as image 3As shown, the punch body is composed of a punch 1 , a punch connection fixing plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com