Medium temperature glass-metal structure solar vacuum thermal-collecting tube

A technology of vacuum heat collecting tube and metal structure, which is applied in the field of solar energy utilization, and can solve problems such as peeling off of copper oxide skin, affecting the heat collection effect of heat collecting tube, and oxidation of copper surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

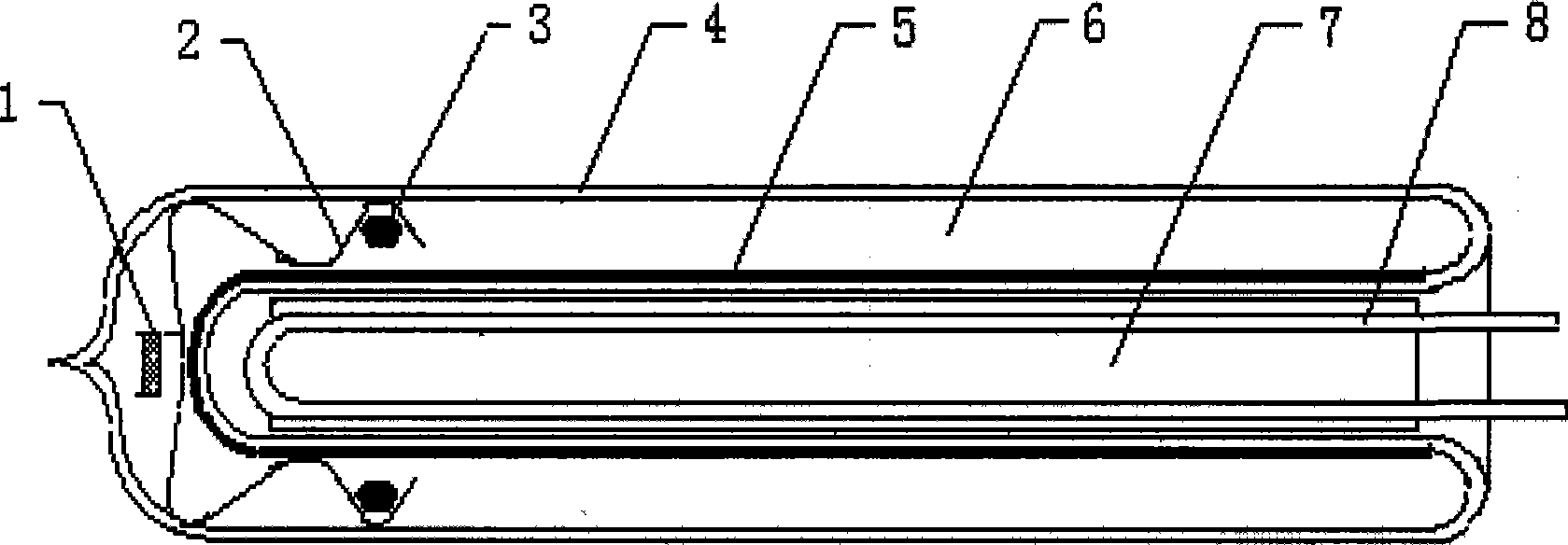

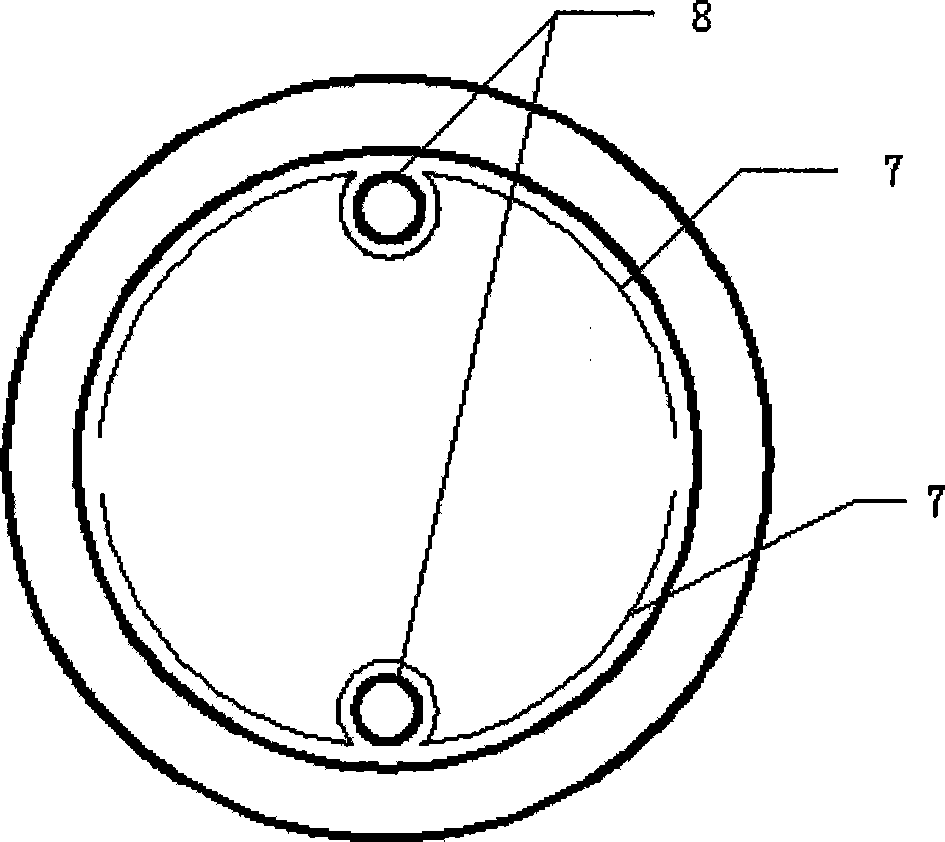

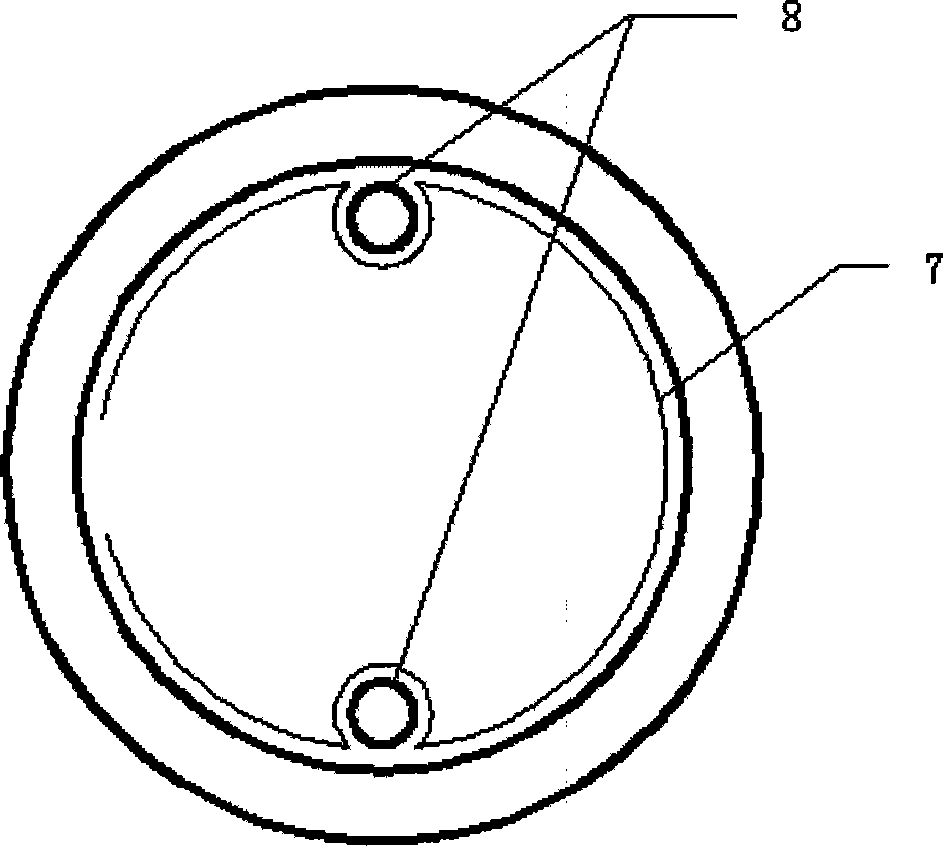

[0015] The invention proposes a solar vacuum heat collecting tube with a medium temperature glass-metal structure. Structure Fig. 1 is a kind of novel mid-temperature glass-metal solar vacuum heat collecting tube (U-shaped copper tube structure) structure schematic diagram of the present invention and Fig. 2 is a kind of novel medium temperature glass-metal solar vacuum heat collecting tube (copper tube) of the present invention Heat pipe structure) Schematic diagram of the structure.

[0016] In Fig. 1, the heat transfer tube 8 with a temperature-resistant and anti-oxidation film is tightly crimped or welded on the heat conduction fin 7, the inner glass heat collector tube 5 with a selective absorption film, the heat conduction fin 7 and the all-glass vacuum solar collector The inner walls of the heat pipe 4 are in close contact. The non-evaporable getter 3 is fixed on both sides of the metal support 2, the evaporable getter 1 is fixed on the top of the metal support 2, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com